Periodic suction type textile fabric dust removal device

A technology of textile cloth and dust cleaning device, which is applied in the field of textile equipment, can solve the problems of secondary pollution of cloth, difficult dust collection in dust removal and exhaust outlets, difficulty in dust removal work to achieve the expected effect, and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

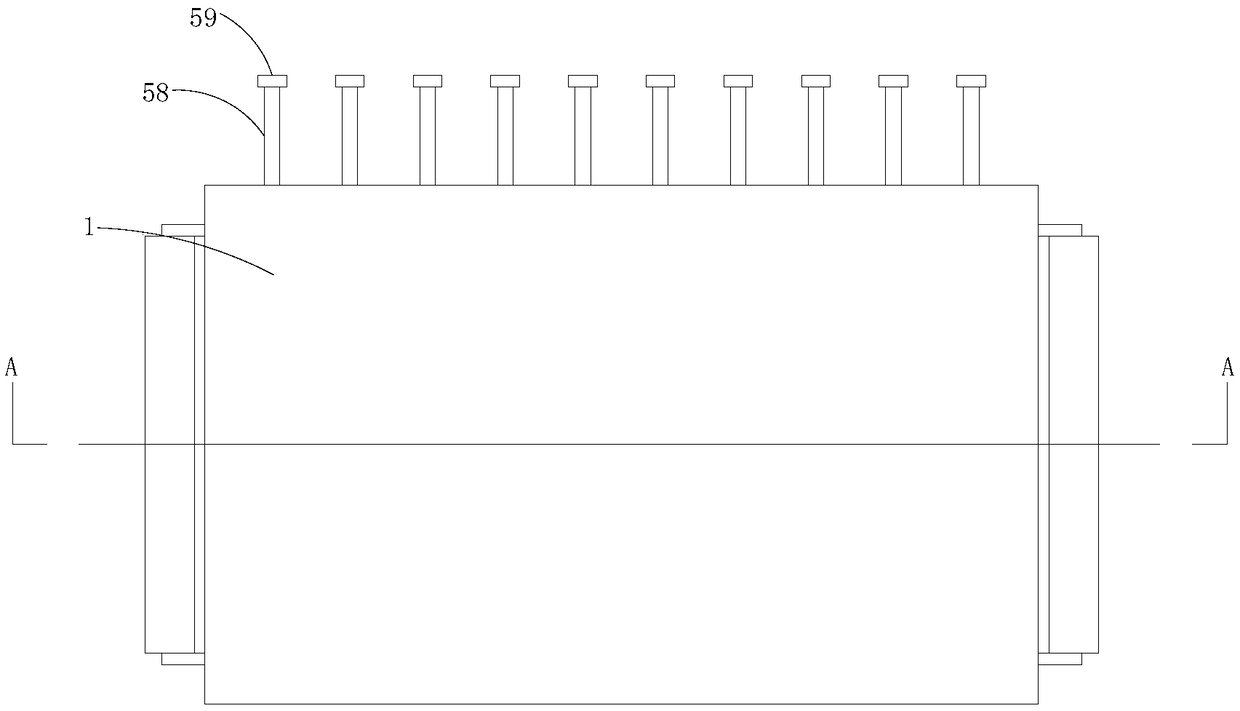

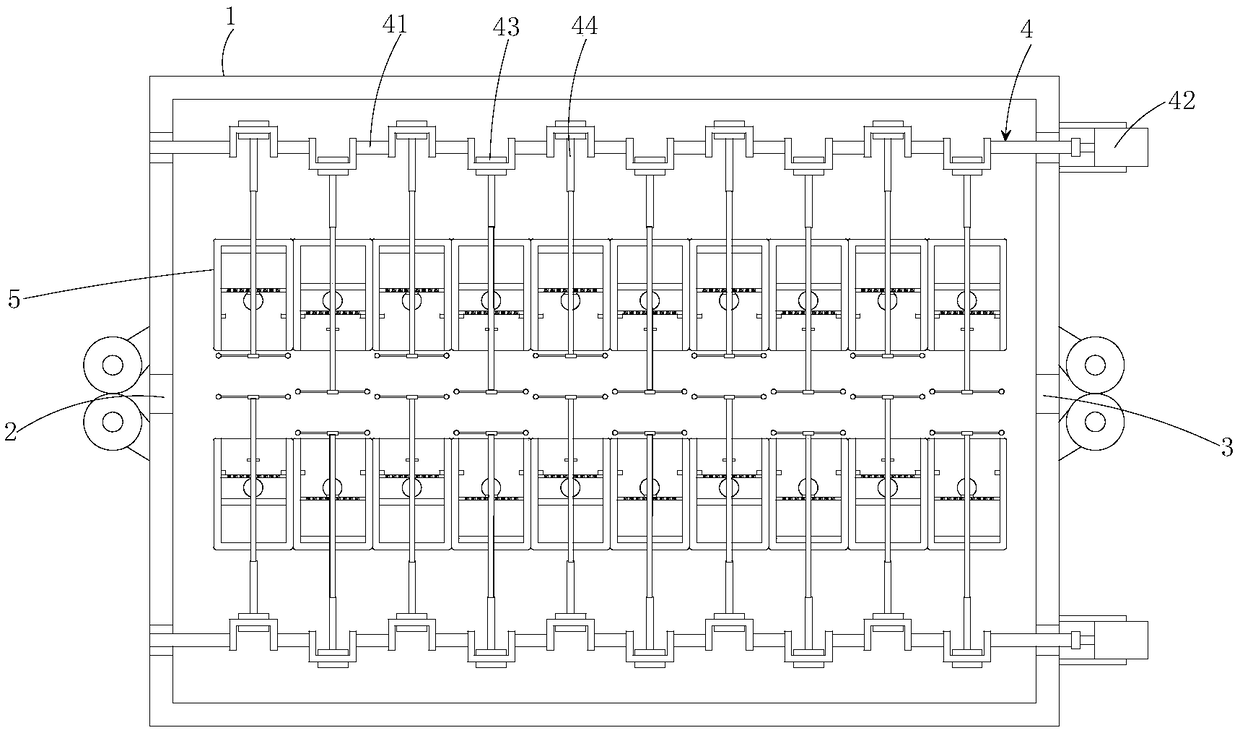

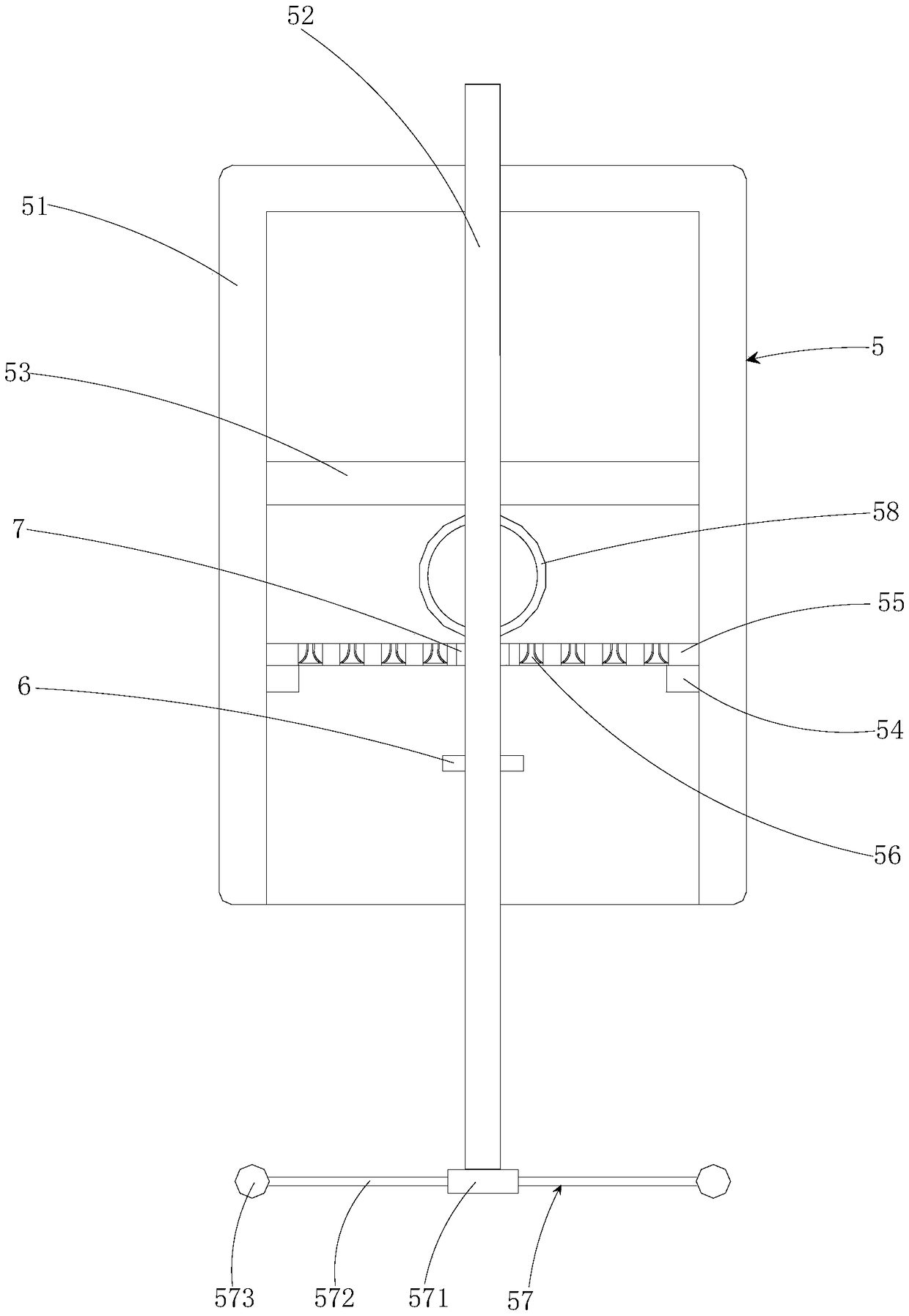

[0028] see Figure 1-3 , the present invention provides a technical solution: a periodic suction type textile cloth dust cleaning device, including a box body 1, a strip-shaped feed port 2, a strip-shaped discharge port 3, two transmission mechanisms 4 and two dust collectors Mechanism 5, the strip-shaped feeding port 2 and the strip-shaped discharging port 3 are set on the left and right side walls of the box body 1 respectively and are symmetrical to each other. Two transmission mechanisms 4 are set at the upper and lower ends of the box body 1. The mechanism 5 is set inside the box body 1 and is located between the two transmission mechanisms 4, and the two dust removal mechanisms 5 and the two transmission mechanisms 4 are all based on the connection line between the strip-shaped feed port 2 and the strip-shaped discharge port 3 symmetry.

[0029] The transmission mechanism 4 includes a crankshaft 41, a drive motor 42, a collar 43 and a transmission rod 44. The two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com