Patents

Literature

277results about How to "Make sure to enter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard compound reinforcing bridging agent

ActiveCN101671550AMake sure to enterStrong bridging supportFluid removalDrilling compositionFiberGeological exploration

The invention discloses a hard compound reinforcing bridging agent comprising the following materials in parts by weight: 30-40 parts of shell powder, 15-30 parts of calcium carbonate, 30-40 parts ofnatural hard rubber and 20-30 parts of natural hard fiber. A preparation method comprises the following step: uniformly mixing and stirring the materials in parts by weight at normal temperature and pressure. The hard compound reinforcing bridging agent is prepared by compounding elastic plugging materials with a certain rigidity according to a scientific mixing proportion, and rigid solid granules with different granule diameters enter leaking cracks, leaking pores and leaking passages in the plugging construction process and play bridging and supporting roles in the leaking cracks, the leaking pores and the leaking passages with different sizes. The invention has high supporting capability and plugging characteristic, wide using range, and the like and is widely applied to leakage prevention and plugging technologies of oil and geological exploration.

Owner:DONGYING TAIER GASOLINE TECH

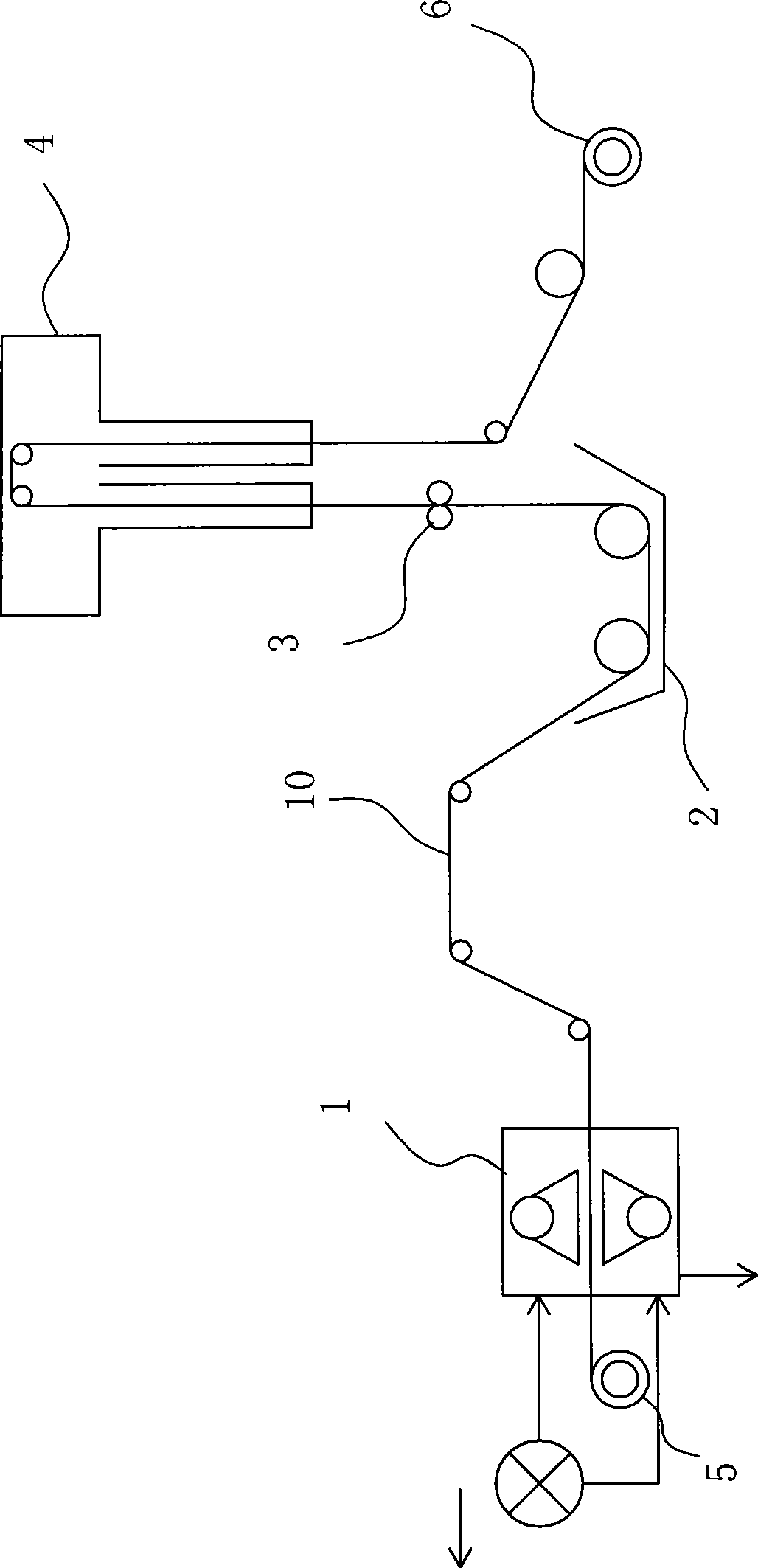

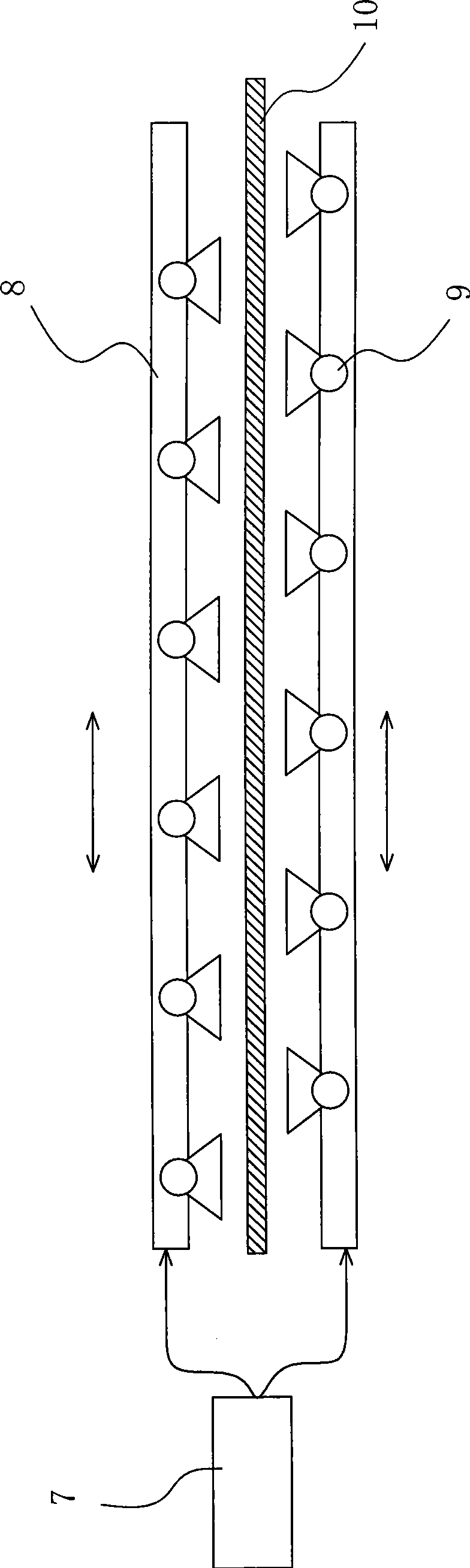

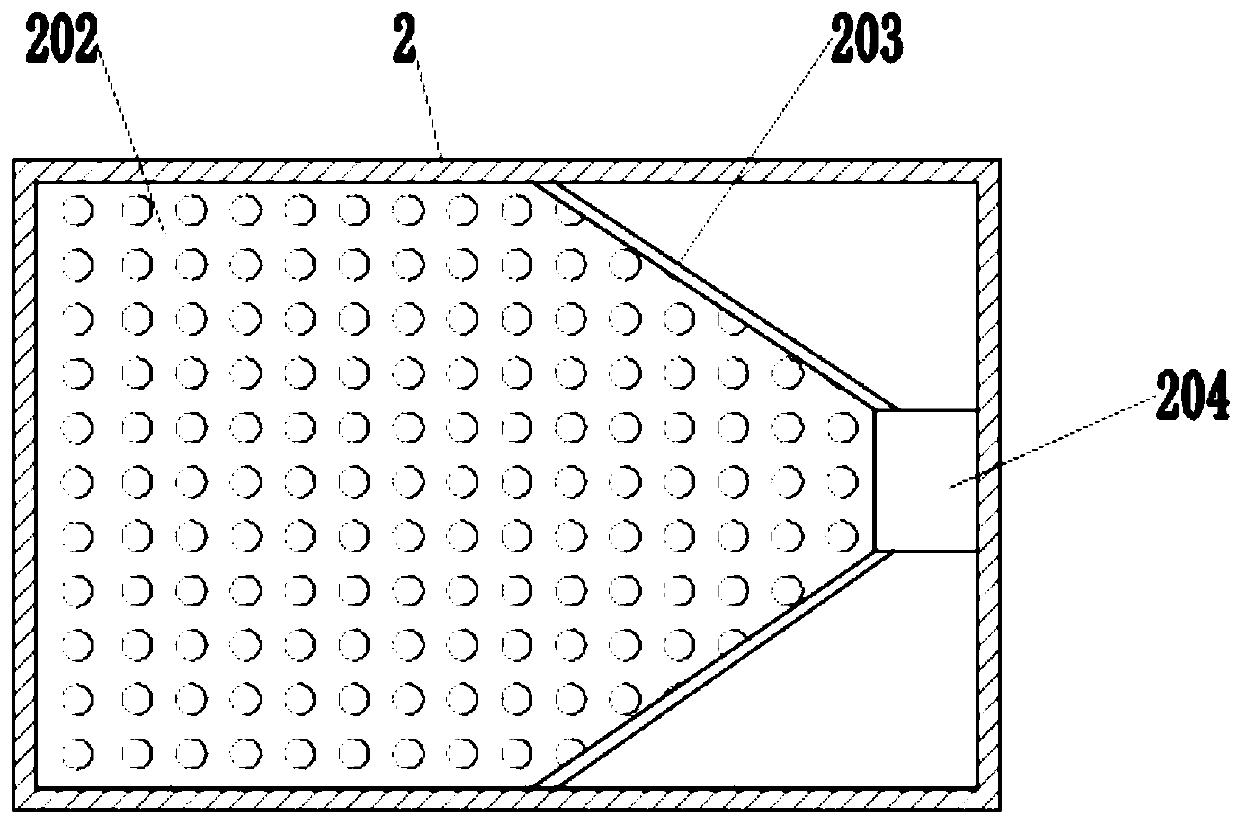

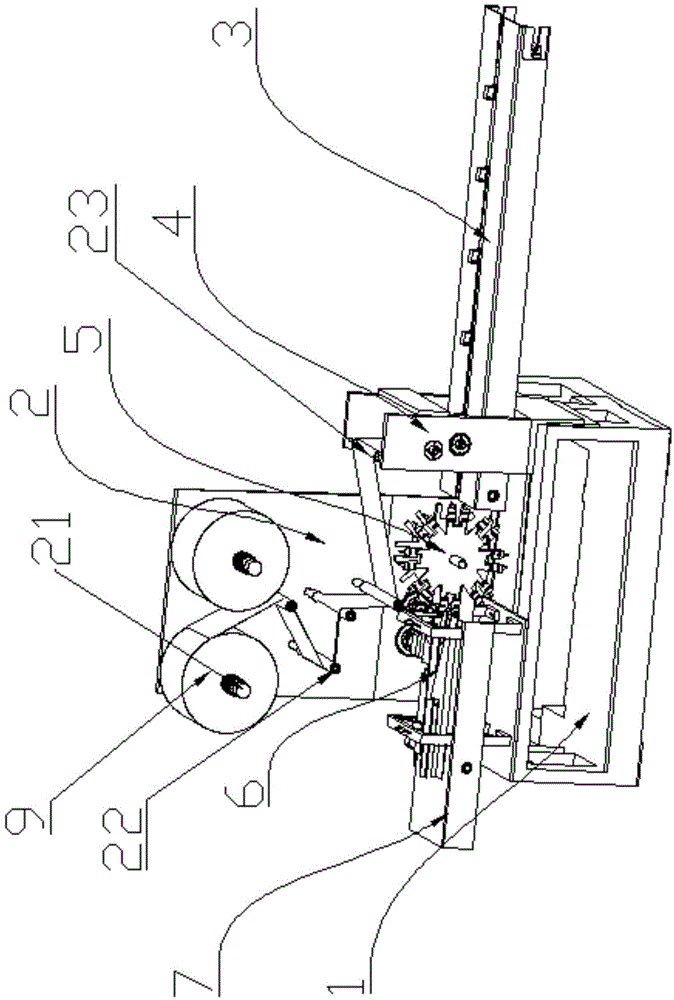

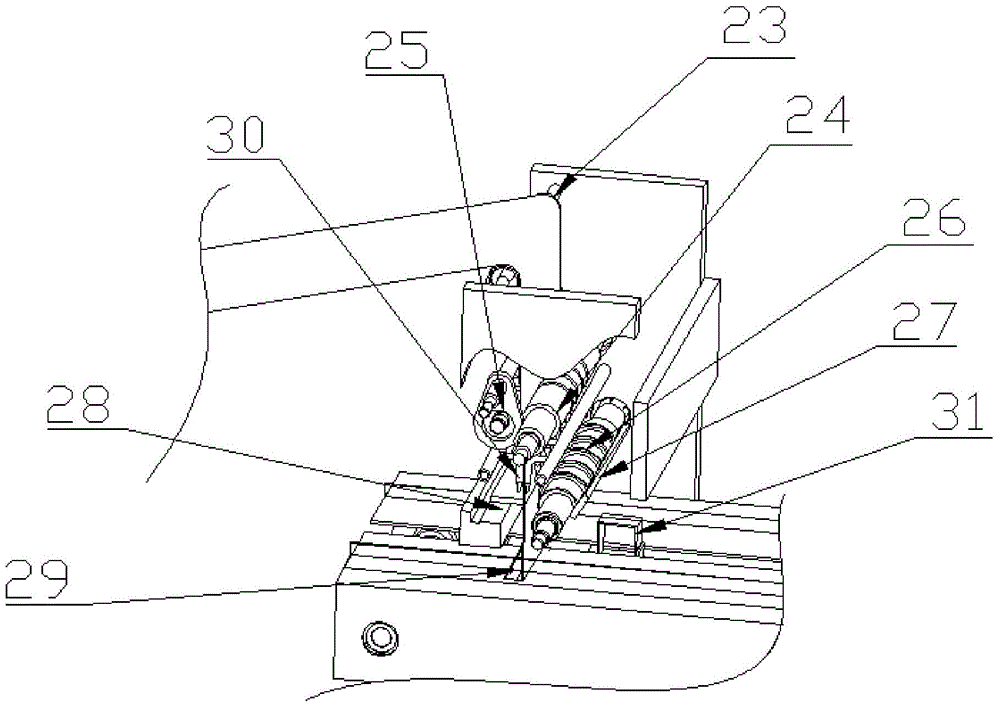

Method for producing semi-curing piece and device thereof

The invention discloses a method for manufacturing prepregs. The method comprises the process steps of putting an uncoiled glass-fiber-fabric substrate into a glue groove, impregnating the substrate with glue solution, controlling the content of the glue solution through a metering roll, heating and drying the glue solution through an oven. The method is characterized in that the substrate is impregnated with the glue solution and then is sprayed and smeared with glue; the glue solution is sprayed onto the glass-fiber-fabric substrate through high-pressure nozzles; and the spray pressure is between 1 and 10 km / cm<2>. A device for manufacturing prepregs comprises an uncoiling device, a main impregnation device, the metering roll, a heating-drying device and a coiling device, and is characterized in that the device also comprises a spray chamber positioned behind the uncoiling device, and a high-pressure pump, a horizontal shifting mechanism, an upper spray rod and a lower spray rod arranged in parallel, as well as a plurality of high-pressure nozzles which are uniformly distributed on the upper and lower spray rods respectively are arranged in the spray chamber. The method completes the process of spraying and smearing glue through the high-pressure nozzles in the spray chamber, utilizes high pressure to split the glass-fiber-fabric substrate, enables the glue solution to enter spaces among fibers, realizes the complete and uniform infiltration of the glue solution, and reduces the quantity of bubbles.

Owner:SHENGYI TECH SUZHOU

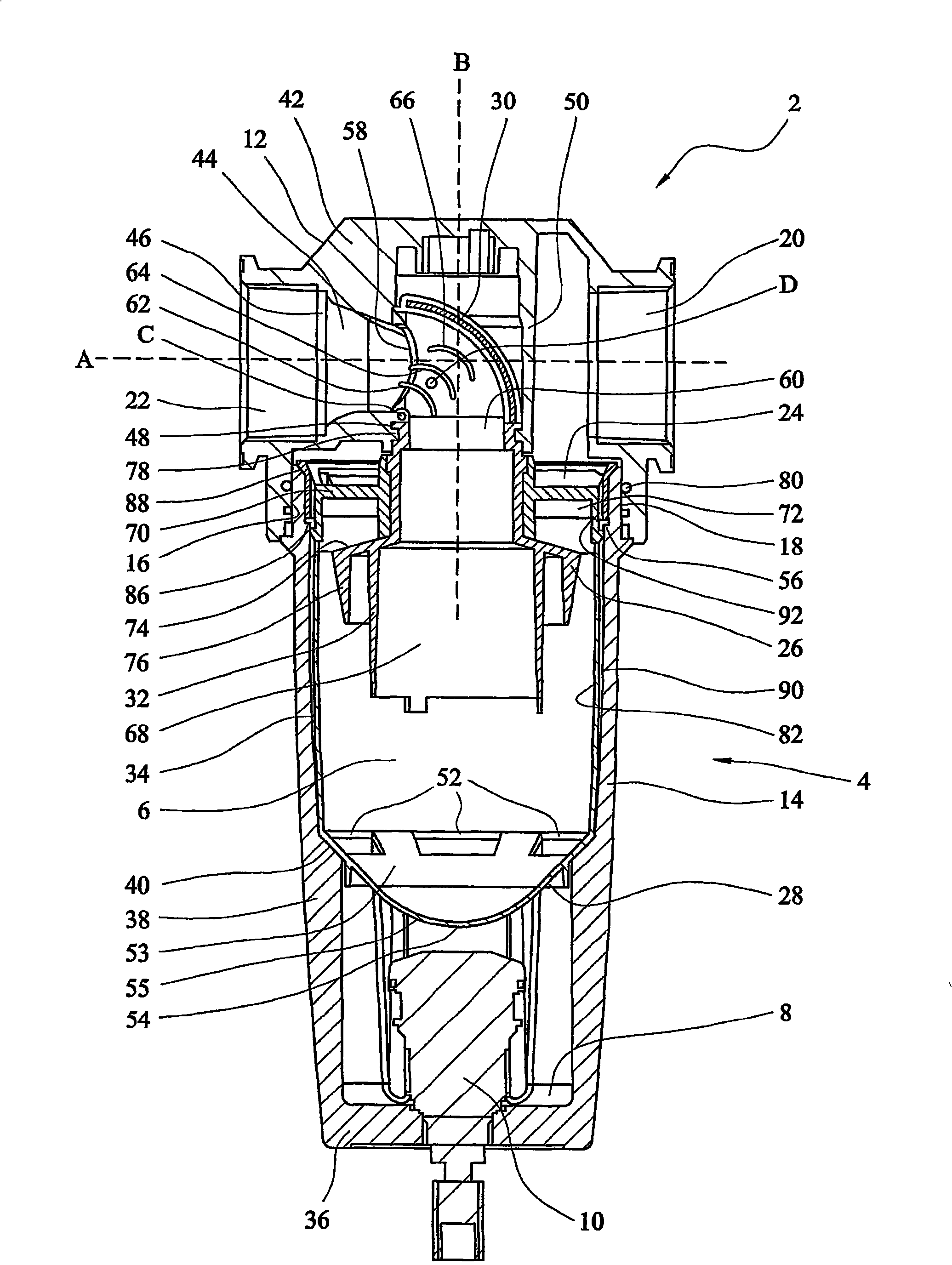

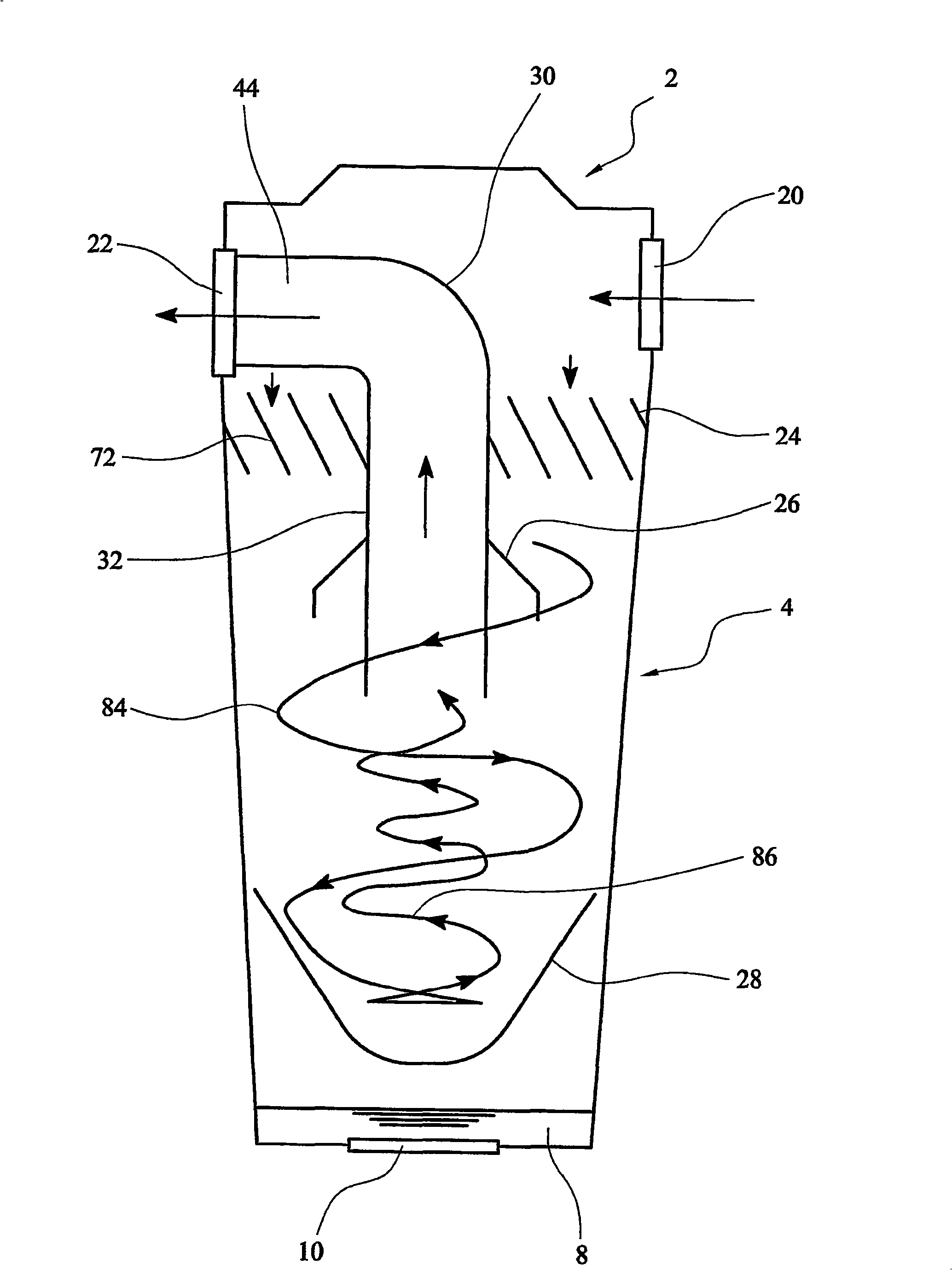

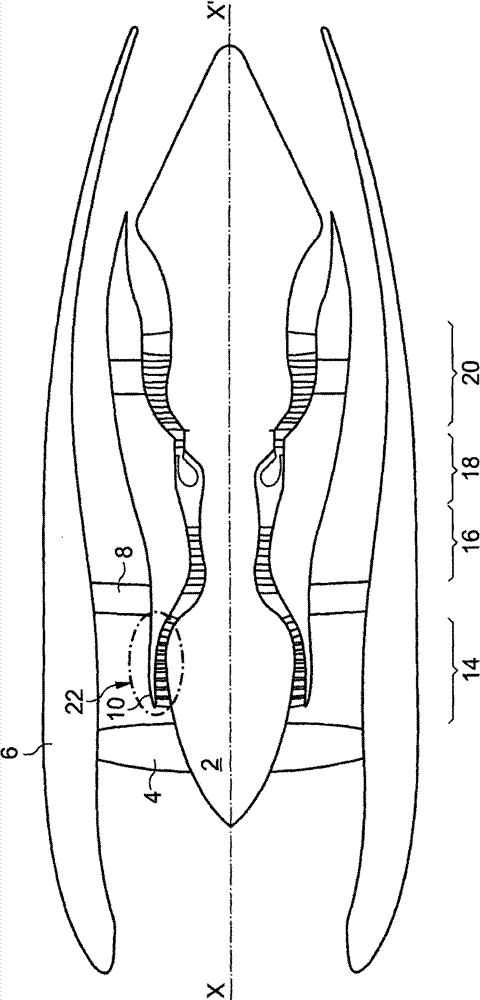

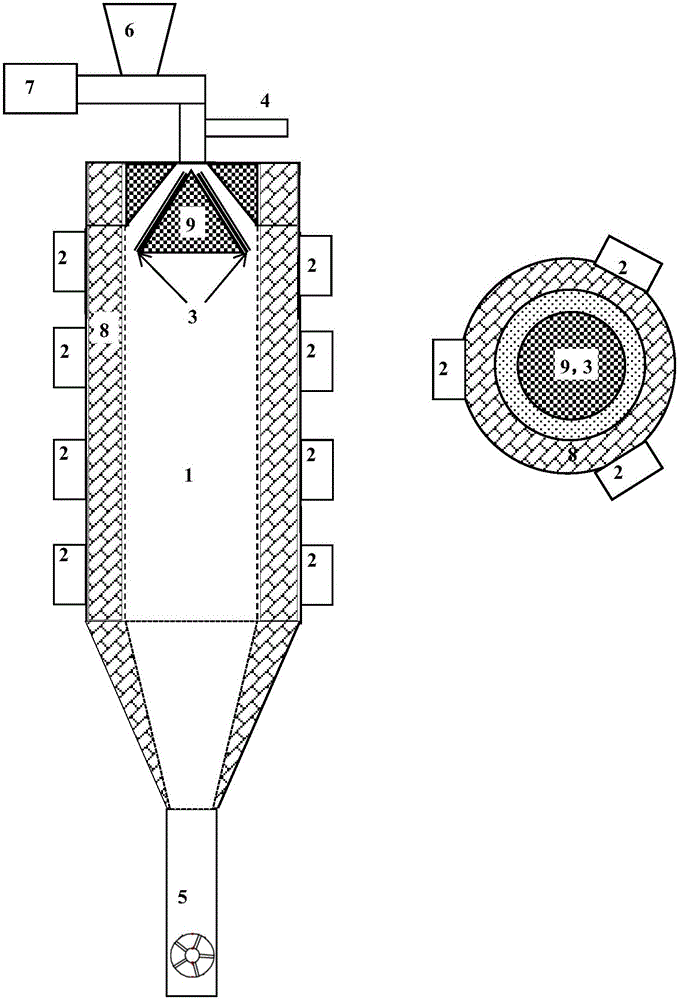

Separator assembly

ActiveCN101272839APromotes spiral flowImproved separation propertiesReversed direction vortexCentrifugal force sediment separationEngineeringMechanical engineering

A separator assembly (2) for removing material that is entrained in a gas stream. The separator assembly (2) comprises a housing having (4) inlet (20) and outlet (22) ports for the gas from which material is to be removed. The inlet (20) and outlet (22) ports are located toward the upper end of the housing. A flow director (24) is positioned so that gas flowing into the housing (4) flows over the flow director (24) so that the incoming gas is made to follow a generally helical path within the housing. The separator assembly (2) also comprises a shield (28) which extends across the housing towards the lower end thereof so as to leave a collection space (8) between it and the lower end in which material that is separated from the gas stream can collect. There is at least one opening (52) in or around the shield through which the material can flow past the shield into the collection space (8). The face of the shield (28) which is directed towards the upper end of the housing is bowl-shaped .

