Small commodity automatic packaging and discharging device for warehouse logistics

An automatic packaging and shipping device technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of unpacking, waste of labor, automatic cutting, etc., to avoid packaging too fast, improve protection, and ensure integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

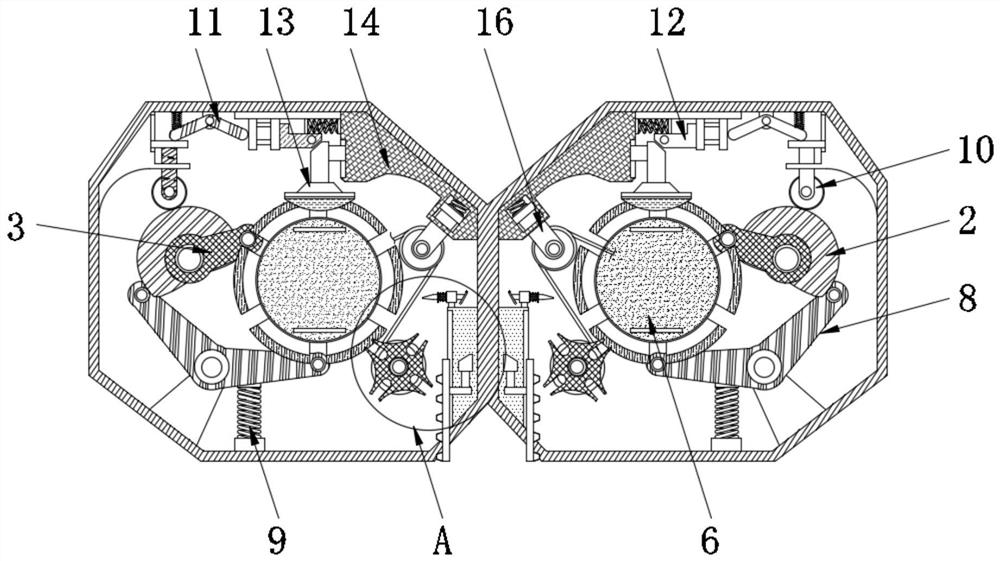

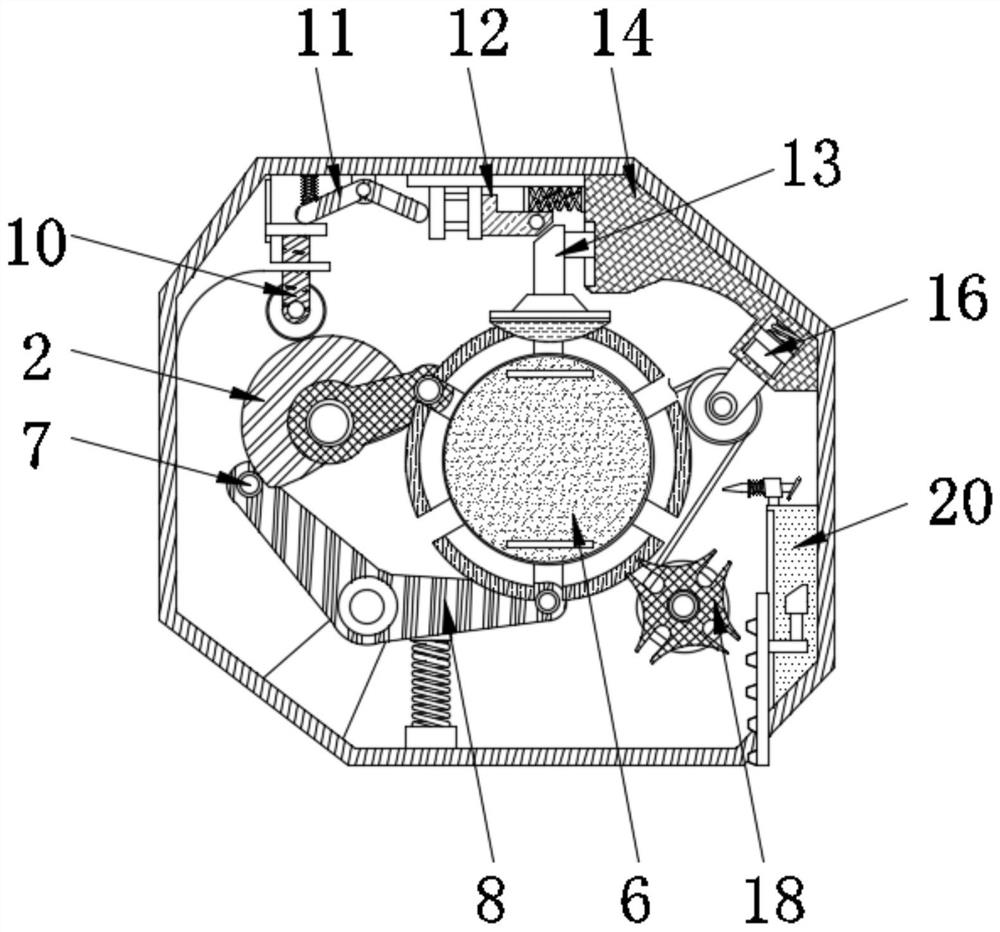

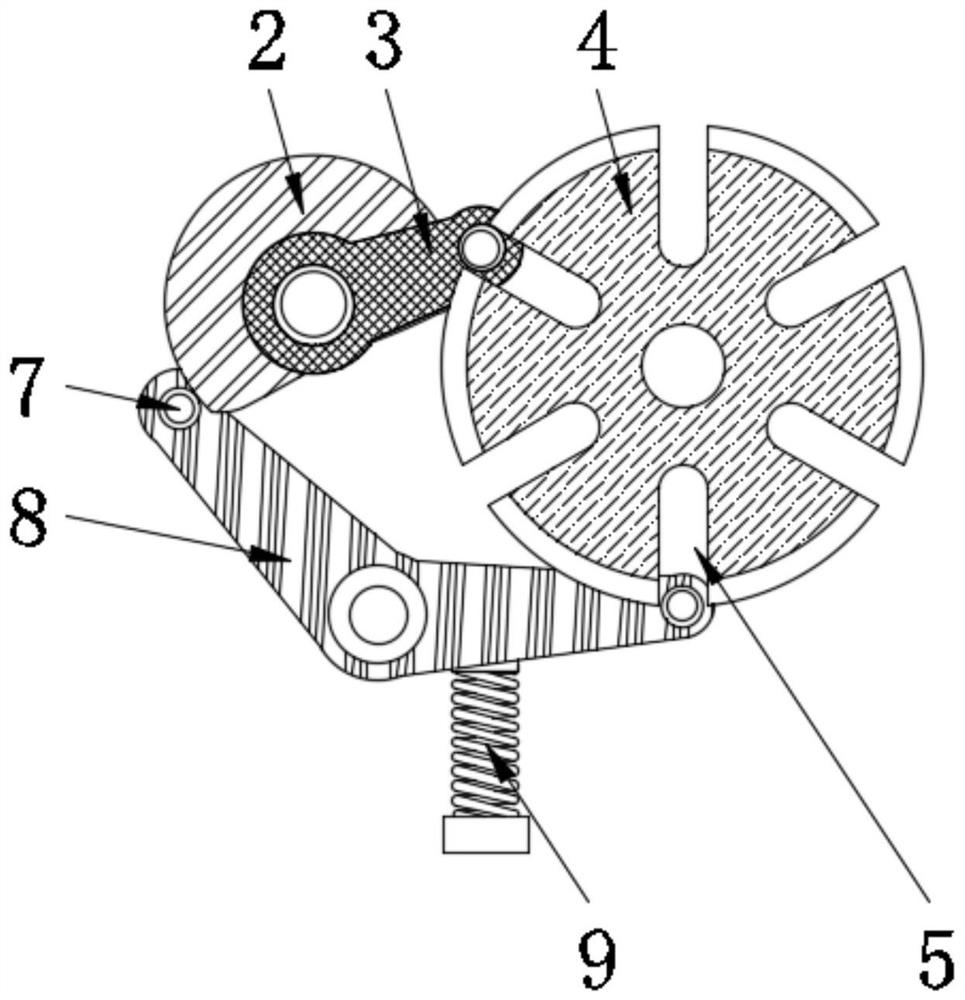

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] The invention provides an automatic packaging and shipping device for small commodities for warehouse logistics, as attached figure 1 To attach Figure 5 Shown: including the packing bin 1, the inside of the packing bin 1 is installed with a concave disc 2, the concave disc 2 is fixedly installed on the output end of the motor, the front surface of the concave disc 2 is fixedly installed with a connecting plate 3, and the outer end of the connecting plate 3 Slidingly installed in the sliding hole 5 provided inside the turntable 4, the front surface of the turntable 4 is fixedly installed with a clamping table 6, the lower surface of the concave plate 2 is attached with a post 7, and the front surface of the connecting plate 3 is provided with a sliding hole 5 Corresponding clamping posts, the interior of the turntable 4 is evenly distributed with sliding holes 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com