Waste lithium battery cool type splash-proof electrolyte recovery device

A technology for electrolyte recycling and lithium batteries, which is applied in battery recycling, electronic waste recycling, waste collector recycling, etc. It can solve problems such as endangering the health of workers, easy splashing of electrolyte, and environmental pollution, so as to save resources and prevent The effect of residual liquid dripping and splashing, avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

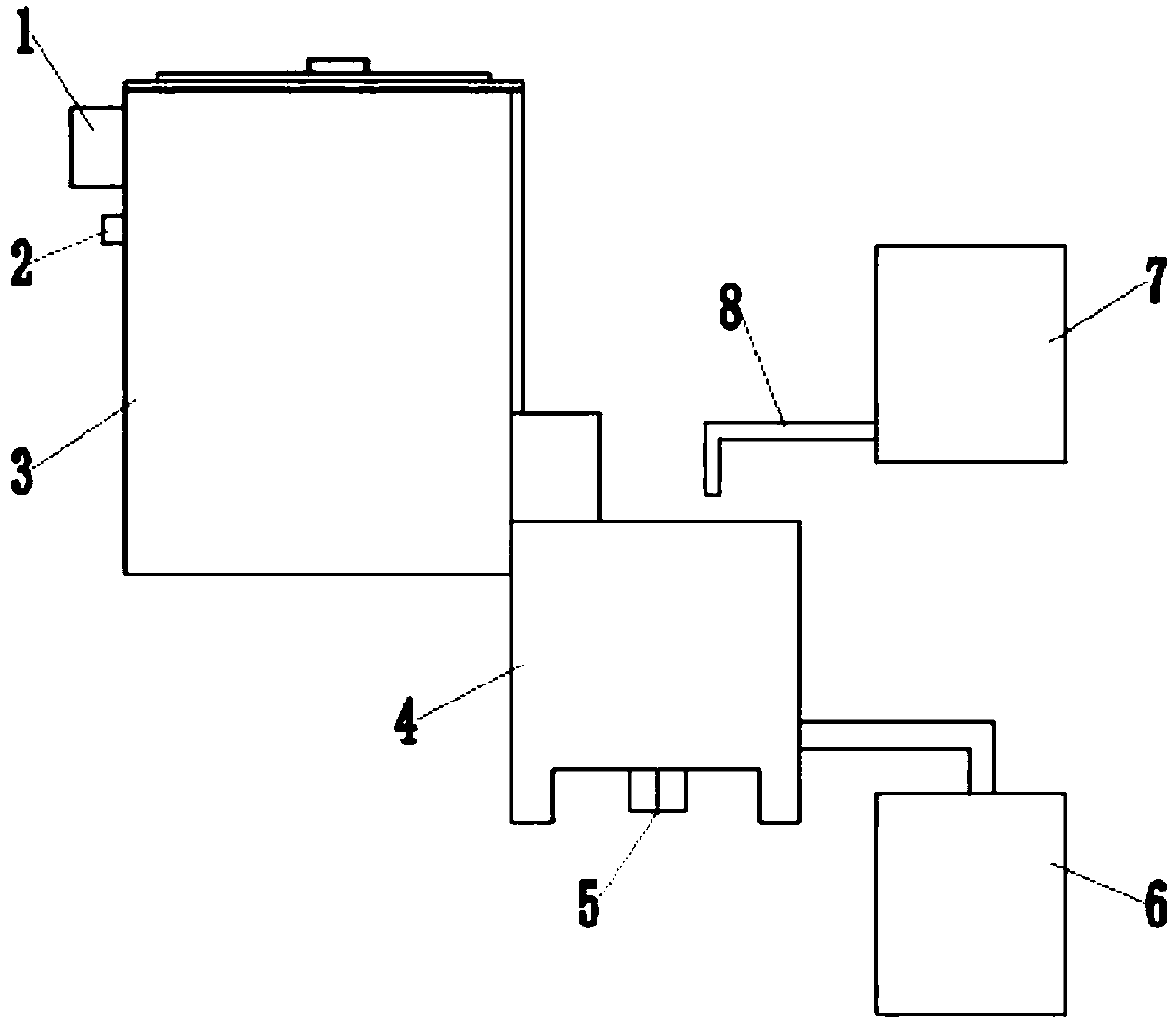

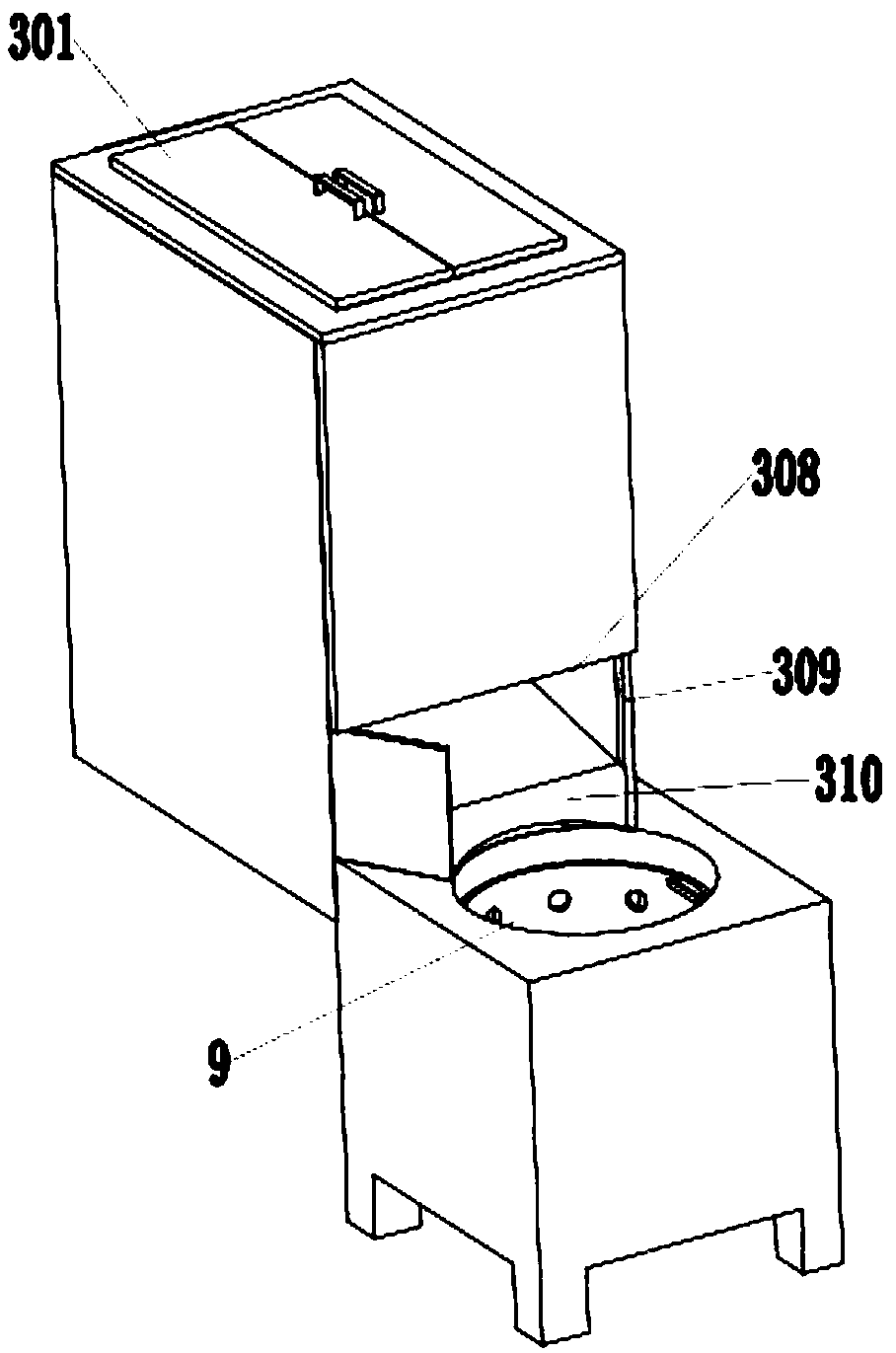

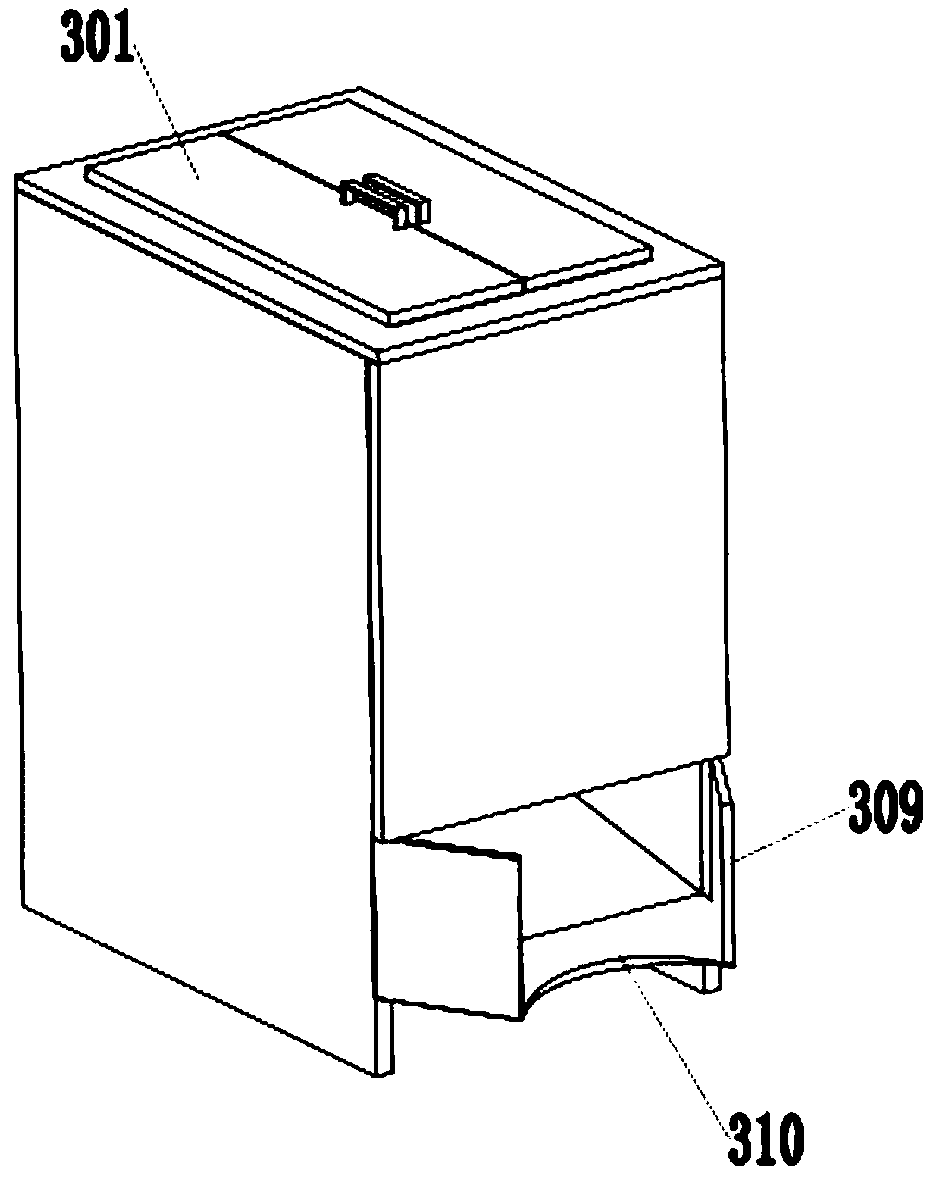

[0030] Such as Figure 1-6 As shown, a cold-type anti-splash electrolyte recovery device for waste lithium batteries is characterized in that it includes a compressor 1, a crushing box 3, a filter box 4, a liquid collection box 6, and a solvent box 7. The crushing box 3 There is a freezer box 302 inside, the outside of the freezer box 302 is wrapped with a condenser 101, the compressor 1 is arranged outside the crushing box 3, the condenser 101 is connected with the compressor 1, and the freezer The lower end of the box 302 is provided with a partition door 304, the bottom of the partition door 