Owner:PARKER HANNIFIN CORP

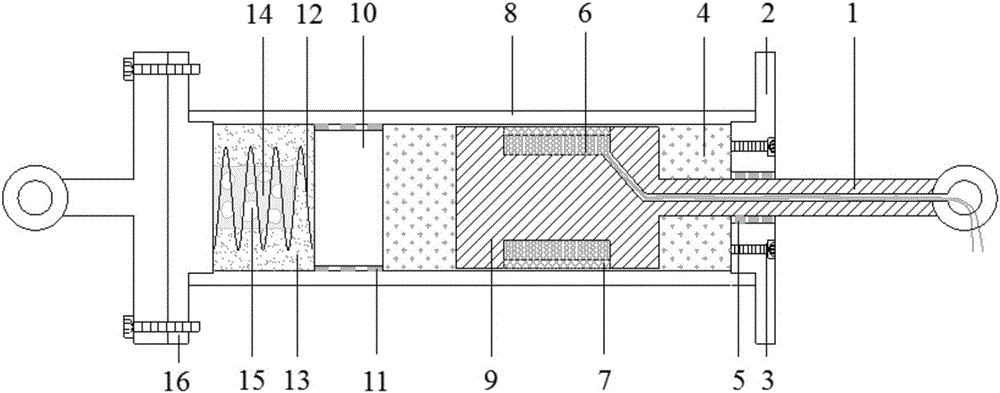

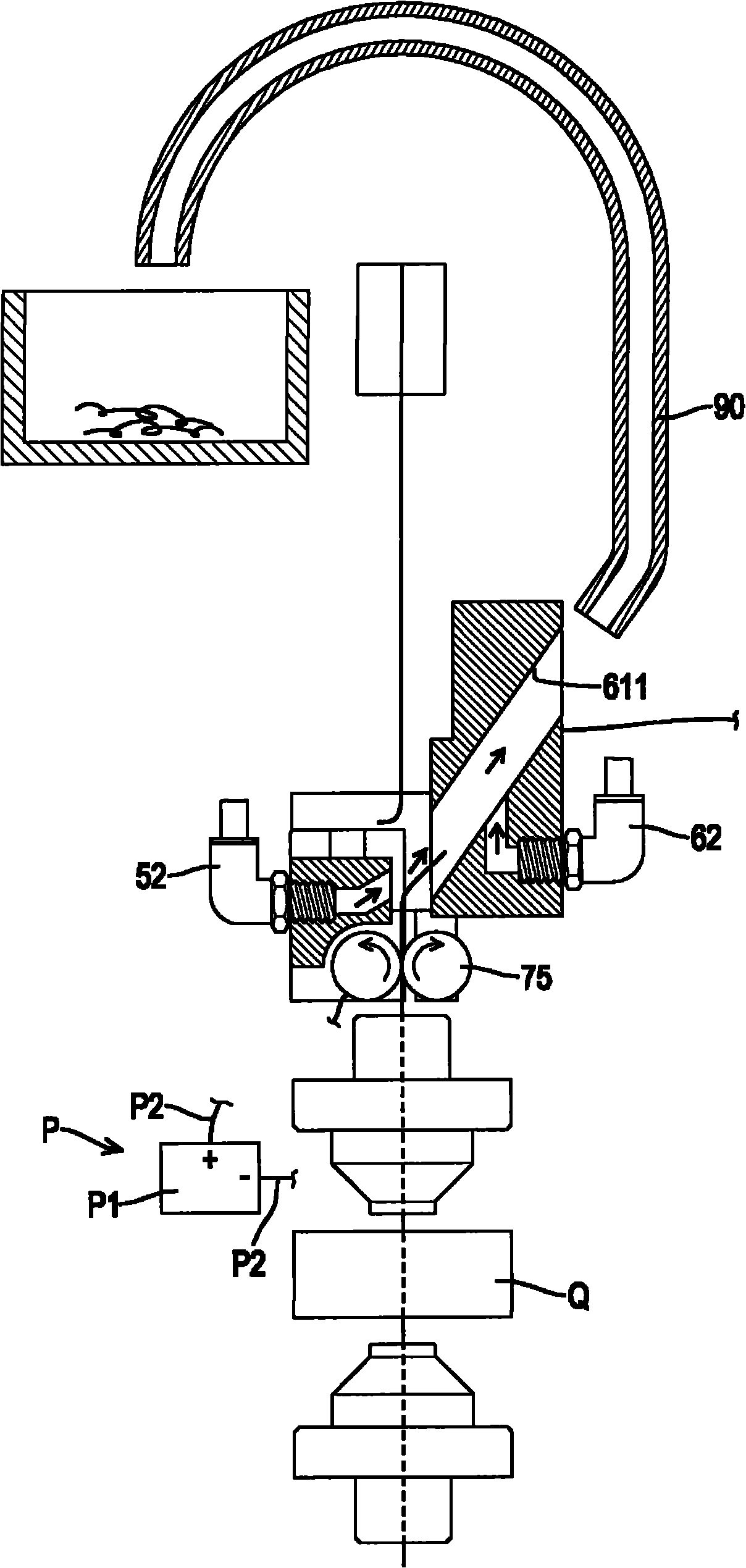

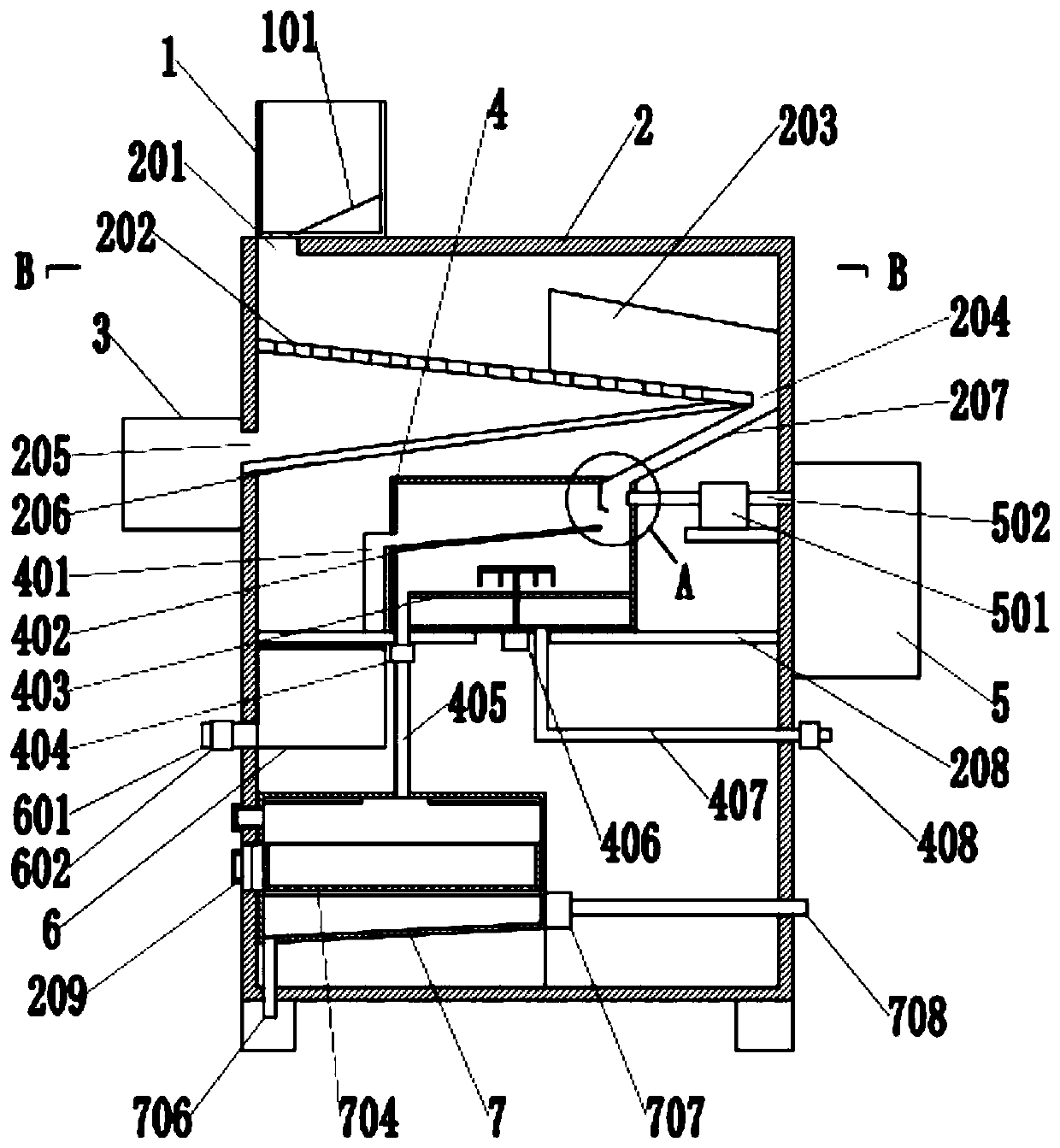

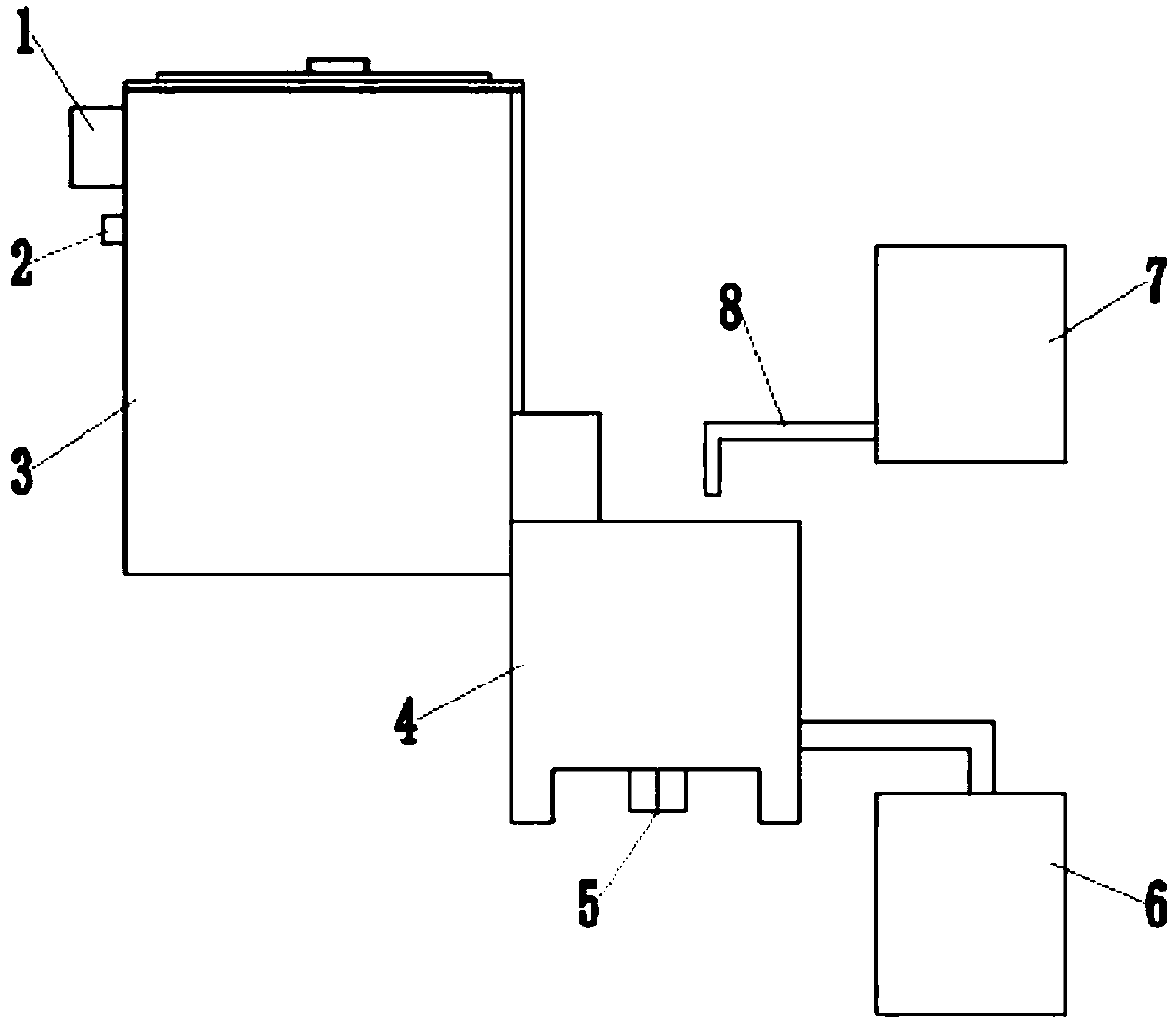

Volume compensation isolation type single rod magneto-rheological damper

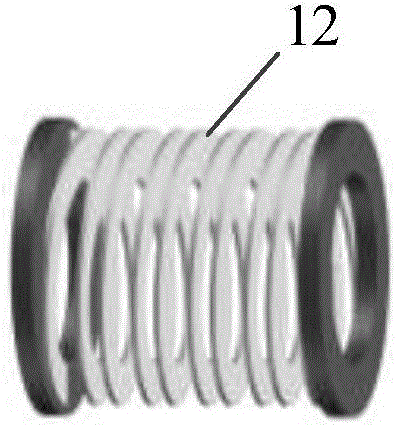

ActiveCN106678257AGuaranteed to workMake sure to enterSpringsNon-rotating vibration suppressionMagneto rheological damperSilicone oil

The invention discloses a volume compensation isolation type single rod magneto-rheological damper. The damper comprises a single rod magneto-rheological damper working cavity and a volume compensation cavity; the damper working cavity is encircled by a damper outer cylinder barrel (8), a floating plug (10) and a top sealing cover plate (2); the working cavity internally contains a piston and magneto-rheological fluid (4); the piston consists of a piston head (9) and a piston rod (1); the volume compensation cavity is encircled by the damper outer cylinder barrel (8), the floating plug (10) and a bottom sealing cover plate (16); a prepress high performance spring (12) is placed in the encircled cavity which is filled with high grade silicon oil (13); the upper end of the prepress high performance spring (12) is connected to the floating plug (10), and the lower end is connected to the bottom sealing cover plate (16); a porous rubber block (15) wrapping air is placed in the prepress high performance spring (12); the lower end of the porous rubber block (15) is connected to the bottom sealing cover plate (16) and does not make a contact with the prepress high performance spring (12), and normal working performances of the single rod magneto-rheological damper are ensured.

Owner:SOUTHEAST UNIV

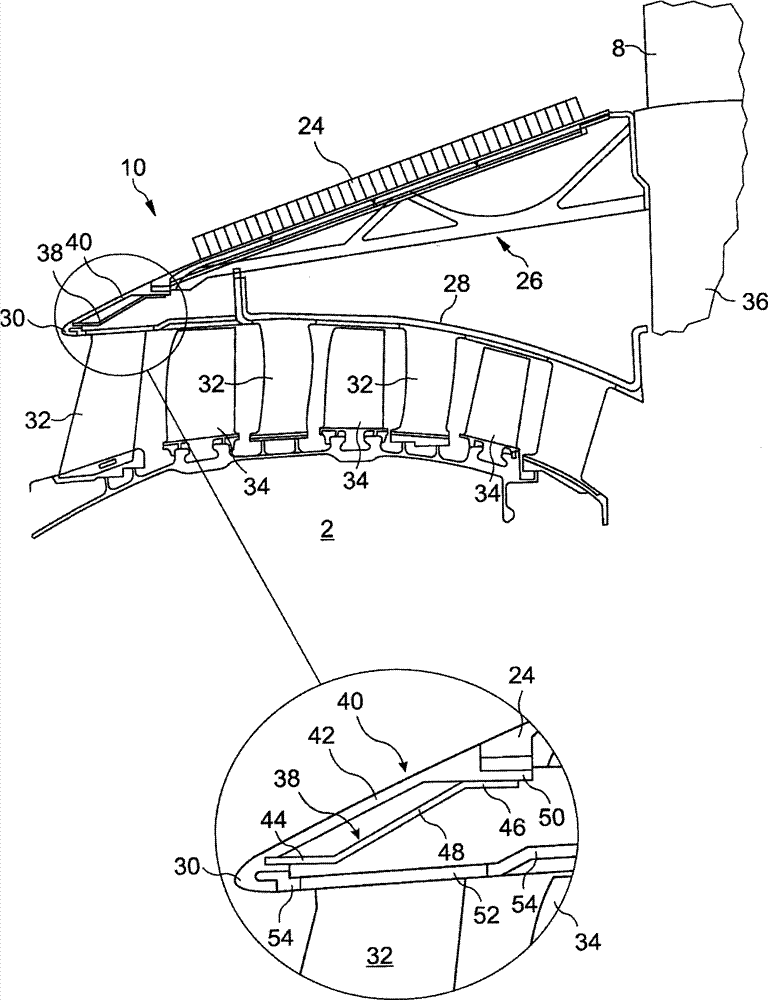

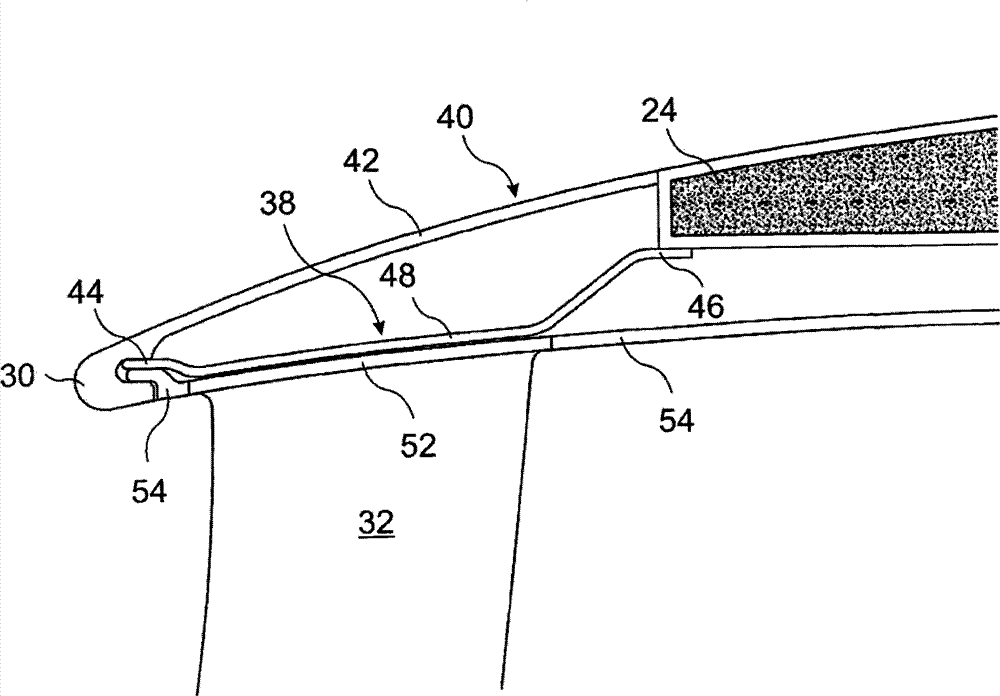

Gaseous flow separator with device for thermal-bridge defrosting

InactiveCN102733957AFavorable accommodationEfficiently obtainedPump componentsEngine fuctionsLeading edgeThermal bridge

The invention relates to a gas flow separator dividing the flow into a primary and a secondary stream, especially for a dual rotor axial turbomachine. The separator 10 comprises a splitter nose of the turbomachine and includes a generally wedge-shaped leading edge 30 in the gas flow to be split. The flow separator also comprises a metal blade 38 having a longitudinal section in the form of an S and located in the nose in contact with the back of the leading edge 30 and extending from the leading edge 30 to a rear end of the separator 10 at some distance from the leading edge, so as to be in contact with a heat source 24, such as a heat exchanger, located at some distance from the leading edge.

Owner:SAFRAN AERO BOOSTERS SA

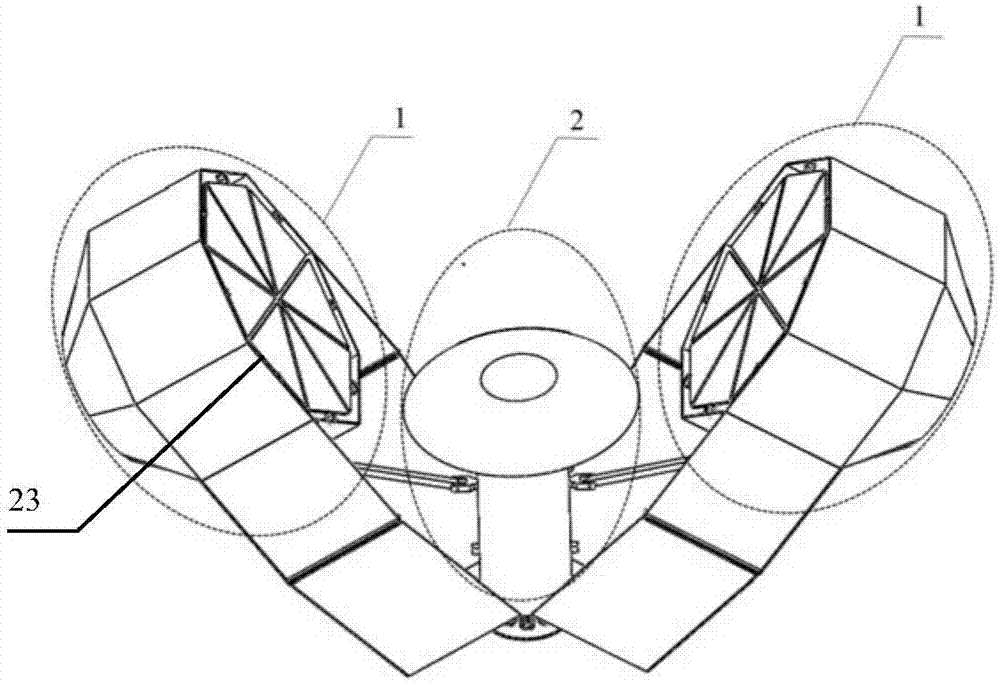

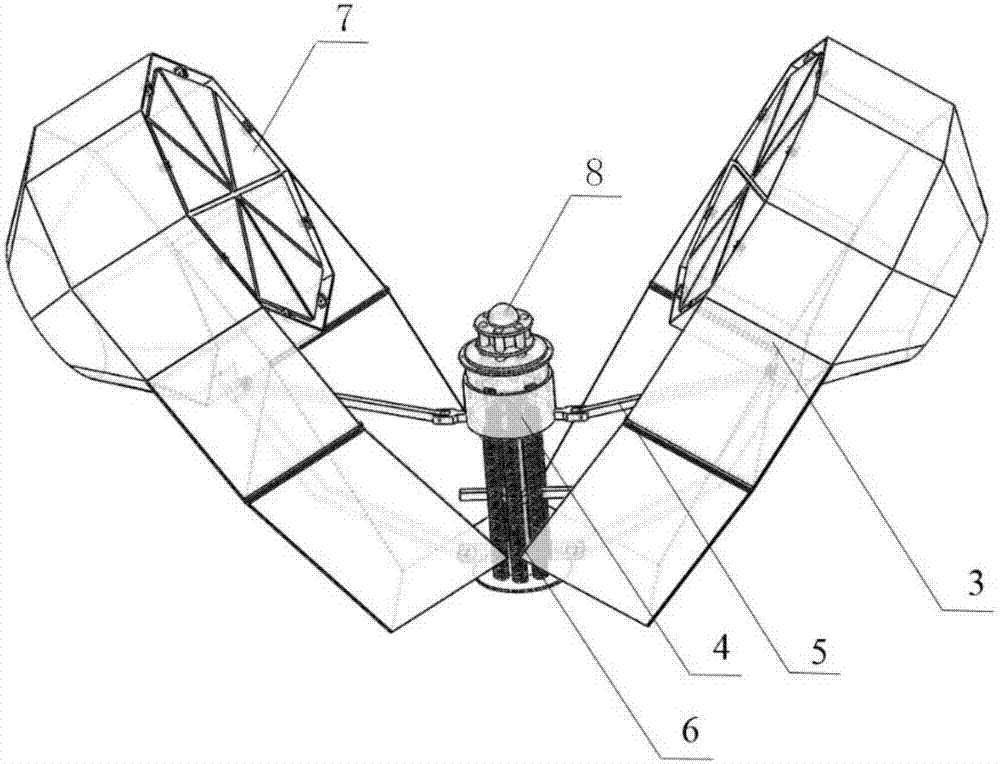

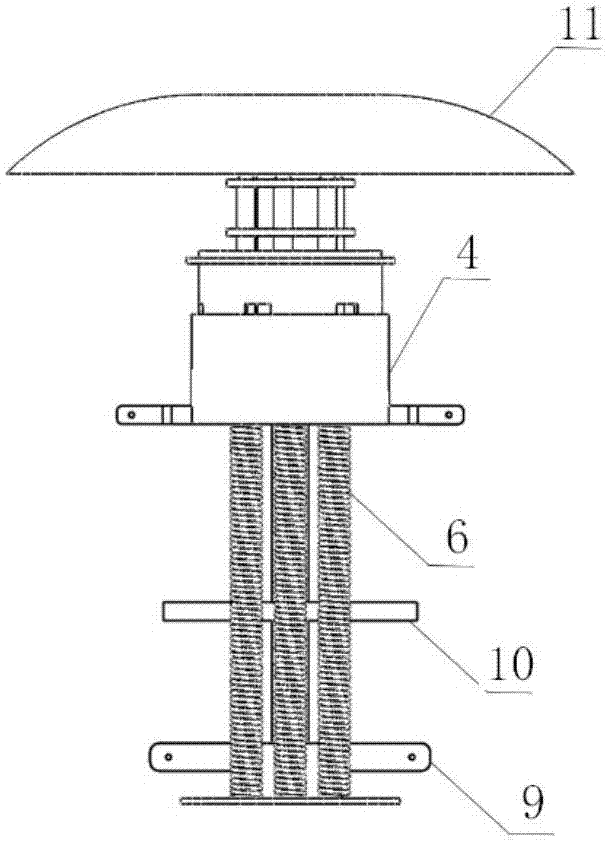

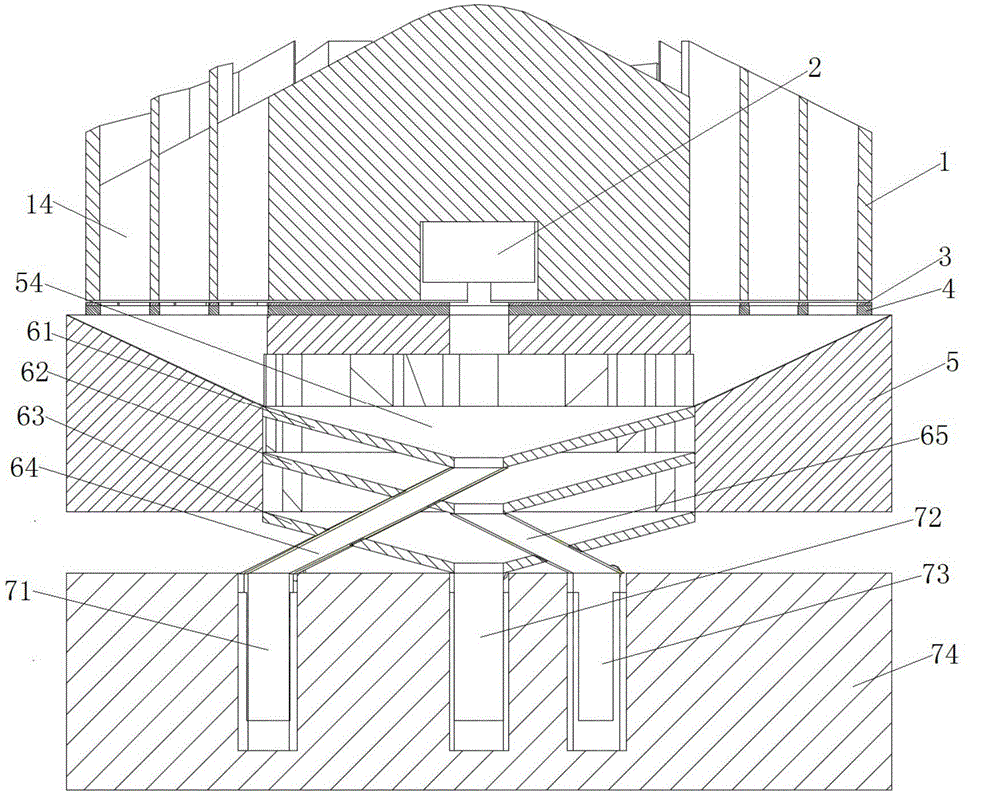

Passive-trigger-type space debris capturing device

The invention discloses a passive-trigger-type space debris capturing device. The passive-trigger-type space debris capturing device comprises two capturing storage bins, a trigger system and a base, wherein the trigger system and the base are connected between the two capturing storage bins, and the trigger system and the base are connected. The capturing storage bins comprise storage bin bodies and storage bin connecting rod assemblies connected with the storage bin bodies; and storage bin openings are formed in the storage bin bodies, the storage bin connecting rod assemblies are connected with the base, and the trigger system comprises a motor, a lead screw driving system, a sliding-block-type opening and closing system and a spring trigger. The passive-trigger-type space debris capturing device has the beneficial effects that the space debris capturing device belongs to a passive cleaning method, space debris can be effectively acquired through an integral enveloped-type structure of the two capturing storage bins, and the debris is acquired passively by arranging the trigger system; and because the debris is cleaned mainly depending on natural factors of the outside world, the consumed energy is extremely little, and the cost is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

