Patents

Literature

144results about How to "Will not flow back" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

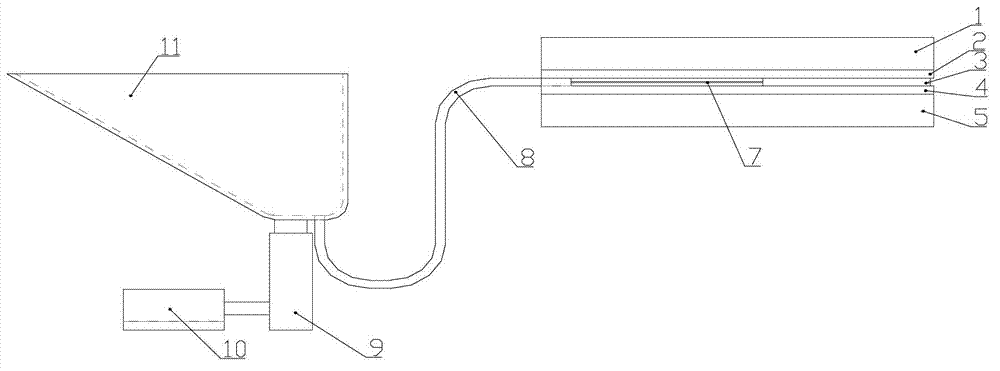

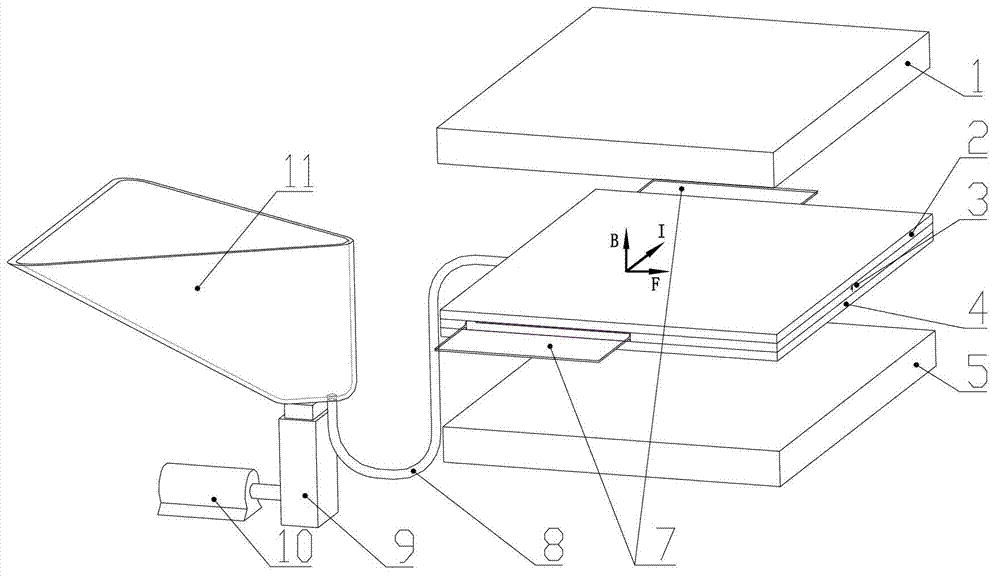

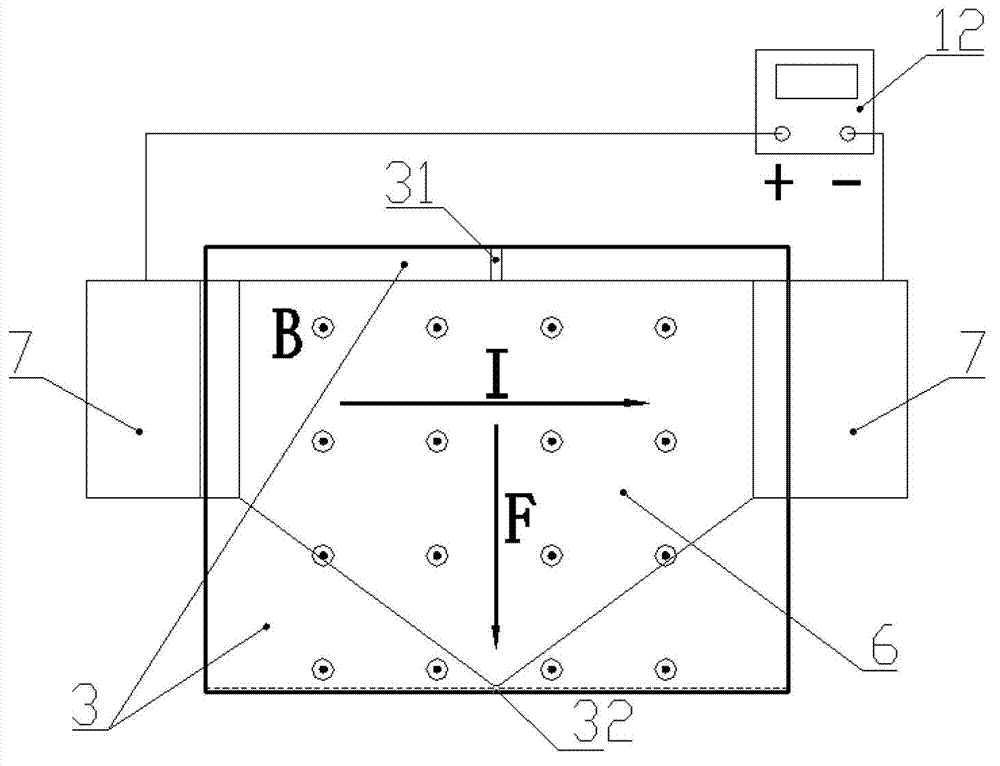

Electromagnetic micro jet device

ActiveCN103203294ASimple mechanical structureSupply pressure is stableElectrostatic spraying apparatusEngineeringMagnet

The invention discloses an electromagnetic micro jet device, and relates to a micro jet device. The electromagnetic micro jet device is suitable for jet of metal liquid as required, and is provided with an upper magnet, a jet cavity, a lower magnet, electrodes, a liquid feed pipe, a liquid feed tank, a lifting mechanism, a stepping motor and a pulse current device, wherein the upper magnet and the lower magnet are fixed on the upper surface and the lower surface of the jet cavity respectively; the jet cavity is provided with a liquid inlet and a liquid nozzle; the electrodes are arranged on the two sides of the jet cavity and stretch into the jet cavity; one end of the liquid feed pipe is communicated with an inner cavity of the jet cavity; the other end of the liquid feed pipe is communicated with the liquid feed tank; an input end of the lifting mechanism is connected with the stepping motor; an output end of the lifting mechanism is connected with the liquid feed tank; and the two ends of the pulse current device are connected with the electrodes.

Owner:XIAMEN UNIV

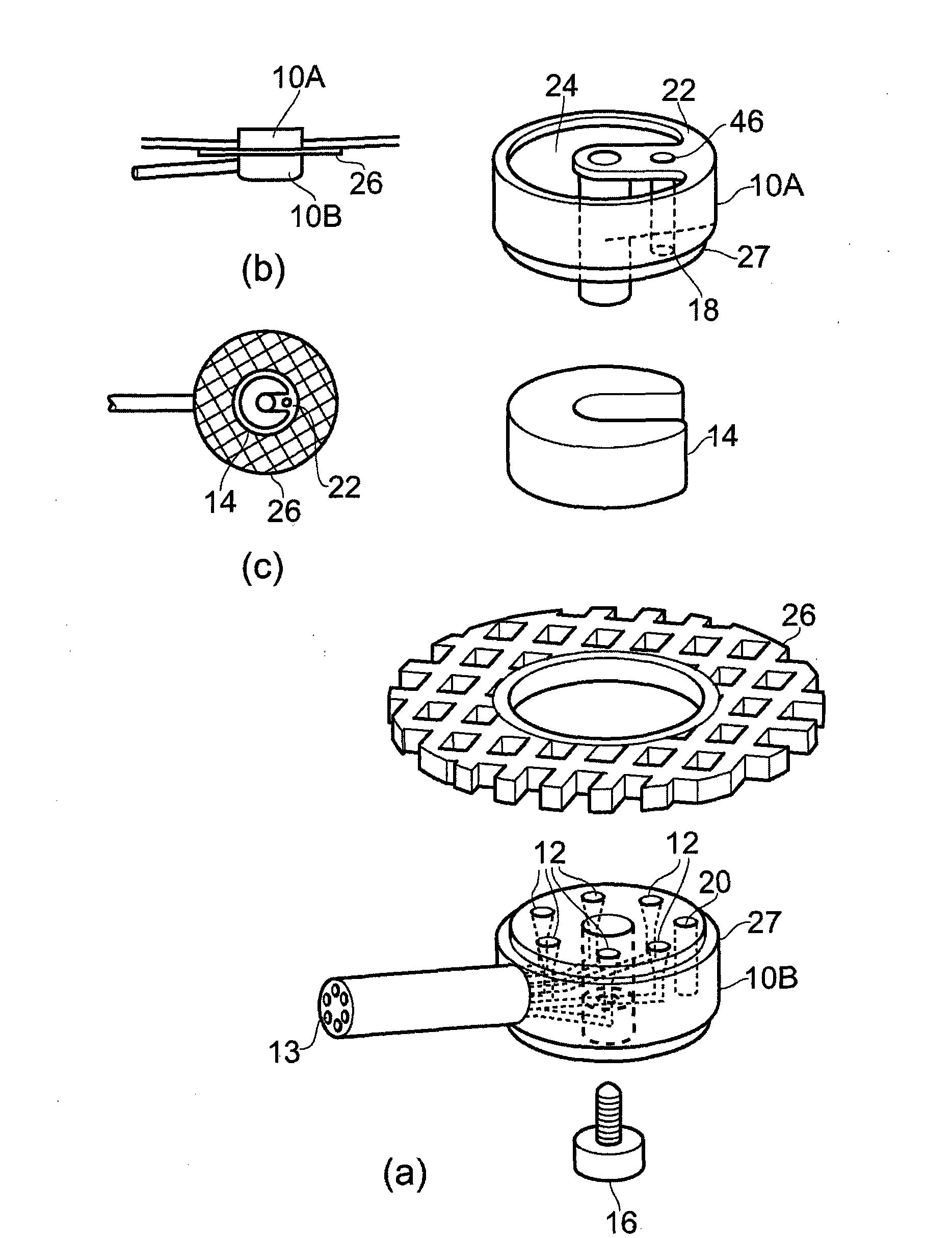

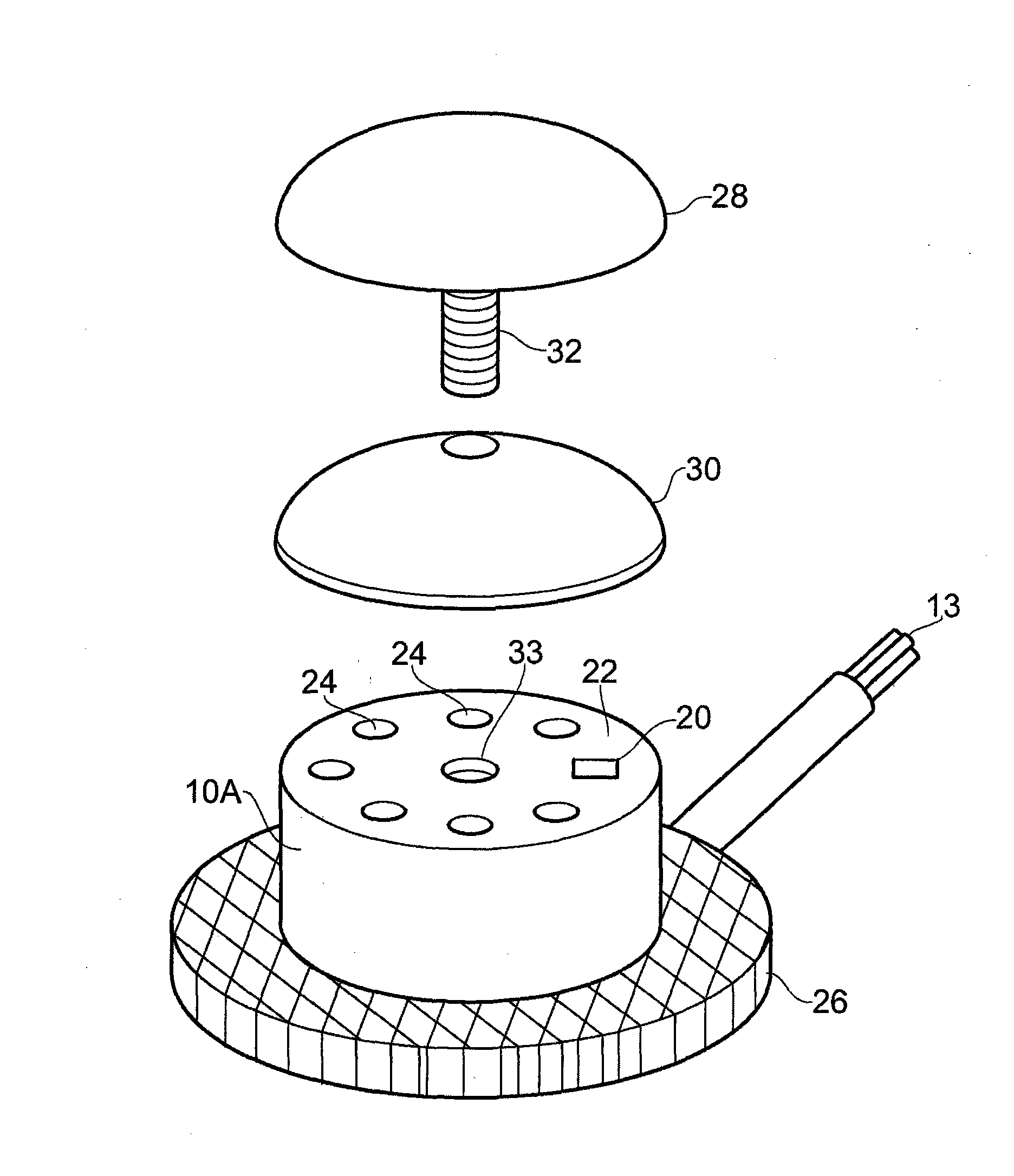

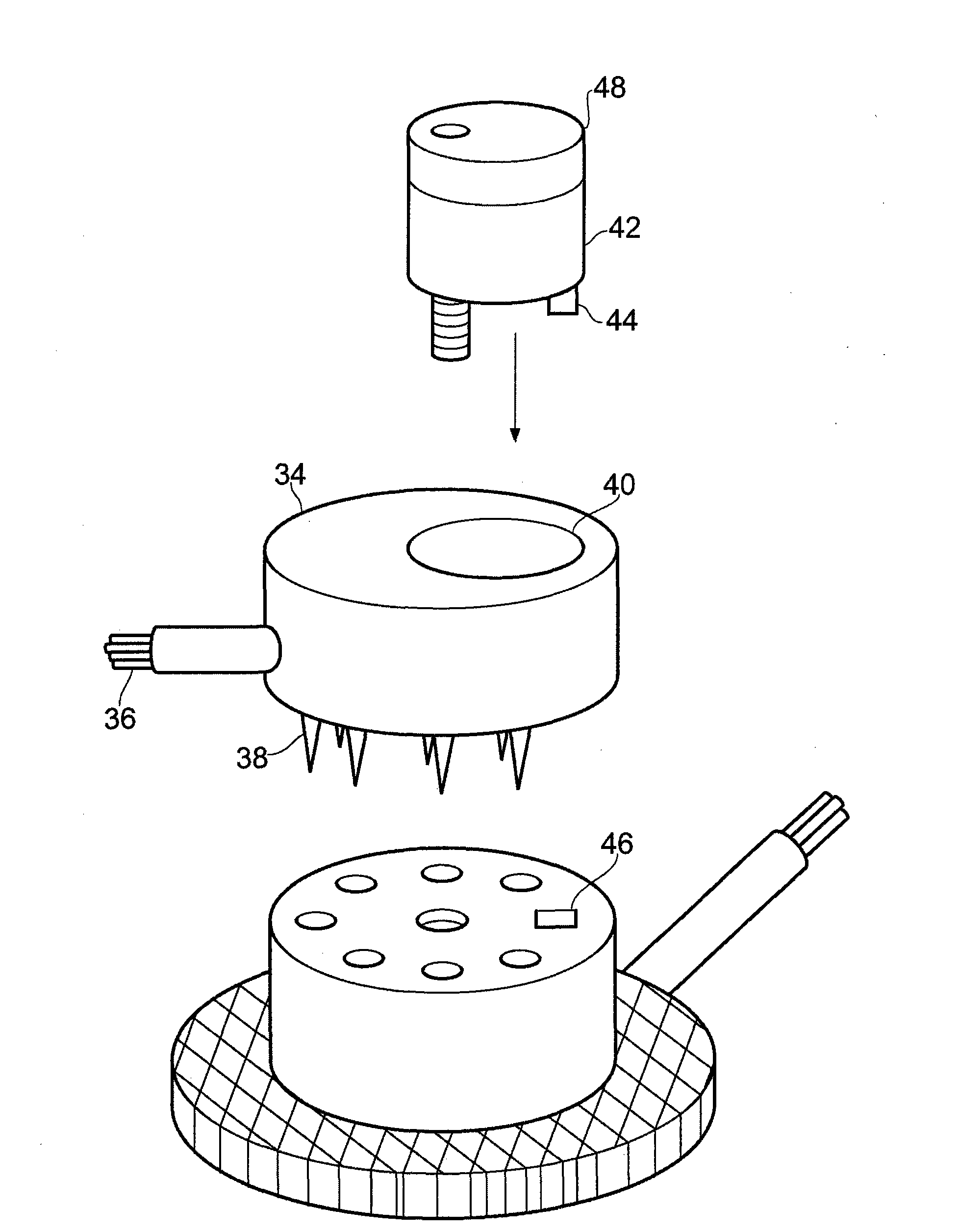

Neurological apparatus comprising a percutaneous access device

ActiveCN101541356AWill not flow backWill not be exposedMedical devicesSuction devicesCentral nervous systemBung

Apparatus for delivering therapeutic agents to the central nervous system of a subject is described. The apparatus comprises at least one intracranial catheter and a percutaneous access device (50; 140; 150; 160). The percutaneous access device comprises a body (10; 52; 152) having at least one extracorporeal surface (22; 68) and at least one subcutaneous surface, the body (10; 52) defining at least one port (12; 116) for connection to an implanted intracranial catheter. The port (12; 116) is accessible from the extracorporeal surface (22; 68) of the device, but is provided with a seal (14; 112; 142; 146) such as a rubber bung between the lumen of the port and the extracorporeal surface (22; 68). The percutaneous access device may have more than two ports (12; 116) and / or a flange (26; 54). A method of implanting the percutaneous access device(50; 140; 150; 160) is also described.