304 is provided with a crushing tooth 305, and the bottom of the crushing tooth 305 is provided with a slide plate 307, and the slide plate 307 is arranged obliquely. One side of the crushing box 3 A discharge port 308 is provided, the lower end of the slide plate 307 is connected with the discharge port 308, the upper end of the filter box 4 is an open structure, the discharge port 308...

Embodiment 2

[0032] Such as Figure 1-6 As shown, a cold-type anti-splash electrolyte recovery device for waste lithium batteries is characterized in that it includes a compressor 1, a crushing box 3, a filter box 4, a liquid collection box 6, and a solvent box 7. The crushing box 3 There is a freezer box 302 inside, the outside of the freezer box 302 is wrapped with a condenser 101, the compressor 1 is arranged outside the crushing box 3, the condenser 101 is connected with the compressor 1, and the freezer The lower end of the box 302 is provided with a partition door 304, the bottom of the partition door 304 is provided with a crushing tooth 305, and the bottom of the crushing tooth 305 is provided with a slide plate 307, and the slide plate 307 is arranged obliquely. One side of the crushing box 3 A discharge port 308 is provided, the lower end of the slide plate 307 is connected with the discharge port 308, the upper end of the filter box 4 is an open structure, the discharge port 308...

Embodiment 3

[0035] Such as Figure 1-6 As shown, a cold-type anti-splash electrolyte recovery device for waste lithium batteries is characterized in that it includes a compressor 1, a crushing box 3, a filter box 4, a liquid collection box 6, and a solvent box 7. The crushing box 3 There is a freezer box 302 inside, the outside of the freezer box 302 is wrapped with a condenser 101, the compressor 1 is arranged outside the crushing box 3, the condenser 101 is connected with the compressor 1, and the freezer The lower end of the box 302 is provided with a partition door 304, the bottom of the partition door 304 is provided with a crushing tooth 305, and the bottom of the crushing tooth 305 is provided with a slide plate 307, and the slide plate 307 is arranged obliquely. One side of the crushing box 3 A discharge port 308 is provided, the lower end of the slide plate 307 is connected with the discharge port 308, the upper end of the filter box 4 is an open structure, the discharge port 308...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com