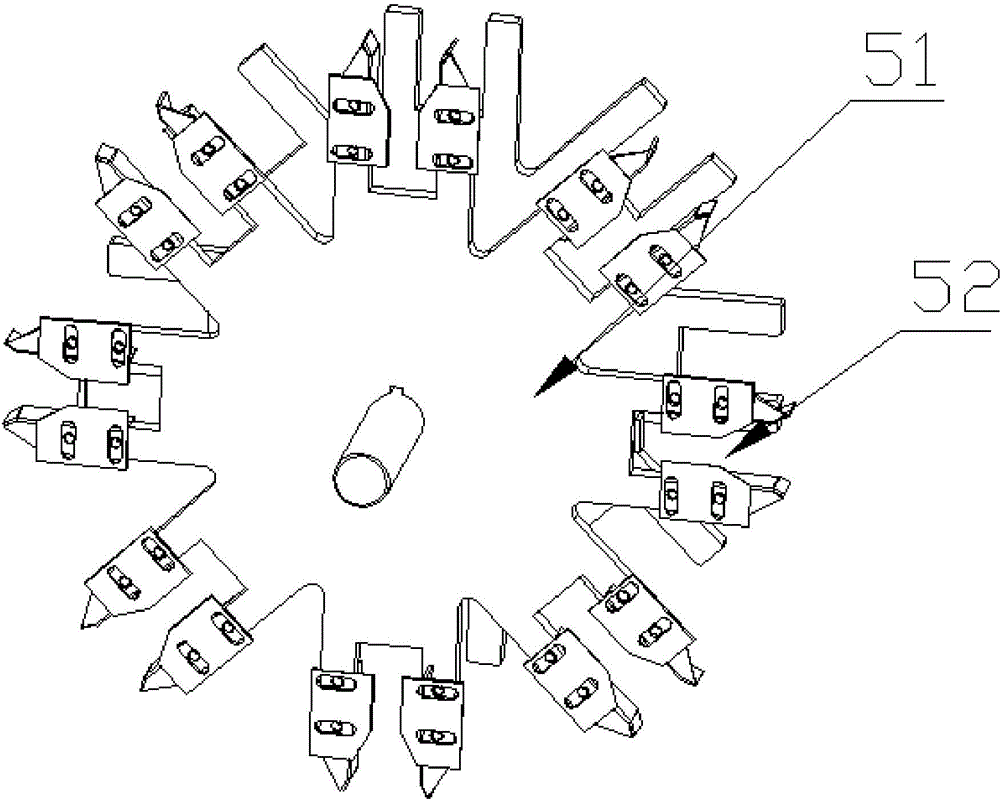

Mechanical device for classification, counting, and arrangement of coins

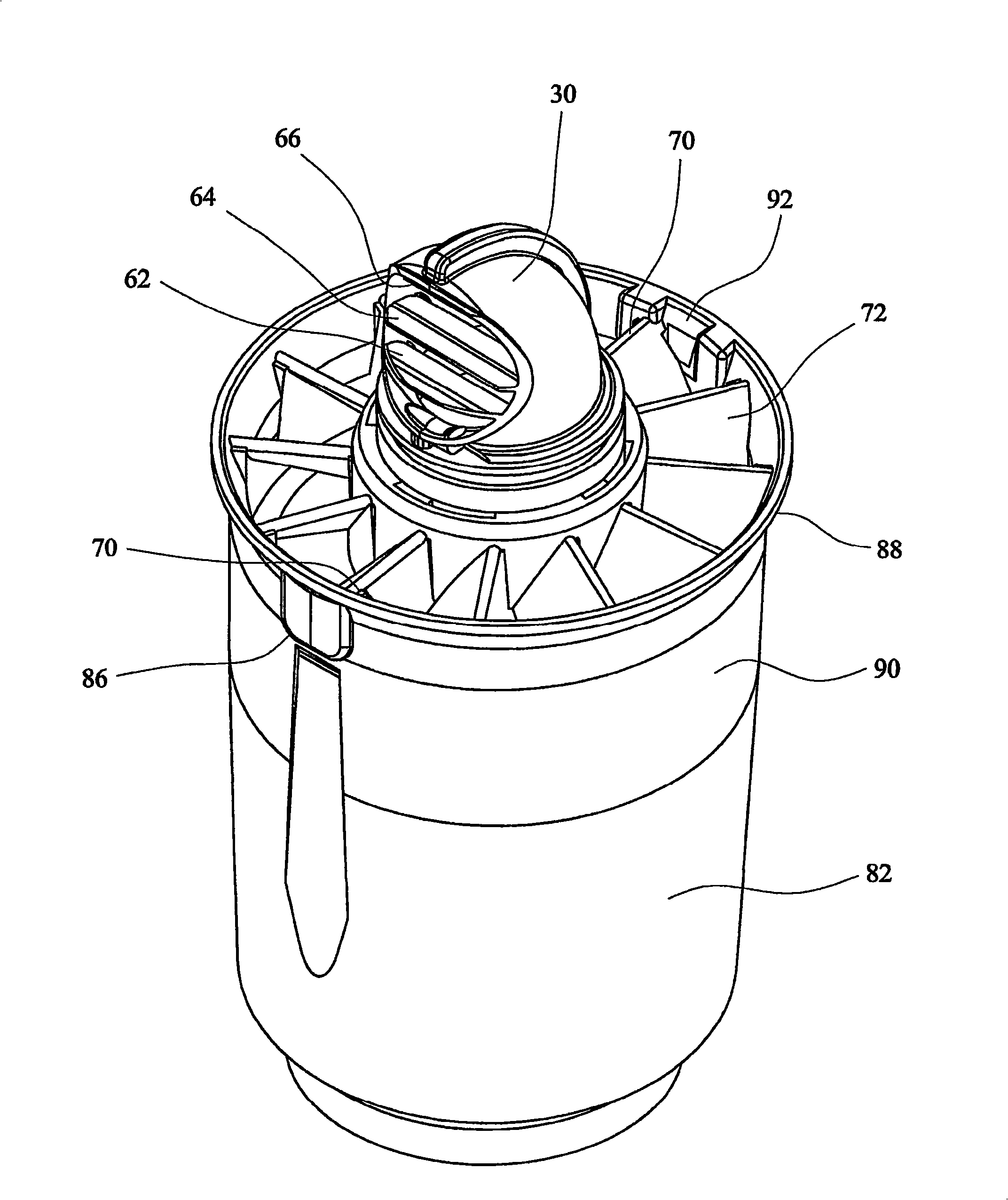

ActiveCN105023338ACompact structureEasy to assemble and disassembleCoin/paper handlersImpellerEngineering

The invention discloses a mechanical device for classification, counting, and arrangement of coins. A coin dividing device, an impeller, a sieving tray, a coin conveying device, a coin guide assembly embedded into the coin conveying device and a coin collection device are successively arranged from top to bottom. The device has advantages of compact structure, convenient mounting and dismounting, and small size; and an objective of classification, counting, and arrangement of various coins mixed together can be achieved efficiently and accurately.

Owner:淮安叶清源食品有限公司

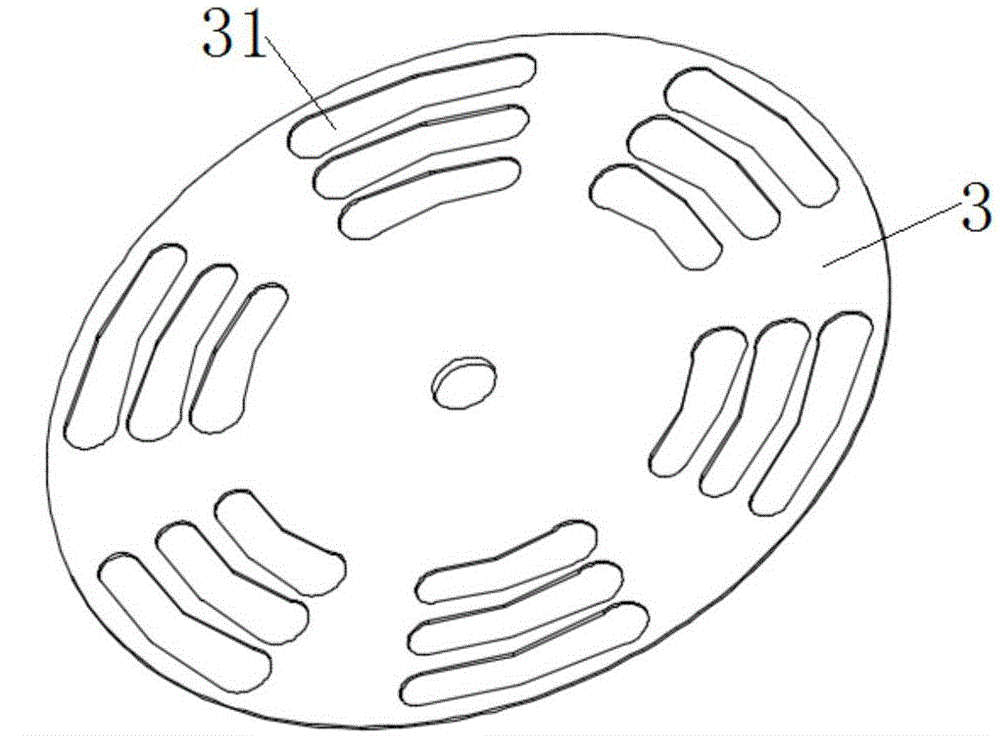

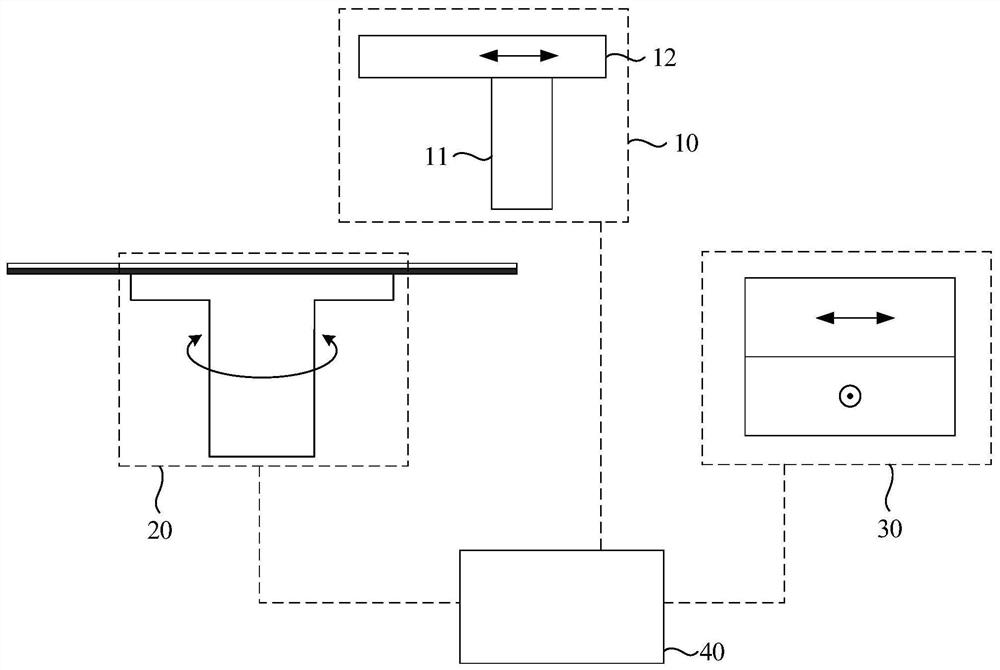

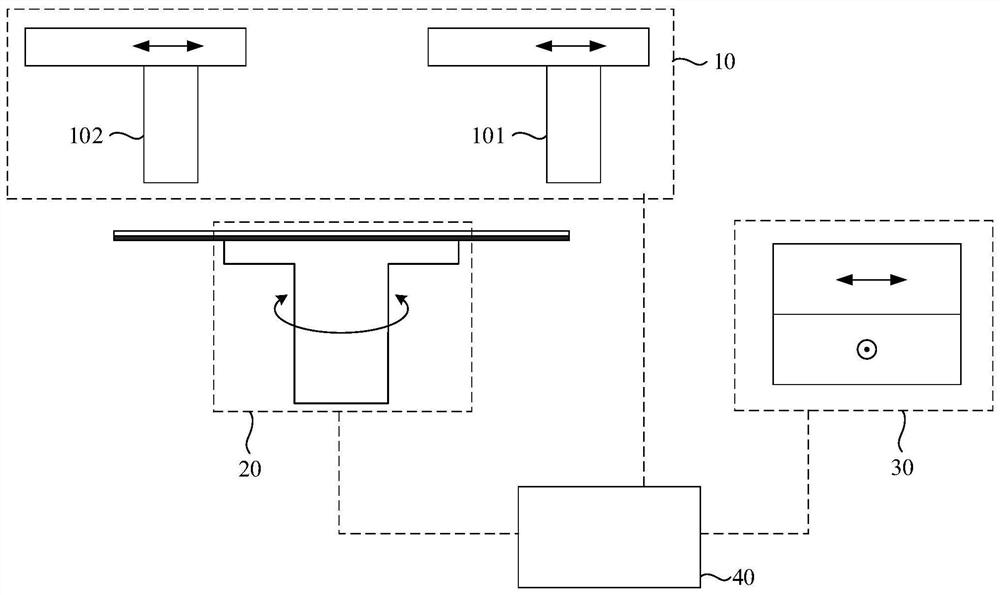

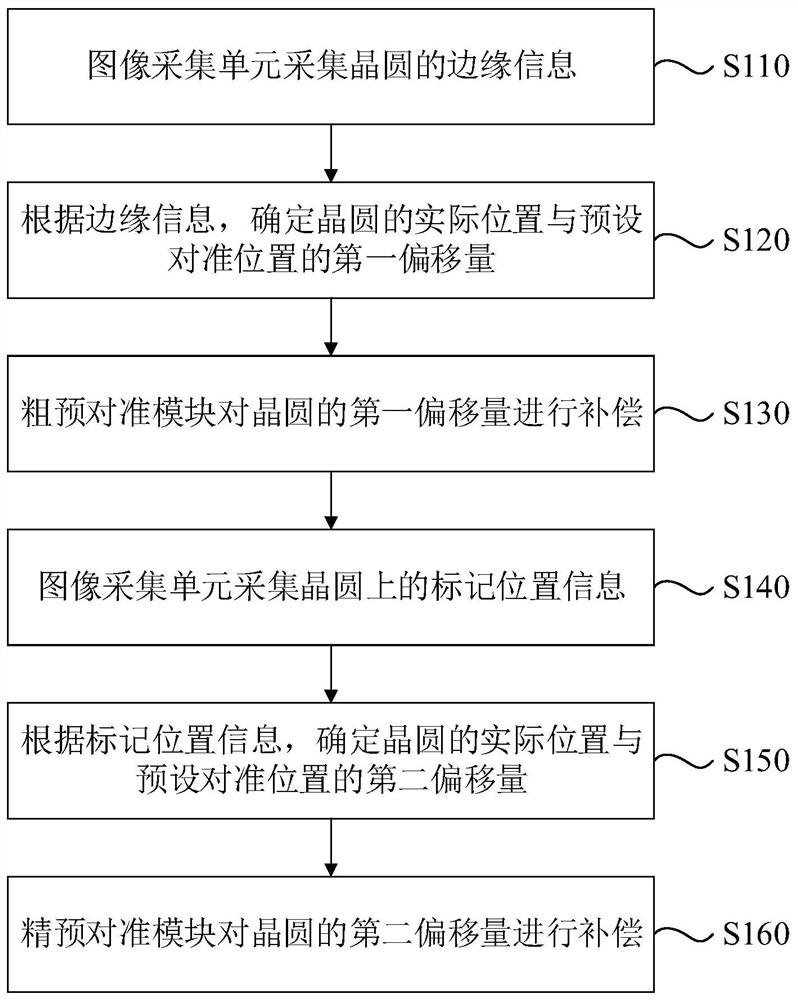

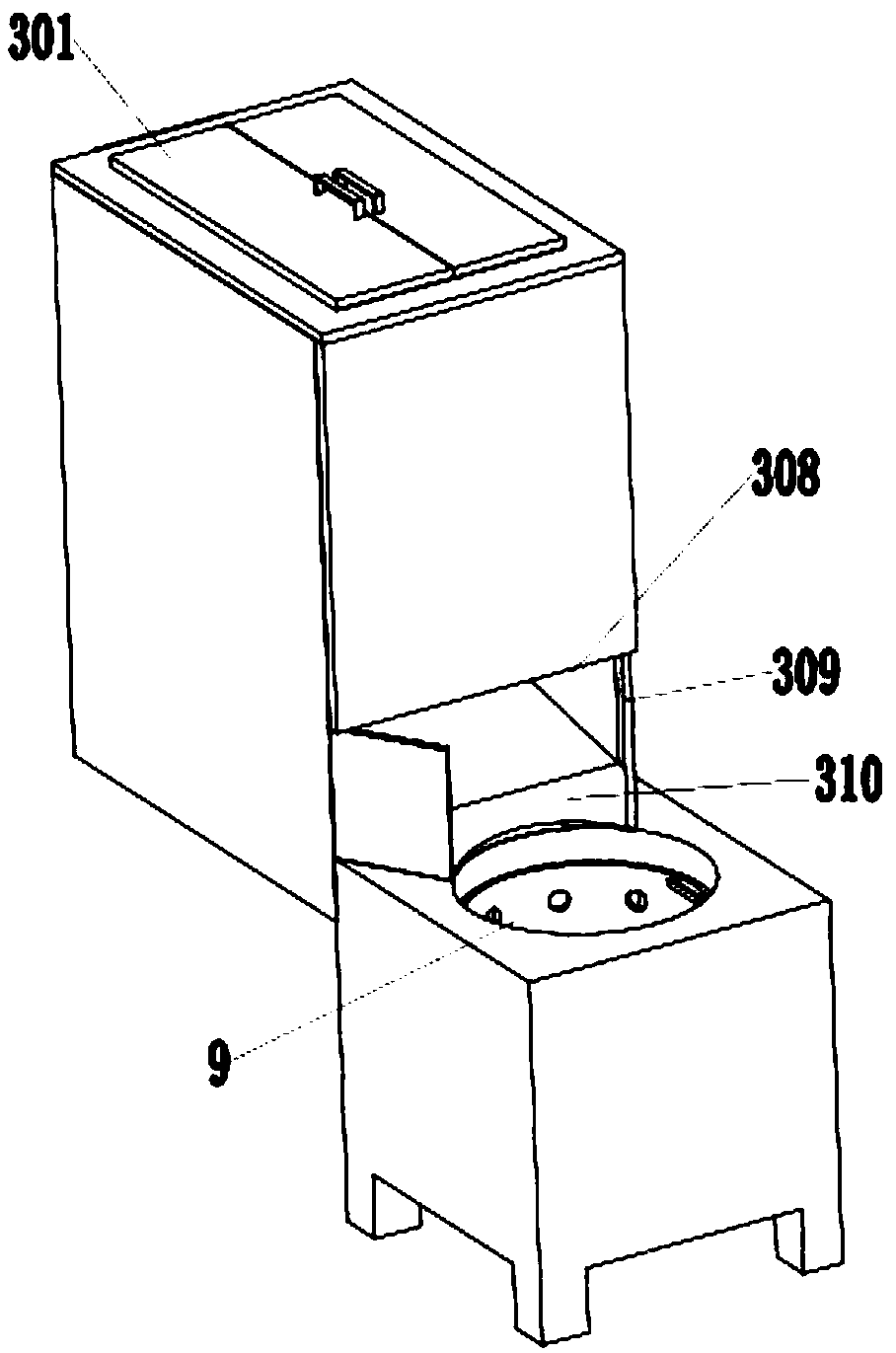

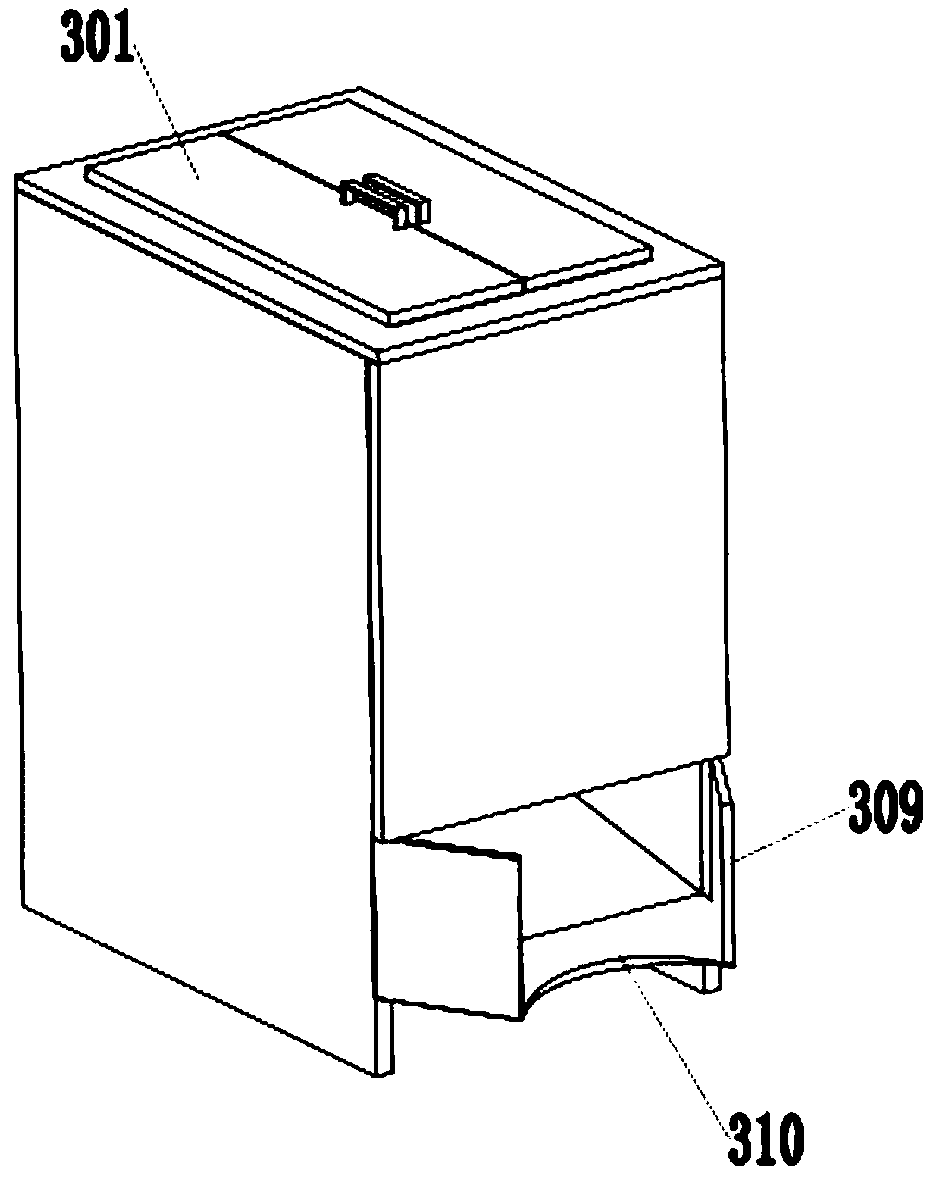

Wafer pre-alignment device and wafer pre-alignment method

PendingCN114695225ASolve the problem of large accuracy deviationHigh precisionSemiconductor/solid-state device detailsSolid-state devicesWaferEngineering

The embodiment of the invention discloses a wafer pre-alignment device and a wafer pre-alignment method. The device comprises an image acquisition module which comprises an image acquisition unit and a camera position switching mechanism and is used for respectively acquiring edge information of a wafer and position information marked on the wafer; the data processing module is used for respectively determining a first offset and a second offset between the actual position of the wafer and a preset alignment position according to the edge information and the mark position information; the coarse pre-alignment module is used for compensating the first offset of the wafer; and the fine pre-alignment module is used for compensating the second offset of the wafer. The problem that an existing alignment device is large in pre-alignment precision deviation is solved, the pre-alignment precision can be improved, the device can be suitable for pre-alignment of various bonding pieces, and the follow-up wafer photoetching alignment requirement is met.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

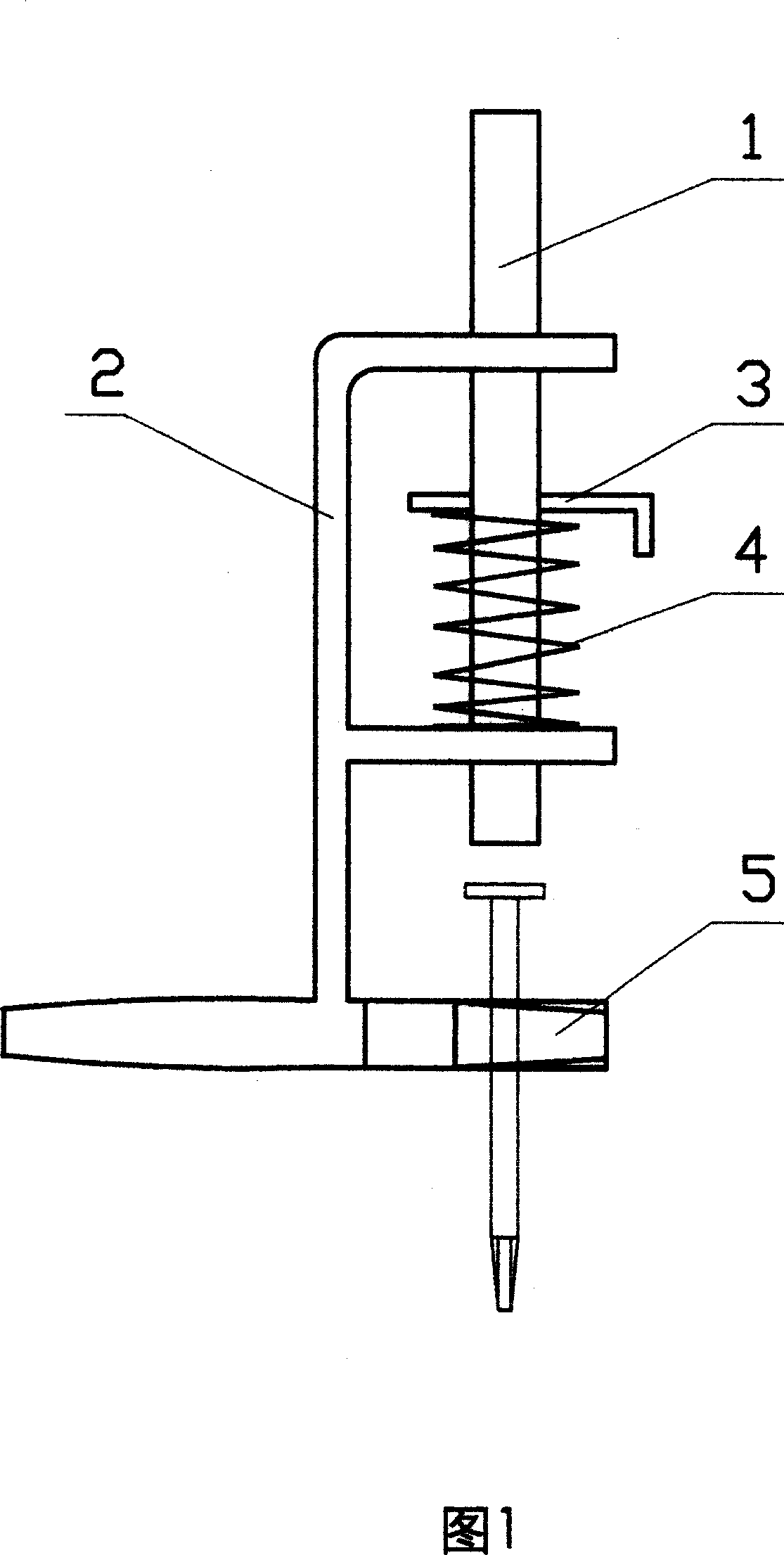

Device for vertical nailing

InactiveCN1970237AWill not cause the phenomenon of knocking people's handsMake sure to enterDispensing apparatusNail dispensersEngineering