Owner:RENISHAW (IRELAND) LTD

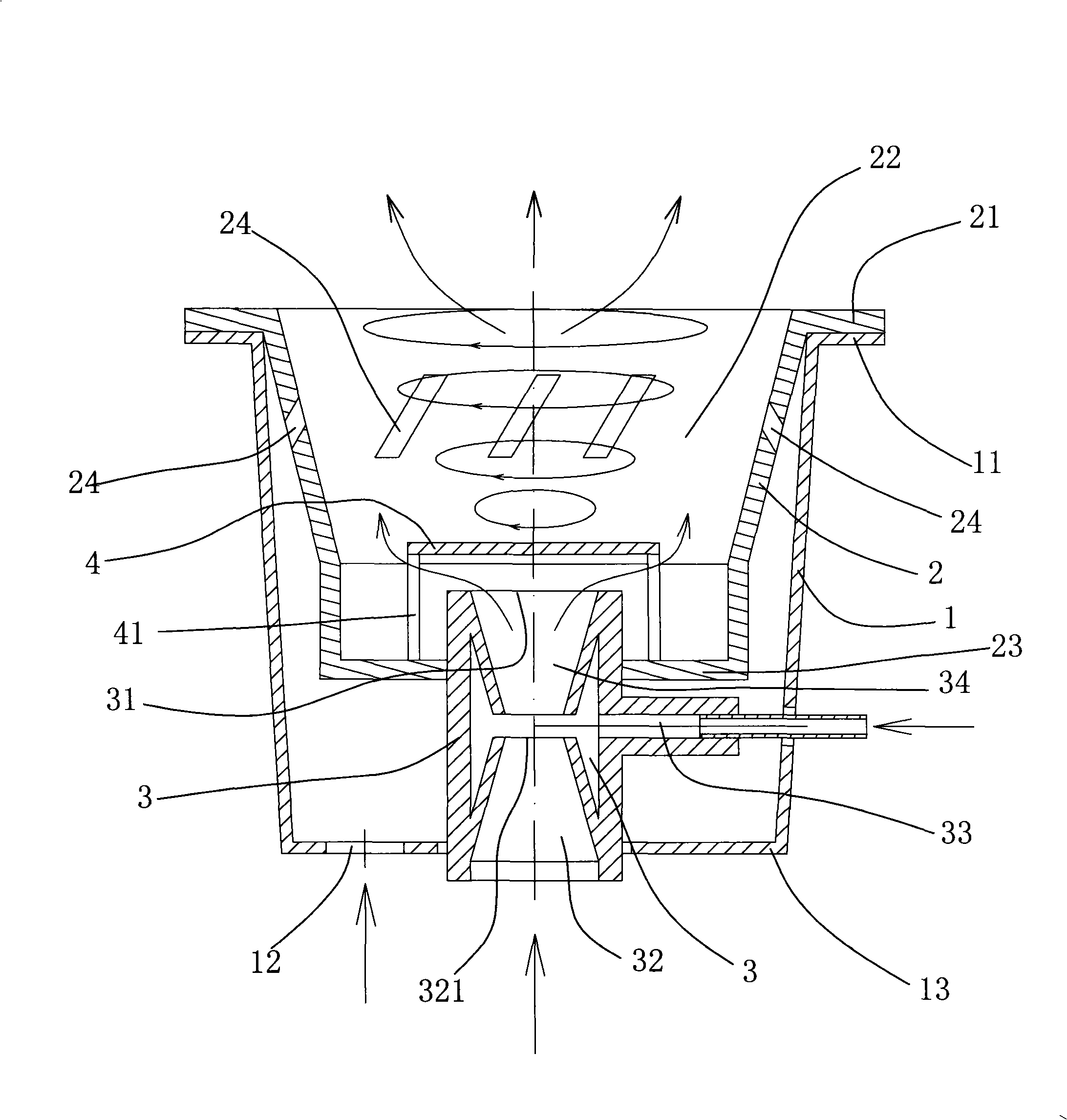

Safe and energy-saving gas stove

InactiveCN101526233AImprove securityImprove the mixing effectDomestic stoves or rangesCooking fumes removalCombustion chamberGas mixing

A safe and energy-saving gas stove comprises an outer housing and a combustion chamber body, wherein the combustion chamber body is positioned at the upper part of the outer housing, the lower part of the combustion chamber body is provided with a jet mixer in the outer housing, the outlet end of the jet mixer is connected with the bottom surface of the combustion chamber body and communicated with the combustion chamber of the combustion chamber body, the lower end of the jet mixer is internally provided with a horn-shaped primary pressure air intake jet passage which has a larger lower part, a gas inlet is arranged on the external wall of the jet mixer, and the air outlet of the primary pressure air intake jet passage is communicated with the gas inlet. The safe and energy-saving gas stove has the advantages of safety, better gas mixing effect and higher combustion efficiency. The experiments show that the combustion efficiency of the stove is doubled or more, compared with the combustion efficiency of the existing ordinary stoves.

