Novel method for separating mixture of ethylene glycol and 1, 2-butanediol by adopting azeotropic distillation and extraction coupling technologies

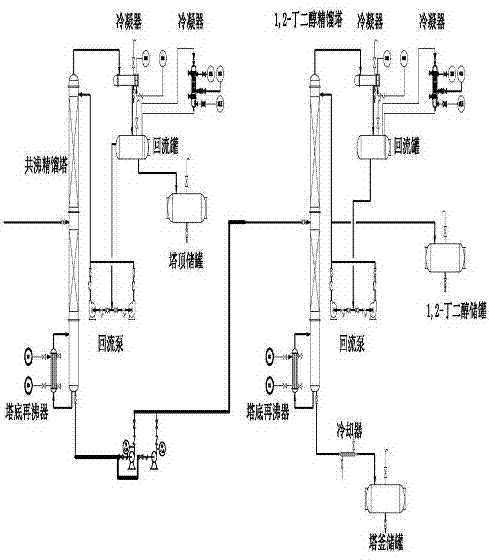

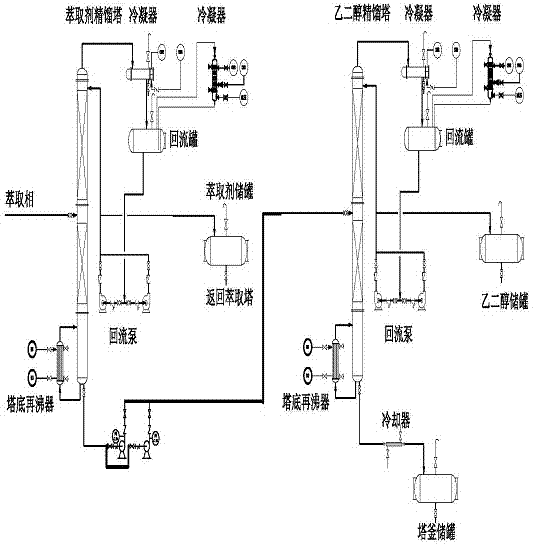

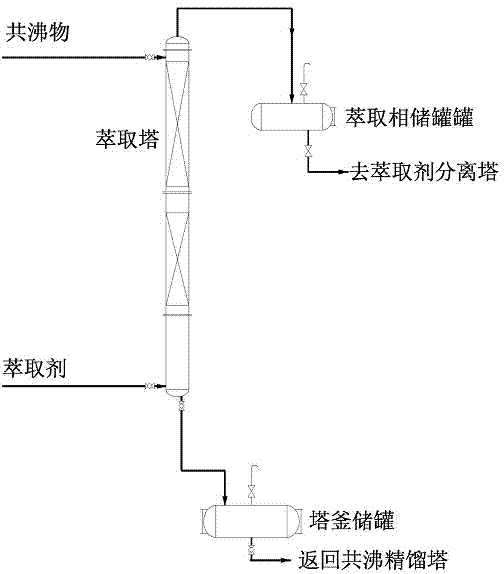

The technology of azeotropic distillation and azeotropic distillation column is applied in the field of separation of polyol mixed liquid, which can solve problems such as difficulty in separation, and achieve the effects of strong versatility, strong device operation stability and large processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0012] Design, manufacture, install azeotropic rectification column and perform batch operation, the raw material is a mixture of ethylene glycol-1,2-butanediol-zeotropic agent (including ethylene glycol: 1,2-butanediol: azeotropic The boiling agent mass ratio is 2:1:7.46), the operating pressure is set to 80kpa, and the reflux ratio is 10. The temperature at the top of the tower is stable at about 170°C, and the temperature at the bottom of the tower changes from 180°C to 189°C. The azeotrope liquid of ethylene glycol and entrainer is obtained at the top of the tower, and the azeotrope content is 99.8%. The batch rectification operation has obtained a good separation effect, which proves that the experimental rectification tower can obtain azeotrope.

example 2

[0014] Adopt the equipment and operating conditions of the above example to carry out continuous rectification operation, and feed from the middle part of the rectification tower at normal temperature. The azeotrope can still be obtained at the top of the tower. After the stable production, adjust the reflux ratio, and continue to rectify under this condition to obtain high-concentration 1,2-butanediol in the bottom of the tower. After separation, the color of the product is qualified and the purity reaches over 98%.

example 3

[0016] Collect the azeotrope at the top of the above two examples, extract with extractant to form a heterogeneous solution, the upper layer is azeotrope, and the lower layer is a mixed solution of ethylene glycol and extractant; or use an extraction tower to separate to obtain a raffinate phase It is an entrainer, and finally the concentration of the entrainer is 99.24%, and the extraction phase is separated from the extractant by a rectifying tower. The extraction phase is a mixed solution of ethylene glycol and extractant. The extractant can be recycled after being separated by the extractant rectification tower. The obtained ethylene glycol crude product can be purified by the ethylene glycol rectification tower. Alcohol purity above 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com