Owner:崇明县新光中学

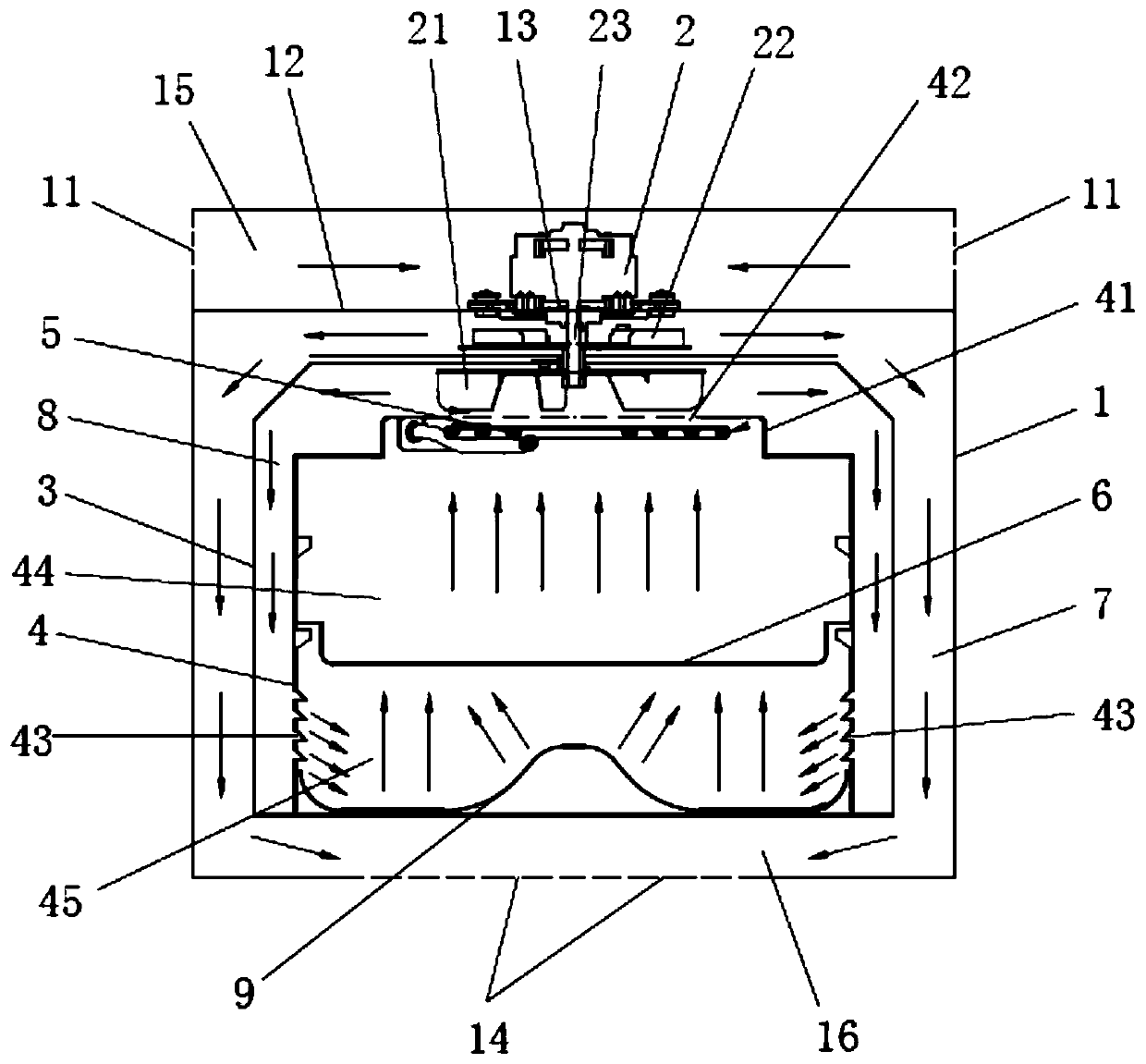

Air fryer with sufficient thermal circulation

PendingCN109820432AMake sure to enterFix bugsRoasters/grillsDeep fat fryersPulp and paper industryHeat cycling

The invention relates to the technical field of air fryers, in particular to an air fryer with sufficient thermal circulation. A hot circulation air duct is formed between the inner wall of a heat circulation shell and the outside wall of a pot, the upper part of the pot body is provided with a hot air outlet, the hot air outlet is provided with a hot air fan, the inner part of the pot or / and thehot circulation air duct are provided with heating assembly, and the lower part of the pot body is provided with a plurality of hot air inlets; the inside of the pot is provided with a food basket, and the food basket divides the inner part of the pot into the upper cavity and the lower cavity. The upper cavity is communicated with the hot-circulation duct through the hot-air outlet, and the lowercavity is communicated with the hot-circulation duct through the hot-air inlet. The food basket is arranged in the middle of the pot, and the upper cavity is communicated with the hot circulation duct through the hot air outlet, and the lower cavity is communicated with the hot circulation duct through the hot air inlet, so that hot air can be ensured to enter from lower part of the food basket and be discharged from the upper part of the food basket to form a complete heat circulation, thus the deficiency and defect of the uneven heating of the existing technology are effectively solved..

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

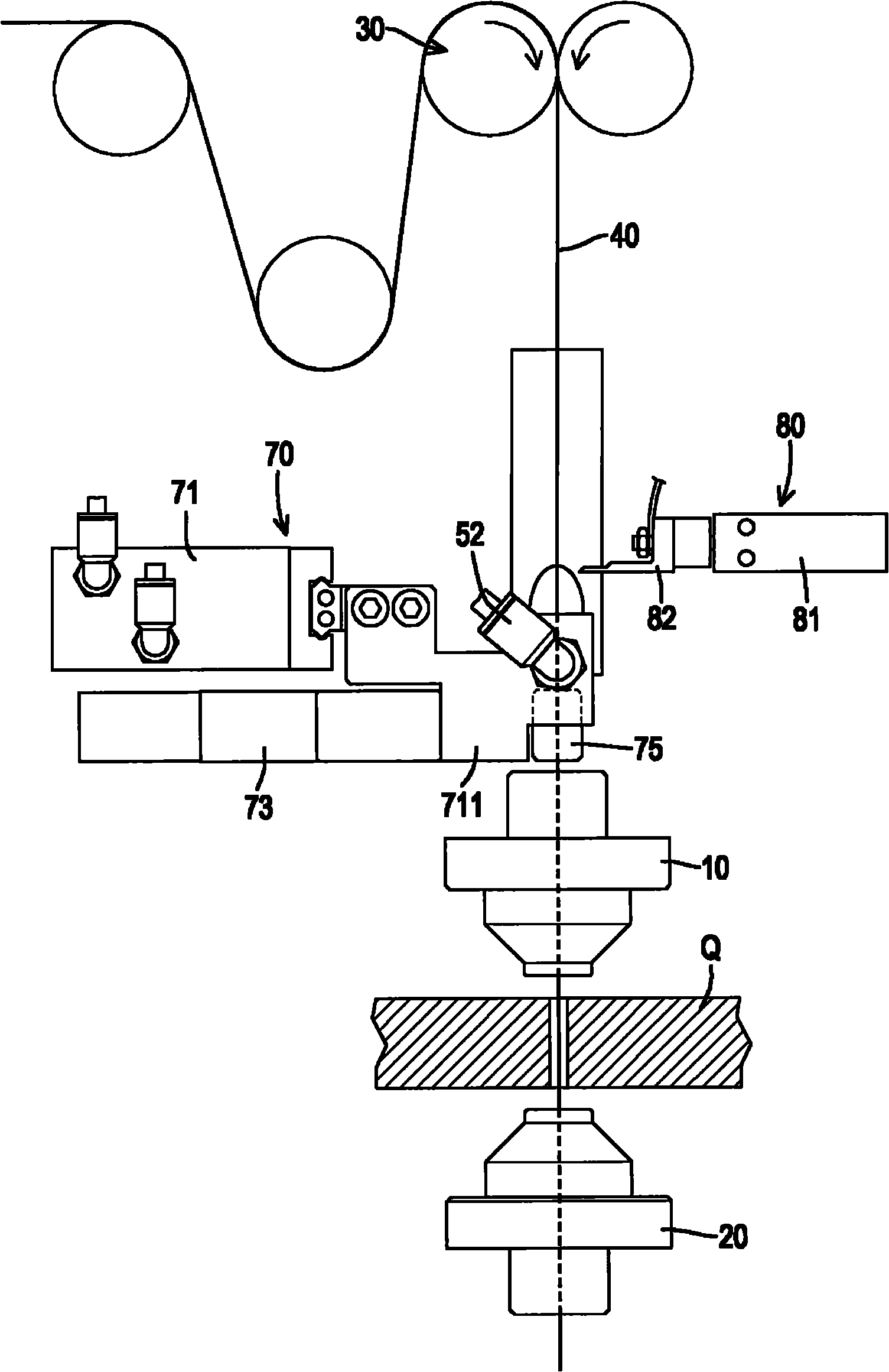

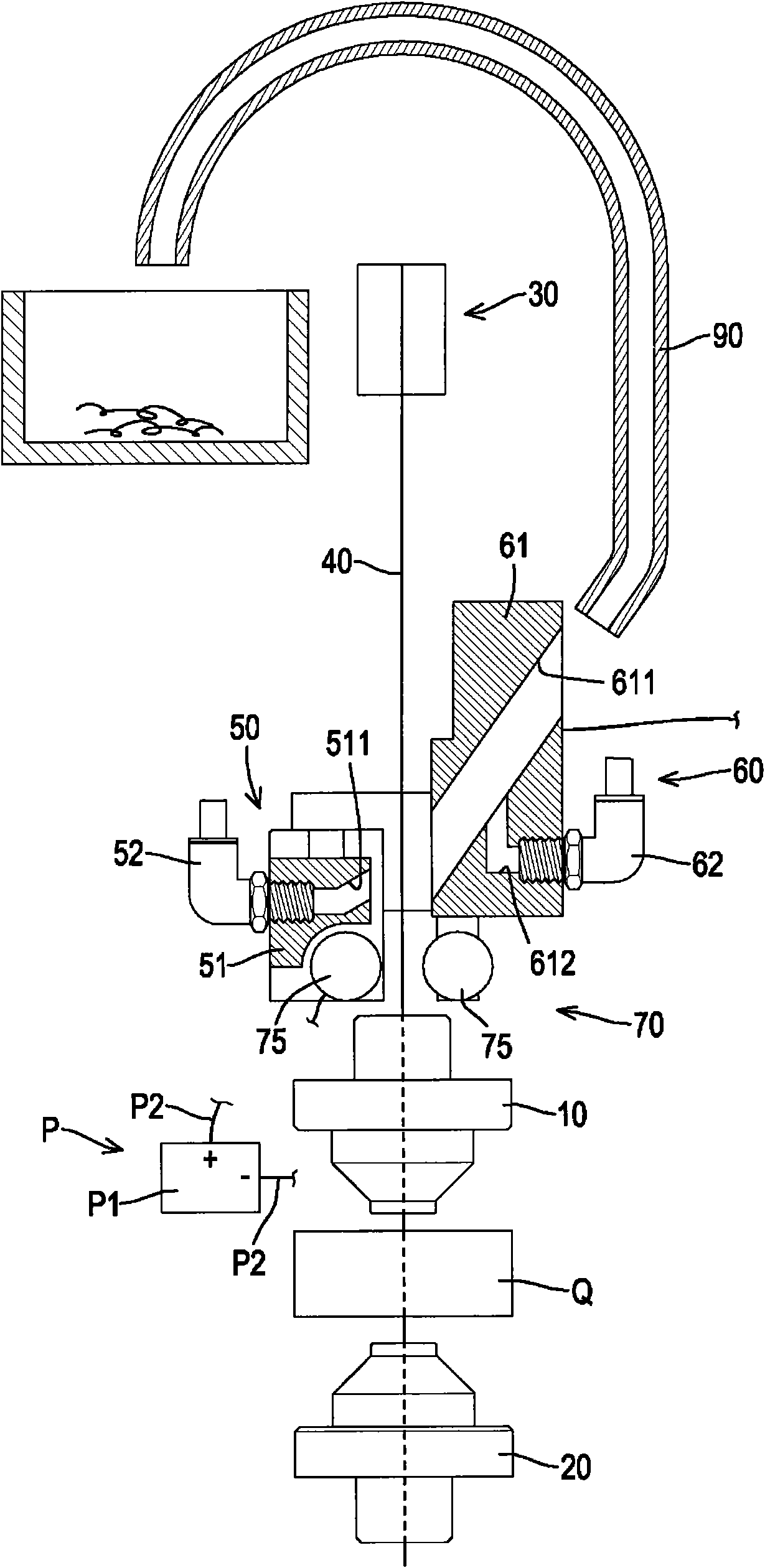

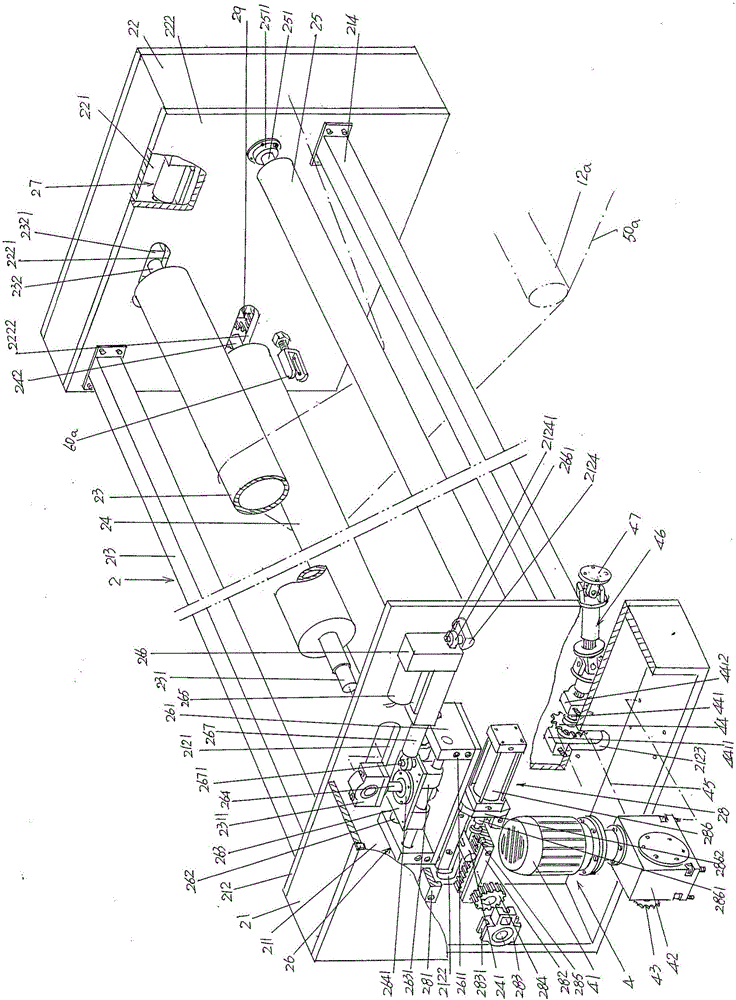

Automatic wire arranging device of wire cutting machine and automatic wire arranging method thereof

InactiveCN102120279AImprove efficiencyImprove efficacyElectrical-based machining electrodesControl systemWire cutting

The invention relates to an automatic wire arranging device of a wire cutting machine, which comprises a blowing unit, a sucking unit, a roller group, a wire fusing unit and a wire arranging tube, wherein the blowing unit generates a blowing air flow, and the sucking unit generates a sucking air flow. The invention also relates to the automatic wire arranging method of the automatic wire arranging device of the wire cutting machine. When the device and the method are used, a waste wire pushing action is not need, the blowing power and the sucking power of the air flows are used to generate a stable flow field to effectively solve the problem that the waste wire offsets and cannot be sucked in along a preset path, and whether the waste wire is removed completely can be judged according to the sensing signals of a sensing detection unit and a control system.