Owner:胡端志 +1

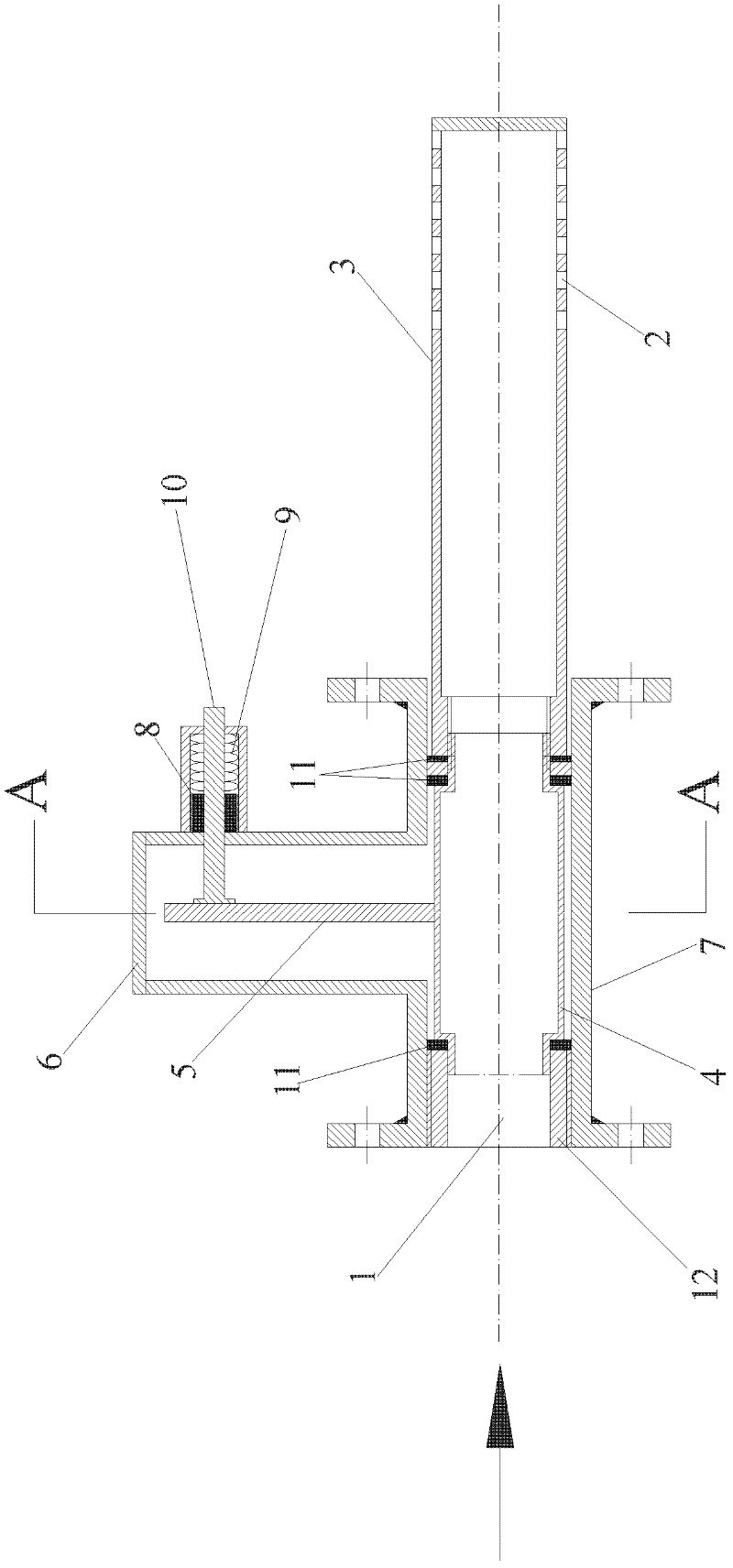

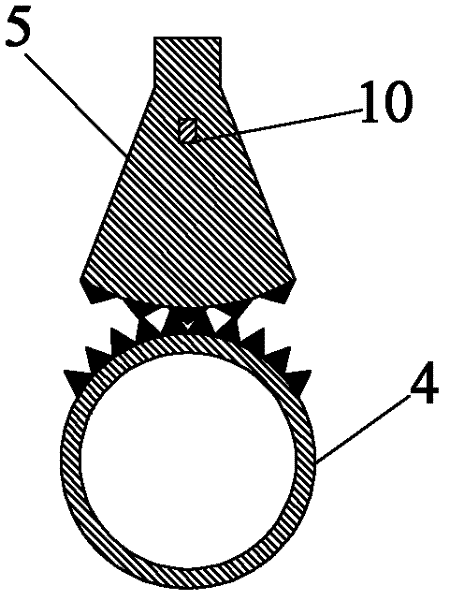

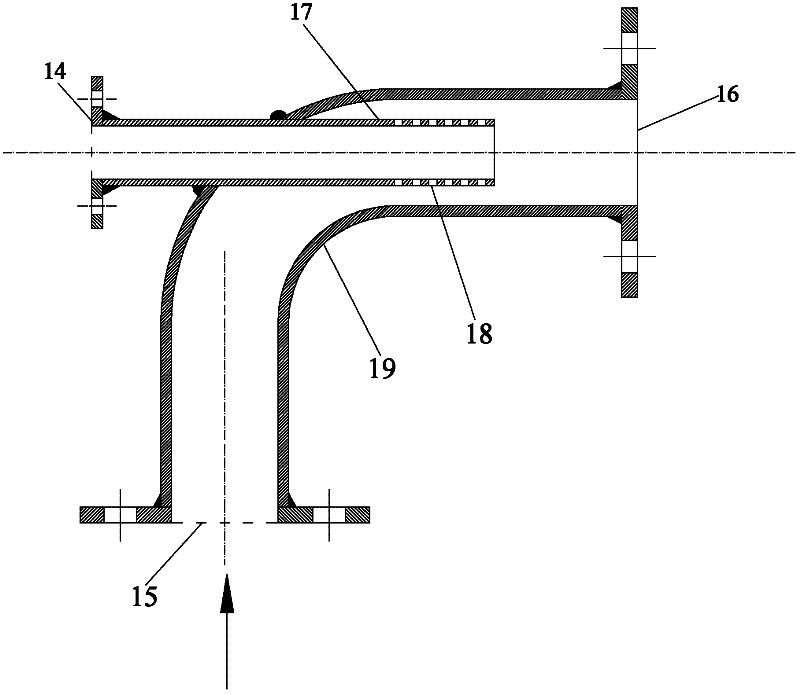

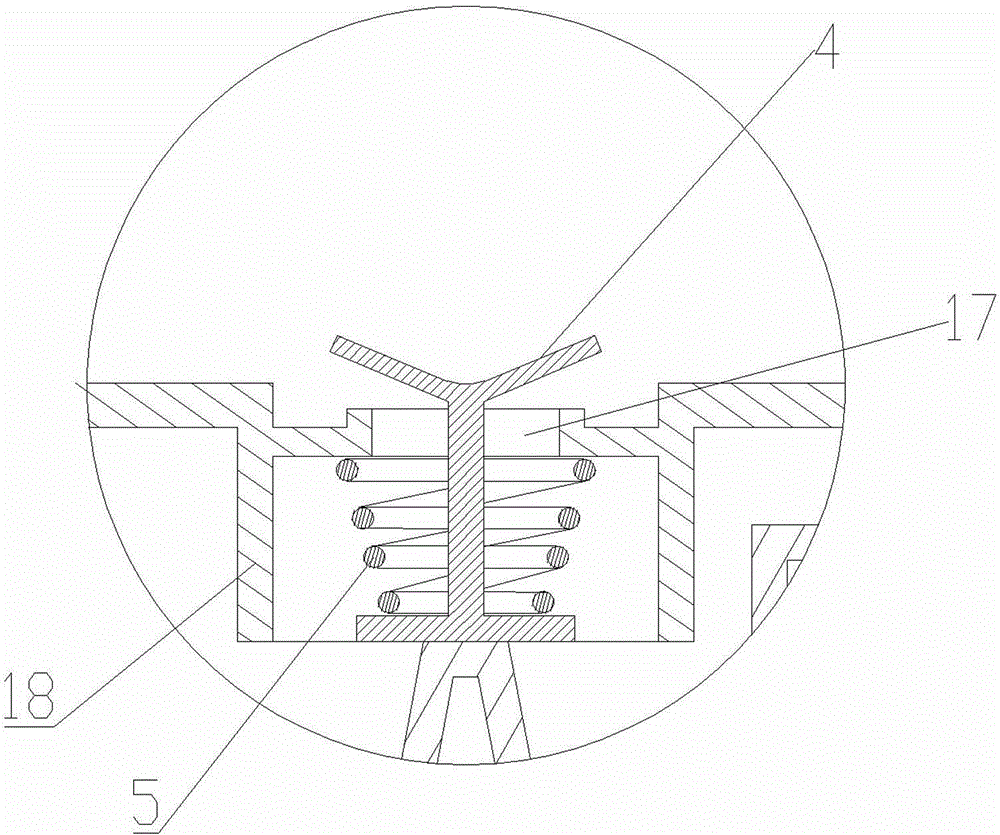

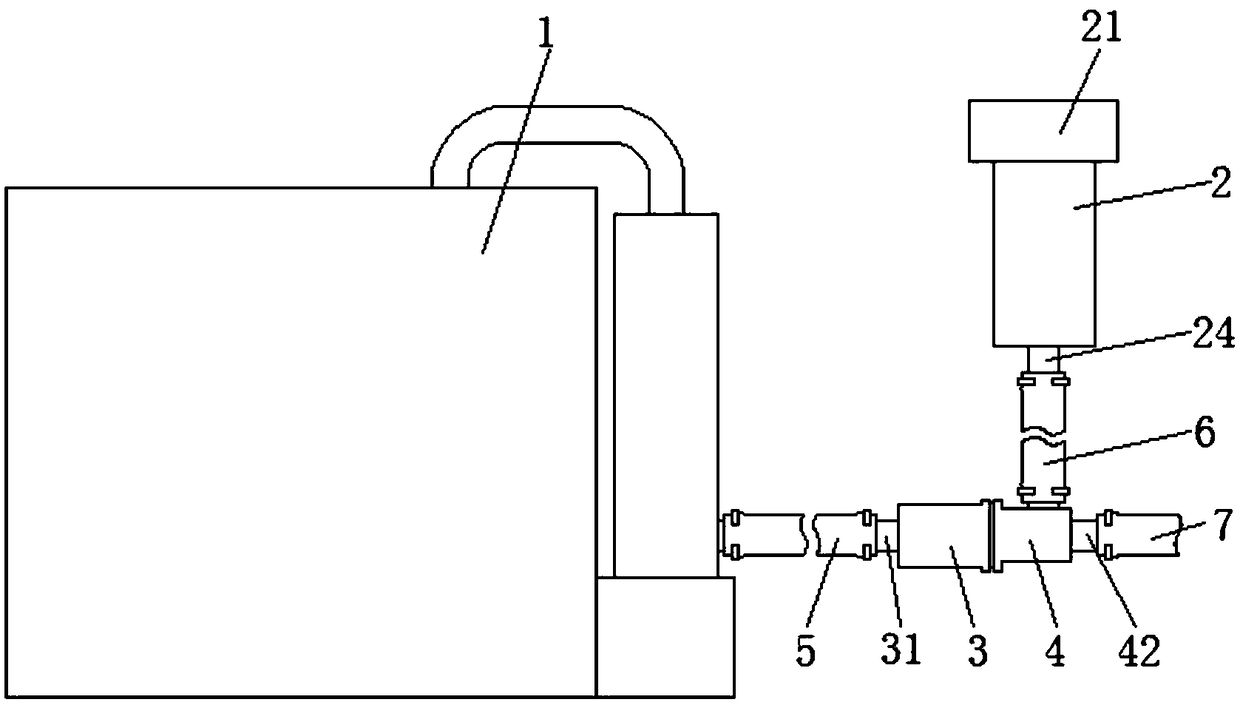

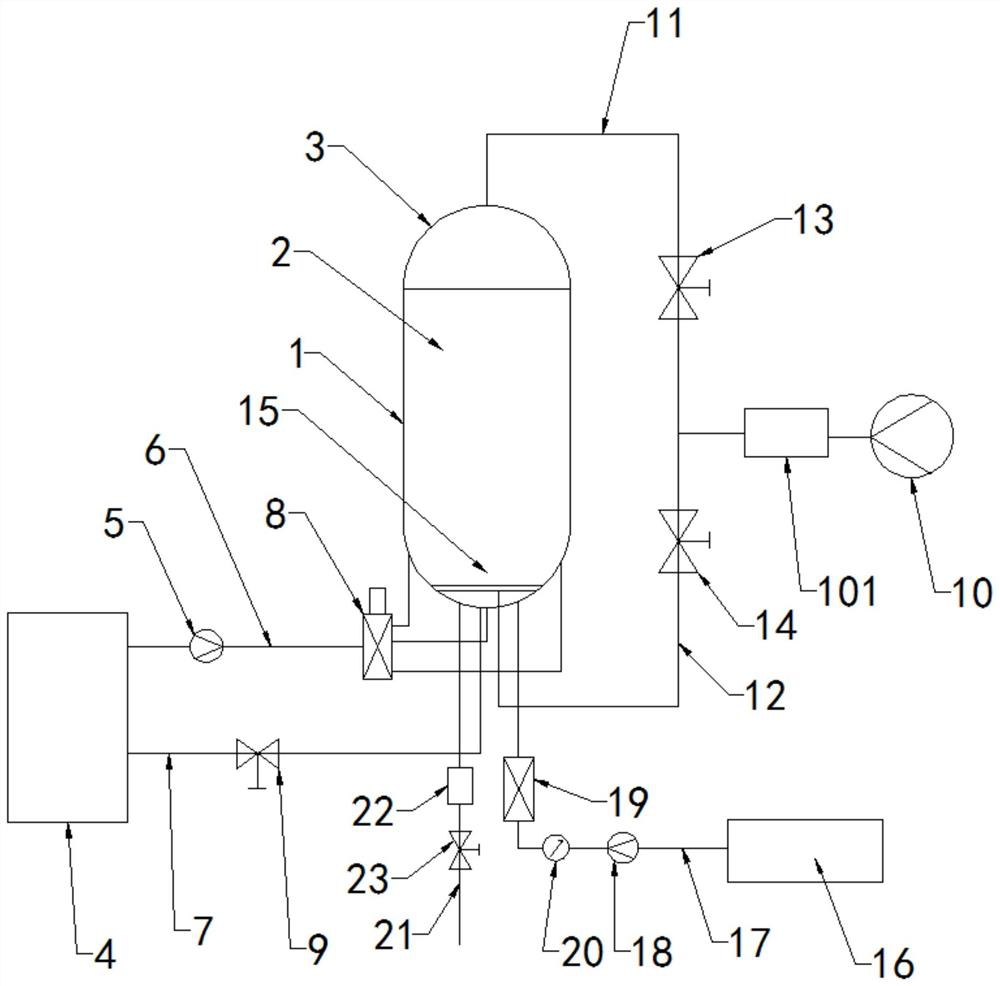

Gas liquid mixing apparatus and application method thereof

ActiveCN102309932AGuaranteed mixing effectWill not flow backFlow mixersMixing methodsEngineeringProcess engineering

The invention provides a gas liquid mixing apparatus and an application method thereof. The gas liquid mixing apparatus comprises a liquid inlet pipe (19) and a gas inlet pipe (17), and is characterized in that the gas liquid mixing apparatus also includes a gas distributor pipe (3) and a drive unit. One end of the gas inlet pipe (17) is equipped with a plurality of first gas spray orifices (18),which are inserted into liquid inlet pipe (19); the gas distributor pipe (3) is sleeved in the gas inlet pipe (17) and is equipped with a plurality of second gas spray orifices (2) on corresponding positions of the first gas spray orifices (18) at one end; the drive unit drives the gas distributor pipe (3) to move, so as to adjust relative positions of the first gas spray orifices (18) and the second gas spray orifices (2). The gas liquid mixing apparatus of the present invention can rapidly cut out gas feed when gas lateral pressure and flow are reduced, so as to guarantee no backflow.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

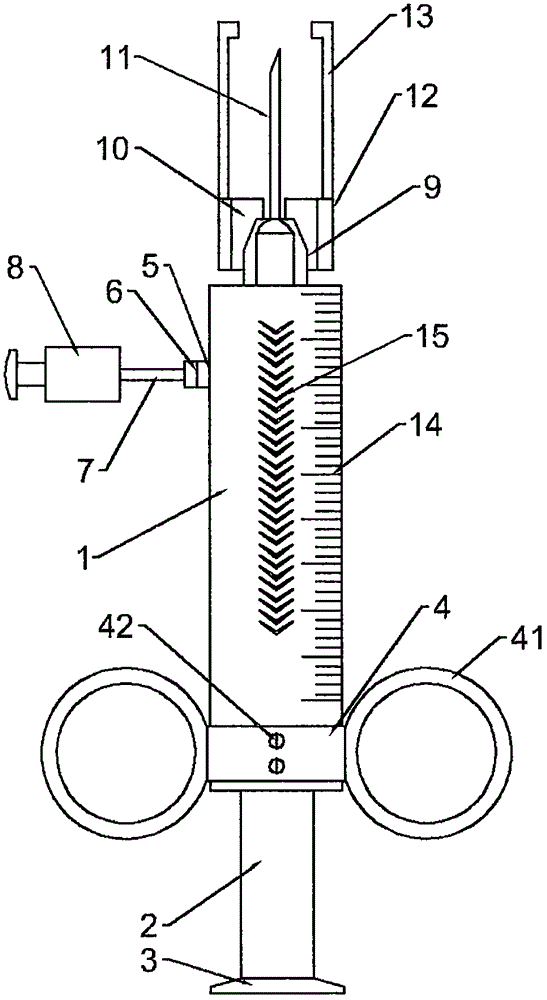

Injector with fluid infusion function

InactiveCN105771034ARehydration is convenientWill not flow backInfusion syringesMedical devicesFluid infusionEngineering

The invention discloses an injector with a fluid infusion function.The injector comprises a needle cylinder.A piston is arranged in the needle cylinder in a matched mode.The outer surface of the needle cylinder is provided with a fixed ring.Two finger rings are symmetrically arranged on the circumferential face of the fixed ring.The front end of the needle cylinder is provided with a needle head holder.A fluid drainage tube is sleeved with the needle head holder and is in threaded connection with the needle head holder.The fluid drainage tube is provided with a needle head.Sliding slots are formed in the two sides of the needle head holder.Protective sleeves are clamped in the sliding slots.The side wall, close to the fluid drainage tube, of the needle cylinder is provided with a fluid infusion opening.The fluid infusion opening is provided with a fluid inlet one-way valve.The fluid inlet one-way valve is connected with a fluid inlet tube.The fluid inlet tube is connected with a fluid infuser.The structure is simple, use is convenient, fluid can be infused to the needle cylinder conveniently, and fluid medicine will not flow back; the needle head holder can be matched with the fluid outlet tube for threaded connection, so that the needle head is fixed and prevented from being disengaged, and the injector is low in cost and suitable for being used and popularized.

