Device for separating 2-methyl butanol, 3-methyl butanol from iso amyl alcohol and its application method

A technology of methyl butanol and isoamyl alcohol, which is applied in chemical instruments and methods, fractionation, preparation of hydroxyl compounds, etc., can solve the problems of not mentioning the rectification device and implementation process, difficulty in realizing industrial scale-up, and high operational stability requirements problems, to achieve the effect of strong operational stability, less equipment, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

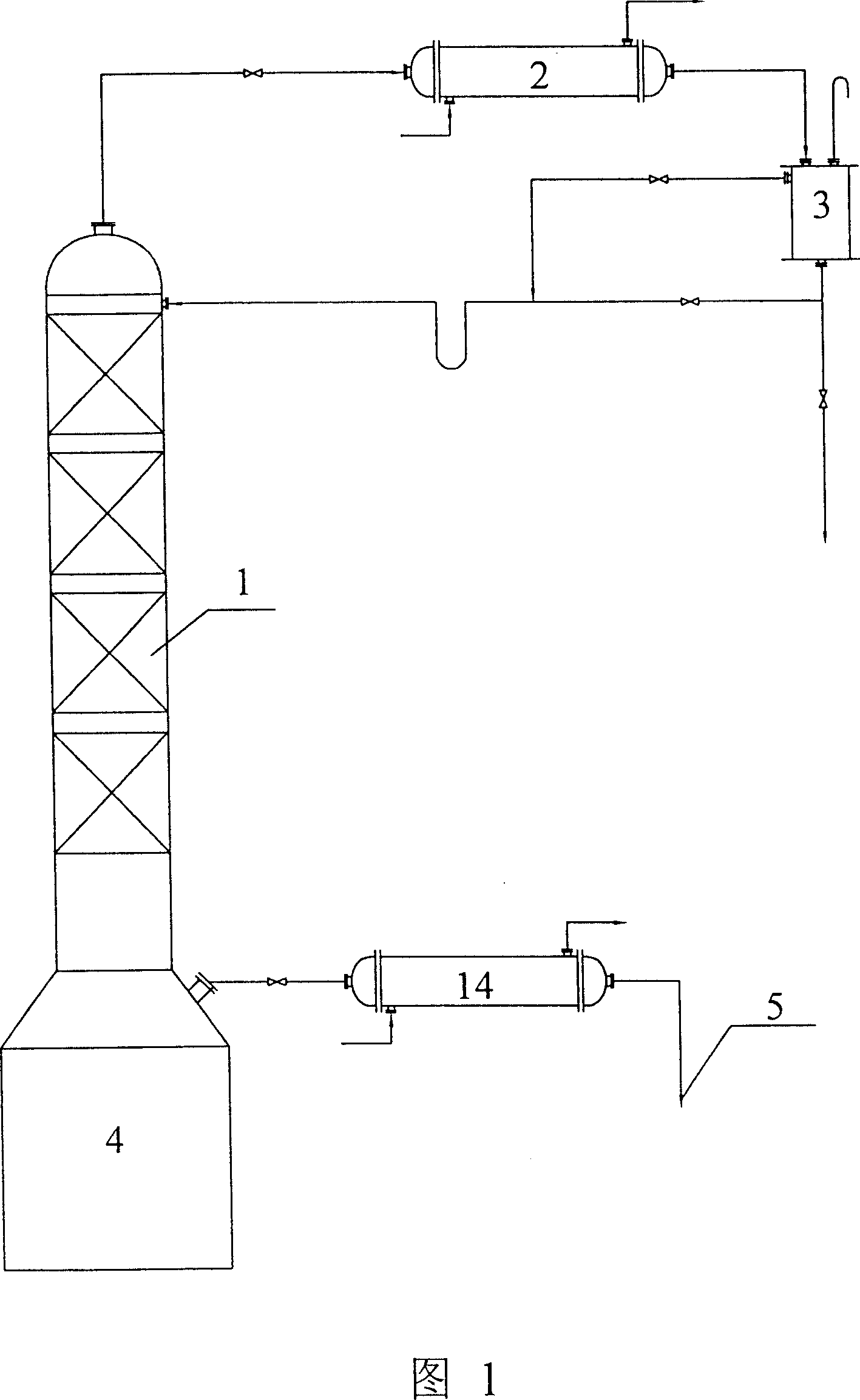

[0023]Fusel oil batch rectification tower has a diameter of 200mm and a packing height of 6.0m. Fusel oil is added to 2000L to conduct sufficient mass transfer and exchange in the packed tower. After being condensed by the cooler, it is refluxed. The moisture in the raw material is separated from the isobutyl Alcohol is carried out azeotropically, and after the materials in the tower kettle are tested and qualified, the gasification amount is increased, and isoamyl alcohol is quickly evaporated from the outlet of the simple distillation of the tower kettle, so as to avoid the light components in the packing from polluting the tower kettle products, and a total of qualified The isoamyl alcohol product is 1000L, and the yield is more than 95%, including 20% of 2-methyl butanol and 80% of 3-methyl butanol.