Owner:台湾线割科技股份有限公司

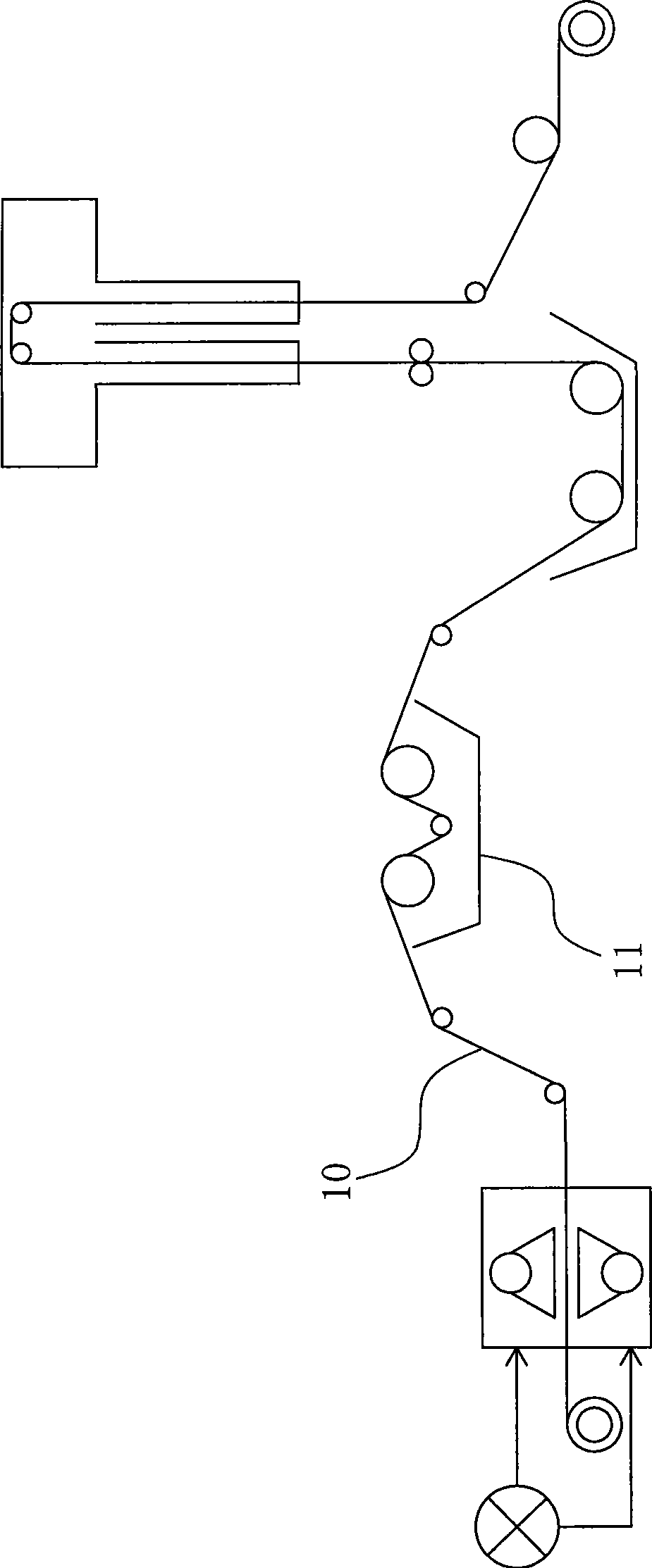

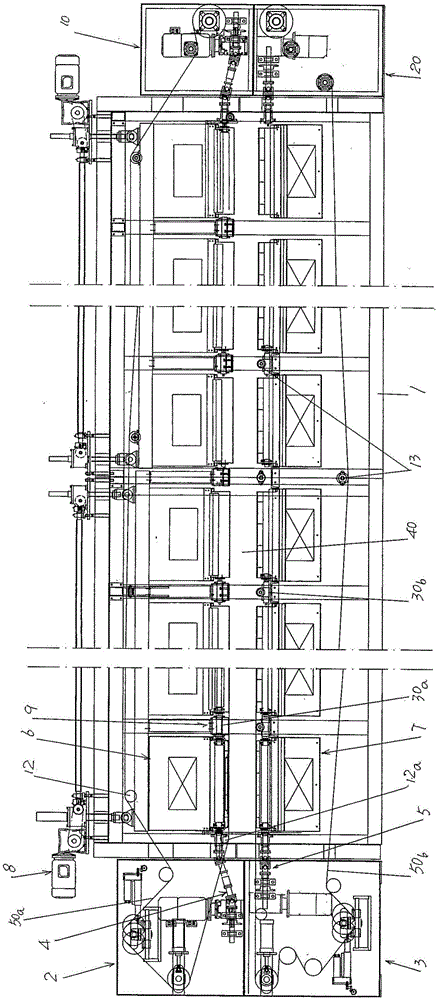

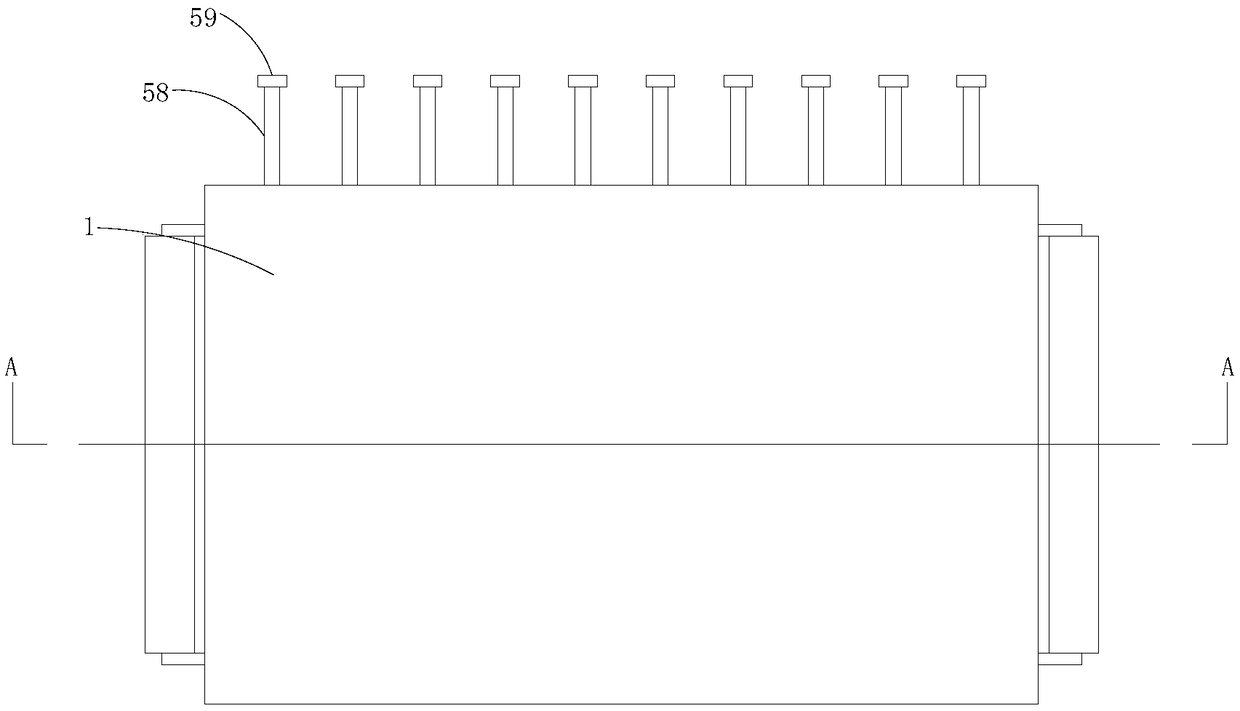

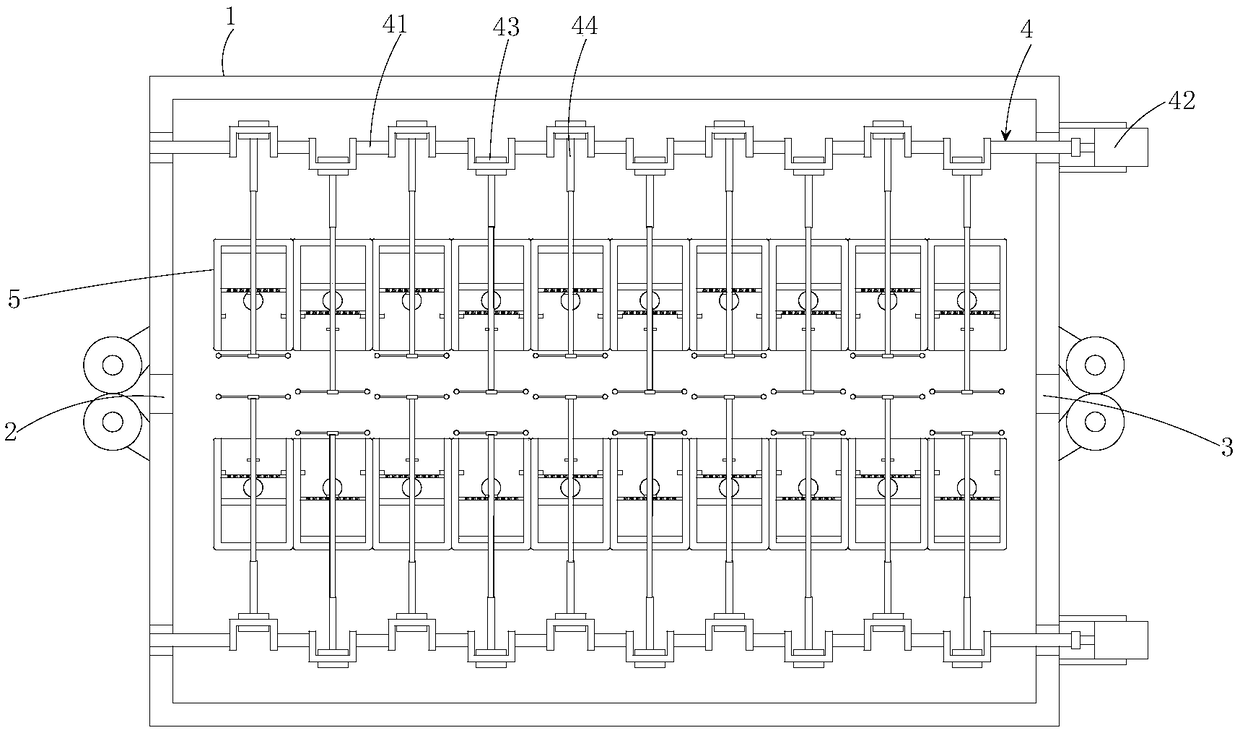

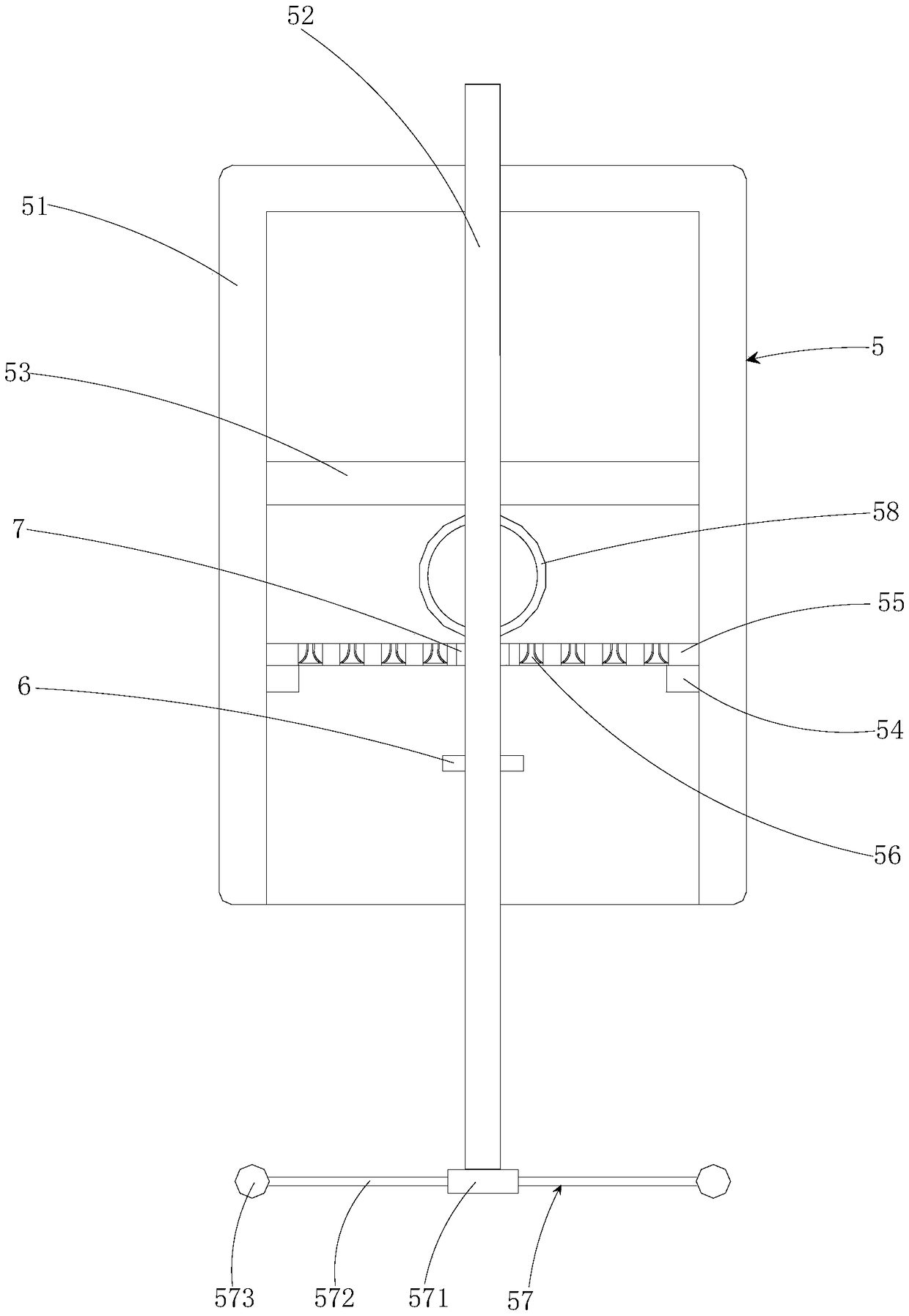

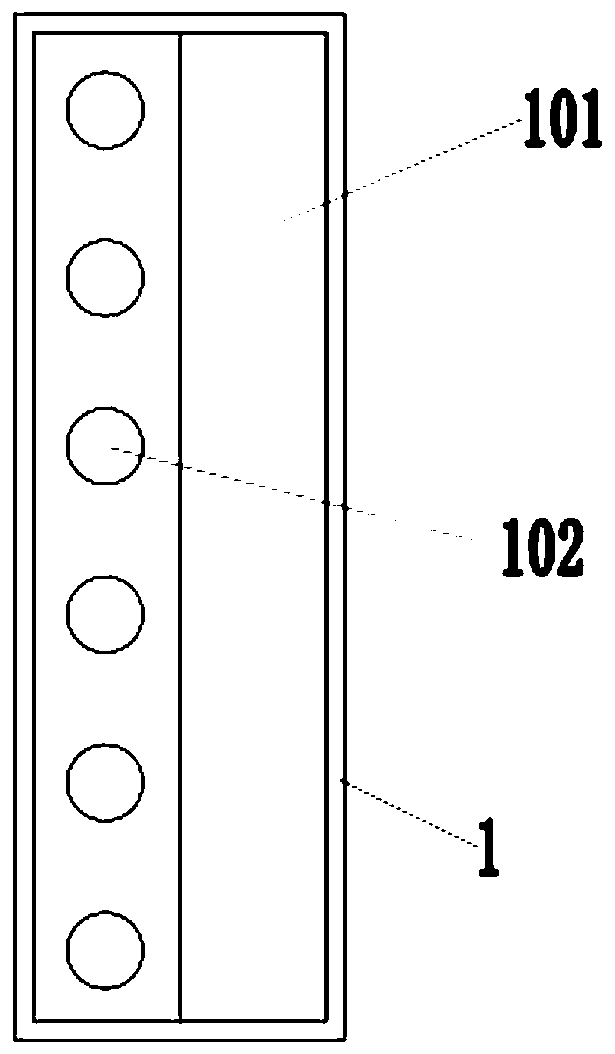

Hot air non-woven fabric setting machine

ActiveCN106087248AComply with hygienic specification requirementsMake sure to enterLiquid/gas/vapor removalNon-woven fabricsPulp and paper industryEngineering

The invention discloses a hot air non-woven fabric setting machine, and belongs to the technical field of non-woven product processing machines. The hot air non-woven fabric setting machine comprises a machine frame, upper and lower net curtain rectifying mechanisms, upper and lower net curtain driving mechanisms, upper and lower hot air box hot air outlet width adjustment driving mechanisms, a plurality of upper and lower hot air boxes, an upper hot air box lifting adjusting mechanism, an upper net curtain, a lower net curtain and an upper net curtain magnetic attraction mechanism. A high-temperature air generation mechanism is connected to the rear side of the machine frame in an extended mode. The upper and lower net curtain rectifying mechanisms are connected with the machine frame. The upper and lower net curtain driving mechanisms are connected with the machine frame. The upper and lower hot air box hot air outlet width adjustment driving mechanisms are arranged on the left side of the machine frame. The upper and lower hot air boxes are arranged along the upper portion and the lower portion of the length direction of the machine frame from left to right. The upper hot air box lifting adjusting mechanism is arranged on the upper portion of the machine frame. The upper net curtain rectifying mechanism is sleeved with one end of the upper net curtain, and the upper net curtain driving mechanism is sleeved with the other end of the upper net curtain. The lower net curtain rectifying mechanism is sleeved with one end of the lower net curtain, and the lower net curtain driving mechanism is sleeved with the other end of the lower net curtain. The upper net curtain magnetic attraction mechanism is attracted to the upper net curtain. The high-temperature air generation mechanism is made communicated with the upper and lower hot air boxes. Manufacturing and assembly are convenient, the using and maintenance cost is saved, energy consumption is saved, and setting efficiency and quality are ensured.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

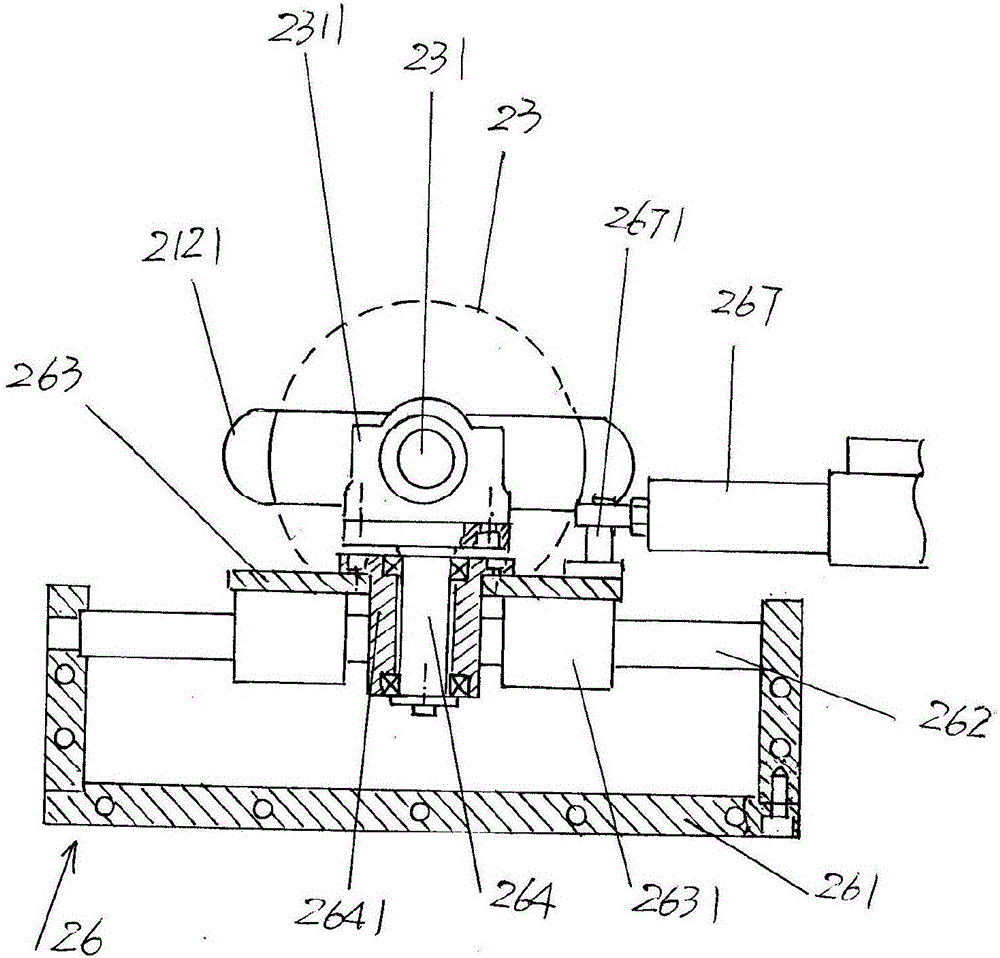

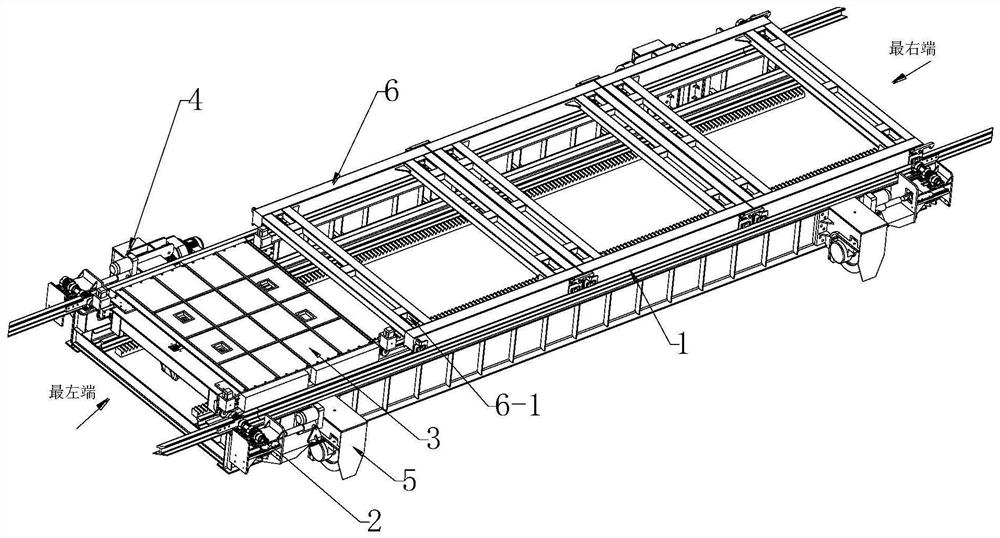

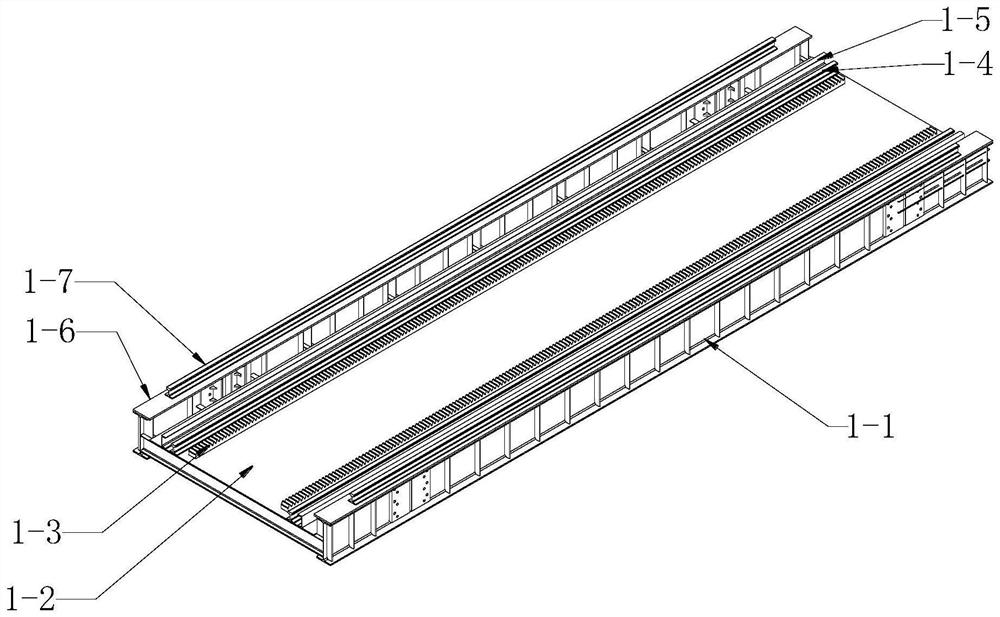

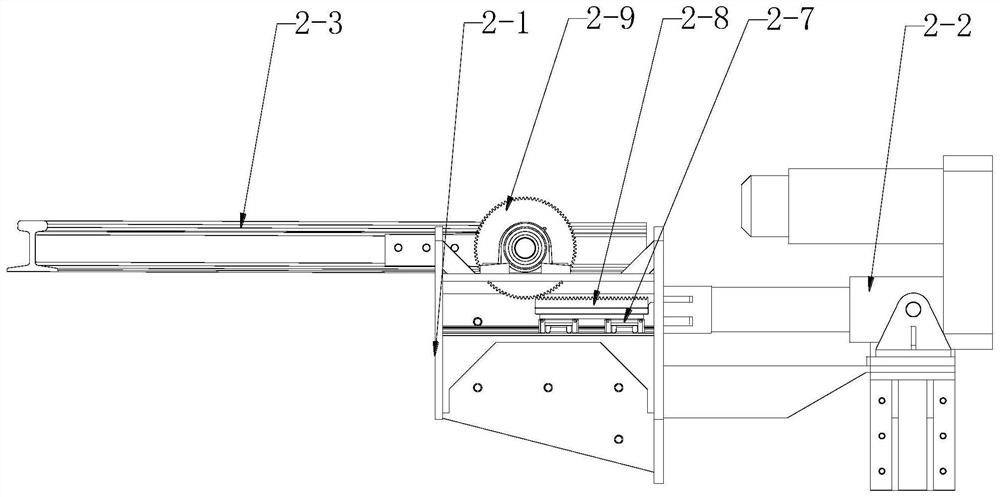

Implementation method for bidirectional reversible feeding and discharging of annealing furnace

ActiveCN112079067ASolve the problem that materials cannot be fed in and out in opposite directions, but materials can only be fed in and out on the same sideFully automatedFurnace typesConveyor partsLap jointRelative motion

The invention discloses an implementation method for bidirectional reversible feeding and discharging of an annealing furnace, and belongs to the field of feeding and discharging of annealing furnaces. The technical problem to be solved by the invention is how to meet the feeding and discharging requirements of aluminum foil annealing furnaces arranged in opposite directions and realize bidirectional reversible feeding and discharging. According to the technical scheme, the method comprises the following steps that rail lapping mechanisms are installed at the two ends of a large material vehicle supporting frame correspondingly, so that the large material vehicle supporting frame is in lap joint with guide rails in the annealing furnaces; and then a material pushing assembly capable of pushing a material frame tray in a reciprocating and reversible mode is installed on the large material vehicle supporting frame, the height of the material pushing assembly is lower than the lower edgeof the material frame tray, and bidirectional reversible feeding and discharging of the annealing furnaces are realized. The material pushing assembly comprises a material pushing trolley mechanism and a guide rail layer walking mechanism, the material pushing trolley mechanism moves in a reciprocating and reversible mode along the large material vehicle supporting frame, moreover, the material pushing trolley mechanism is connected with or separated from any end of the guide rail layer walking mechanism through a first lock pin mechanism, so that synchronous movement or relative movement of the material pushing trolley mechanism and the guide rail layer walking mechanism is realized.

Owner:NINGBO SACHSEN IND TECH CO LTD

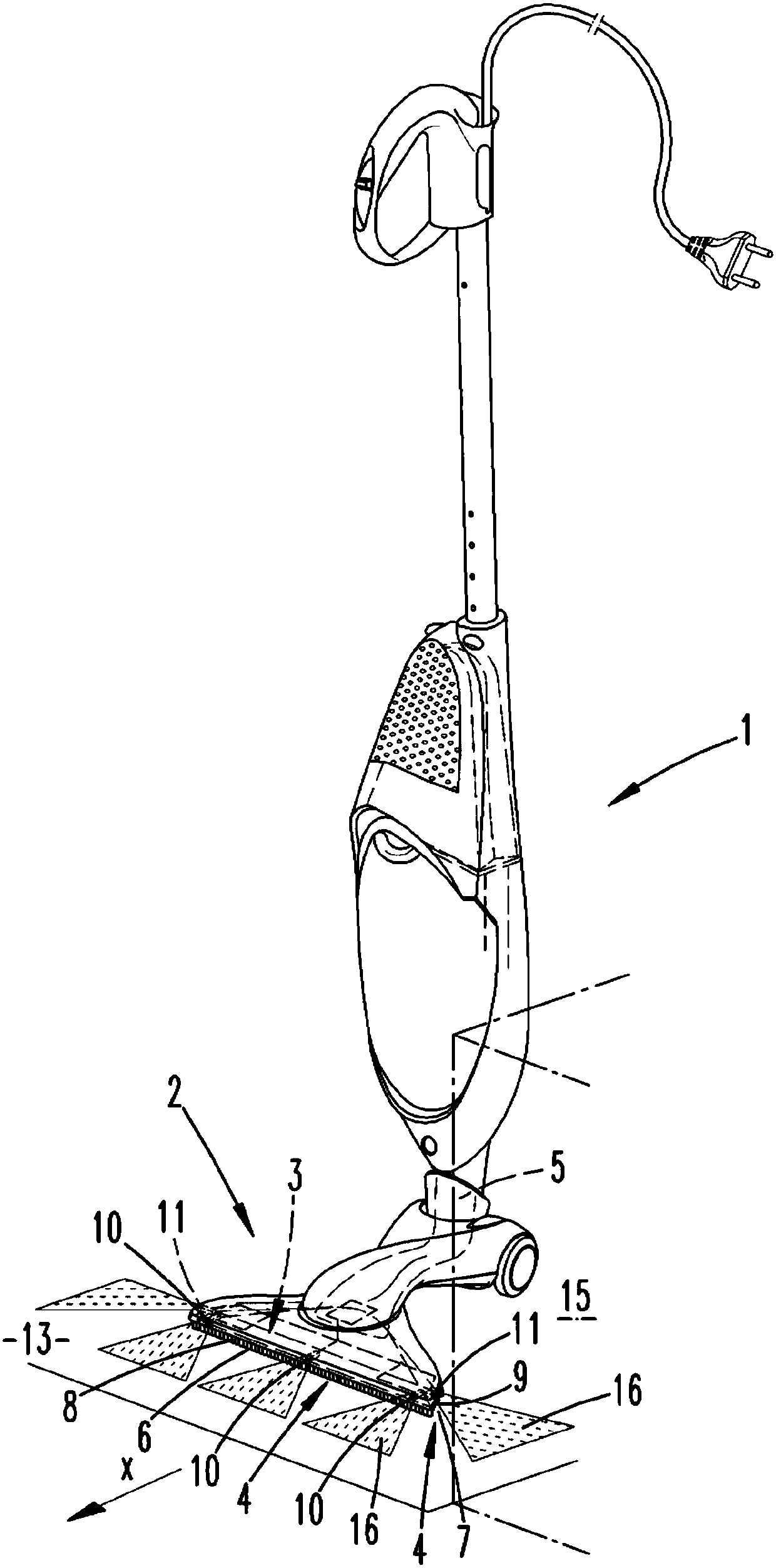

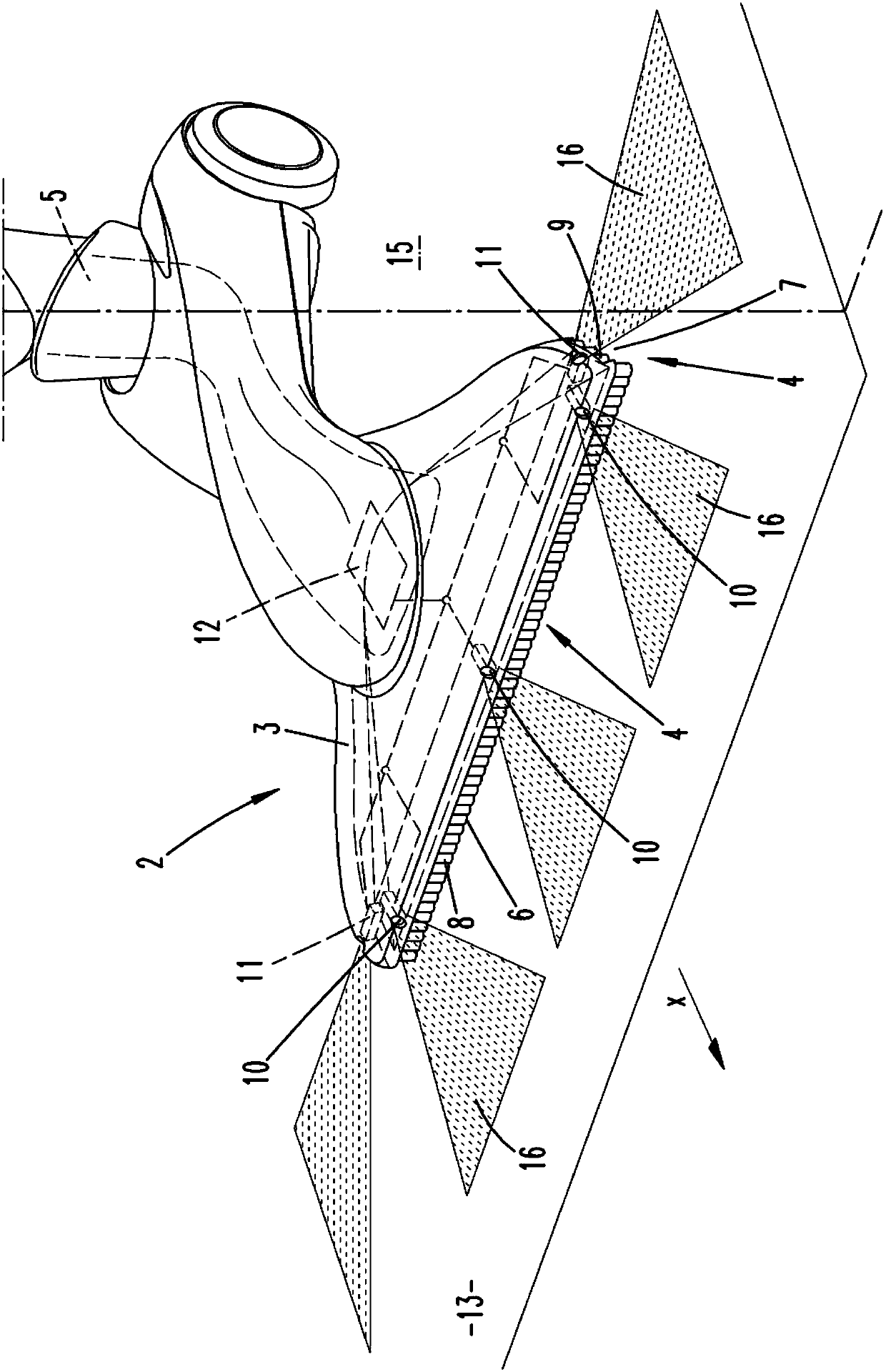

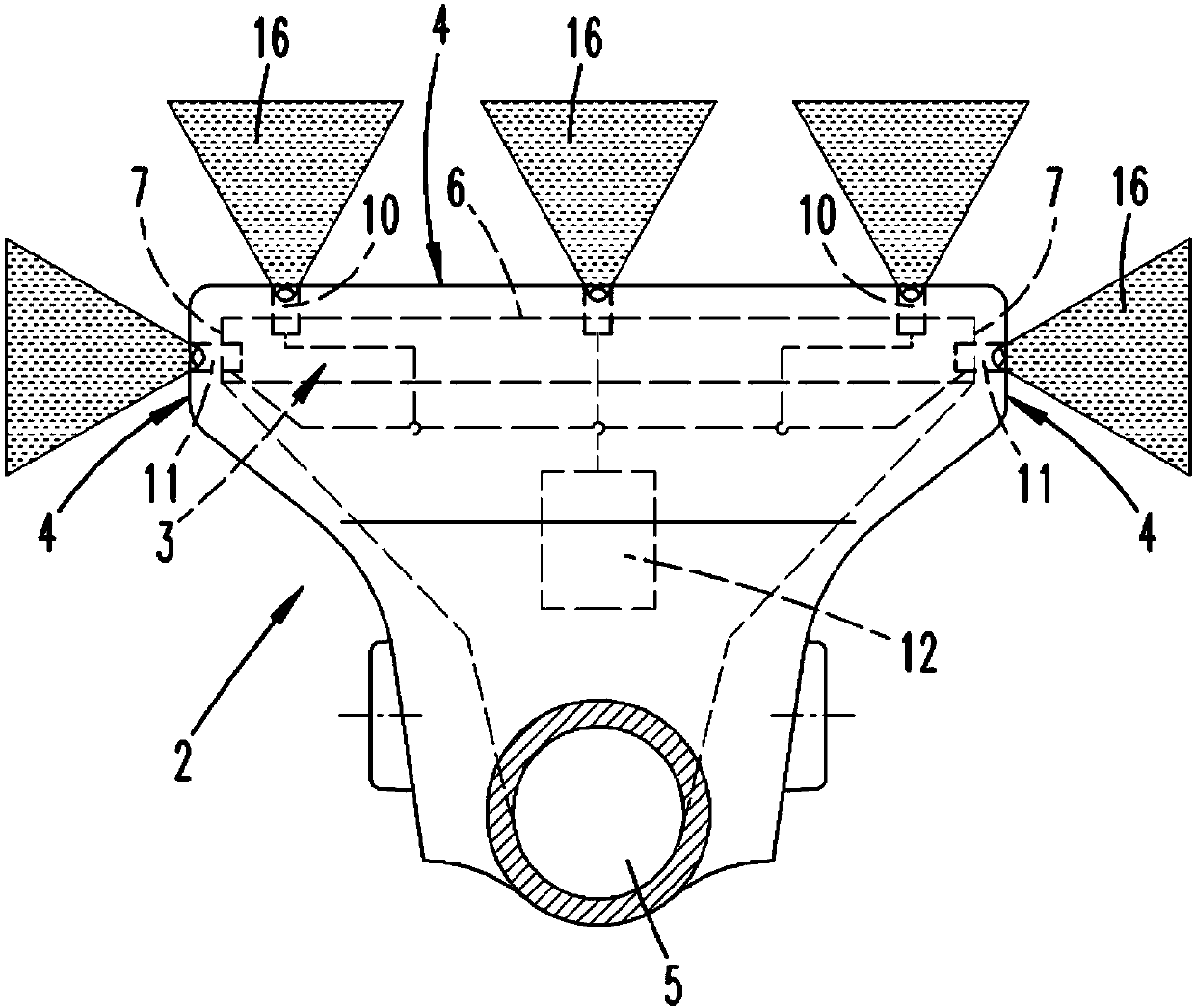

Suction nozzle for a vacuum cleaner

ActiveCN107708512AEasy to moveMake sure to enterSuction nozzlesElectric equipment installationVacuum cleanerAirflow

The invention relates to a suction nozzle (2) for a vacuum cleaner (1) for sucking up items to be vacuumed from a surface (13) to be cleaned by means of a vacuum air stream, wherein the suction nozzle(2) has: a suction mouth (3) which can be arranged adjacently to the surface (13) to be cleaned and which comprises a suction edge (4) that delimits a sub-surface exposed to the vacuum air stream; avacuum air stream extraction opening (5); and a delimiting means (8, 9) associated with the suction edge (4), which means can be controlled according to a detection result of a sensor. In order to produce a suction nozzle (2) whose delimiting means (8, 9) can be moved variably if other events occur, the sensor is an obstacle sensor (10, 11) for detecting a substantially stationary obstacle (15) located in front of the suction nozzle (2), in particular a wall or piece of furniture, wherein the obstacle sensor (10, 11) is configured to detect obstacles (15) that are disposed outside the portionof the surface (13) over which the suction nozzle (2) projects and, in relation to an arrangement of the suction nozzle (2) during typical cleaning operation, that protrude beyond a suction edge planethat has the suction edge (4). The invention further relates to a vacuum cleaner (1) with such a suction nozzle (2) and a method for sucking up items to be vacuumed by means of a suction nozzle (2).