Owner:金柯楠

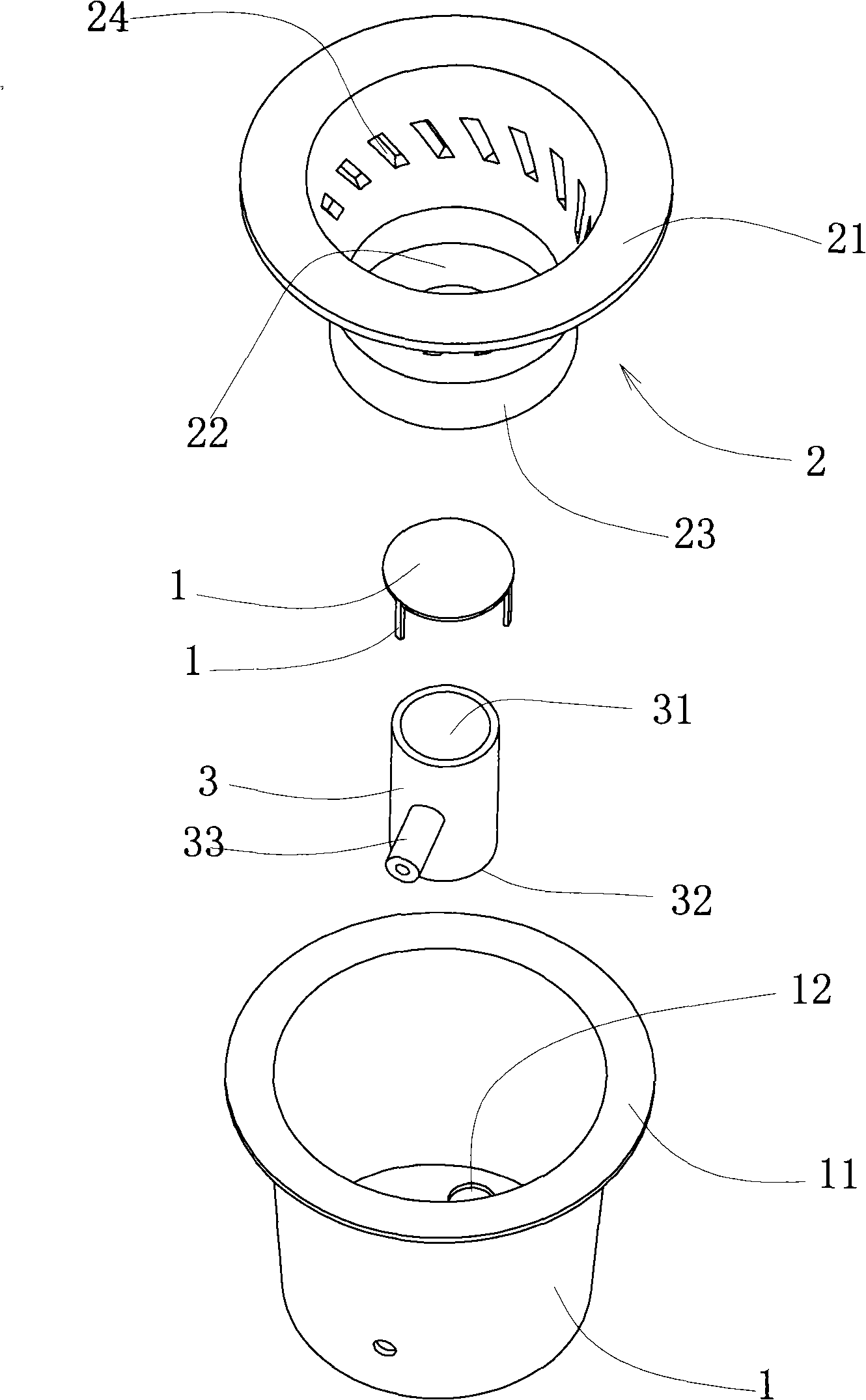

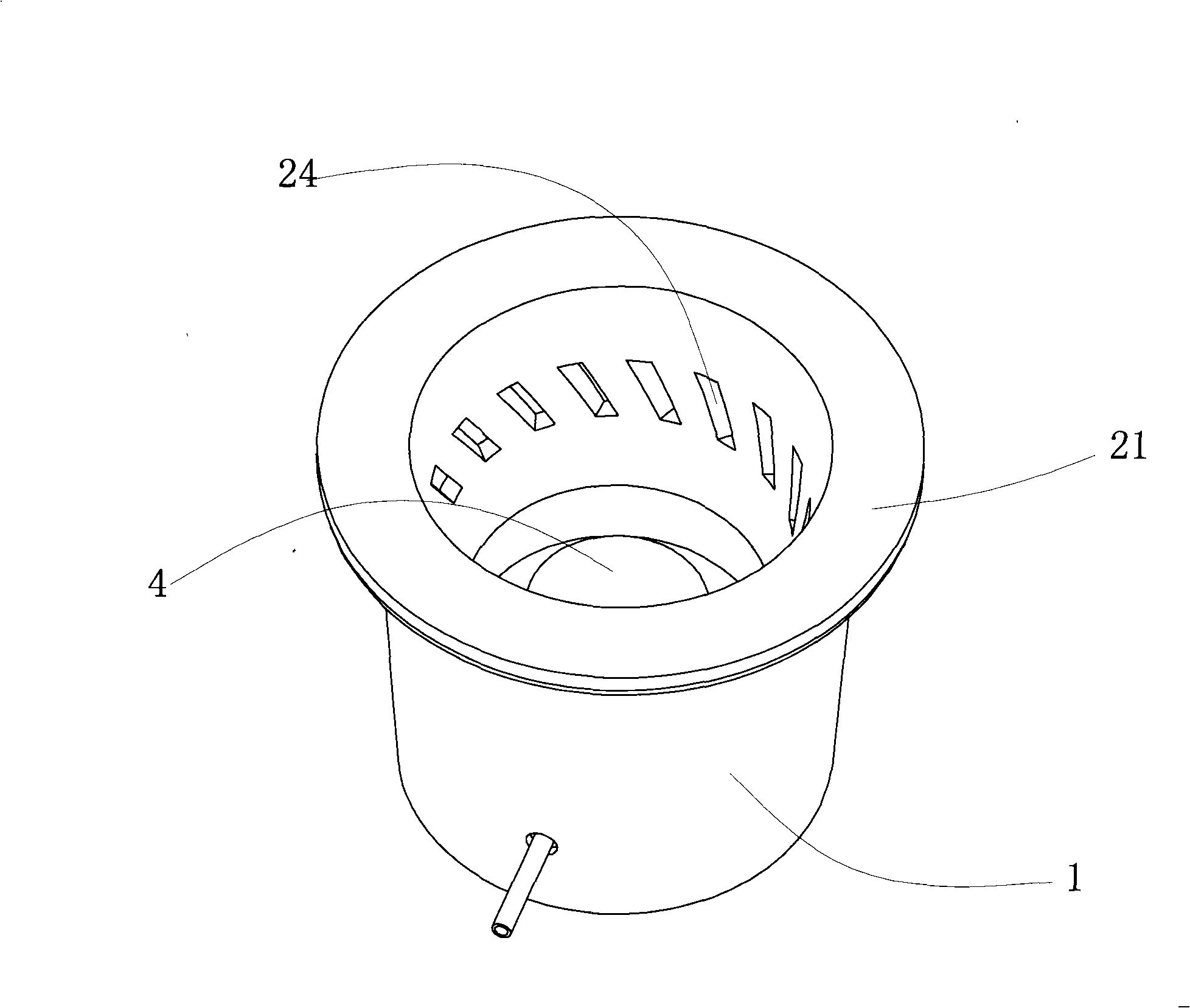

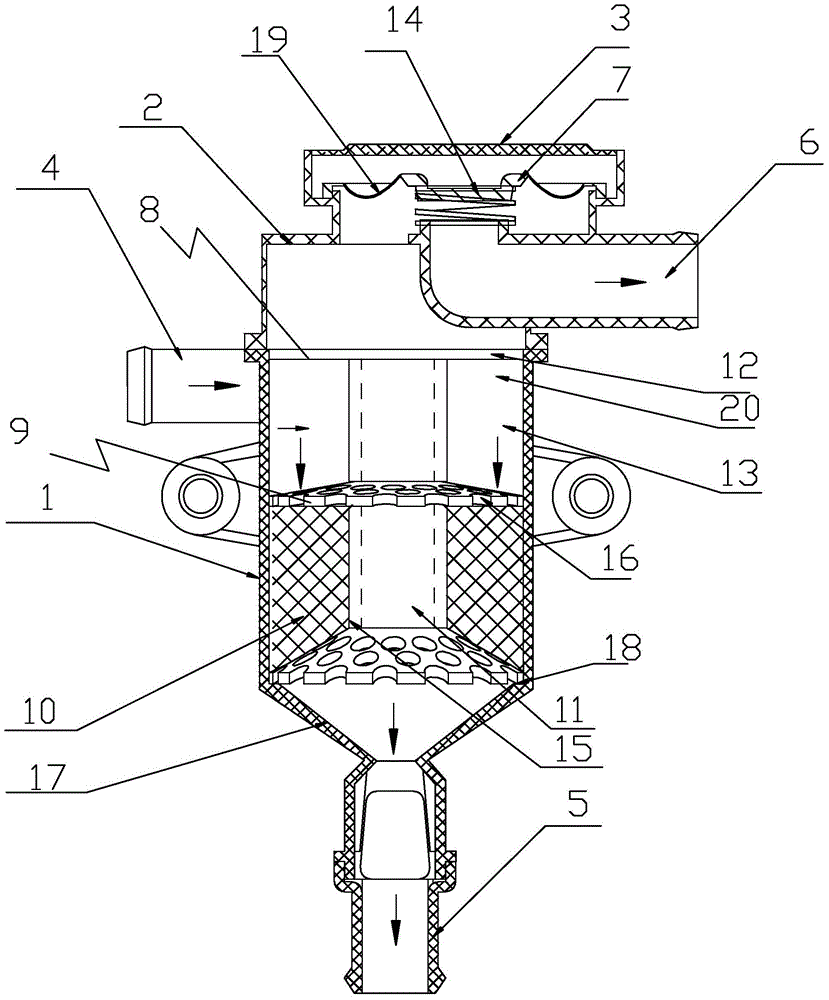

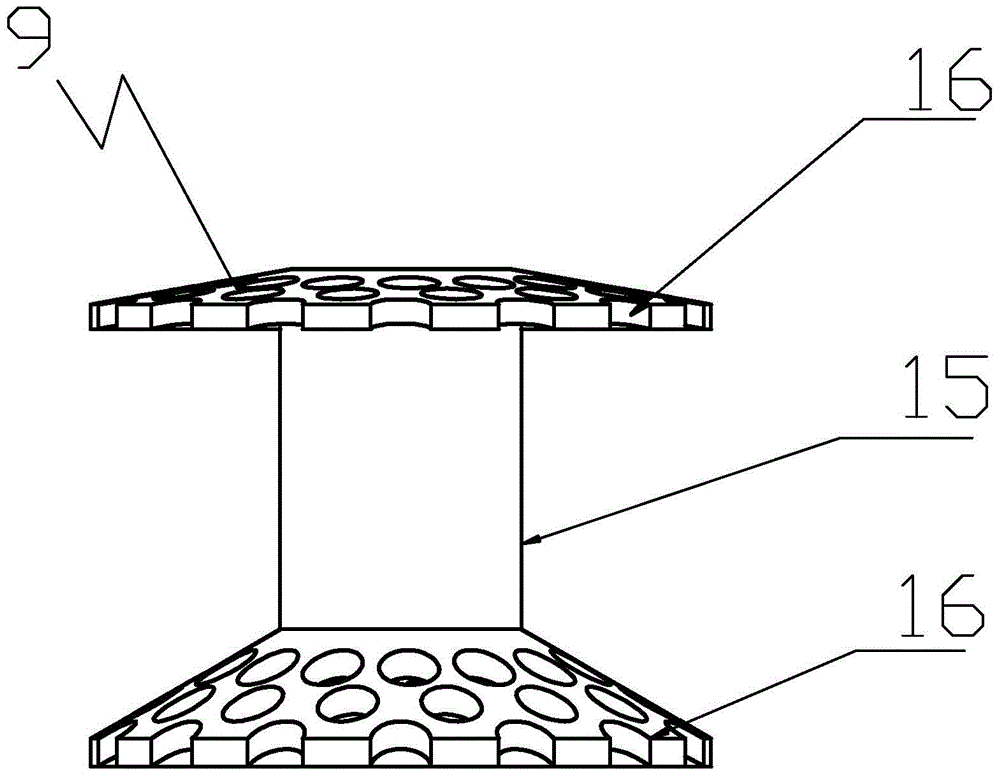

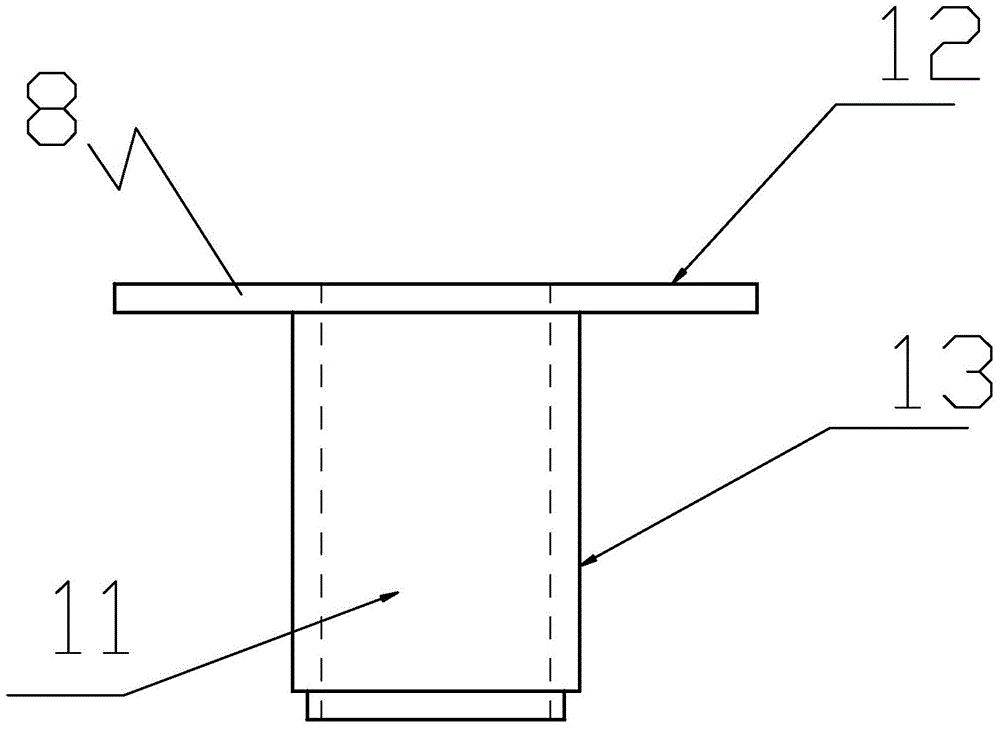

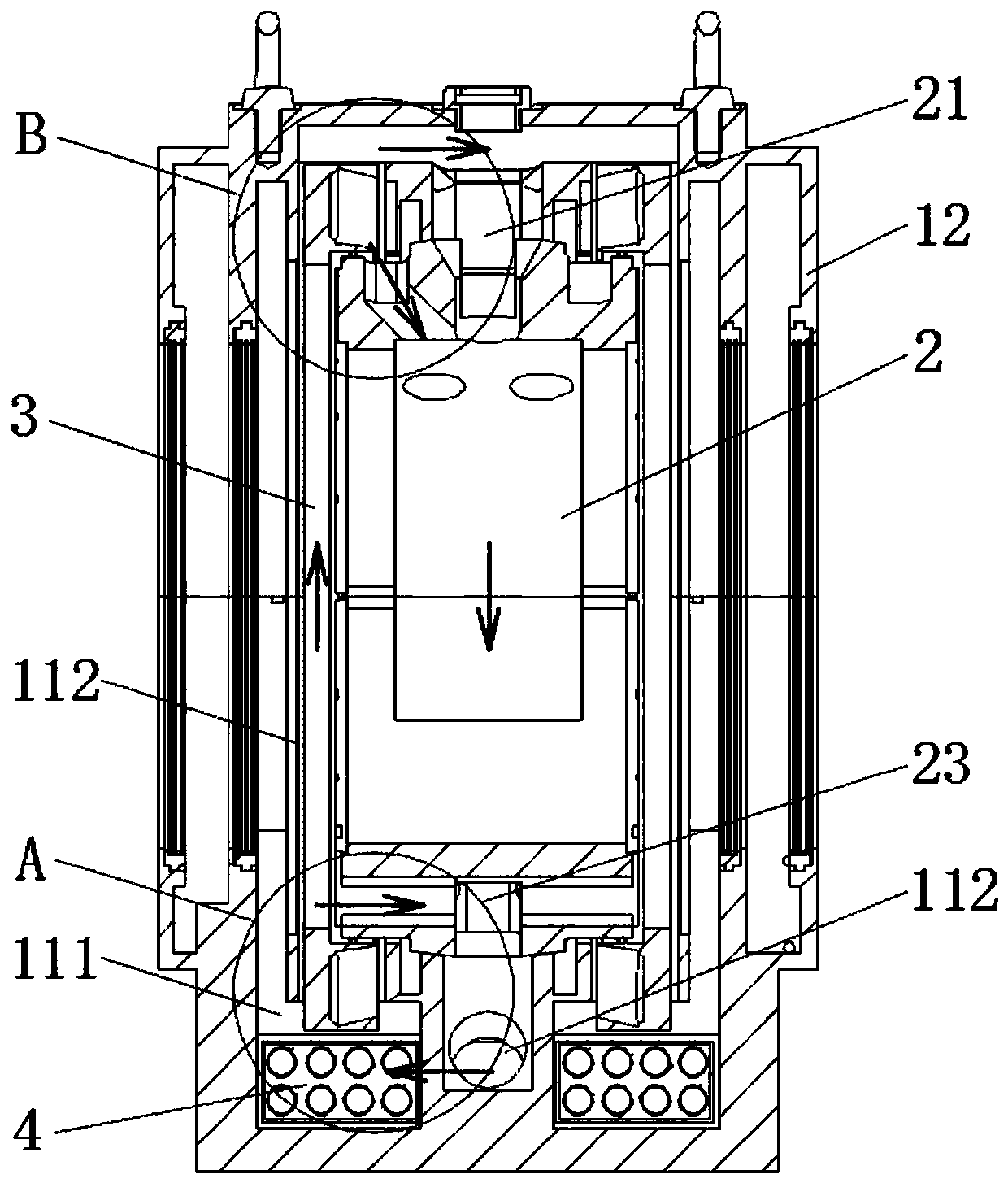

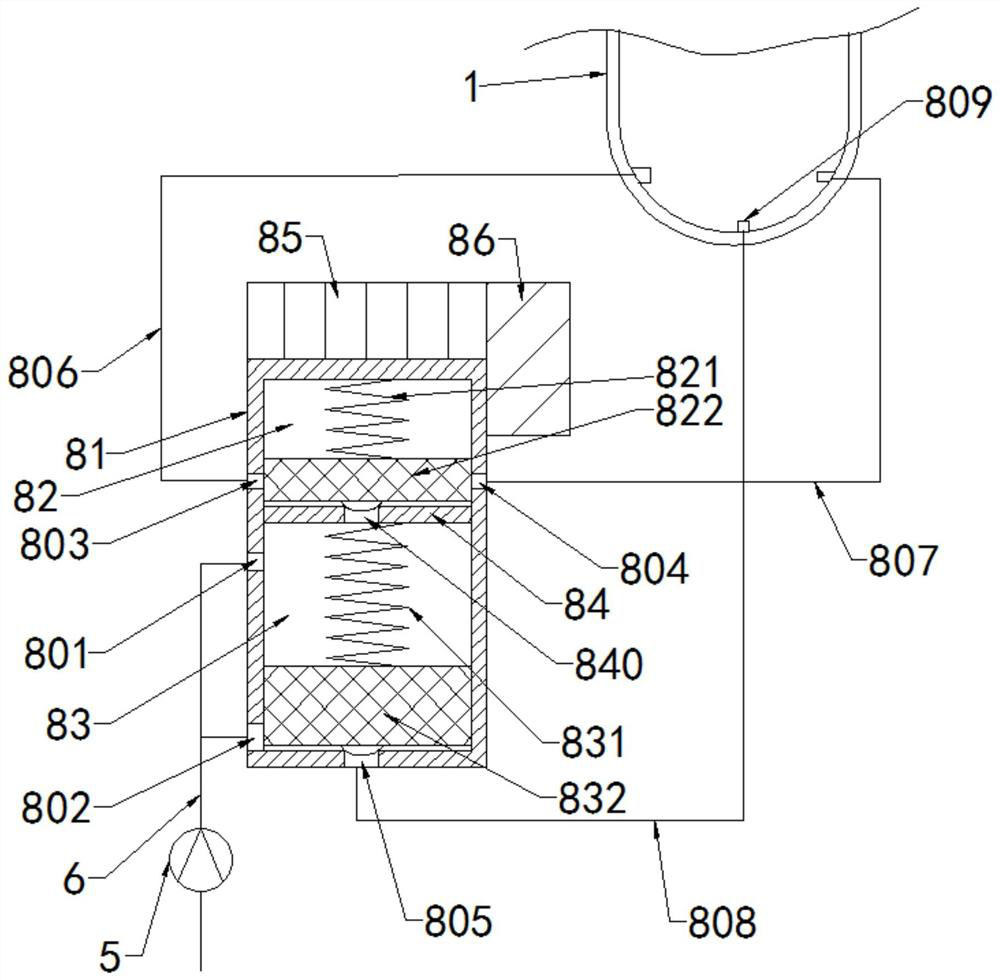

Automobile engine oil-gas separator

ActiveCN105041425AReduce tensionImprove efficiencyMachines/enginesCrankcase ventillationFilter effectAutomotive engine

The invention discloses an automobile engine oil-gas separator. The automobile engine oil-gas separator comprises a lower hollow cavity (1) and an upper shell (2); a gas inlet pipe (4) where mixed oil and gas enters is connected to the lateral face of the lower hollow cavity (1); an oil outlet pipe (5) is arranged at the bottom of the lower hollow cavity (1); a gas outlet pipe (6) is arranged on the upper shell (2); the lower hollow cavity (1) is internally provided with a first separation mechanism and a second separation mechanism; the first separation mechanism comprises a separation support (8) used for guidance and a cavity body (20) communicated with the gas inlet pipe (4); the cavity body (20) is located in the upper portion of the lower hollow cavity (1); the upper end of the separation support (8) is fixed to the inner wall of the upper portion of the cavity body (20) in a sealed mode; the gas inlet pipe (4) and the outer circumference of the cavity (20) is in tangential connection. The automobile engine oil-gas separator is high in efficiency and good in filtering effect.

