Automatic packaging device for cigarette case cardboard finished product

An automatic packaging and cardboard technology, applied in paper product packaging, packaging material feeding devices, packaging, etc., can solve the problems of unsatisfactory automation, high-efficiency production, different kraft paper belts, and low binding efficiency, and achieve simple structure, The effect of reducing the operation of personnel and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

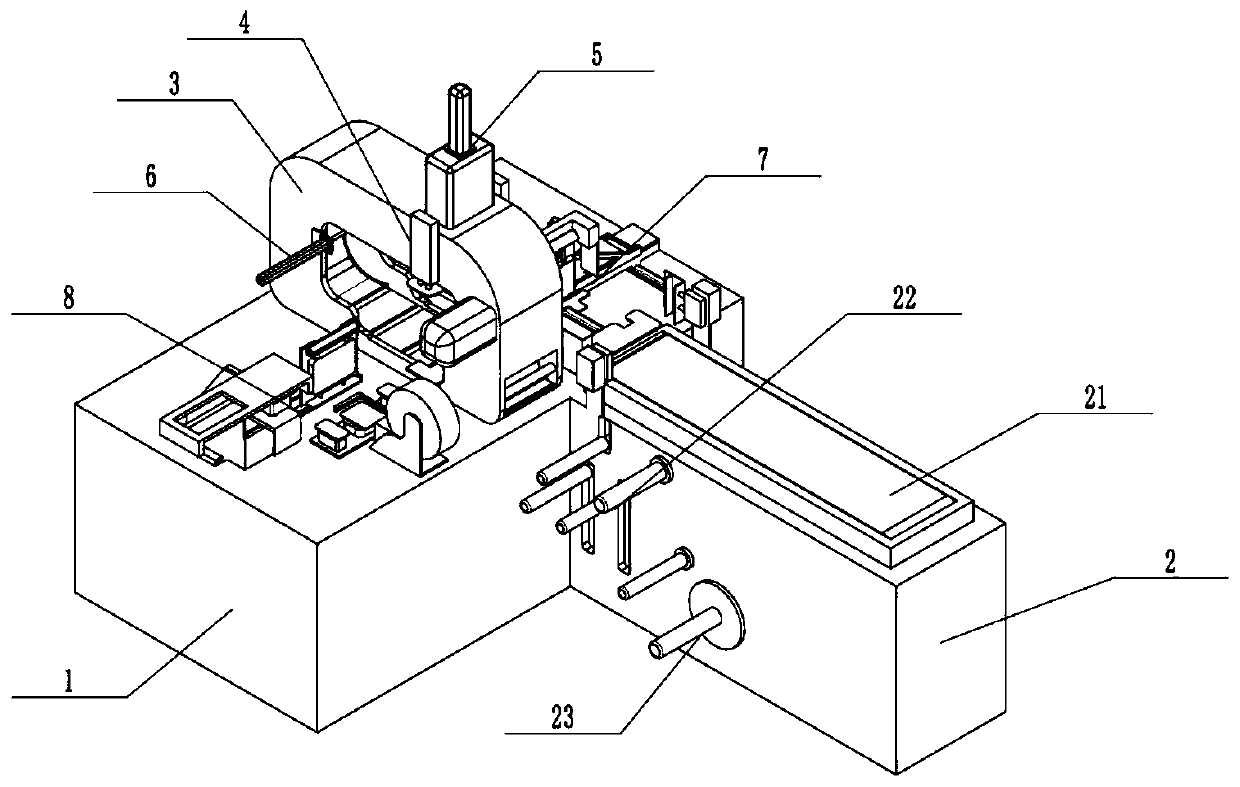