Owner:VORWERK & CO INTERHOLDING GMBH

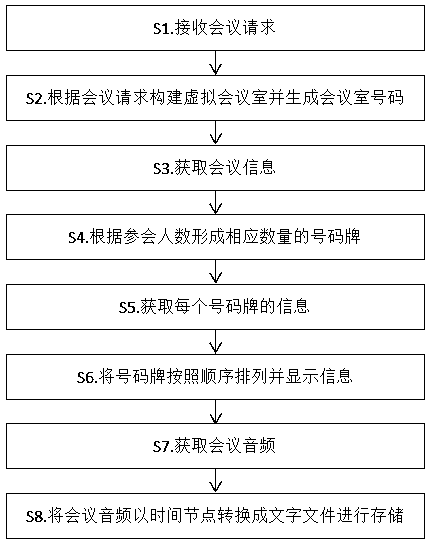

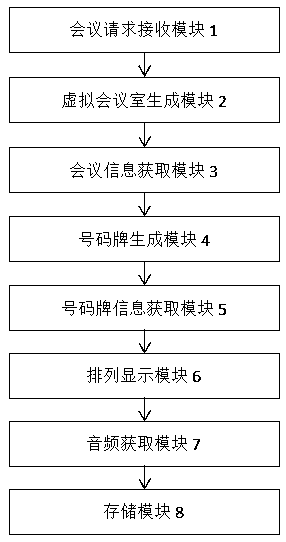

Cloud conference system and method

InactiveCN109660368ALower deployment costsGuaranteed confidentialitySpecial service provision for substationTelevision conference systemsComputer terminalHuman–computer interaction

The invention relates to a cloud conference system and method. The cloud conference method comprises the steps of receiving a conference request; establishing a virtual conference room according to the conference request and generating a conference room number; acquiring conference information; forming a corresponding quantity of number plates according to the number of participants; arranging thenumber plates in sequence and displaying the information; acquiring a conference audio; and converting the conference audio into a text file by using a time node to carry out storage. According to the cloud conference method, the virtual conference room is constructed; a terminal participation mode is provided; the deployment cost is low; and the use is convenient.

Owner:广州维速信息科技有限公司

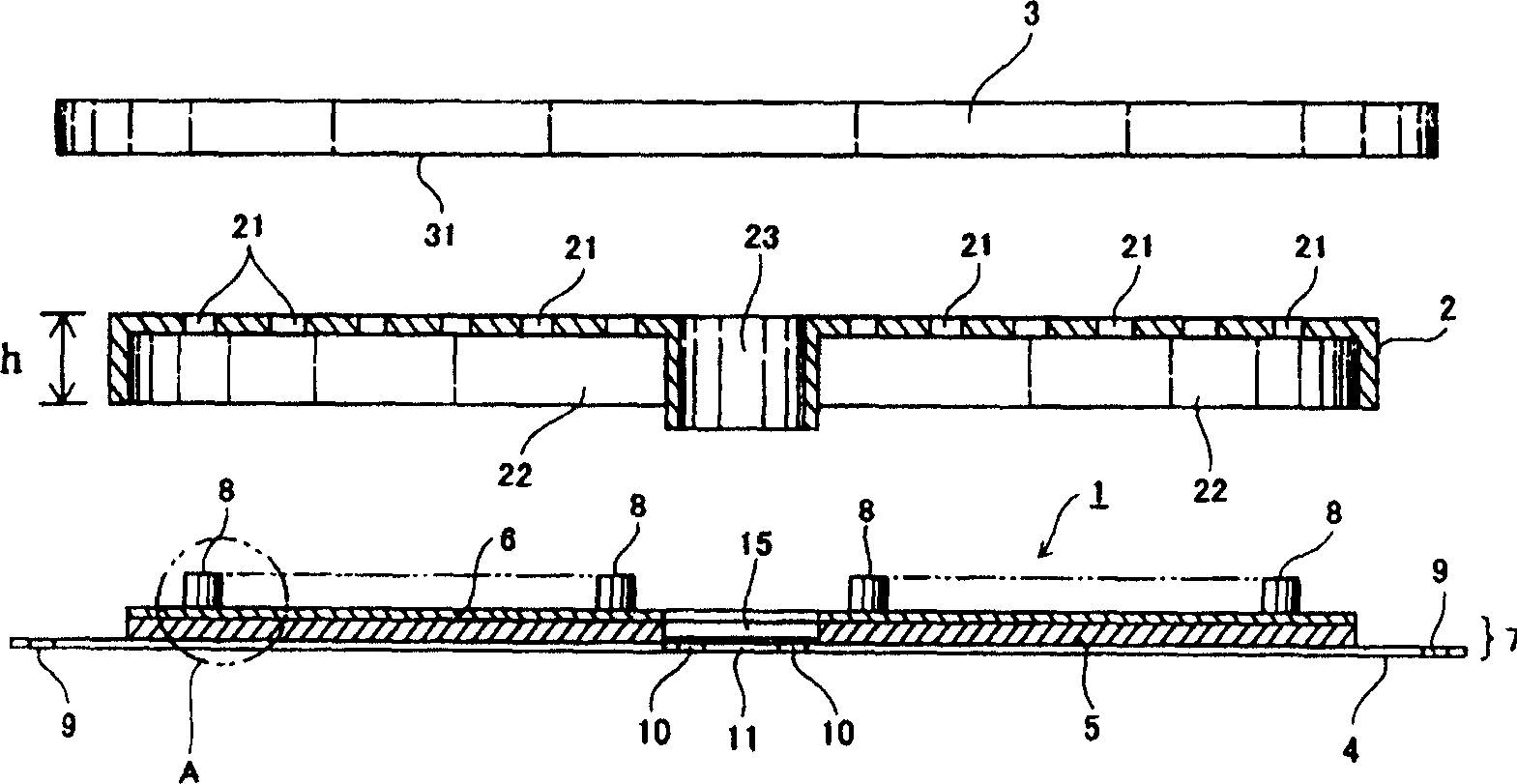

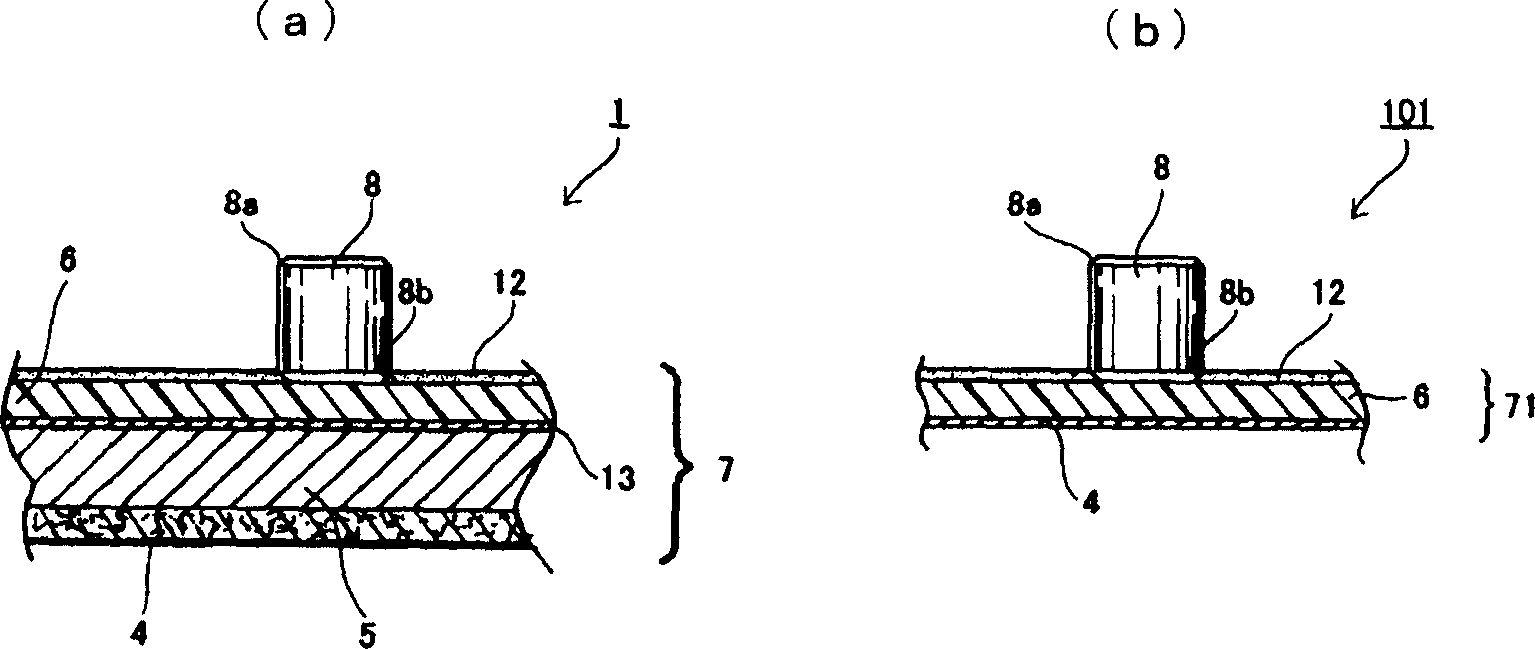

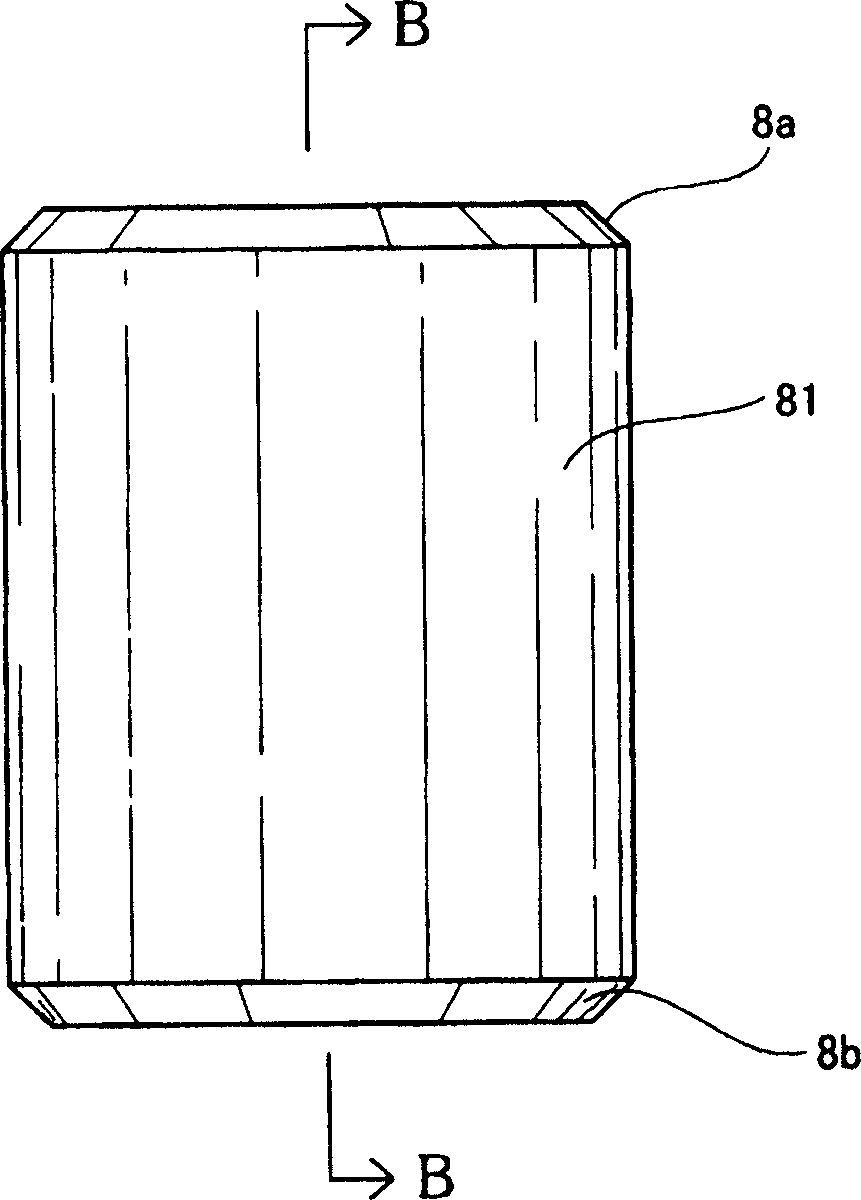

Polishing piece, polishing lap, and method of polishing glass panel for CRT

InactiveCN1684802AImprove installation work efficiencyNo lodgingBonded abrasive wheelsRubber materialEngineering

A method for manufacturing polishing lap capable of firmly fixing a polishing piece onto the upper surface of a base layer without using a vulcanized forming device and a vulcanized forming process for unvulcanized rubber material layer, comprising the steps of forming both end parts of the piece in a general flat or a general recessed curve surface without providing any irregular part for increasing an engagement force on the outer periphery of the polishing piece, and pressingly fixing the piece into an adhesive layer on the base layer at any end side of piece, whereby a working efficiency and an economic efficiency can be remarkably increased more than that of a system pressingly fixed into the unvulcanized rubber material layer and, since the polishing piece is firmly fixed to the base layer, and accidents such as falling down and falling during polishing operation can be prevented.

Owner:POBAALE INDS +1

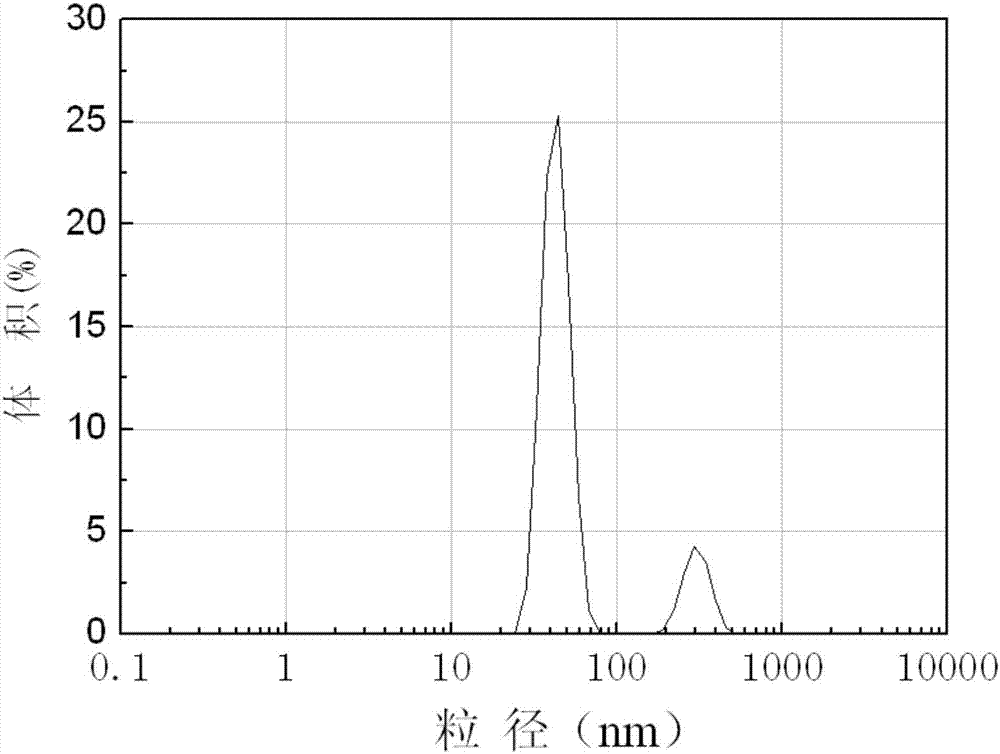

Nano-composite fracturing fluid as well as preparation method and application thereof

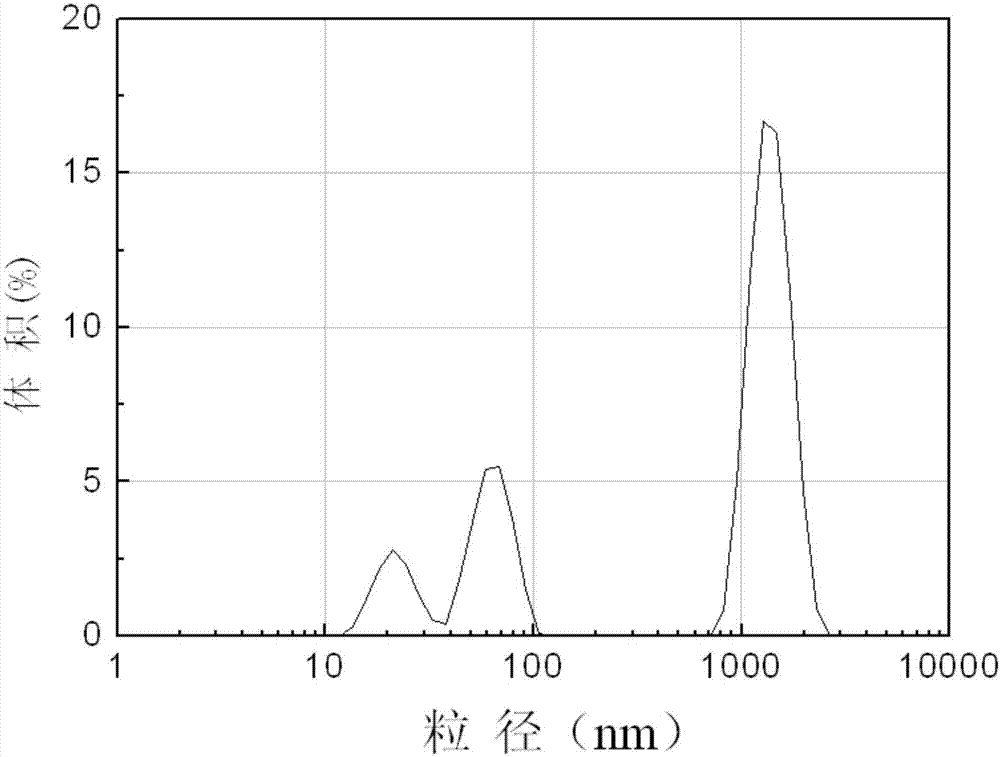

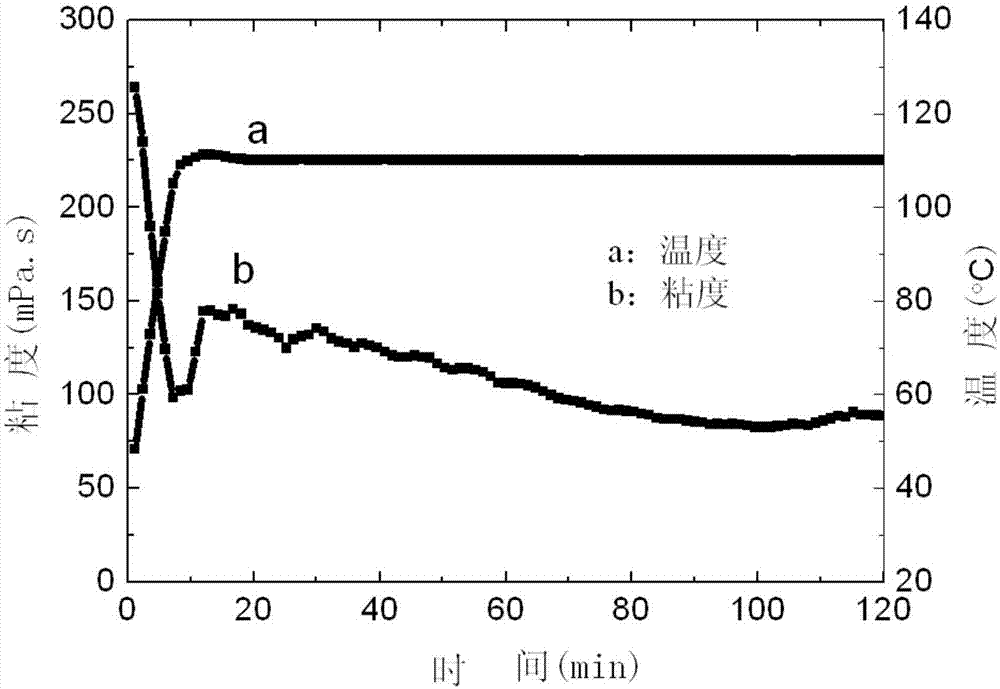

ActiveCN107325805AImprove high temperature resistanceImprove shear resistanceDrilling compositionFoaming agentFracturing fluid

The invention provides a nano-composite fracturing fluid as well as a preparation method and an application thereof. The nano-composite fracturing fluid is prepared from components in parts by weight as follows: 0.1-3.0 parts of a nano-composite thickening agent, 0.1-0.5 parts of a structure regulator, 0.1-1.0 part of a clay stabilizer, 0.1-1.0 part of a cleanup additive, 0.1-1.0 part of a foaming agent, 0.1-2.0 parts of an organic crosslinking agent, 0.01-0.5 parts of a gel breaker and 90.0-99.39 parts of water. Due to interaction between the structure regulator and the nano-composite thickening agent, the nano-composite fracturing fluid has extremely excellent sand carrying performance, good high-temperature resistance and anti-shearing performance, can effectively break gel in situ under a formation condition, can form multiscale nano-composite micelle through separate nano-dispersion and nucleation processes, is applicable to oil and gas exploitation in various stratum environments and improves the oil and gas injection and exploitation efficiency.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

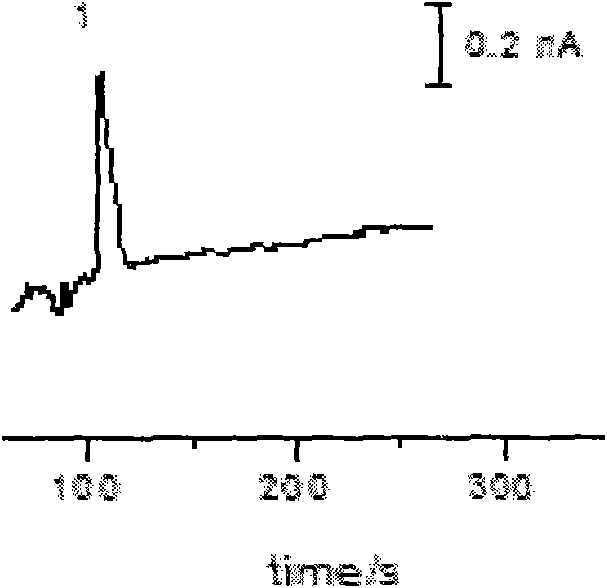

Capillary electrophoresis electrochemical enzyme linked immunoassay for detecting amnesic shellfish toxicity

InactiveCN101949931AImprove separation efficiencyHigh sensitivityMaterial analysis by electric/magnetic meansAmount of substanceToxin

The invention discloses capillary electrophoresis electrochemical enzyme linked immunoassay for detecting amnesic shellfish toxicity, which belongs to the technical field of assay and detection. Solution of standard substances and shellfish samples with the amnesic shellfish toxicity are assayed by combining the capillary electrophoresis technology and electrochemical enzyme linked immunoassay technology. The capillary electrophoresis electrochemical enzyme linked immunoassay comprises the following steps of: reacting sample solution and an amnesic shellfish toxicity antibody marked by a horse radish peroxidase (HRP) in a noncompetitive mode; separating an amnesic shellfish toxicity-enzyme labeled antibody compound and the rest amnesic shellfish toxicity antibody marked by the HRP in the mixed solution by capillary electrophoresis; generating a 3-aminophenazine with electrochemical activities by using aminophenol which is the oxidogenic substrate of peroxide in the presence of a catalyst; and performing electrochemical detection. The method simplifies a sample treatment process and has high selectivity and high accuracy. The linear detection range of the solution of amnesic shellfish toxicity standard substances of the method is 0.5 to 50ng / mL and a detection limit of the method is 0.2ng / mL. The method is an ideal method for detecting the amnesic shellfish toxicity of shellfish samples.

Owner:QINGDAO UNIV OF SCI & TECH

Periodic suction type textile fabric dust removal device

ActiveCN109440431AAvoid secondary pollutionSmooth dischargeMechanical cleaningPressure cleaningEngineeringTextile

The invention belongs to the technical field of textile instruments and discloses a periodic suction type textile fabric dust removal device. The periodic suction type textile fabric dust removal device comprises a box body, a strip-shaped feeding port, a strip-shaped discharging port, two transmission mechanisms and two dust removal mechanisms; the strip-shaped feeding port and the strip-shaped discharging port are symmetrically formed in the left and right side walls of the box body respectively, the two transmission mechanisms are disposed at the upper and lower ends of the interior of thebox body respectively, and the two dust removal mechanisms are disposed in the box body and located between the two transmission mechanisms. According to the periodic suction type textile fabric dustremoval device, through arrangement of the dust removal mechanisms, both sides of a fabric are beaten synchronously to remove dust, and meanwhile the periodicity formed by the rotation of crankshaftscan be adopted for making dust obtained by beating of each beating mechanism below a single air cylinder recycled by an adjacent air cylinder, so that a dust recovery process is more targeted. At thesame time, the dust can be uniformly discharged during the cycle operation. After the dust is beaten out, the circulation of the dust cannot occur in the box body, and secondary contamination of the fabric is avoided.