Owner:宁海县雄达模塑有限公司

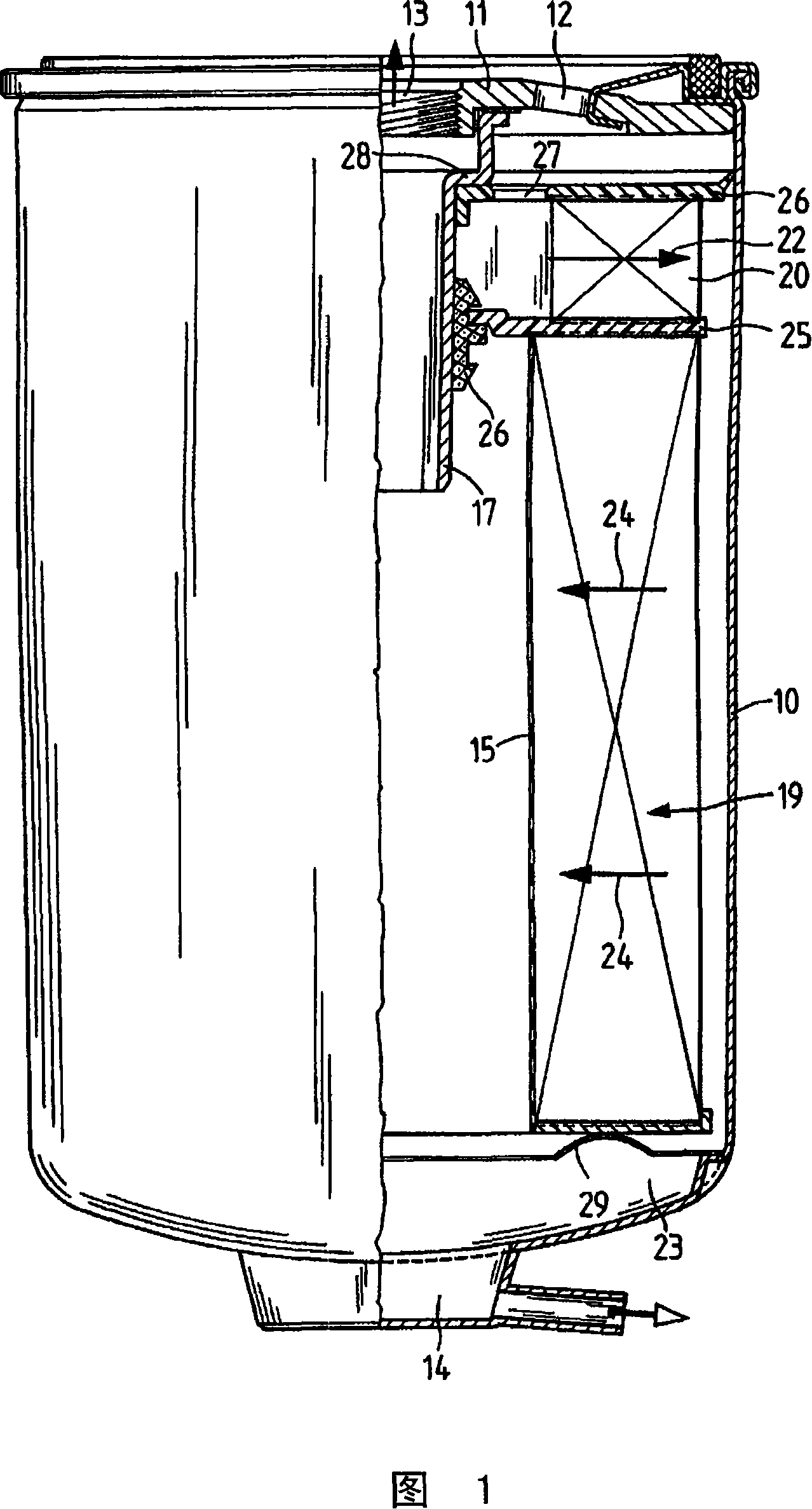

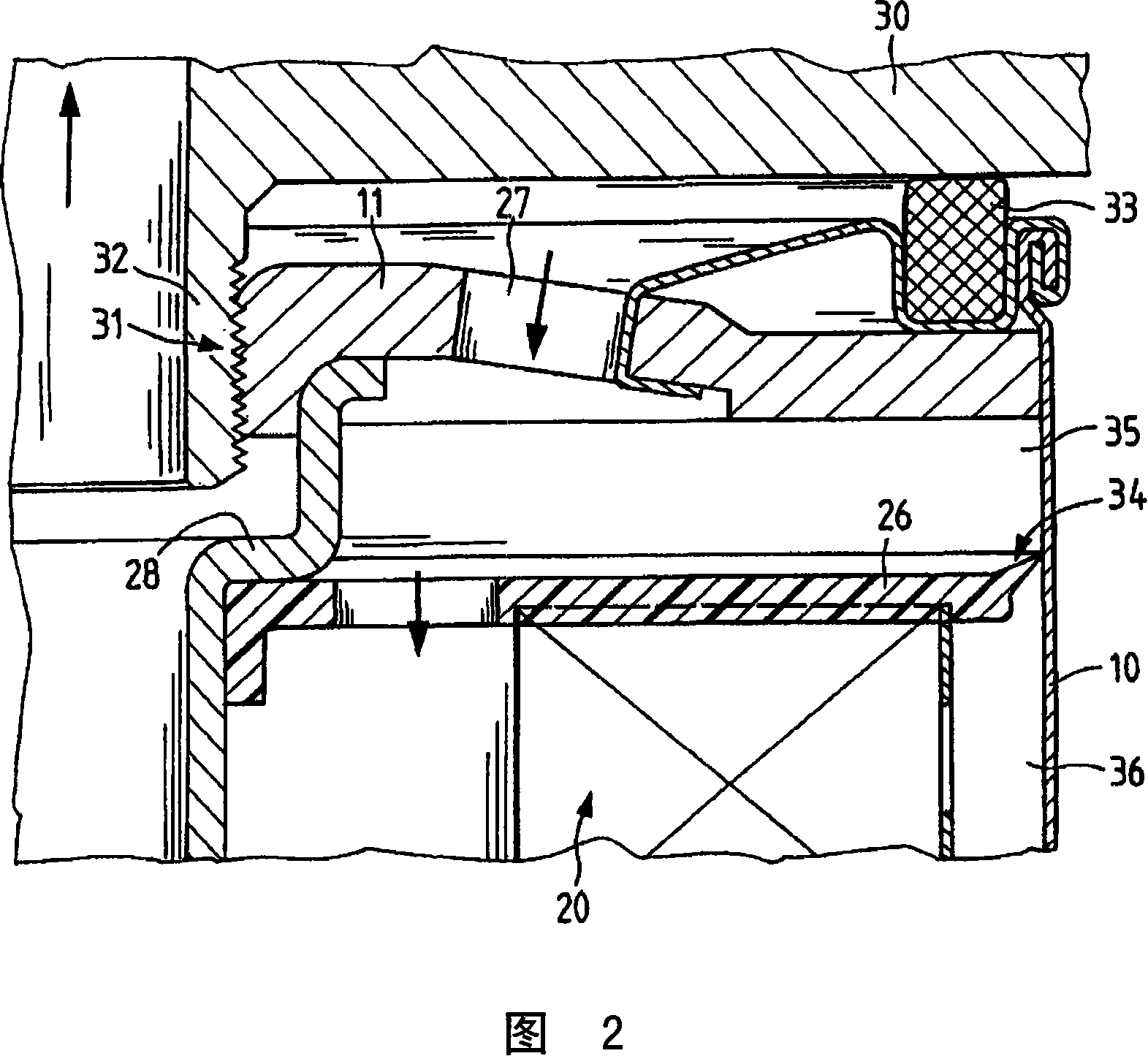

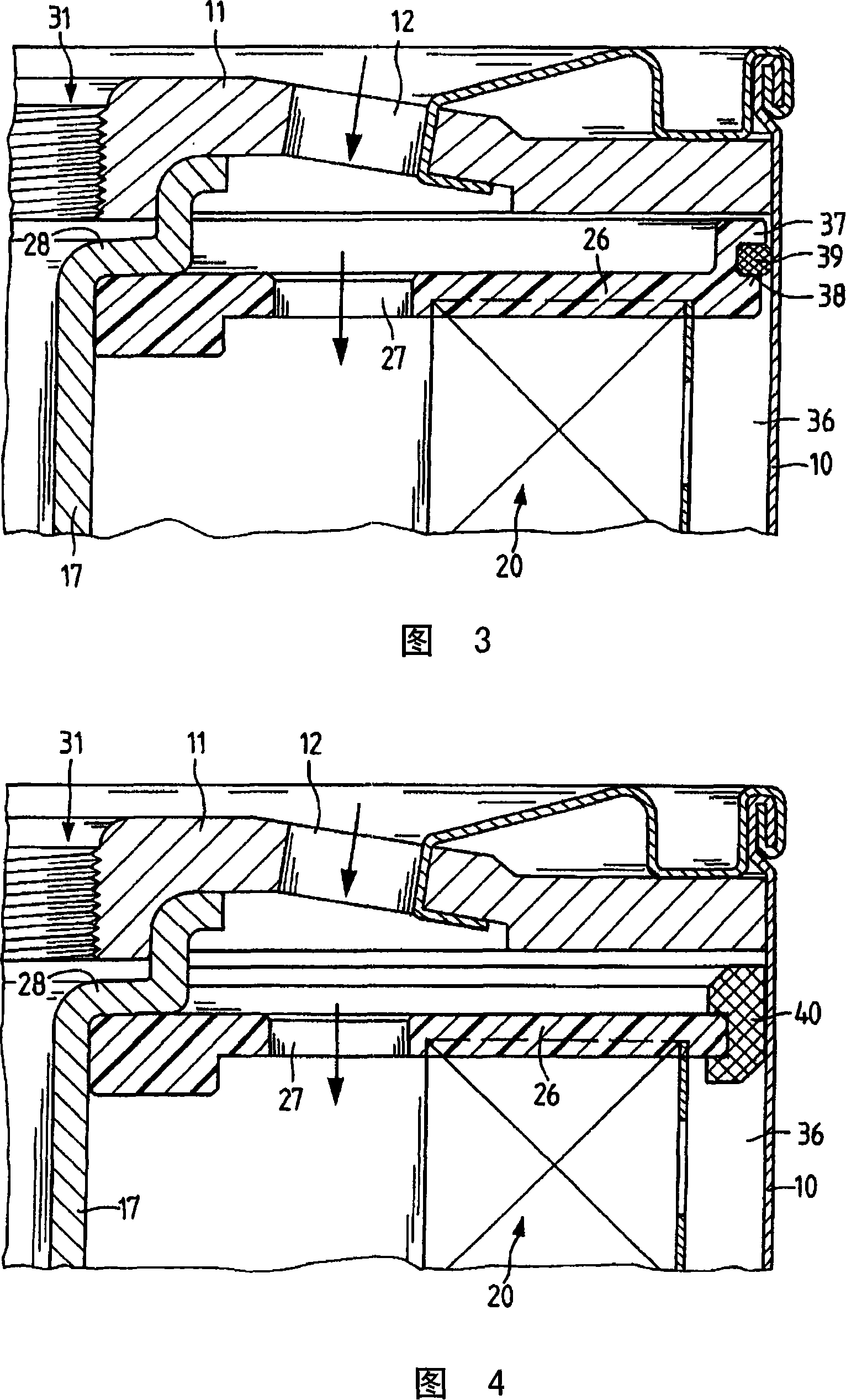

Fuel filter system

InactiveCN101115541AEffective Coalescing Filtration SurfaceWill not flow backMachines/enginesCartridge filtersParticulatesPlastic materials

The invention relates to a fuel filter provided with a coalescing element (20). The coalescing element serves to improve the separation effect of the water droplets and is arranged in the immediate inlet region of the fuel. The fuel filter is distinguished by its simple construction. The coalescing element therefore has an upper end gasket (26) which extends as far as the inner wall of the housing (10) and thus not only seals the coalescing element but also simultaneously Seal the inflow area and the bulk solution area outside. The coalescing element (20) and the particle filter (19) are arranged on a common partition (25). This spacer is supported by a profiled seal on a standpipe (17) arranged in the middle of the fuel filter. The end gaskets of the coalescing element can be produced with two-component injection molding technology or also with plastics technology with profiled seals molded from elastomeric materials.

Owner:MANN HUMMEL GMBH

Filtering dust collector for environmental protection

InactiveCN109011871AImprove filtering effectNo need for frequent cleaningDispersed particle filtrationTransportation and packagingSpiral bladeEngineering

The invention discloses a filtering dust collector for environmental protection. The filtering dust collector comprises a body, the middle of the rear side of the body is fixedly provided with a second motor by a support, a base is arranged at the bottom of the body, a collection bin is fixed on the left side of the base, a first motor is fixed on the right side of the base, a conveying tube is mounted above the middle of the base, a rotating tube is fixed to the conveying tube by a bearing, a spiral blade is mounted on the rotating shaft in a welding manner, the right end of the rotating shaft is connected with the output end of the first motor, a dust bin is arranged above the middle of the body, and a support shaft is mounted between the front side and the rear side of the middle of thedust bin. A stopper block fixed by a spring at an angle of 70 DEG with the horizontal plane is arranged, so dust filter plate collides with the stopper block in every ring of the filter plates rotate, and dusts on the dust filters drop down and are collected, so the dust filter plates keep a good filtering effect in every filtering process, and have no need to be frequently cleaned, thereby the filtering dust collector is convenient to use.

