Process for conducting dehydration control on white clay calcium carbonate

A calcium carbonate and process technology, applied in the field of automatic dehydration control of white mud calcium carbonate, can solve the problems of unclean scraping, unsatisfactory feeding of centrifuge, high water content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

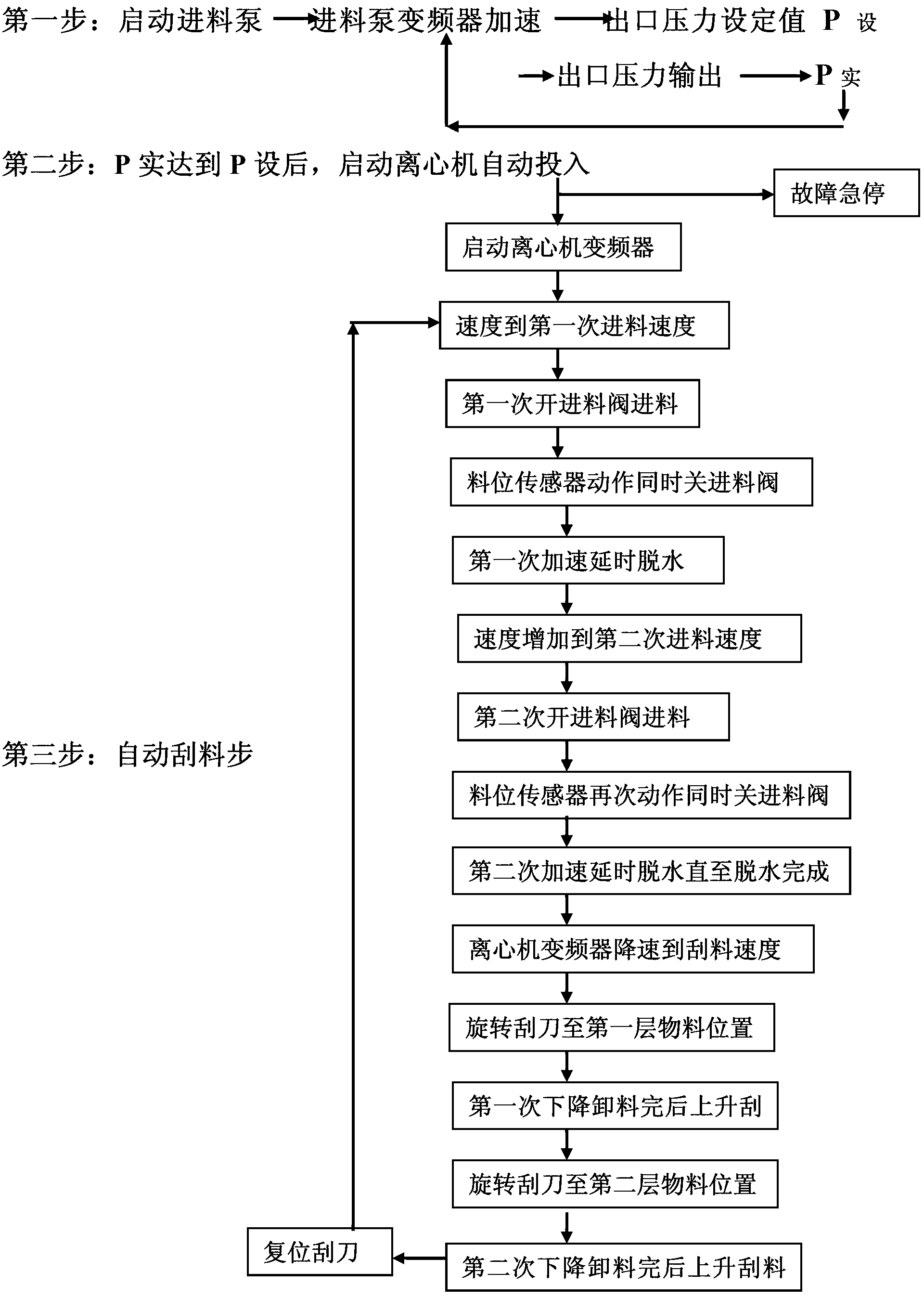

[0011] Embodiment 1: a kind of technology that white mud calcium carbonate is carried out dehydration control, as figure 1 shown, including the following steps:

[0012] Automatically start the motor of the feed pump, and at the same time start the frequency converter of the feed pump to accelerate until the outlet pressure of the feed pump increases to 0.15MPa, and then the speed of the feed pump tracks the pressure change to ensure the flow rate is stable;

[0013] Automatically start the centrifuge. The inverter centrifuge starts to accelerate. When the speed increases to 700 rpm (the acceleration time is about 1 minute), the feed valve is automatically opened. When the level sensor senses that the material is almost full, the feed valve is immediately closed. (This feeding time is about 60 seconds), at the same time, the frequency converter of the centrifuge continues to accelerate to 850 rpm and starts to delay, about 60 seconds, open the valve for the second feeding (Thi...

Embodiment 2

[0016] Embodiment 2: a kind of technology that white mud calcium carbonate is carried out dehydration control comprises the steps:

[0017] Automatically start the motor of the feed pump, and at the same time start the frequency converter of the feed pump to accelerate until the outlet pressure of the feed pump increases to 0.2MPa, and the feed pump accelerates to stop;

[0018] Automatically start the centrifuge. The inverter centrifuge starts to accelerate. When the speed increases to 800 rpm, the feed valve will be opened automatically (the acceleration time is about 1 minute). When the level sensor senses that the material is almost full, the feed valve will be closed immediately. (This feed time is about 30 seconds), and at the same time, the centrifuge inverter continues to accelerate to 900 rpm and starts to delay. When the delay reaches the set time (such as 40 seconds), open the valve for the second feed (this feed The feeding time is about 20 seconds), at this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com