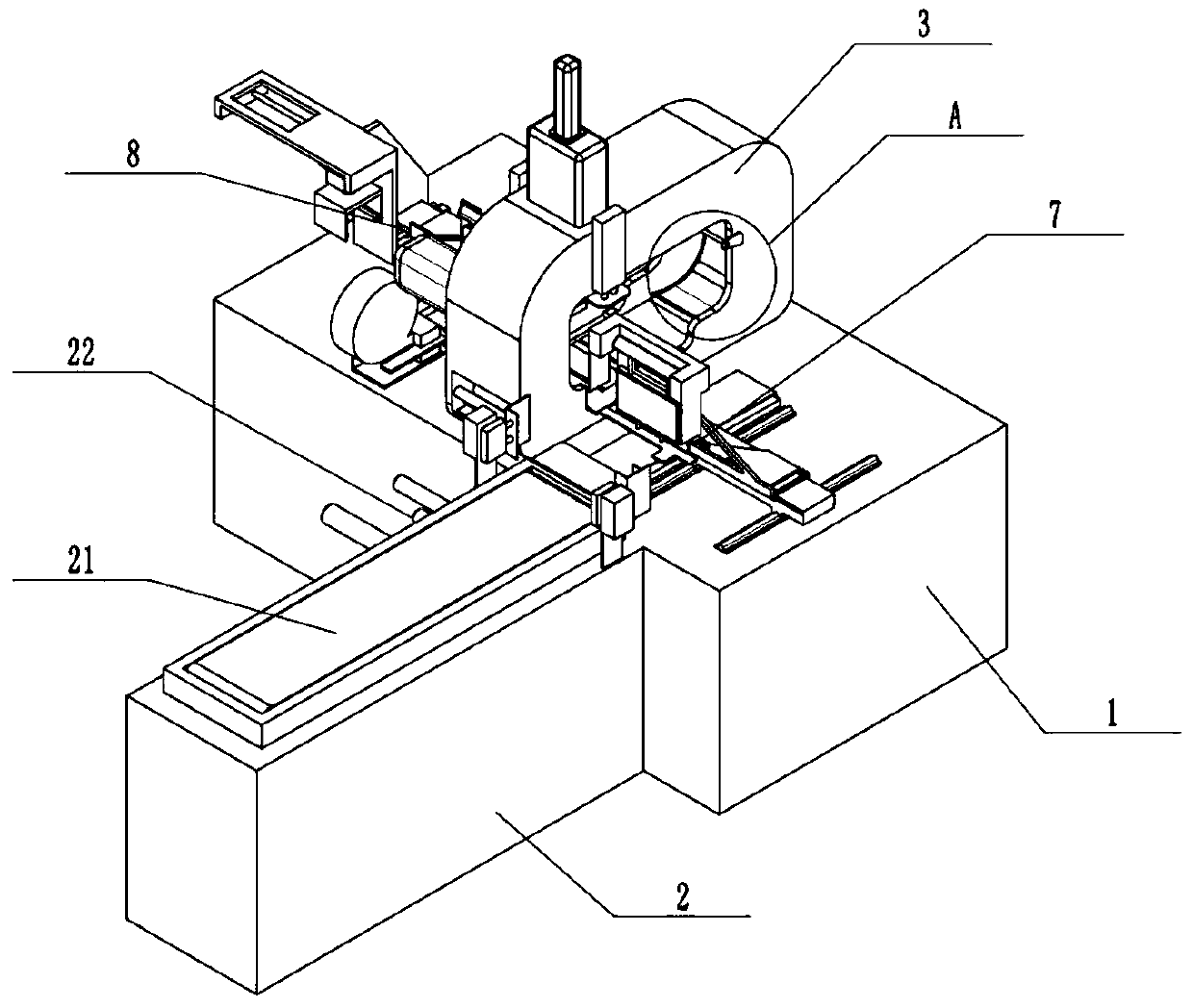

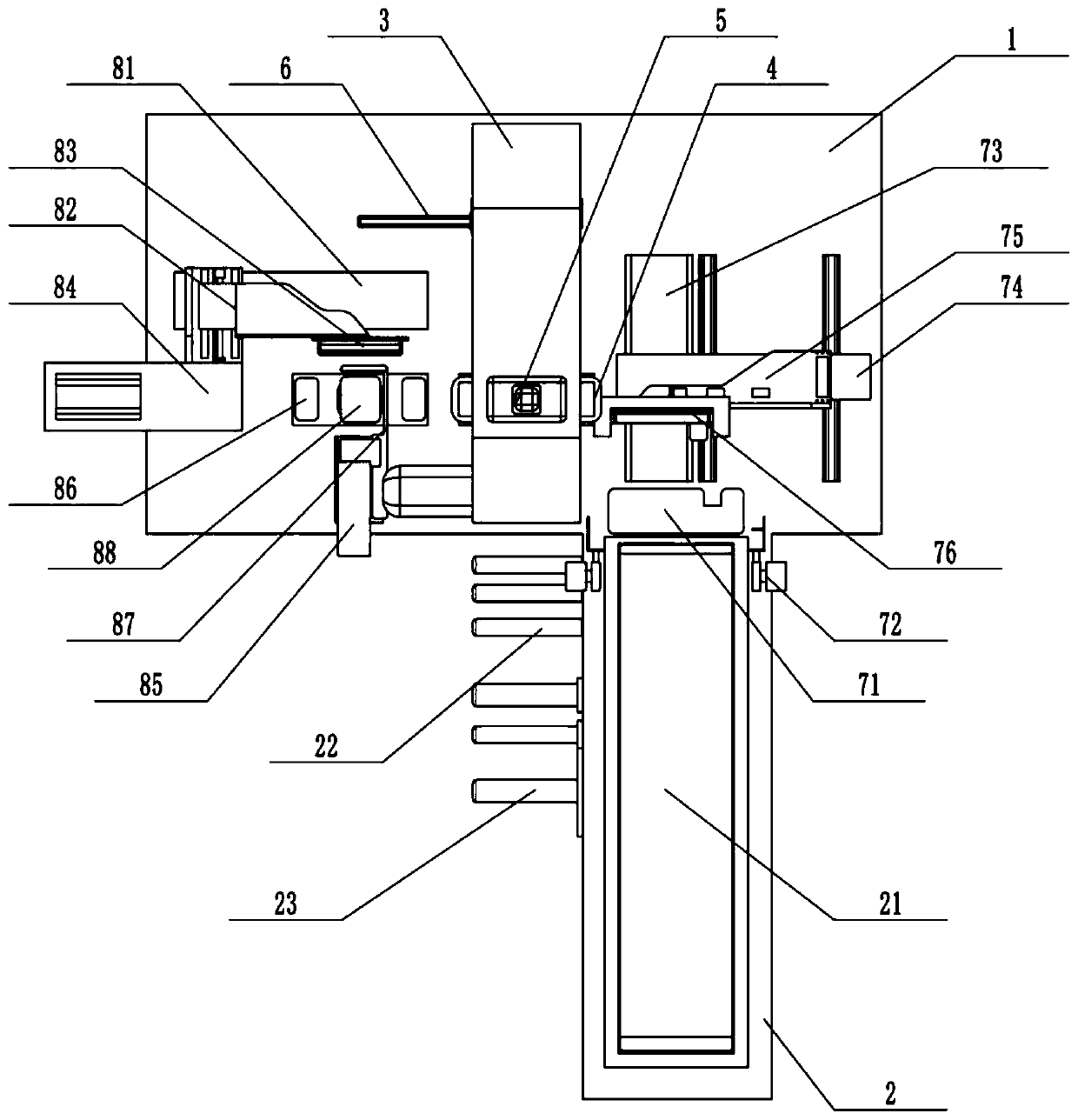

[0026] An automatic packaging device for cigarette case cardboard products according to an embodiment of the present invention is as follows: Figure 1-6 As shown, it includes a machine base, and also includes a packaging mechanism arranged on the machine base, a neat feeding mechanism 7, an adhesive discharge mechanism 8, a conveyor belt 21, and a tension adjustment mechanism 22 and a tension adjustment mechanism placed in the machine base. The roller 23 is placed, the machine base includes a worktable 1 and a transmission table 2, the packing mechanism is placed in the middle above the workbench 1, the neat feeding mechanism 7 and the sticky discharging mechanism 8 are placed in a left-right position On both sides of the packaging mechanism, the conveyor belt 21 is placed on the transmission platform 2 and cooperates with the neat feeding mechanism 7, the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com