Owner:湖南钜晟环保科技股份有限公司

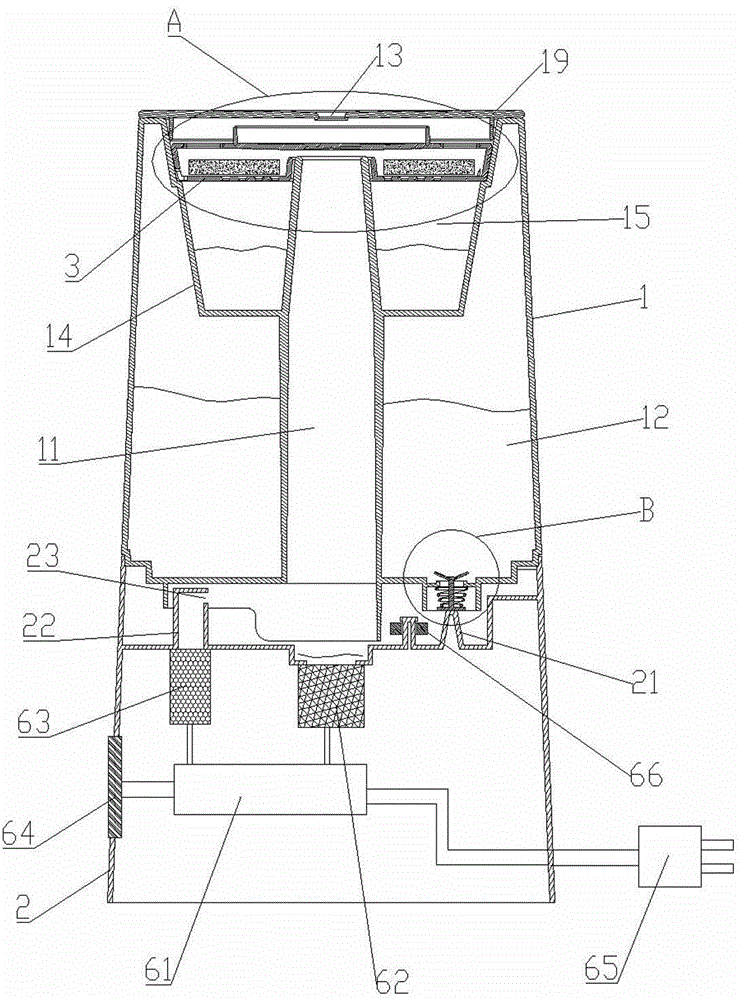

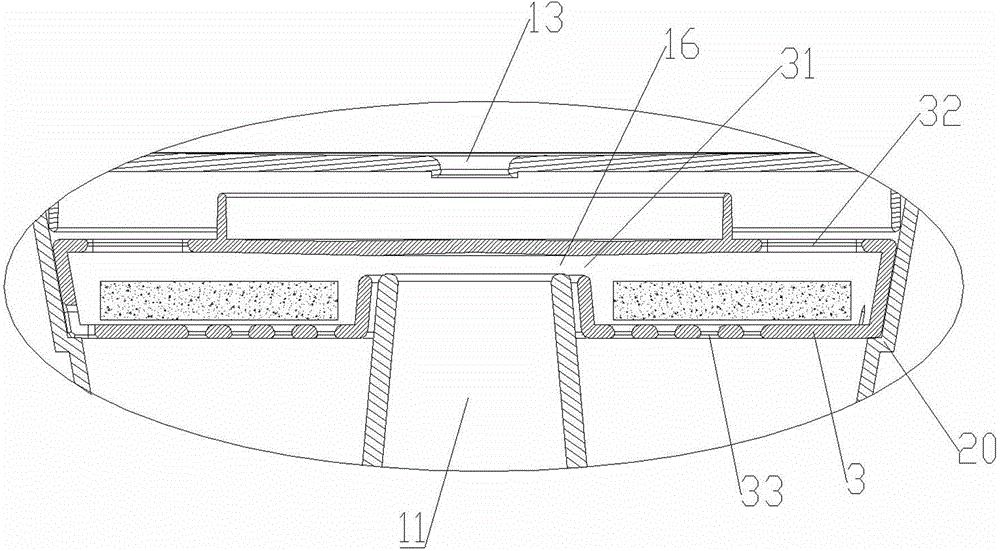

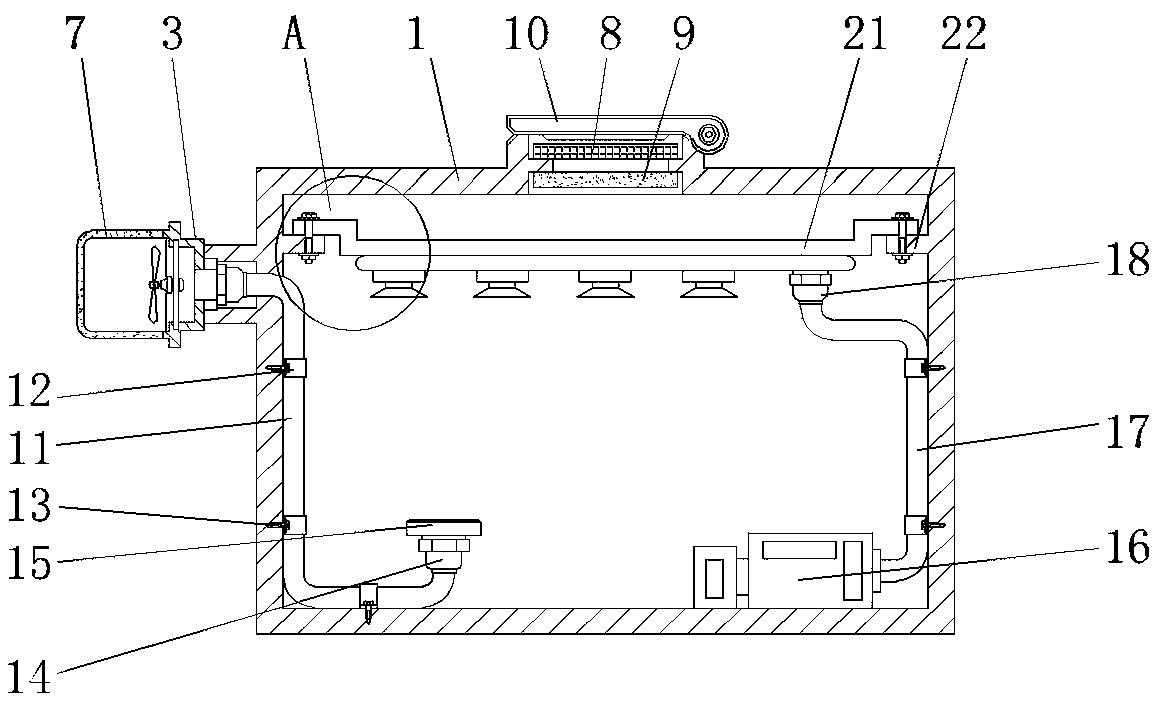

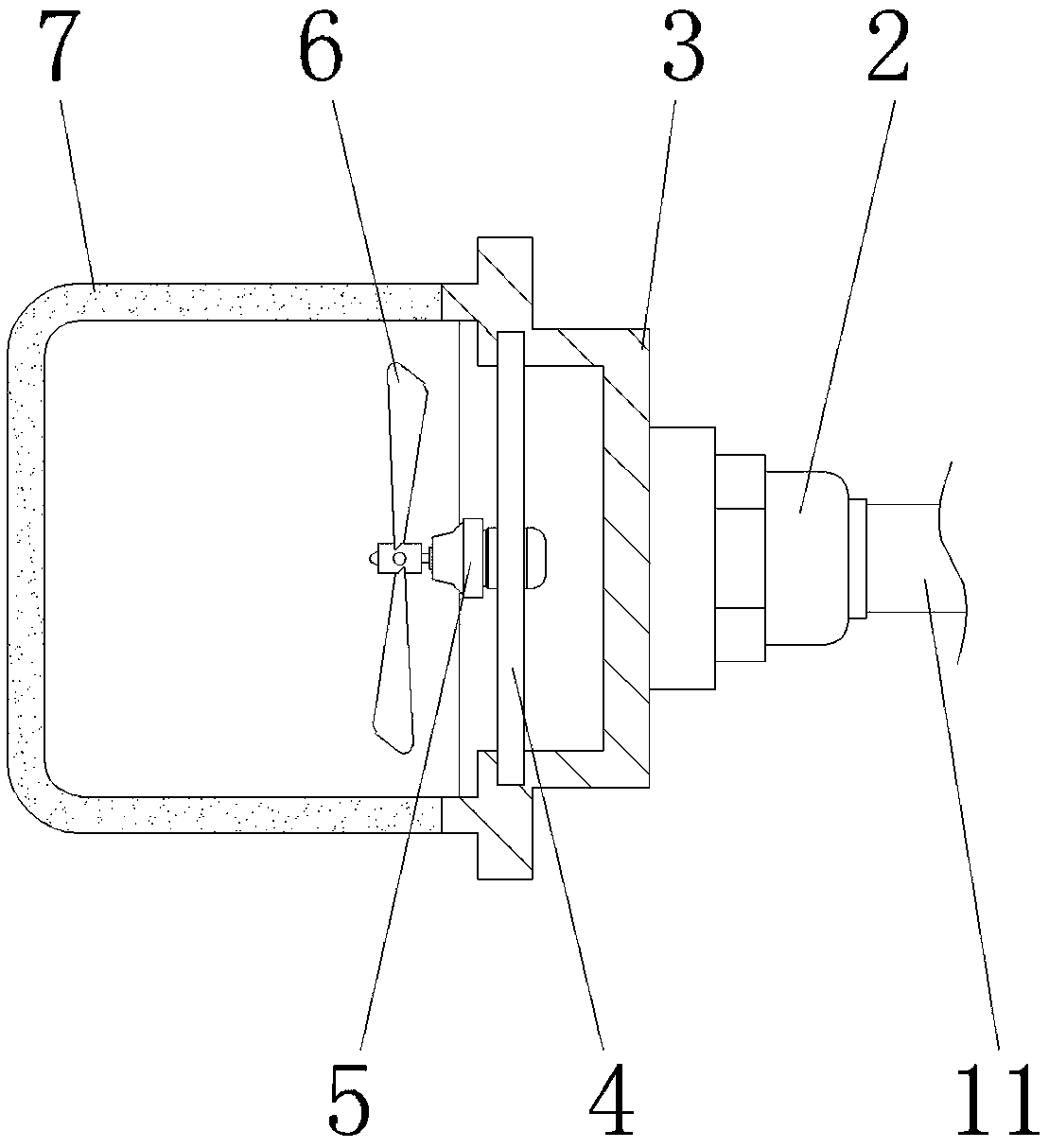

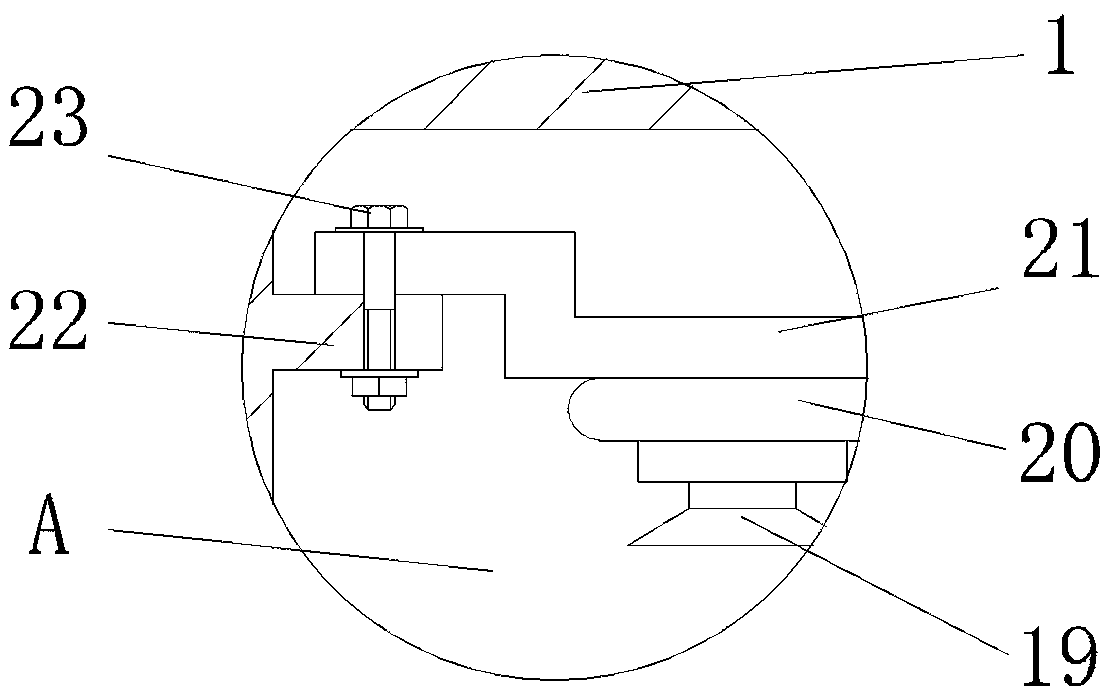

Humidifier

InactiveCN104019515APrevent backflowWill not flow backLighting and heating apparatusMedical atomisersWater storageWater vapor

The invention discloses a humidifier. The humidifier comprises an upper box body and a lower box body. The lower box body is internally provided with an atomizing assembly, an inner cavity of the upper box body is divided into a mist outlet channel and a water storage chamber, the top face of the upper box body is provided with a mist outlet, the two ends of the mist outlet channel are communicated with the atomizing assembly and the mist outlet respectively in an airflow mode, a separation plate is arranged between the outer wall of the upper end of the mist outlet channel and the inner wall of the top end of the upper box body and concaved inwards to form a sewage chamber, the top end of the sewage chamber is provided with a medicine box, the inner side of the top face of the medicine box extends to cover the opening in the top end of the mist outlet channel, the side wall of the top end of the mist outlet channel is provided with an air outlet adjacent to the medicine box, the top end of the inner side wall of the medicine box is provided with an air inlet communicated with the air outlet, vent holes communicated with the mist outlet are evenly formed in the outer side of the top face of the medicine box, and liquid leakage holes are evenly formed in the bottom face of the medicine box. According to the humidifier, a guiding structure is arranged between the mist outlet channel and the medicine box, the water vapor can make full contact with the whole medicine box, materials in the medicine box can be fully utilized, the sewage chamber is arranged below the medicine box, and waste water can be effectively prevented from reversely flowing and corroding the atomizing assembly.

Owner:黄俊杰

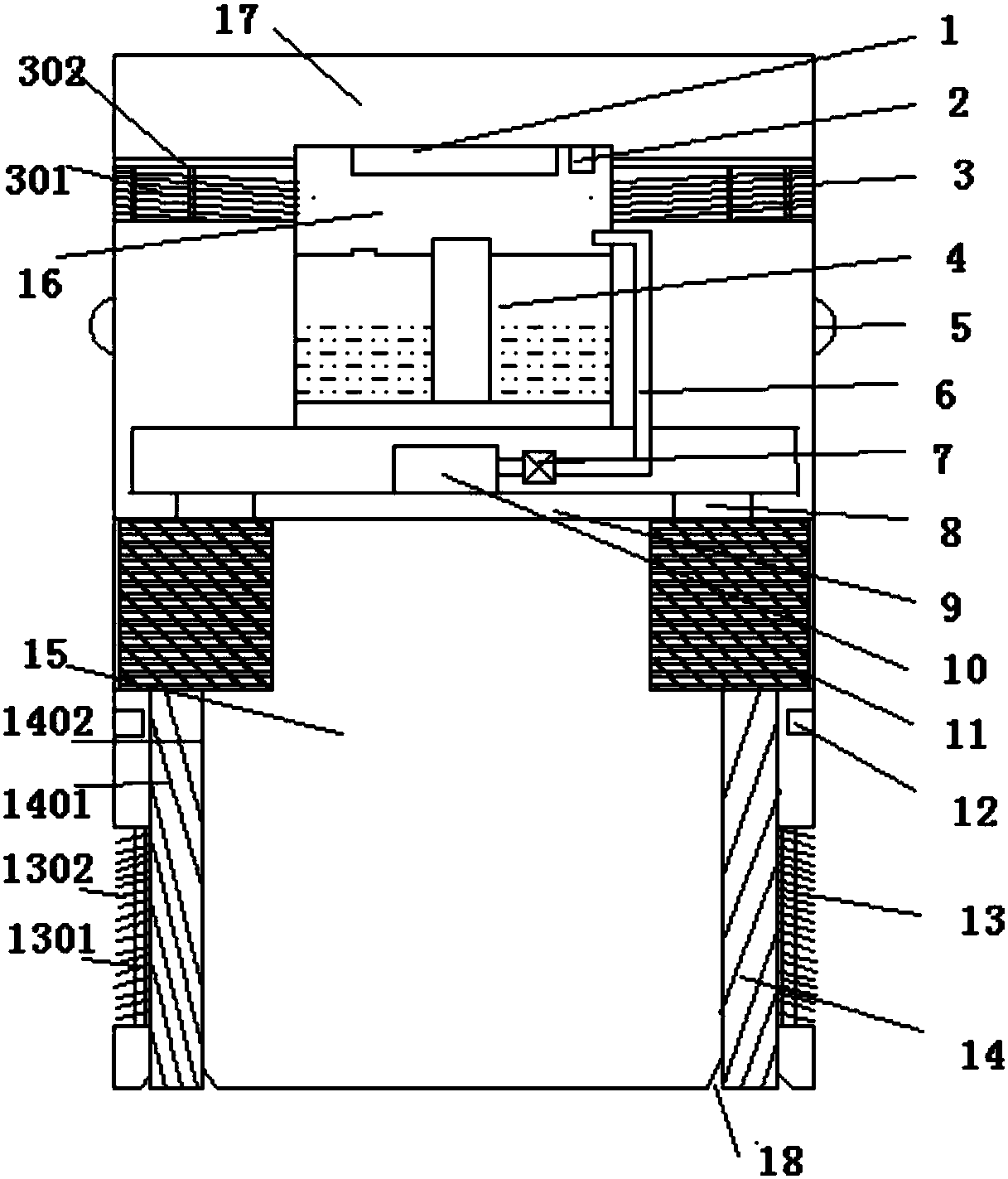

Self-lubricating bearing

ActiveCN110805621AGuaranteed buildSolve the technical problems of easy-to-burn tilesEngine sealsLubrication elementsOil storage

The embodiment of the invention provides a self-lubricating bearing, and belongs to the technical field of bearings. The self-lubricating bearing comprises a shell, wherein the shell is divided into abearing block, a bearing cover, a bearing bush and an oil flinger, an oil storage cavity is formed in the bottom of the bearing block, the bearing cover is arranged on the bearing block, the bearingbush is located in the middle of the shell and is provided with an oil injection position and an oil outlet position, the oil flinger is arranged on one side of the bearing bush, the oil flinger is located in the shell, the lower part of the oil flinger is located in the oil storage cavity, the upper part of the oil flinger corresponds to the bearing bush, the oil flinger is provided with an oil conveying cavity with an opening, the oil conveying cavity can contain lubricating oil in the oil storage cavity through the opening, and the oil conveying cavity carries the lubricating oil and acts on the upper end of the bearing bush through the oil flinger. The self-lubricating bearing has the technical effect that the self-lubricating bearing is fully lubricated, and the bearing bush is not burnt.

Owner:ZHUJI JINGZHAN MASCH CO LTD

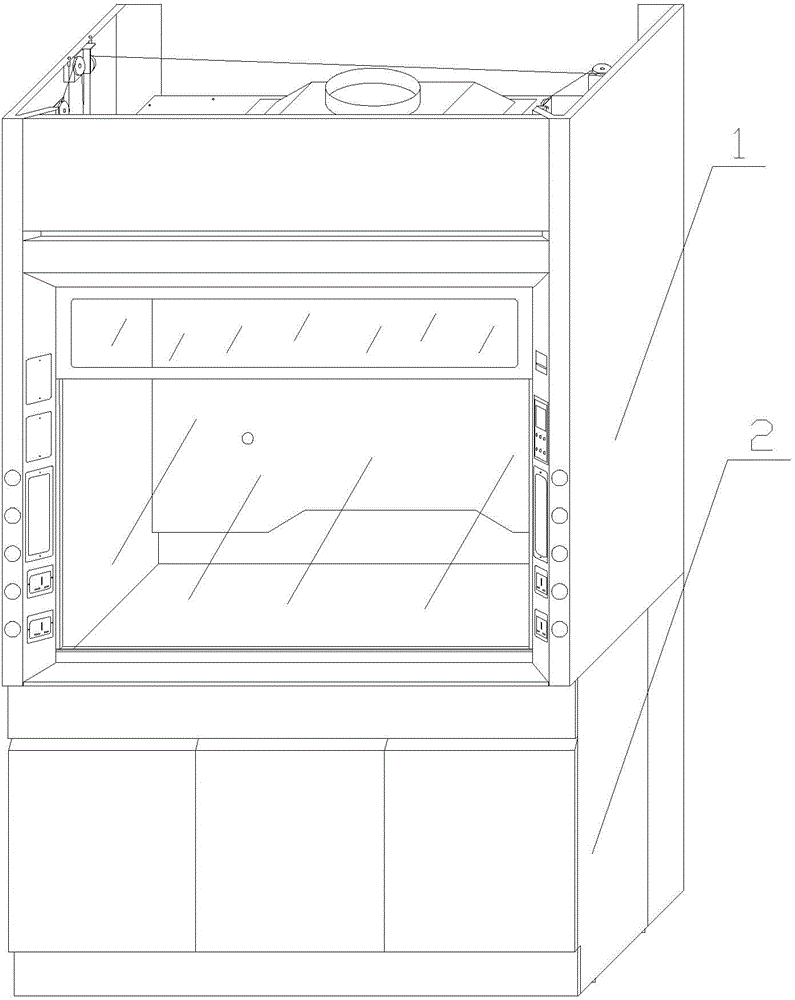

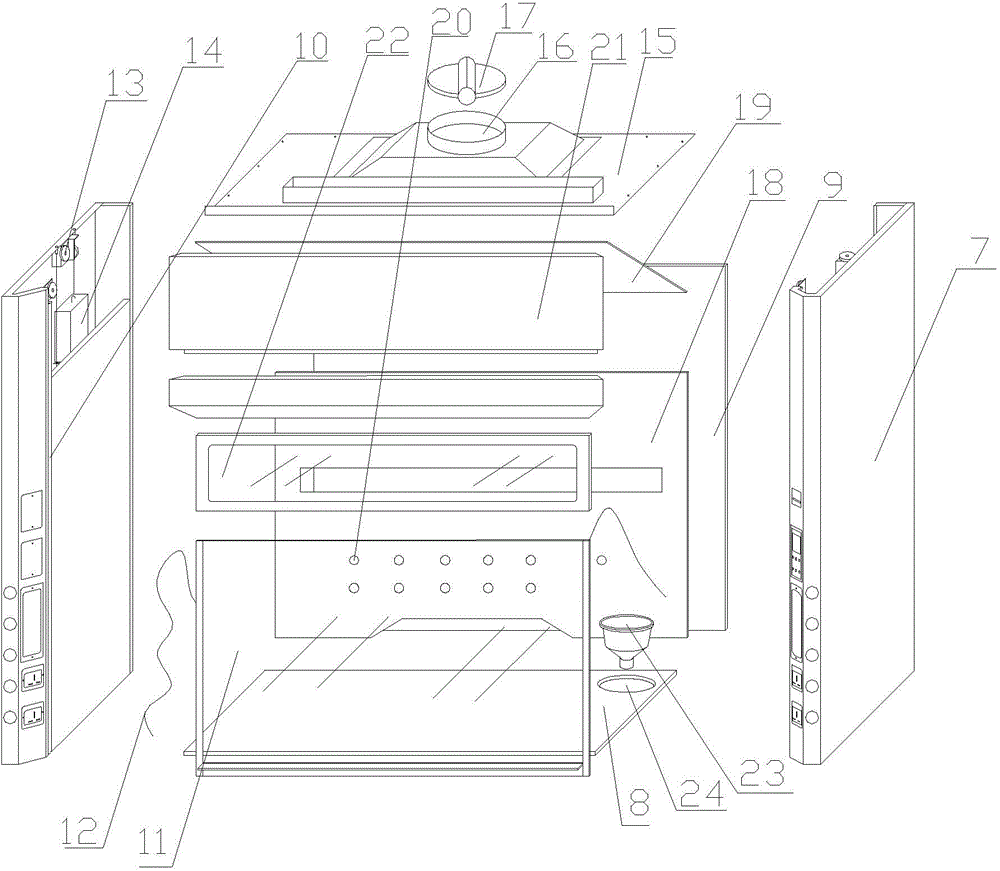

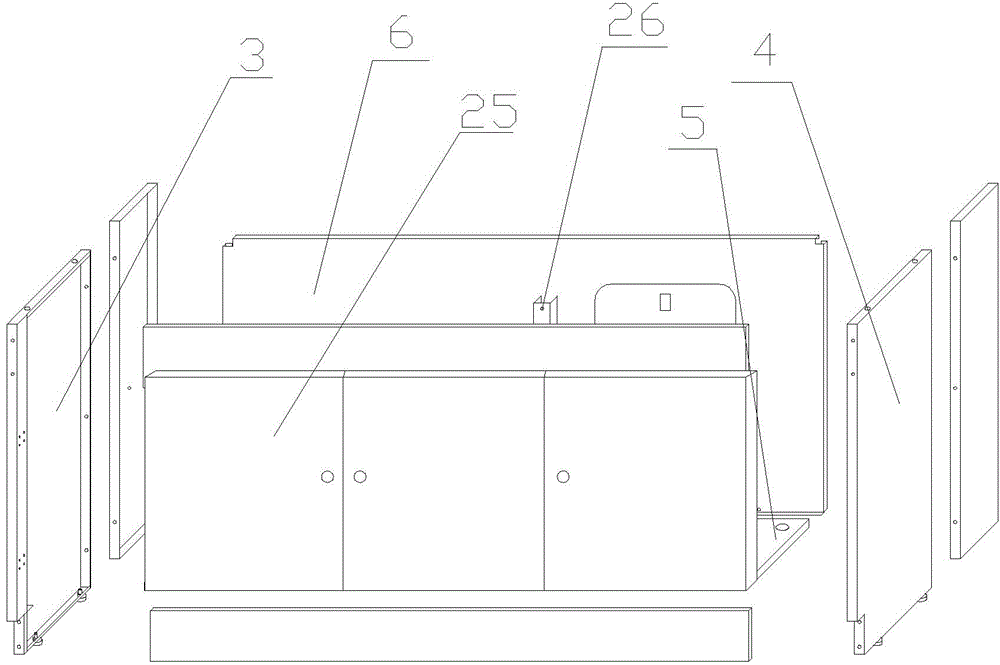

Novel laboratory fume cupboard

The invention relates to the field of experiment equipment manufacturing, in particular to a novel laboratory fume cupboard. A body is composed of an upper cupboard body and a lower cupboard body. The lower cupboard body is a supporting frame which is formed by a left baffle, a right baffle, a bottom plate and a back sealing plate. The upper cupboard body comprises two sets of perpendicular side plates. A table board is arranged at the bottom of the space among the side plates. A rear plate is connected to the rear ends of the side plates. Clamping grooves are formed in the front ends of the side plates, a glass door sheet capable of being pushed and pulled vertically is arranged in the clamping grooves, the two sides of the glass door sheet are each provided with one pull rope, the side plates are hollow, the top of the inner side of each side plate is provided with a pulley, and each pull rope is wound around the corresponding pulley to be connected with a weight. A top plate is fixed to the tops of the side plates, an air outlet is formed in the top plate, and a check valve is arranged on the air outlet. A vertical flow guide plate perpendicular to the table board is arranged at the front end of the rear plate, an inclined flow guide plate is arranged at the top of the vertical flow guide plate, and exhaust holes are formed in the vertical air deflector. The novel laboratory fume cupboard is novel in design and guarantees that harmful gas in a laboratory is thoroughly exhausted.

