Low-cost large-scale continuous production equipment and technology for high-purity graphite worms

A graphite worm and production process technology, applied in the field of low-cost, large-scale continuous production equipment and processes, can solve the problems of low efficiency, high electricity cost, low microwave conversion efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

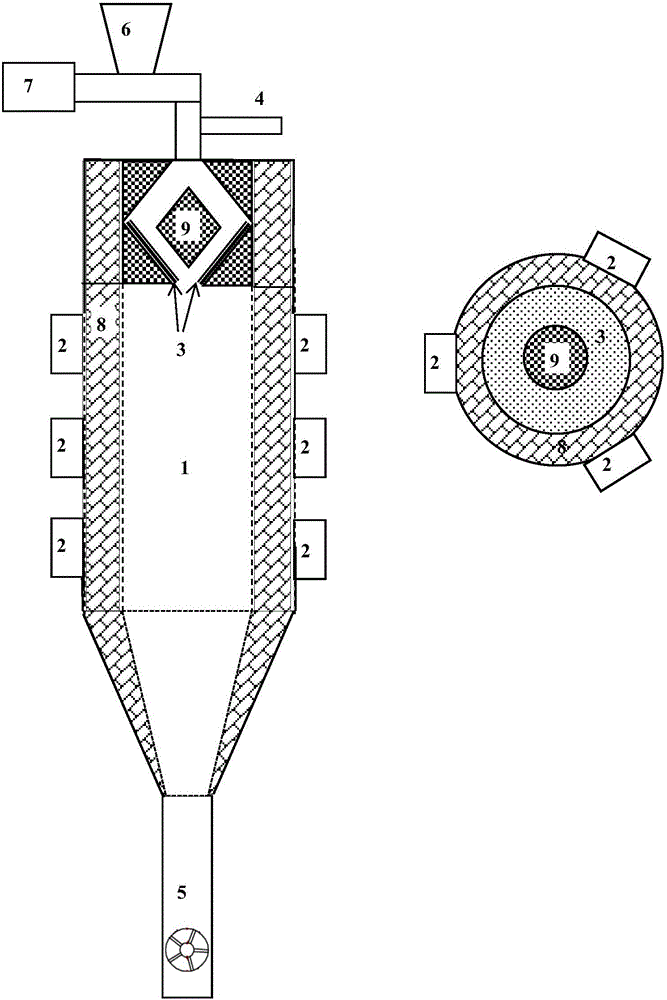

[0028] A low-cost, large-scale continuous production facility for high-purity graphite worms such as figure 1 As shown, the main body of the equipment is a high-temperature microwave expansion furnace 1 with a conical bottom. The feed inlets are connected, and a nitrogen inlet 4 is provided above the high-temperature microwave expansion furnace 1 , and the nitrogen inlet 4 communicates with the outlet of the screw feeder 7 . The bottom of the high-temperature microwave expansion furnace 1 is connected to the outlet 5 of expanded graphite worms with a cooling metal pipe and an air locker. The inside of the outlet 5 of the expanded graphite worm is a cooling zone for the graphite worm to cool down before leaving the closed system. The outlet of the expanded graphite worm is a metal pipe, and the cooling zone reduces the temperature of the graphite worm to below 100 degrees and close to room temperature. The length is based on the actual Production can be set from 0.5 to 5 meter...

Embodiment 2

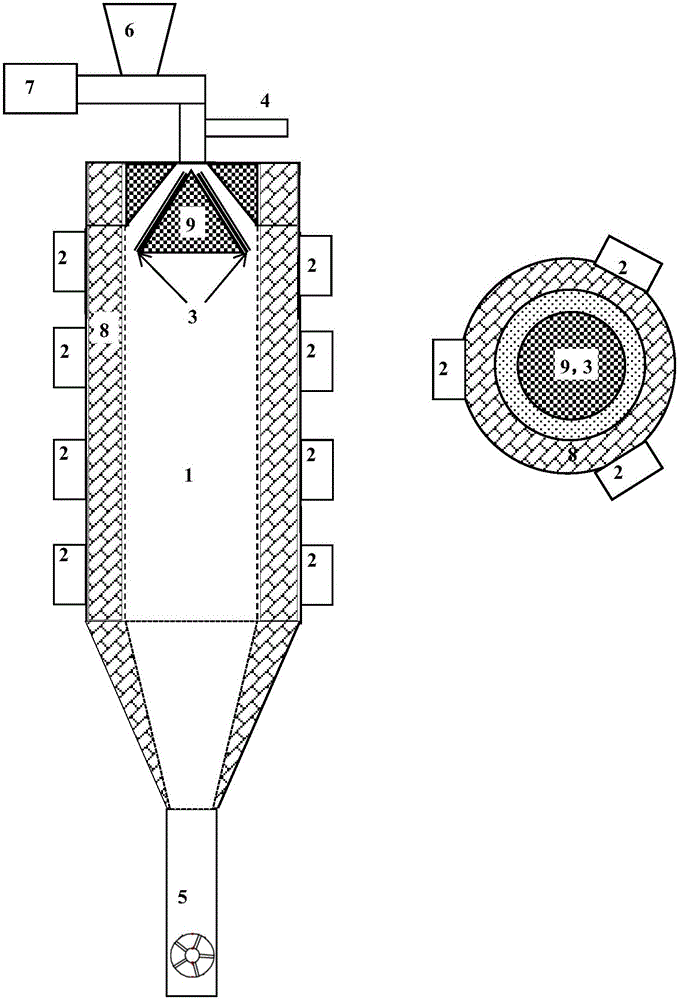

[0038] Concrete structure is the same as embodiment 1, differs from embodiment 1 in the simplification of dispersion disc and heating equipment, equipment schematic diagram is as follows figure 2 As shown, a microwave source 2 is arranged around the high-temperature microwave expansion furnace 1, and an electric heater 3 and a dispersing disk 9 for expandable graphite powder are arranged on the upper part of the high-temperature microwave expansion furnace 1. The top of the dispersion disc is below the discharge port of the screw continuous feeder 7. The expandable graphite powder falls into the microwave heating area from the space on both sides of the dispersing disc.

[0039] a. The dispersing disc 9 is a conical body, and an electric heater 3 is placed on its surface. The temperature on the surface of the electric heater is 500-700°C, which accounts for 40% to 60% of the electric energy required by the expanded graphite. The inclination of the electric heater The angle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com