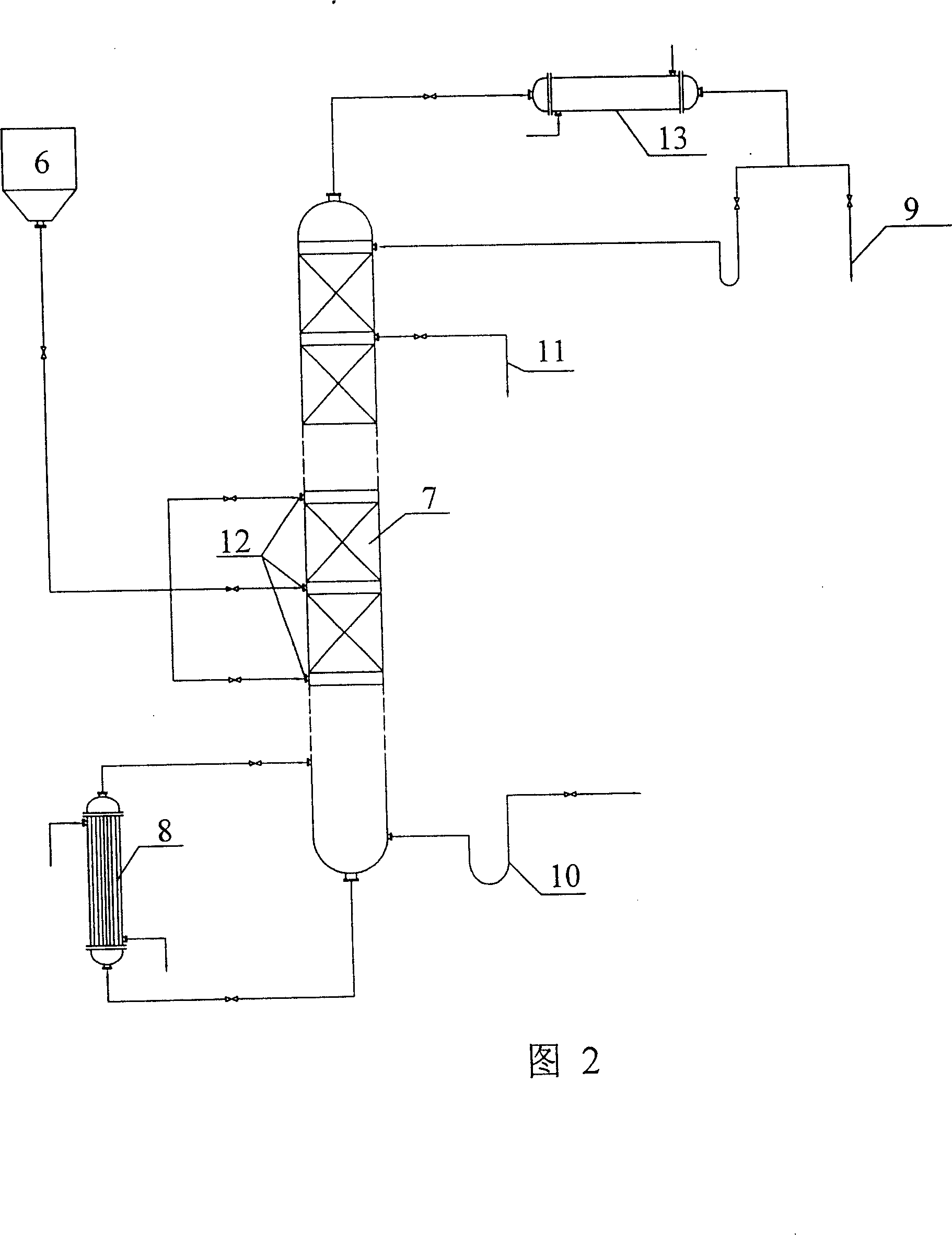

[0024] The diameter of the isoamyl alcohol continuous rectification tower is 200mm, and the packing height is 25m, of which the rectification section is 15m, and the strippi...

Embodiment 2

[0026] Fusel oil batch rectification column has a diameter of 200 mm and a packing height of 6.0 m. Add 2,000 L of fusel oil, conduct sufficient mass transfer and exchange in the packed column, and collect fractions between 127.5° and 128.5°C at a reflux ratio of 50:1 to obtain intermediate Fraction 200L, in which the content of 2-methyl butanol is 50%, and the content of 3-methyl butanol is 50%.

[0027] The diameter of the isoamyl alcohol continuous rectification tower is 200mm, and the packing height is 25m, of which the rectification section is 13m, and the stripping section is 12m. Into the packed tower, 2-methylbutanol with a purity of more than 99.5% is extracted from the side draw outlet below the top of the tower, and 3-methylbutanol with a purity of more than 99.5% is discharged from the automatic draining device of the tower kettle; the feed amount is 8 ~10L / h, 4~5L / h output from the top of the tower, 4~5L / h output from the bottom of the tower, and the optical rotat...

Embodiment 3

[0029] Fusel oil batch rectification column has a diameter of 200 mm and a packing height of 6.0 m. Add 2,000 L of fusel oil, conduct sufficient mass transfer and exchange in the packed column, and collect fractions between 128.5°C and 131.0°C at a reflux ratio of 1:1 to obtain intermediate Fraction 600L, 2-methyl butanol content 10%, 3-methyl butanol content 90%.

[0030] The diameter of the isoamyl alcohol continuous rectification tower is 200mm, and the packing height is 25m, of which the rectification section is 11m, and the stripping section is 14m. Into the packed tower, 2-methylbutanol with a purity of more than 99.5% is extracted from the side draw outlet below the top of the tower, and 3-methylbutanol with a purity of more than 99.5% is discharged from the automatic draining device of the tower kettle; the feed rate is 20 ~30L / h, 2~3L / h for tower top discharge, 18~27L / h for tower kettle discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com