Owner:TIANCHANG MING HUI LAB EQUIP

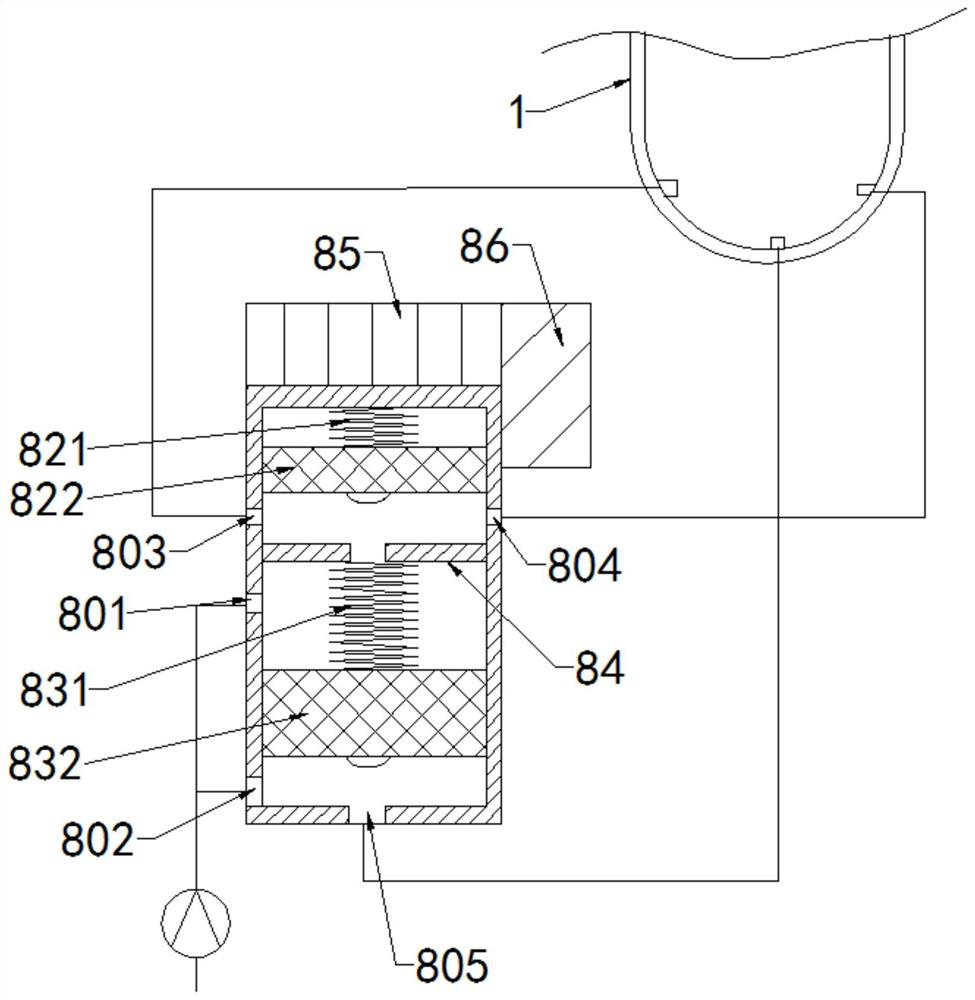

Backflow prevention device for medical negative treatment drainage device

ActiveCN109498860APrevent backflowAvoid infectionSuction drainage systemsWound healingBackflow prevention device

The invention relates to the technical field of medical drainage auxiliary instruments, and discloses a backflow prevention device for a medical negative treatment drainage device. The backflow prevention device comprises the drainage device, a negative-pressure pipe, a fixed pipe and a limiting pipe, the limiting pipe is connected at one end of the fixed pipe in a threaded and sleeving manner, the inside of the fixed pipe is communicated with the inside of the limiting pipe, a first flow guide pipe is communicated between the drainage device and the fixed pipe, a second flow guide pipe is communicated between the limiting pipe and the negative-pressure pipe, a drainage pipe is communicated with the other end of the limiting pipe, and a sealing cover is arranged at the top end of the negative-pressure pipe in a threaded and sleeving manner. According to the backflow prevention device for the medical negative treatment drainage device, drainage is implemented by suction of the drainagedevice, a movable piston is moved to the bottom of the negative-pressure pipe, so that negative pressure is formed in the negative-pressure pipe, liquid in the negative-pressure pipe is prevented fromreturning into a body of a patient by the aid of negative-pressure suction in the negative-pressure pipe when suction of the drainage device is lost, postoperative infection of the patient is prevented, and postoperative wound healing is facilitated.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

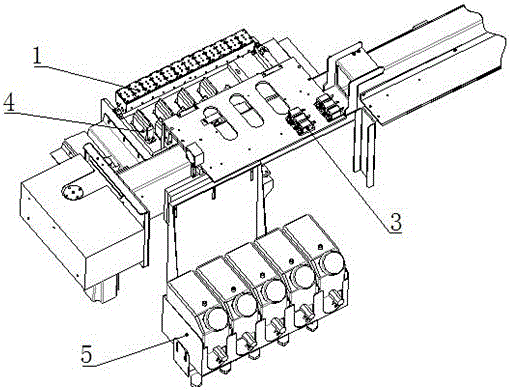

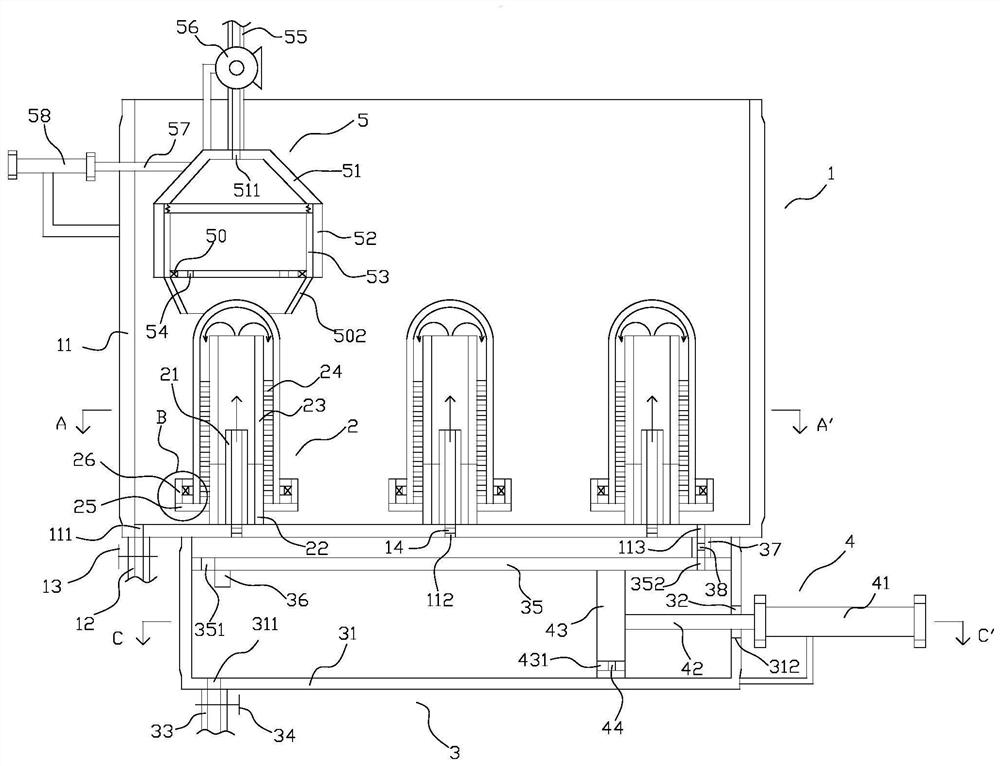

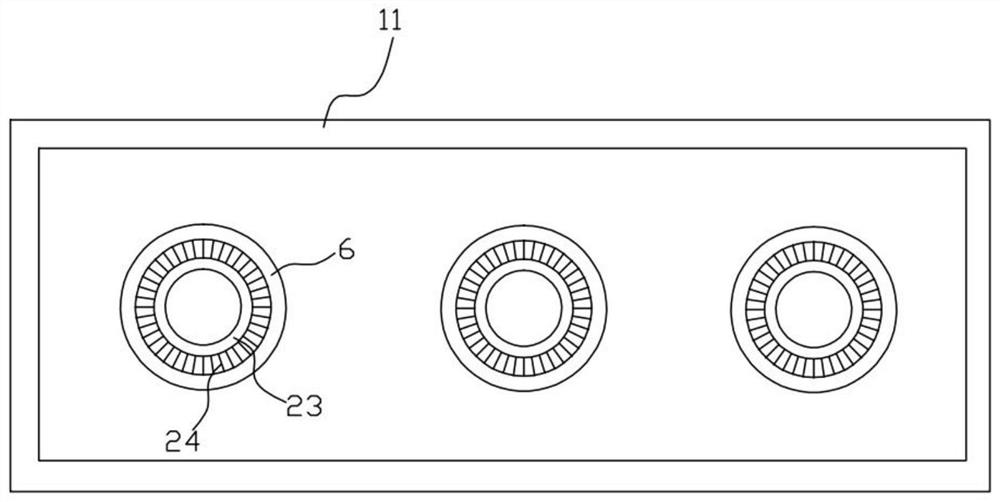

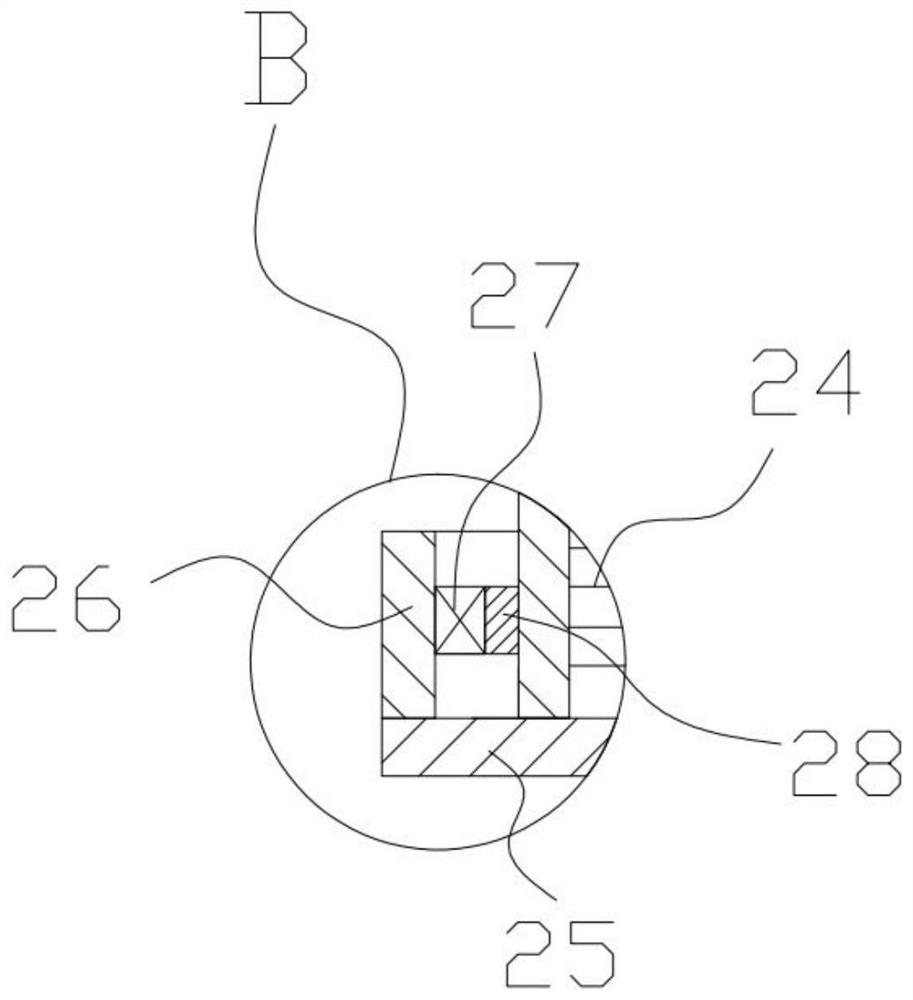

Constant-liquid-level hydraulic ink supply system

The invention belongs to the technical field of printing, and discloses a constant-liquid-level hydraulic ink supply system. The system is used for solving the problems that an existing ink supply device is complex in structure and unstable in liquid level hydraulic pressure. The system comprises a mounting base, a printing spraying head is arranged on the mounting base, and is provided with an ink bag device, and the system is characterized in that the ink bag device comprises a plurality of ink bag cavities, an ink bag cavity gland is arranged at the upper end of each ink bag cavity, each ink bag cavity is provided with an ink bag ink inlet, an ink bag ink outlet and an ink bag heating pipe used for heating ink in the ink bag cavity, and an ink bag soft film is arranged between each ink bag cavity and the corresponding ink bag cavity gland.

Owner:深圳市万德环保印刷设备有限公司

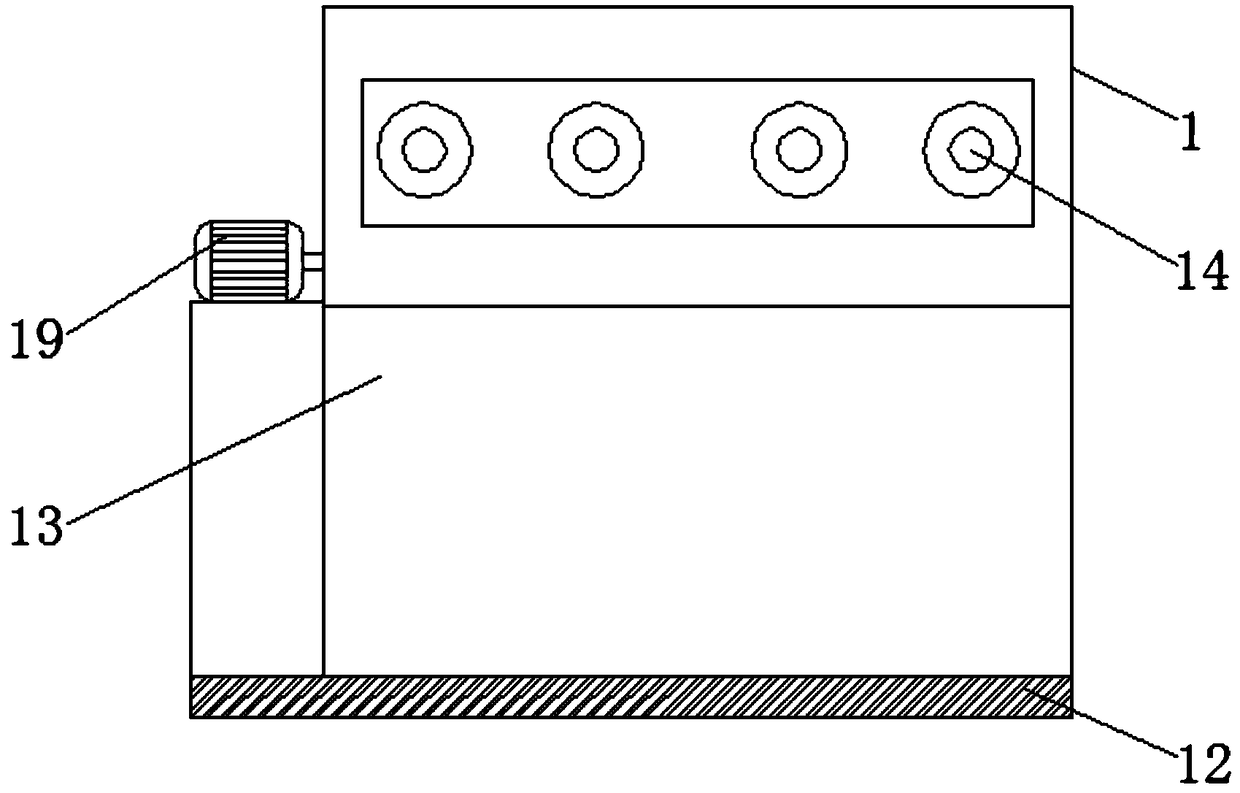

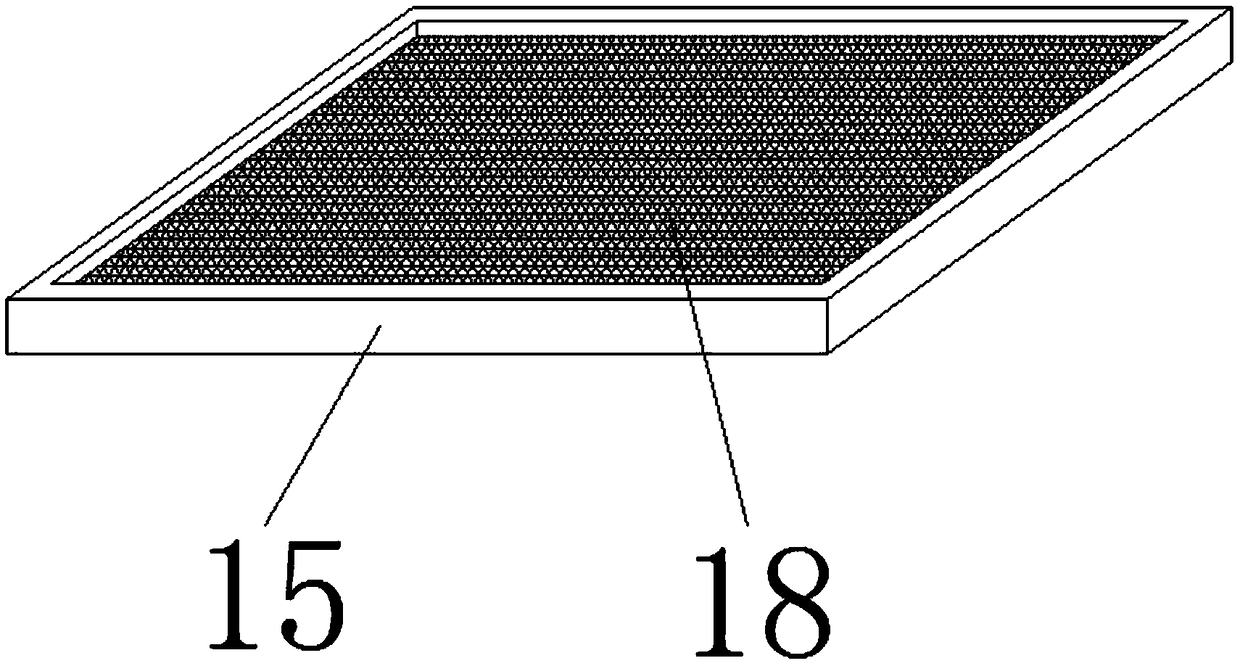

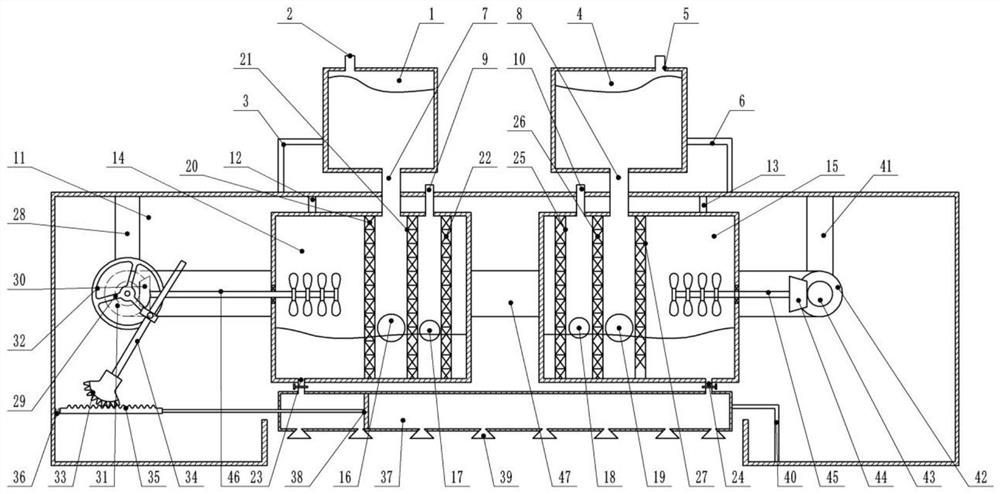

Periodic suction type textile fabric dust removal device

ActiveCN109440431AAvoid secondary pollutionSmooth dischargeMechanical cleaningPressure cleaningEngineeringTextile