Owner:浙江越剑机电科技有限公司

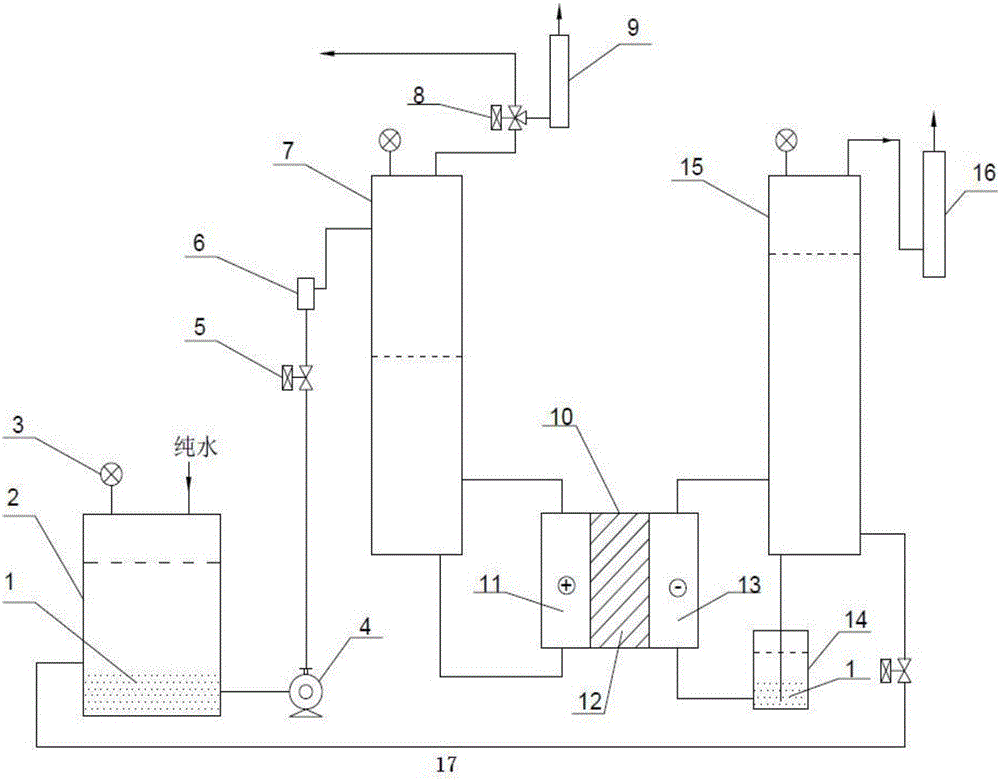

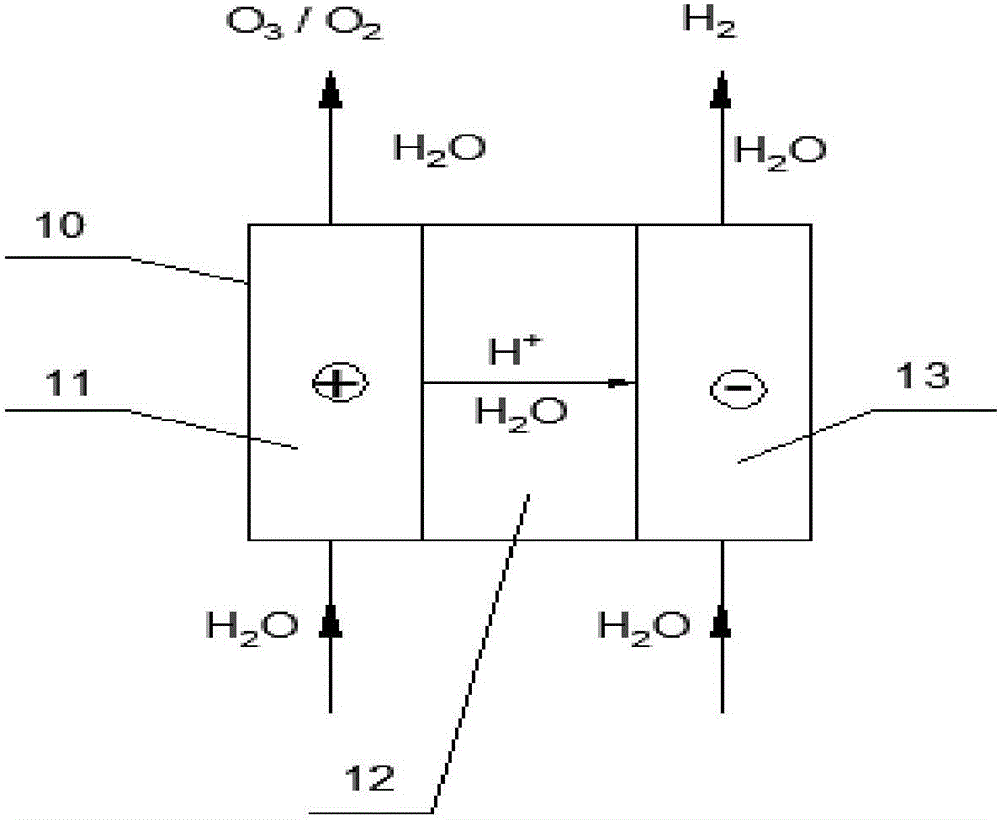

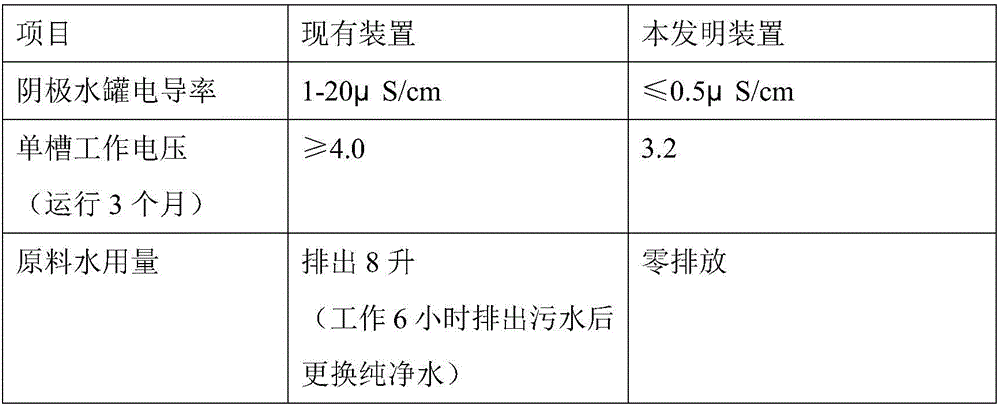

Proton exchange membrane water electrolysis ozone/oxygen generation device with self-purifying function

The invention belongs to the technical field of electro-chemicals, and relates to a proton exchange membrane water electrolysis ozone / oxygen generation device with a self-purifying function. An ion exchanger is serially connected in a cathode chamber and cathode water tank circulating loop; ion exchange resins are filled in a pure water tank for further purifying reflux water of a cathode water tank and fed raw material water; and the purified water is fed to the cathode water tank. The device can effectively exchange metal ions migrated to the cathode chamber through a proton exchange membrane and fed in the water of the cathode water tank by the cathode chamber, reduces the electric conductivity of the water to reduce the working voltage of an electrolysis tank, and largely prolongs the generator operation life.

Owner:WUHAN WEIMENG ENVIRONMENTAL TECH

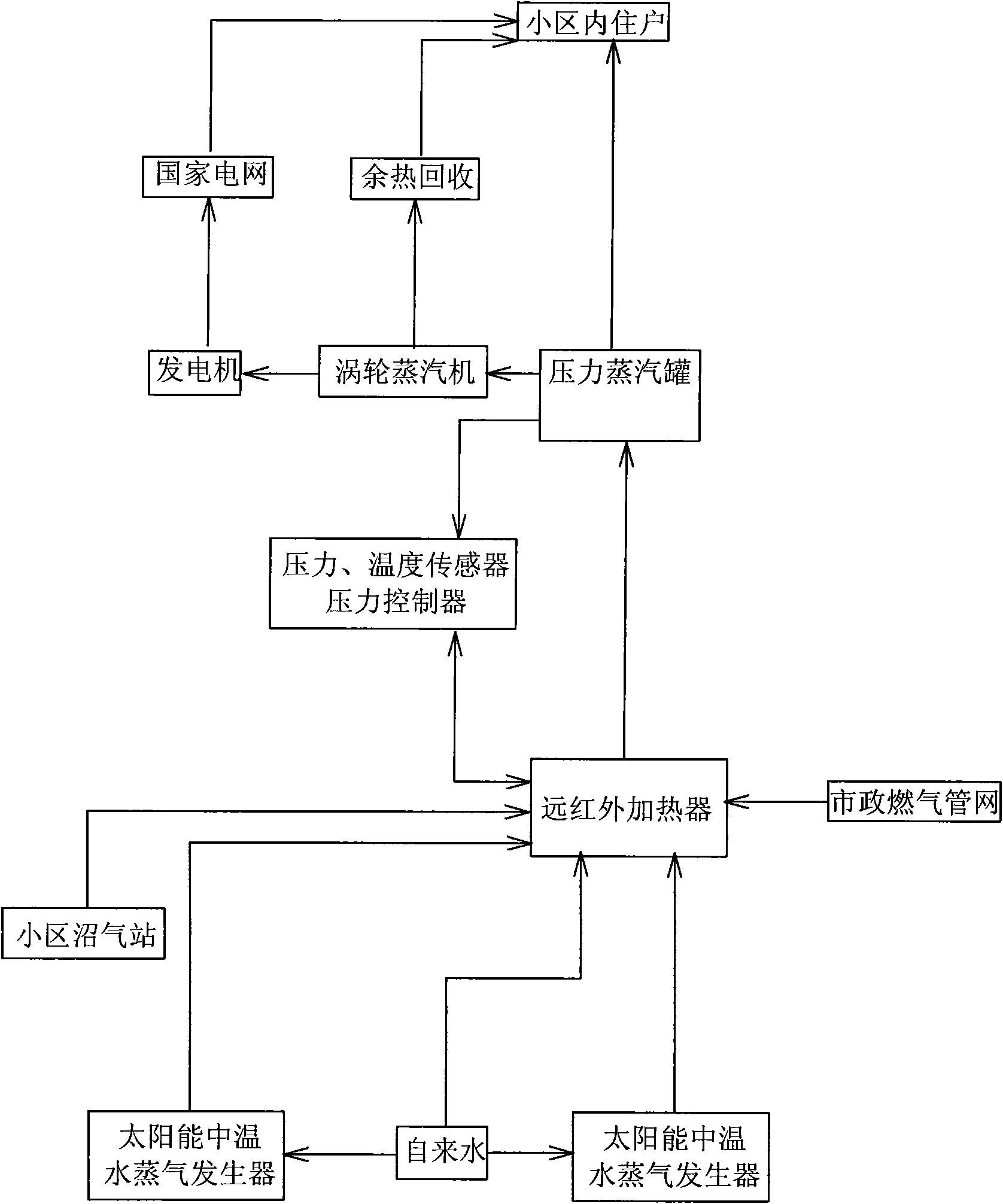

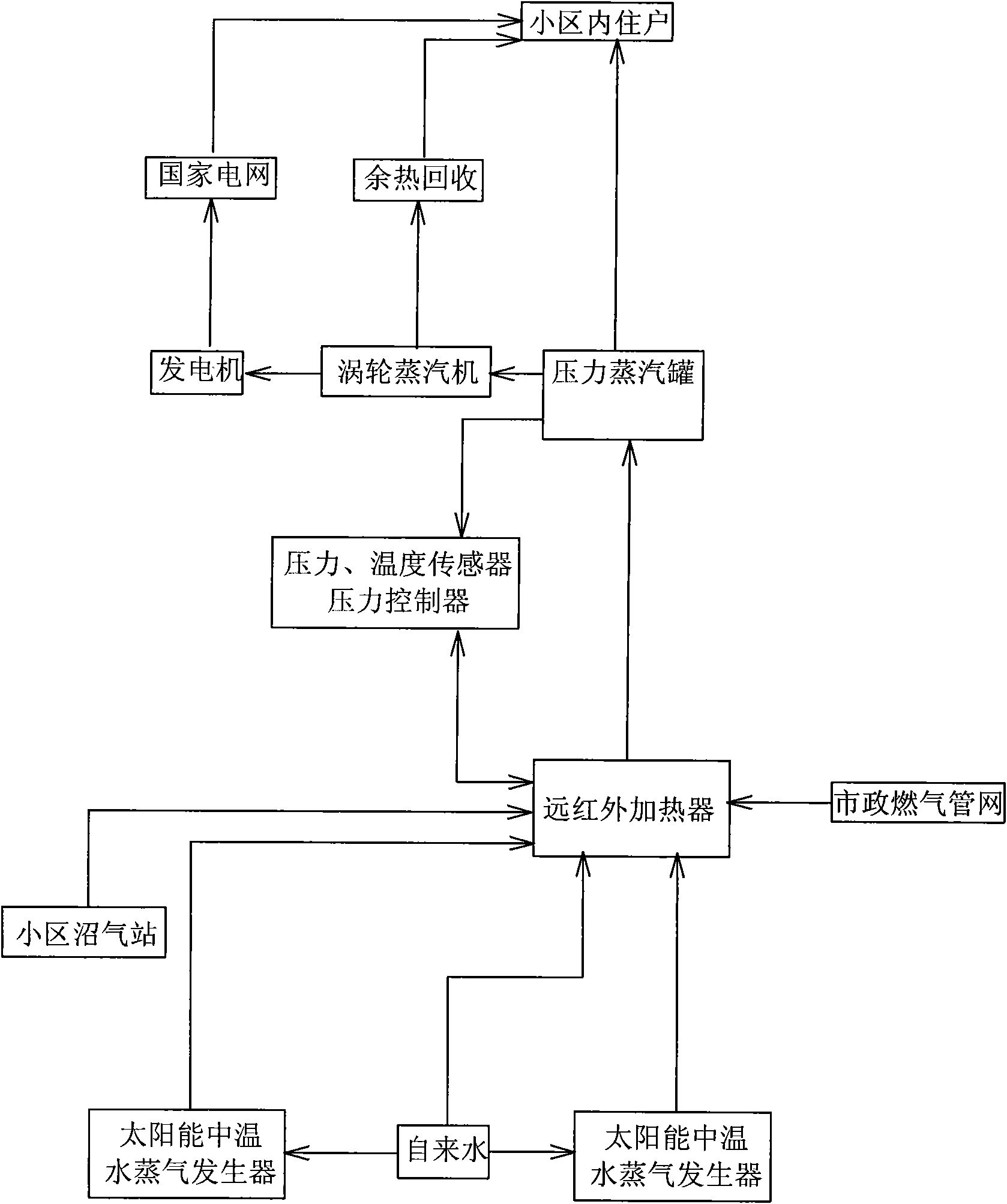

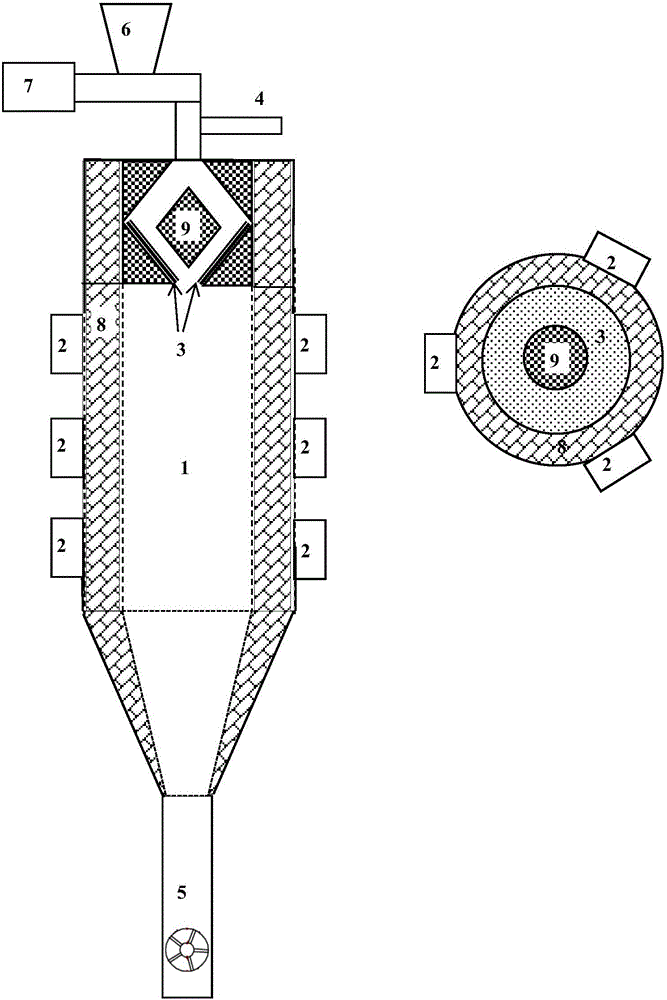

New energy moderate temperate water steam power generating system

InactiveCN101956577AChange emissionsChange handlingBioreactor/fermenter combinationsFrom solar energyNew energyWater vapor

The invention discloses a new energy moderate temperate water steam power generating system which comprises a heating system (1), a pressure steam tank (2) and a steam turbine and a generator (3), wherein the heating system (1) comprises a solar moderate temperature water steam generator, a biogas station and a far infrared heater; the heating system heats tap water for supplying steam for the pressure steam tank (2); and the pressure steam tank supplies steam for the steam turbine, and the steam turbine drives the generator for power generation. The invention adopts advanced technologies of solar energy and biomass energy, comprehensive utilization of straw, production of water steam for driving the steam turbine and power generation by the generator, ensures all-weather uninterrupted power generation, and reutilizes residual heat of power generation for power regeneration and heating of residential plots.

Owner:刘建光 +1

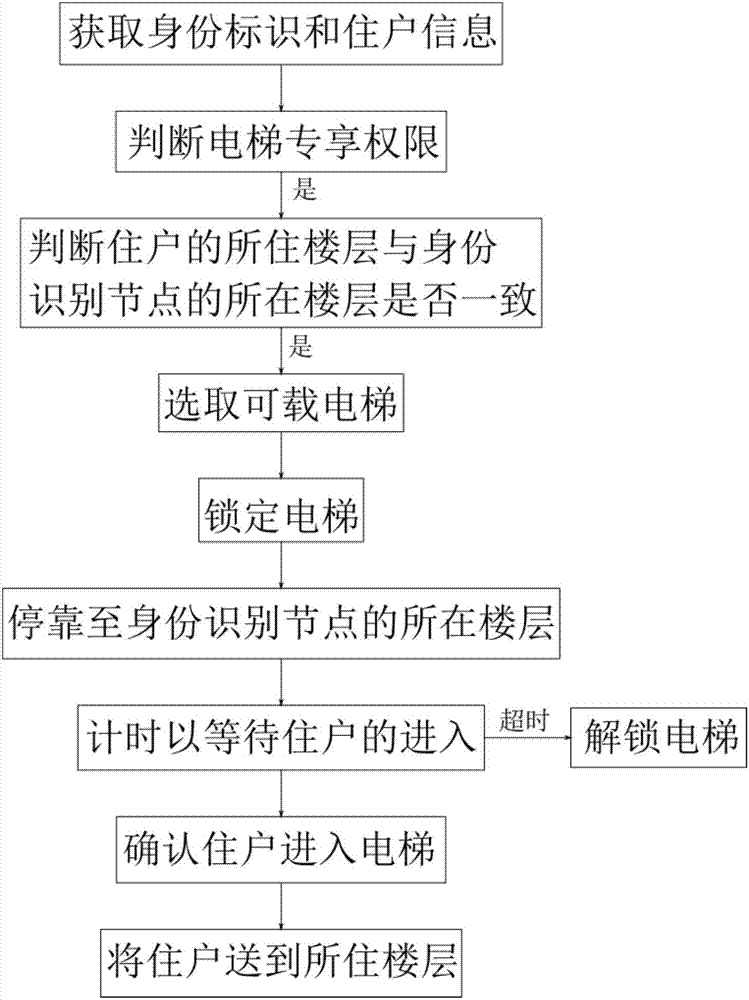

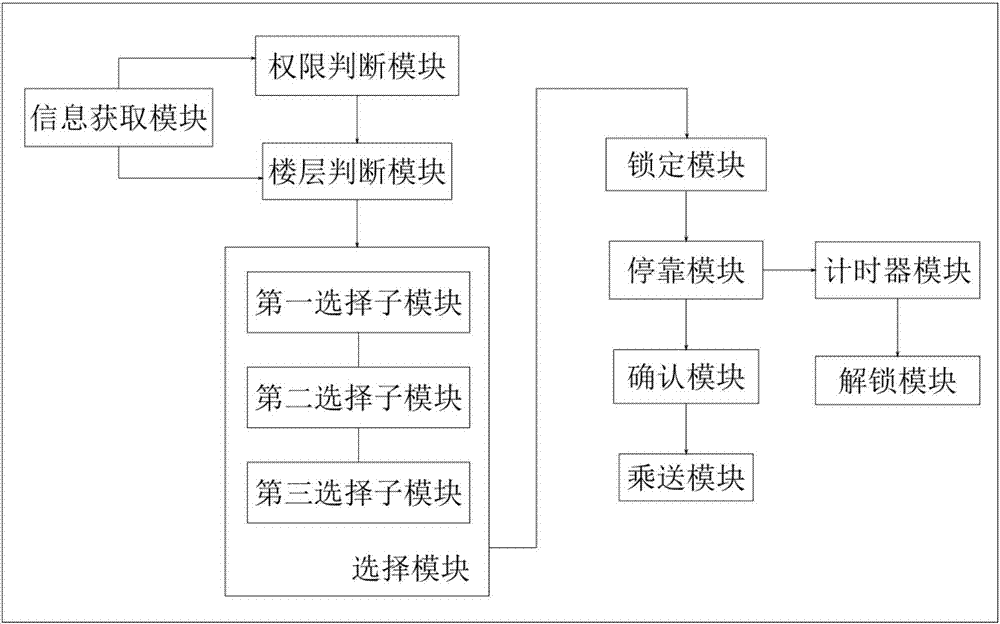

Elevator special control method and system

InactiveCN107021394AReduce waiting time for elevatorsMake sure to enterElevatorsElevator controlEmbedded system

The invention discloses an elevator exclusive control method, which belongs to the technical field of elevator control. The method of the present invention is applied to an intelligent access control system, including information acquisition, selecting a loadable elevator, controlling the loadable elevator to reach the floor where the identification node is located, waiting for the resident to enter the elevator at a preset time, reconfirming the identity of the resident, and sending the resident to the elevator. Steps to the floor where the resident lives. The invention is a highly intelligent and automatic elevator control method and system, which can provide great convenience for residents and is an important improvement over the prior art.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

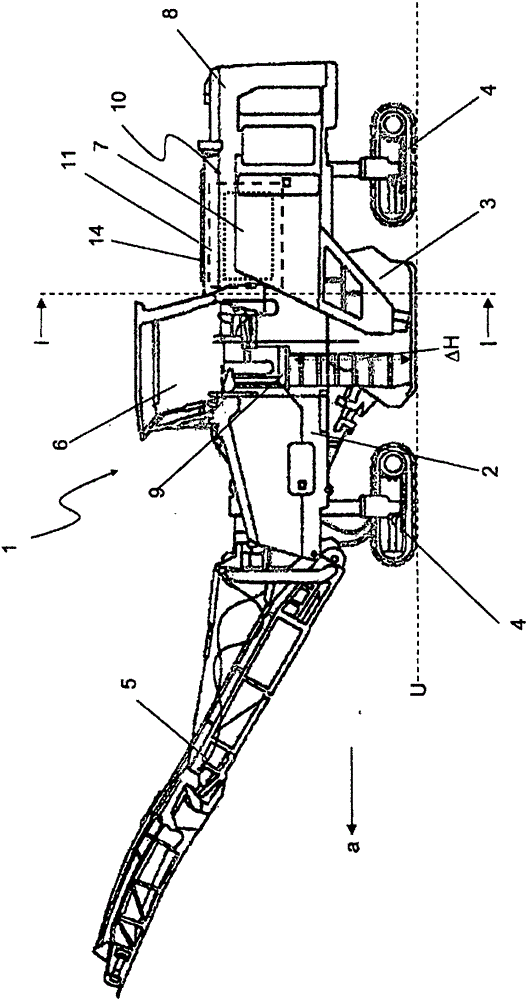

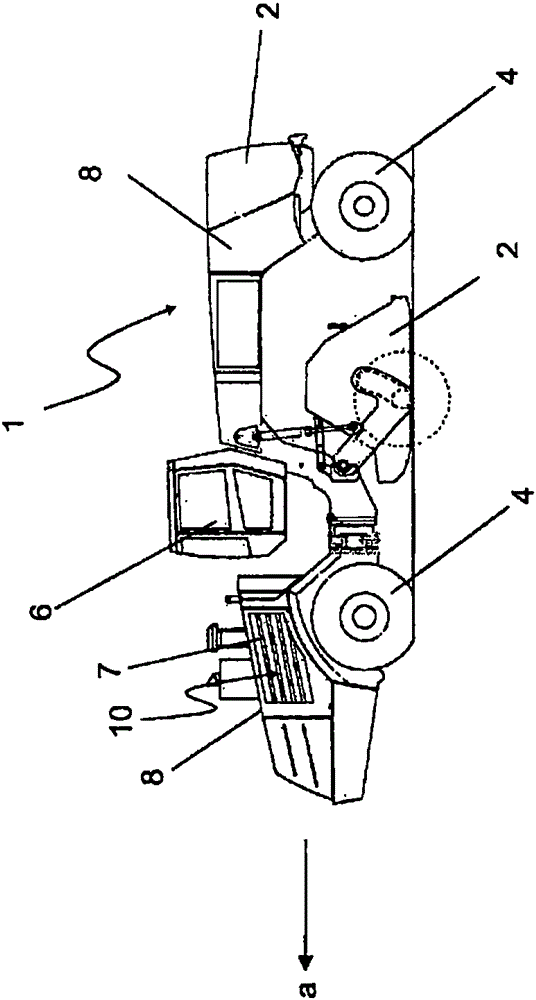

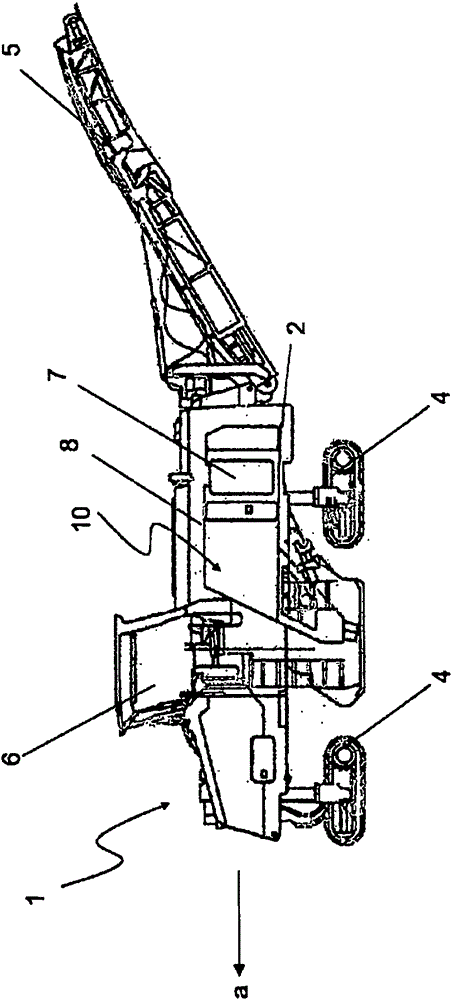

Self-propelled ground milling machine with integrated maintenance platform

InactiveCN105274932AEasy to operateMake sure to enterSuperstructure subunitsSteps arrangementRoad surfaceSurface mining

The present invention relates to a self-propelled ground milling machine with an integrated maintenance platform, comprising a drive engine arranged in an engine compartment and an engine compartment enclosure which covers the engine compartment at least partly to the sides and to the top. A part of the engine compartment enclosure is a cover which is adjustable between a covering position and a maintenance position. At the same time, a maintenance platform is provided which is movable between a stowage position and a maintenance position. When the maintenance platform is in the maintenance position, an operator standing on the floor surface of the maintenance platform can carry out maintenance work in the engine compartment of the self-propelled ground milling machine. The self-propelled ground milling machine preferably is a road milling machine, more particularly a large milling machine, a surface miner, a stabilizer or a recycler.

