Anti-explosion balance valve applied to battery cell module

A battery cell module and balance valve technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of reduced service life of key components of the battery cell, damage to electronic devices, and air pressure discharge to the outside, achieving easy installation and operation , increase the service life, and solve the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

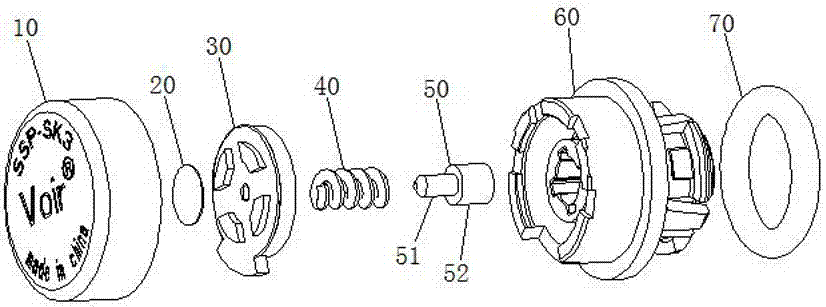

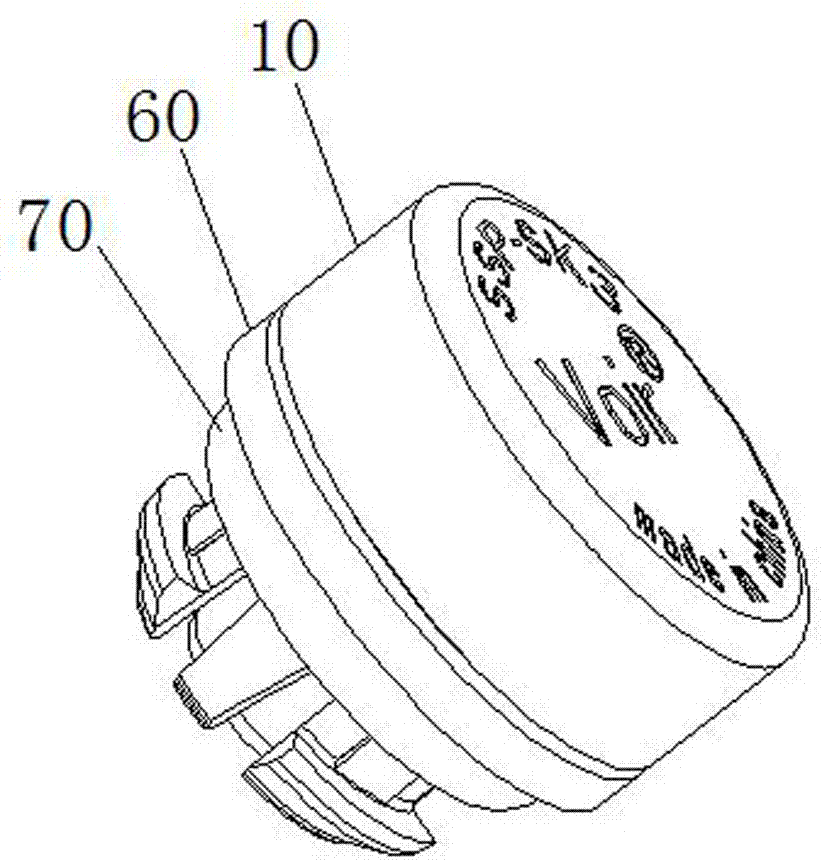

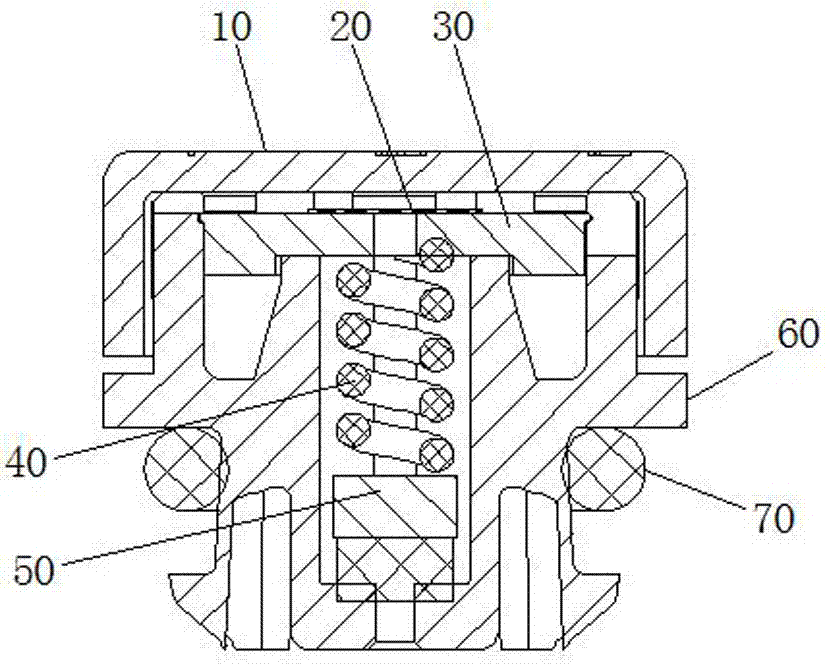

[0030] Such as Figure 1 to Figure 7 As shown, an explosion-proof balance valve applied to the battery module includes a valve main body 60 and a protective cover 10, one end of the valve main body 60 is connected to the protective cover 10, and the other end of the valve main body 60 is sleeved There is a sealing ring 70, and a breathable assembly for blocking the electrolyte is provided between the protective cover 10 and the valve body 60. The breathable assembly includes a breathable gland 30, and a breathable membrane is arranged outside the breathable gland 30 Sheet 20, the valve body 60 is provided with a first gas channel 65 through the valve body 60, the first gas channel 65 is a stepped channel, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com