Owner:BOMAG

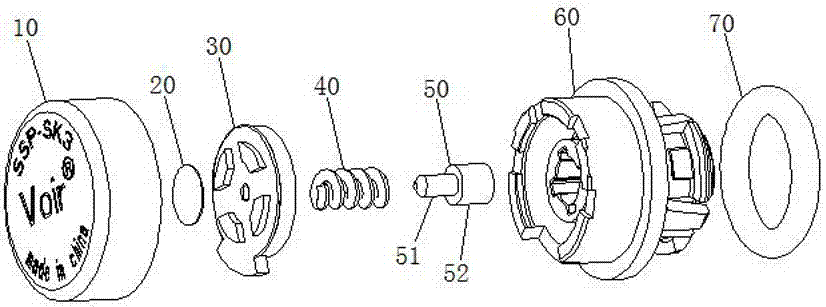

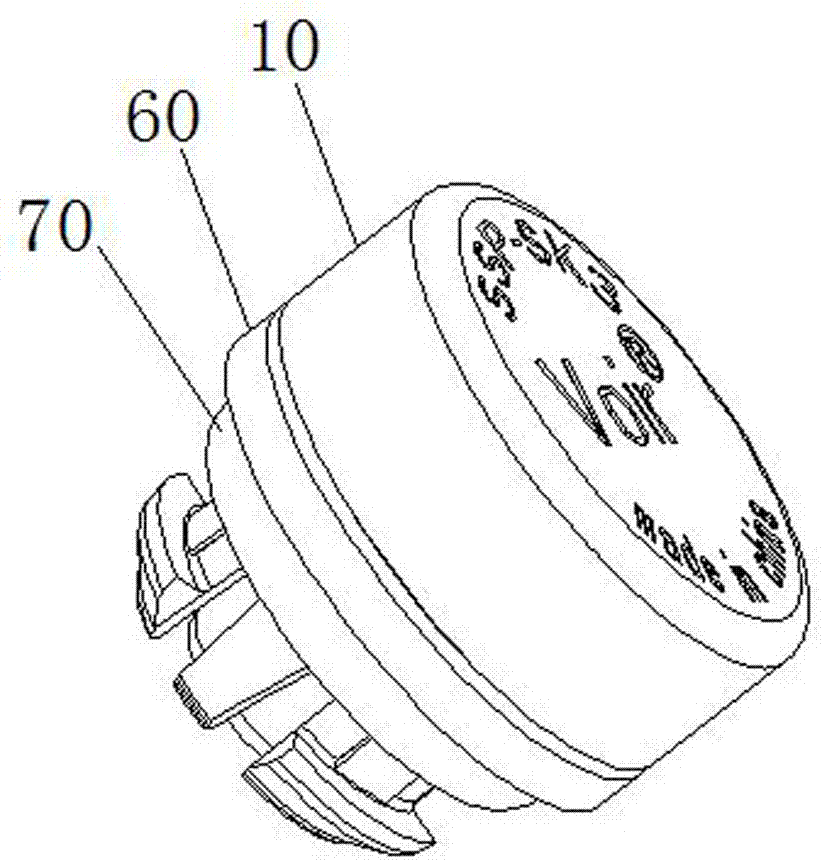

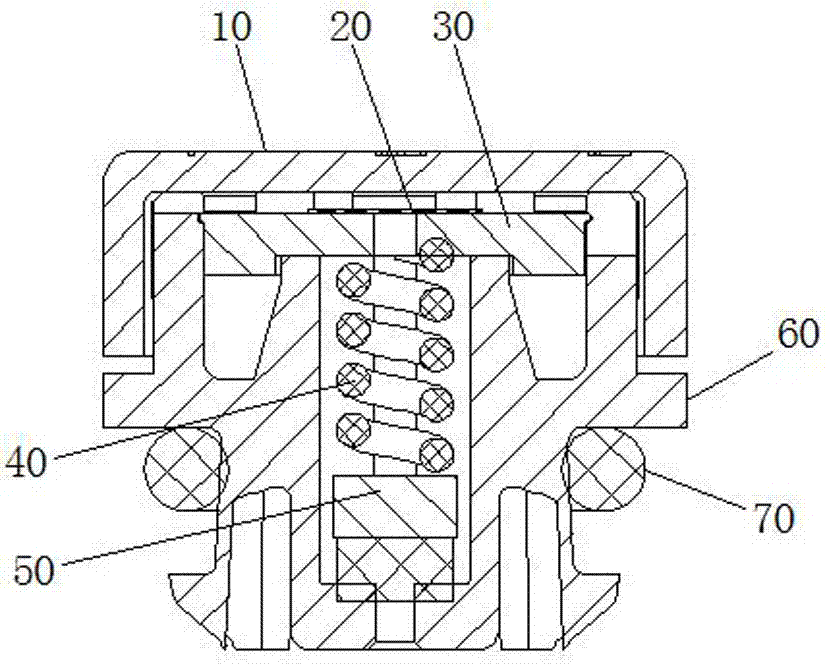

Anti-explosion balance valve applied to battery cell module

PendingCN107394086AMake sure to enterQuick releaseCell component detailsEngineeringMechanical engineering

The invention discloses an anti-explosion balance valve applied to a battery cell module. The anti-explosion balance valve comprises a valve body and a protection cover. One end of the valve body is connected with the protection cover. A ventilated assembly unit is arranged between the protection cover and the valve body. A sealing ring is sleeved on the other end of the valve body. The interior of the valve body is equipped with a first air channel communicated with the valve body. A flexible sealing assembly is arranged in the first air channel. One end of the flexible sealing assembly is in contact type sealing connection with one end of the first air channel. The other end of the flexible sealing assembly is in contact type connection with the ventilated assembly unit. A second air channel is arranged between the ventilated assembly unit and the protection cover. A third air channel is arranged between the protection cover and the valve body. The first air channel is communicated with the second air channel. The second air channel is communicated with the third air channel. The anti-explosion balance valve applied to the battery cell module provided by the invention has the advantages that a structure is simple, the cost is low, the operation is simple and convenient, an electrolyte permeation function in a battery cell is obstructed, and the interior of a product is ventilated with the outside world.

Owner:惠州市沃瑞科技有限公司

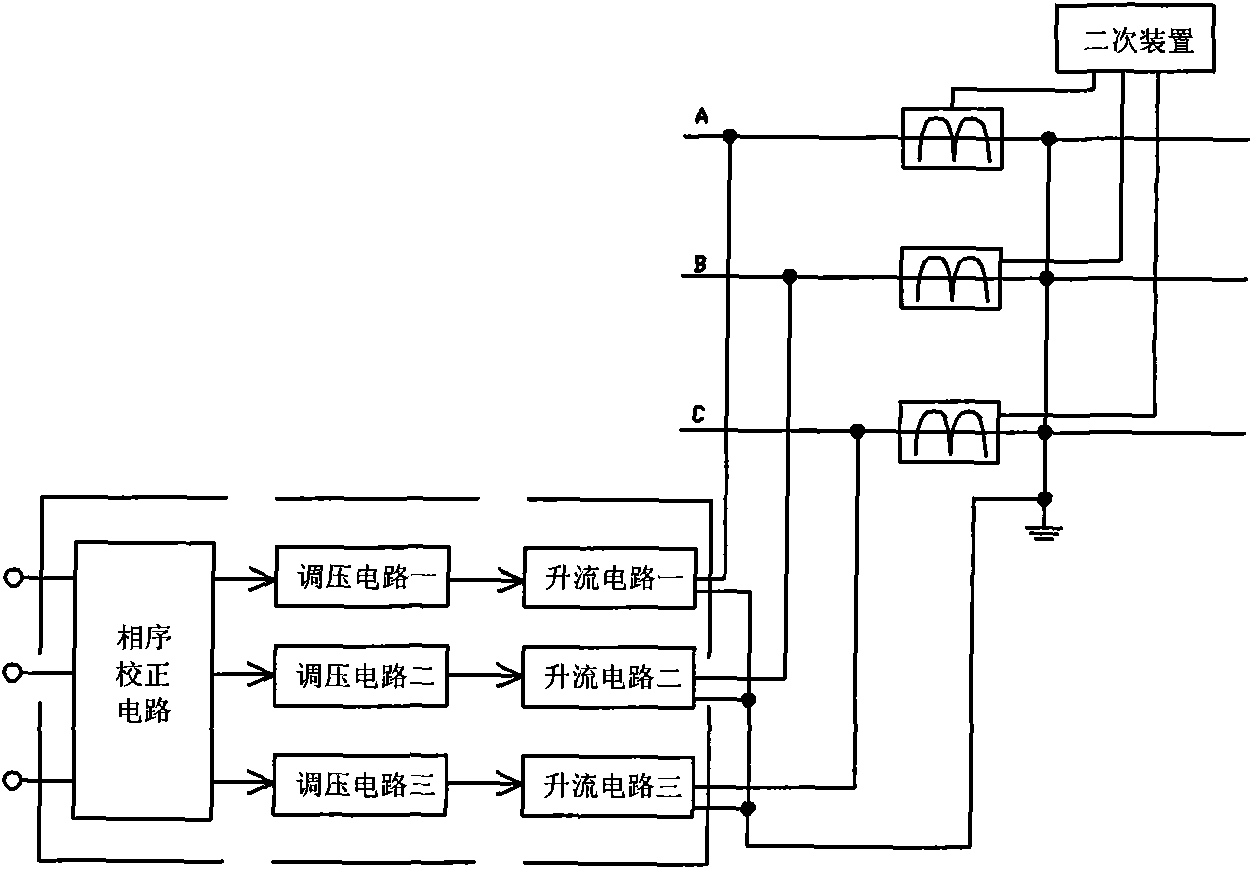

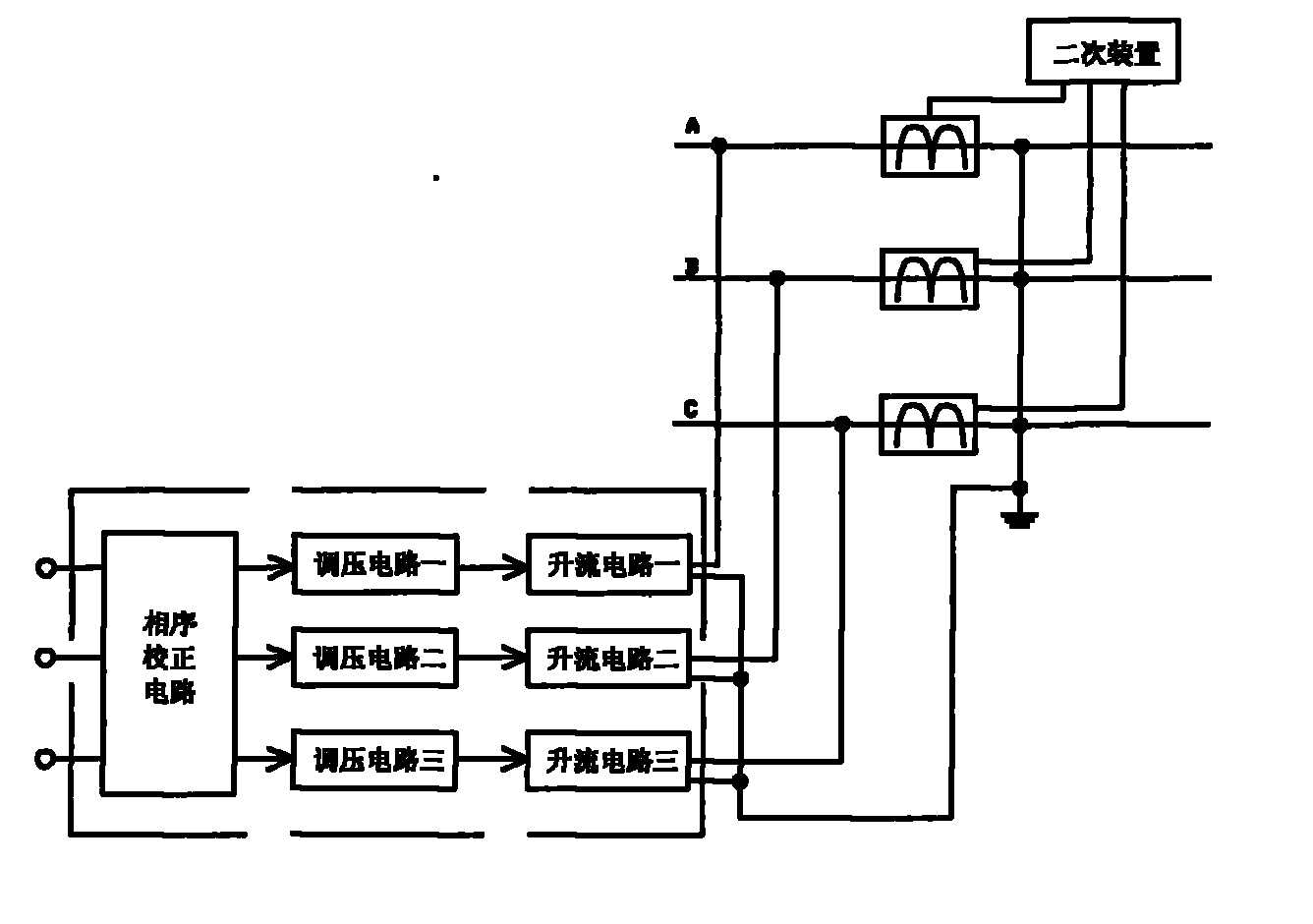

Three-phase heavy current generator for detecting current transformer on power line

InactiveCN101858933AMake sure to enterCheck for correctnessElectrical measurement instrument detailsElectrical testingSecondary loopThree-phase

The invention discloses a three-phase heavy current generator for detecting a current transformer on a power line, and relates to a detection device for the current transformer on the power line. The generator comprises voltage regulating circuits and current increasing circuits which are connected in series; the voltage regulating circuits consist of a voltage regulating circuit 1, a voltage regulating circuit 2 and a voltage regulating circuit 3 which are connected in parallel; the current increasing circuits consist of a current increasing circuit 1, a current increasing circuit 2 and a current increasing circuit 3 which are connected in parallel; the voltage regulating circuits 1, 2 and 3 are connected in series with the current increasing circuits 1, 2 and 3 respectively; and the current increasing circuits 1, 2 and 3 are provided with interfaces for connecting the current transformers on the three-phase power lines respectively. The generator can realize three-phase independent adjustment through the three voltage regulating circuits and the three current increasing circuits; and a phase sequence correction circuit can ensure three-phase positive sequence power input. The generator can detect the correctness of the transformation ratio selection of a secondary loop of the current transformer and the correctness of the connection of the current transformer.

Owner:JIANGSU ELECTRIC POWER COMPANY YANGZHOU POWER

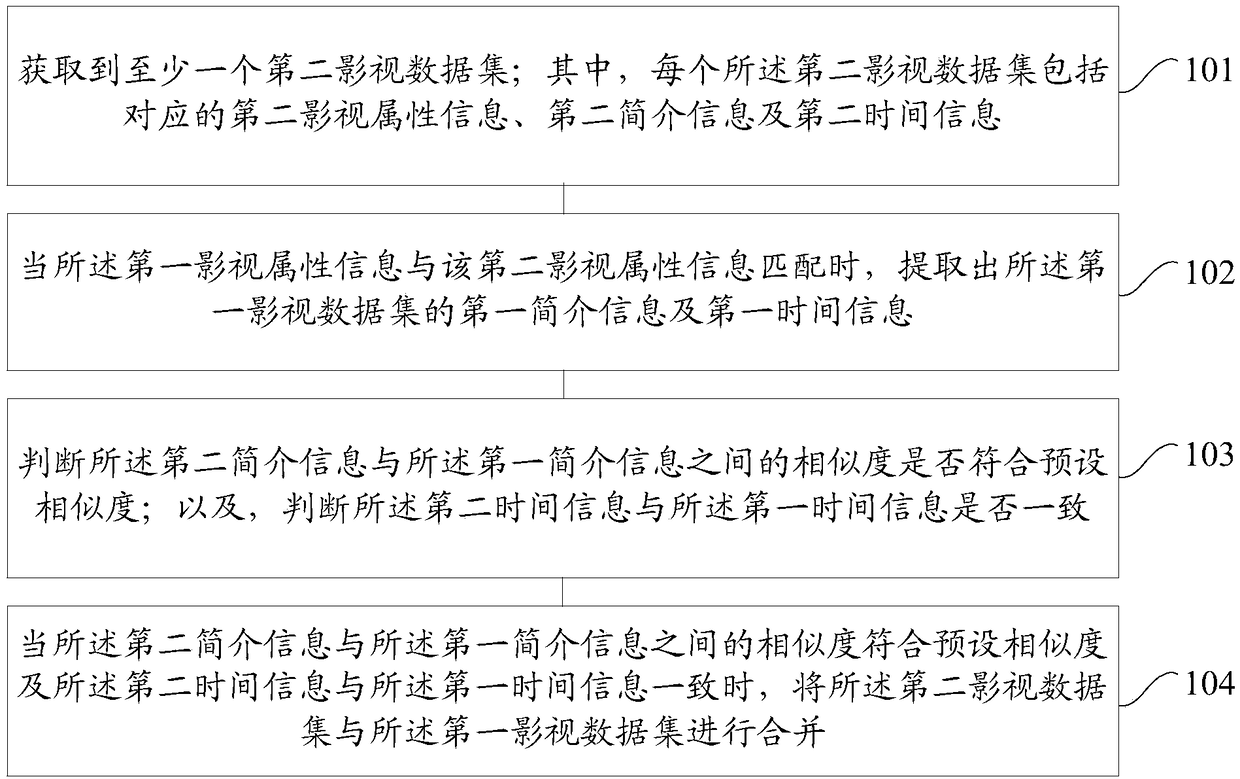

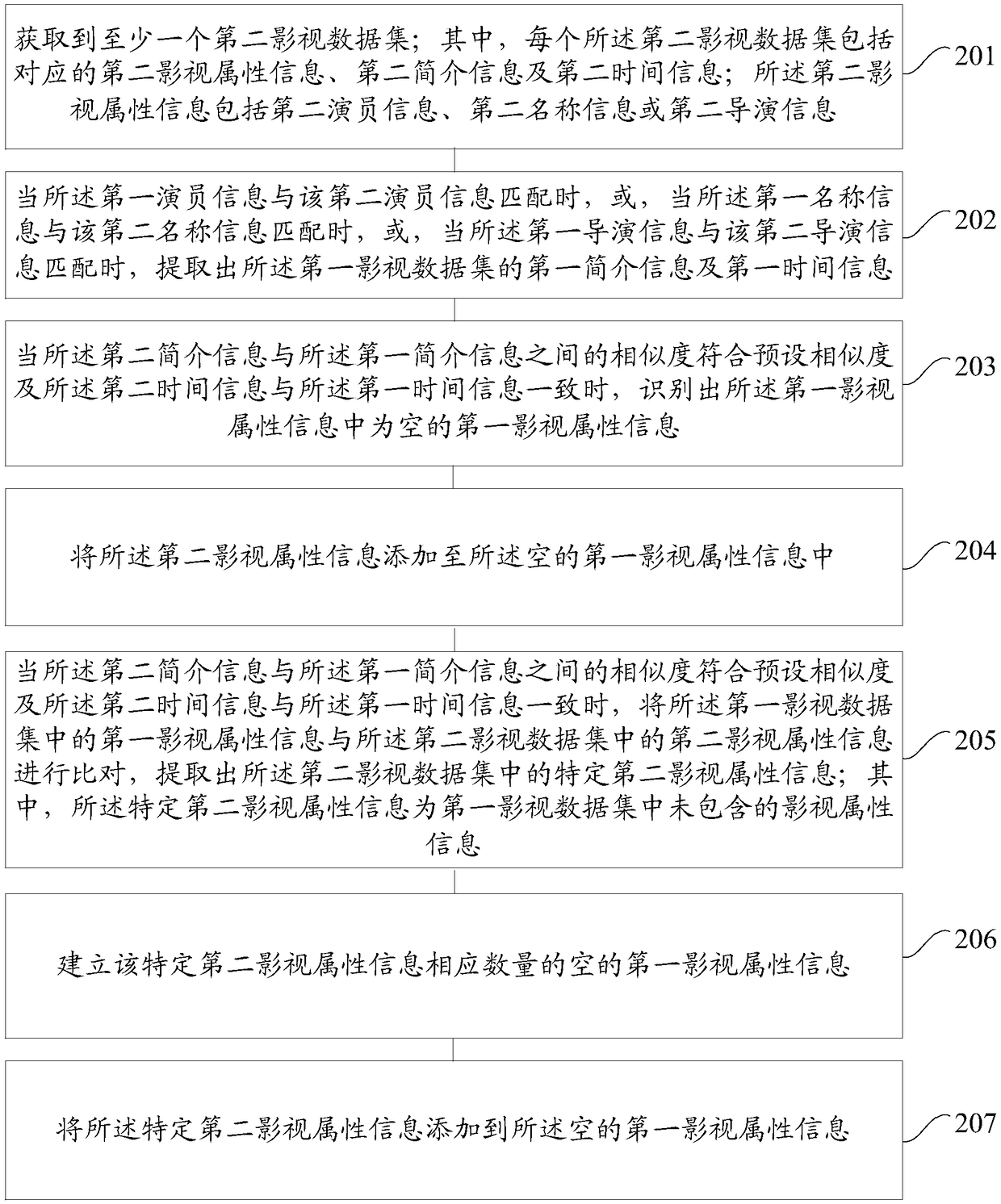

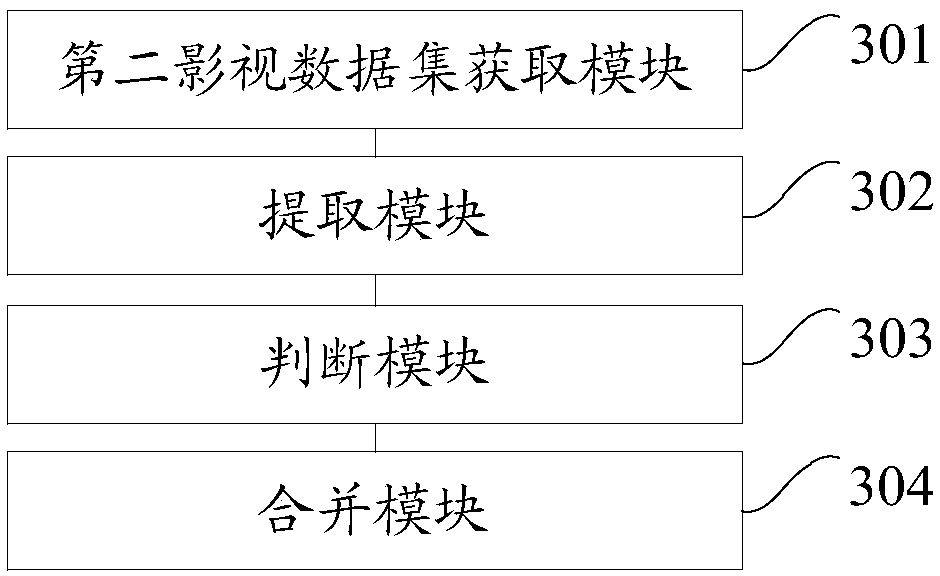

A method and a device for updating a video database

InactiveCN109002522AMake sure to enterAvoid wasting timeSpecial data processing applicationsTime informationProblem of time

The embodiment of the invention provides a method and a device for updating a video database. The method comprises the following steps: acquiring at least one second video data set, wherein each of the second movie and television data sets includes corresponding second movie and television attribute information, second introduction information and second time information; when the first video attribute information matches the second video attribute information, extracting the first profile information and the first time information of the first video data set; judging whether the similarity between the second profile information and the first profile information conforms to a preset similarity; judging whether the second time information coincides with the first time information; when thesimilarity between the second profile information and the first profile information coincides with the preset similarity and the second time information coincides with the first time information, merging the second video data set and the first video data set to avoid the problem of time waste caused by the whole database matching and improve the operation efficiency.

Owner:北京猫眼文化传媒有限公司

Soybean screening and cleaning all-in-one machine

The invention discloses a soybean screening and cleaning all-in-one machine. The machine comprises a feeding box, a machine box and a cleaning box, a screening plate is arranged below a feeding hole,a collecting plate is arranged below the screening plate, collecting holes are formed in the screening plate, the collecting holes communicate with the upper end of the cleaning box through a first material conveying pipe, a partition plate is obliquely arranged in the cleaning box, a filter screen is arranged below the partition plate, a material falling gap is formed between one higher end of the partition plate and the inner wall of the cleaning tank, the side wall of the cleaning box is connected with a water inlet pipe and an impurity removal pipe, a discharge end of the first material conveying pipe, the water outlet end of the water inlet pipe are located above the material falling gap, a feeding end of the impurity removal pipe is positioned above the lower end of the separation plate, the bottom of the cleaning box is connected with a sewage discharge pipe, a second material conveying pipe is arranged at the bottom of the filter screen, wherein one end of the second material conveying pipe is connected with a drying box, a first valve is arranged on the second material conveying pipe, and a second valve is arranged on the sewage discharging pipe.

Owner:SHANDONG CROP GERMPLASM CENT

Ice cream wax paper packing machine

ActiveCN104401524AGuarantee drooping stateMake sure to enterWrapping material feeding apparatusWrappingWaxEngineering

The invention relates to an ice cream wax paper packing machine. The ice cream wax paper packing machine comprises a rack, the rack is provided with a paper hanging mechanism, a feeding mechanism, a paper feeding mechanism, a twining paper pressing mechanism and an output mechanism; the paper hanging mechanism is used for fixing the wax paper coil; the feeding mechanism is used for transporting the ice cream paper to the paper feeding mechanism; the paper feeding mechanism is used for cutting the wax paper and covering the wax paper above the ice cream; the twining paper pressing mechanism is used for bending the paper around the ice cream and rotating the wax paper at the ice cream stick to fix with the ice cream stick; the output mechanism is used for outputting the packed ice cream. The ice cream is guided into the paper feeding mechanism through the feeding mechanism, the paper hanging mechanism hangs the wax paper coil, the paper feeding mechanism feeds and cuts the wax paper, the ice cream passes through the paper feeding mechanism at the same time to be covered by the wax paper, the ice cream is transported to the twining paper pressing mechanism, the wax paper on the ice cream is bent and rotated to fix with the ice cream stick, and the ice cream is packed by the wax paper automatically.

Owner:QINGDAO WENDING AUTOMATION EQUIP

Low-cost large-scale continuous production equipment and technology for high-purity graphite worms

The invention relates to a method for producing graphite worms with heating expandable graphite, in particular to low-cost large-scale continuous production equipment and technology for high-purity graphite worms. The low cost large-scale continuous production technology for the high-purity graphite worms comprises the following steps of using the expandable graphite as a raw material, directly and electrically heating expandable graphite powder under inert gas atmosphere, after the expandable graphite powder is slightly expanded, and performing microwave heating to the temperature of 1000-1800 DEG C so that the expandable graphite powder is completely expanded and the graphite worms are obtained. Besides, impurities are gasified to separate from the graphite, so that the purity of the graphite is improved. The microwave heating is different from other heating methods, the graphite worms absorb microwaves to generate heat, so that the temperature of the graphite worms is higher than surrounding temperature, and if the density of microwave energy is higher, the temperature of the graphite worms is higher; and the expandable graphite powder is the expandable graphite powder with sulfuric acid intercalation, or sulfur-free expandable graphite powder, or any expandable graphite powder.

Owner:苏州鼎烯聚材纳米科技有限公司

Waste lithium battery cool type splash-proof electrolyte recovery device

ActiveCN109560342AAvoid environmental pollutionProtect healthSolid waste disposalWaste accumulators reclaimingSolventOpen structure

The invention discloses a waste lithium battery cool type splash-proof electrolyte recovery device. The waste lithium battery cool type splash-proof electrolyte recovery device comprises a compressor,a crushing box, a filter box, a liquid collection box and a solvent box, wherein a refrigerator is arranged inside the crushing box; a condenser is wound on the outer side of the refrigerator; the compressor is arranged on the outer side of the crushing box; the condenser is connected with the compressor; a partition door is arranged at the lower end of the refrigerator; crushing teeth are arranged below the partition door; a sliding plate is arranged below the crushing teeth; the sliding plate is arranged slantly; an outlet is formed in one side of the crushing box; the lower end of the sliding plate is connected with the outlet; the upper end of the filter box is of an open structure; the outlet is connected with an opening in the upper end of the filter box through a connecting plate;the filter box is internally provided with a centrifugal cylinder; a centrifugal motor is arranged at the lower end of the filter box; the centrifugal motor is connected with the centrifugal cylinder;a liquid inlet pipe is arranged on the solvent box; the outlet end of the liquid inlet pipe is arranged above the filter box; and the liquid collection box is connected with the filter box through apipeline.

Owner:贵州中伟资源循环产业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com