The invention belongs to the technical field of textile instruments and discloses a periodic suction type textile fabric dust removal device. The periodic suction type textile fabric dust removal device comprises a box body, a strip-shaped feeding port, a strip-shaped discharging port, two transmission mechanisms and two dust removal mechanisms; the strip-shaped feeding port and the strip-shaped discharging port are symmetrically formed in the left and right side walls of the box body respectively, the two transmission mechanisms are disposed at the upper and lower ends of the interior of thebox body respectively, and the two dust removal mechanisms are disposed in the box body and located between the two transmission mechanisms. According to the periodic suction type textile fabric dustremoval device, through arrangement of the dust removal mechanisms, both sides of a fabric are beaten synchronously to remove dust, and meanwhile the periodicity formed by the rotation of crankshaftscan be adopted for making dust obtained by beating of each beating mechanism below a single air cylinder recycled by an adjacent air cylinder, so that a dust recovery process is more targeted. At thesame time, the dust can be uniformly discharged during the cycle operation. After the dust is beaten out, the circulation of the dust cannot occur in the box body, and secondary contamination of the fabric is avoided.

Owner:浙江越剑机电科技有限公司

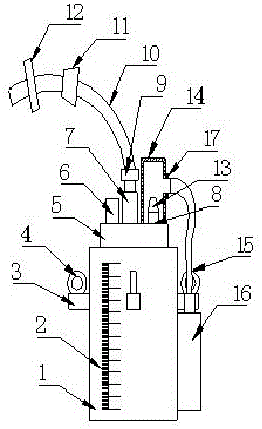

Negative-pressure indicating drainage bottle

InactiveCN105107031AGuaranteed negative pressureWill not flow backIntravenous devicesSuction pumpsReflux valveEngineering

The invention relates to a negative-pressure indicating drainage bottle which comprises a bottle body, wherein measurement scale lines are formed on the front surface of the bottle body, mounting bases are respectively arranged in the middle parts of the front surface, the back surface, the left side and the right side of the bottle body, hanging rings are arranged on the upper sides of the mounting bases, a bottle cap is arranged on the upper side surface of the bottle body, a vacuum indicator, a drainage opening and an extraction opening are arranged on and formed in the bottle cap in sequence from left to right, the drainage opening is connected with a drainage tube through a Ruhr connector, a reflux valve is arranged in the middle of the drainage tube, a tube clamp is arranged on the end of the drainage tube, a check valve is arranged on the upper end of the extraction opening, an extraction chamber is arranged outside the extraction opening, a connecting tube is connected to the right end of the extraction chamber, and a minipump is connected to the other end of the connecting tube. The negative-pressure indicating drainage bottle has the advantages of simple structure, safety, accuracy, good use effect and strong practicability.

Owner:HENAN YADU IND

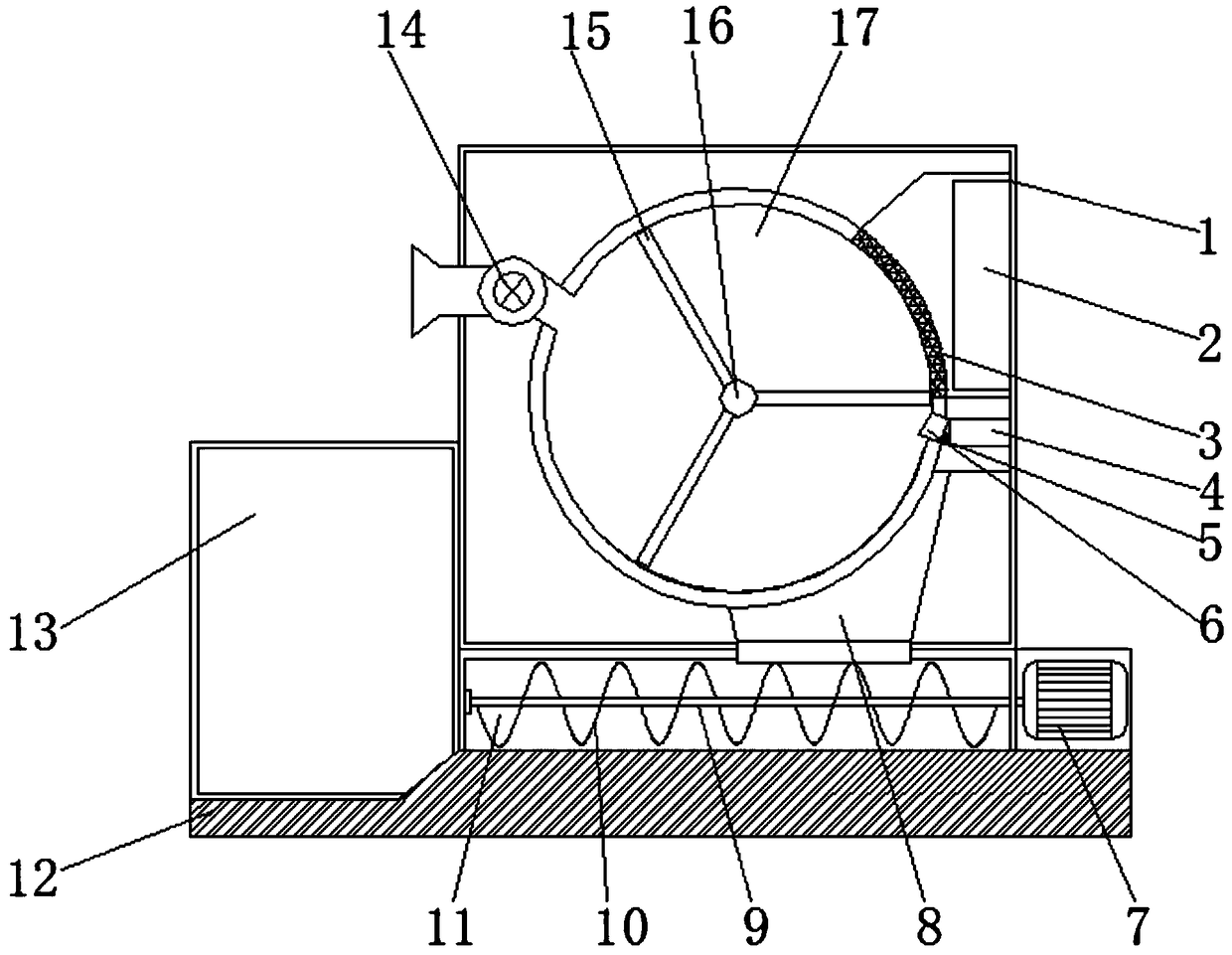

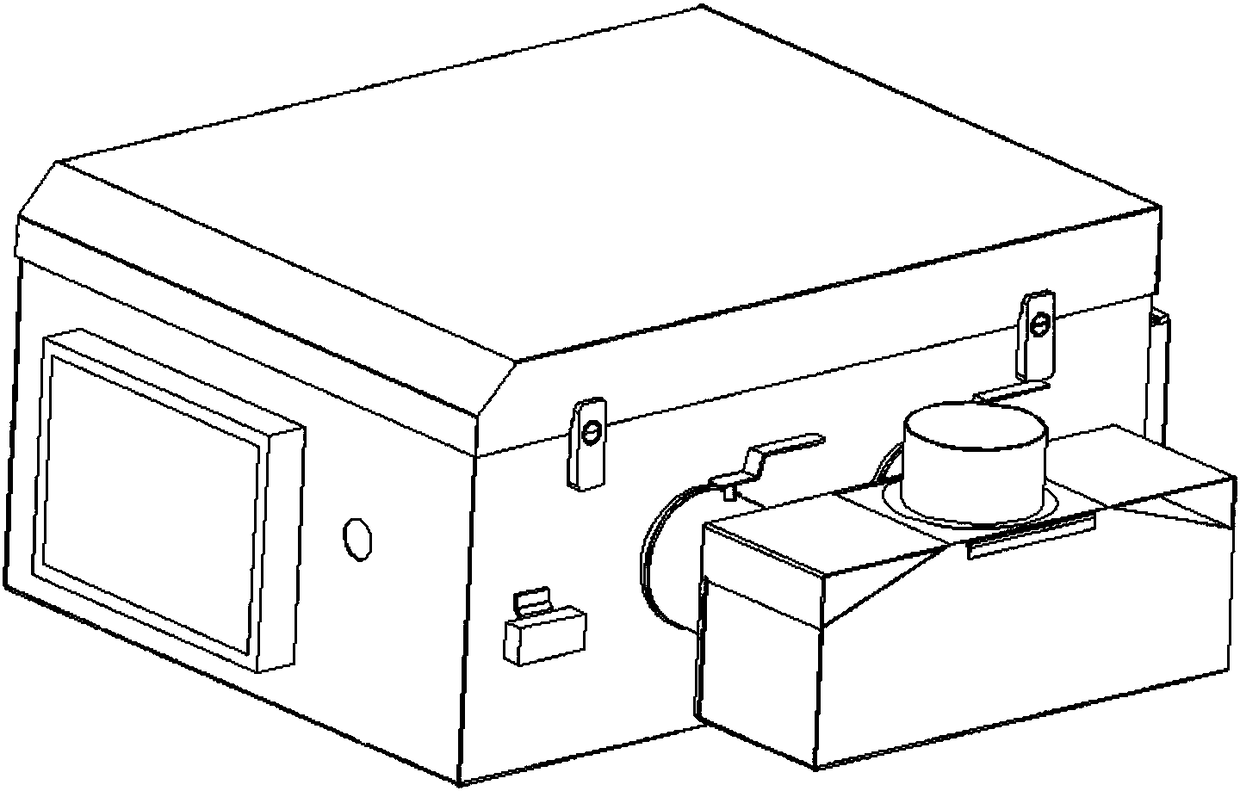

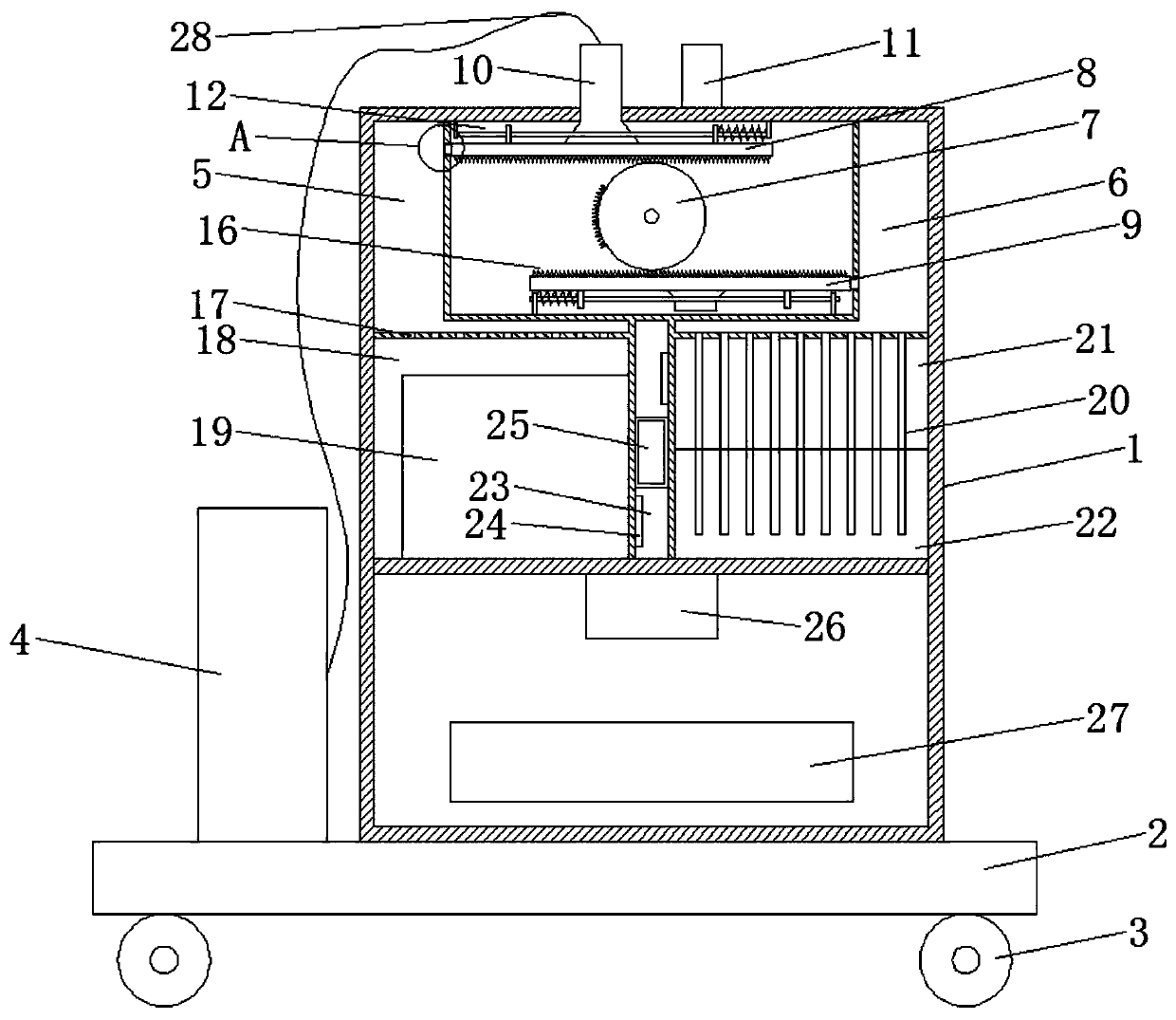

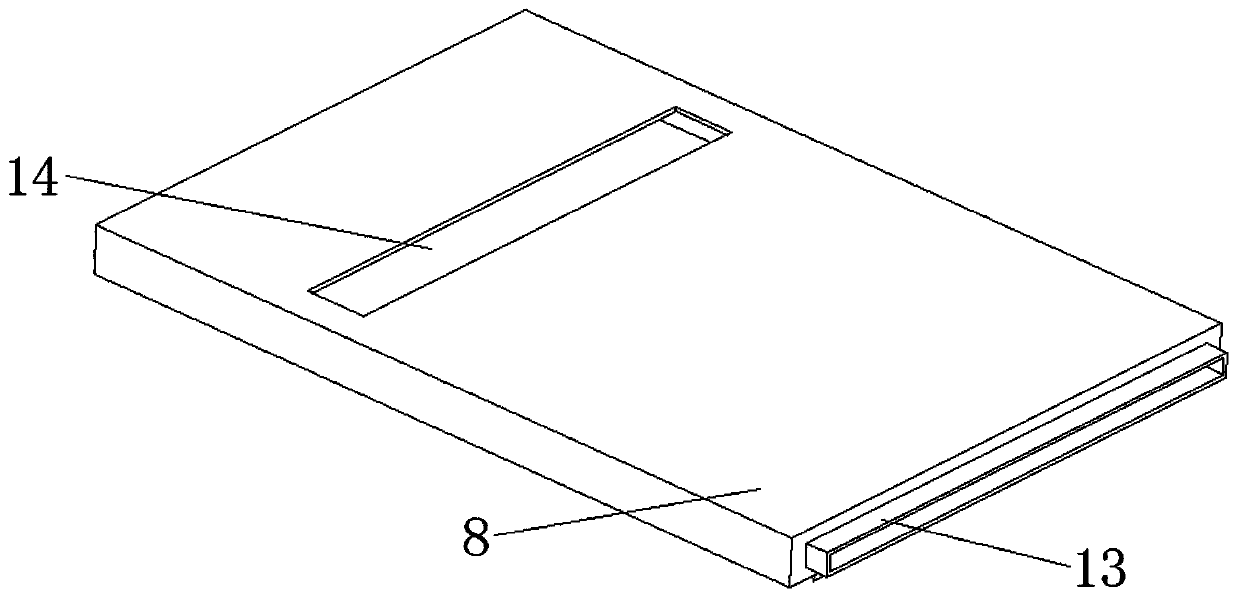

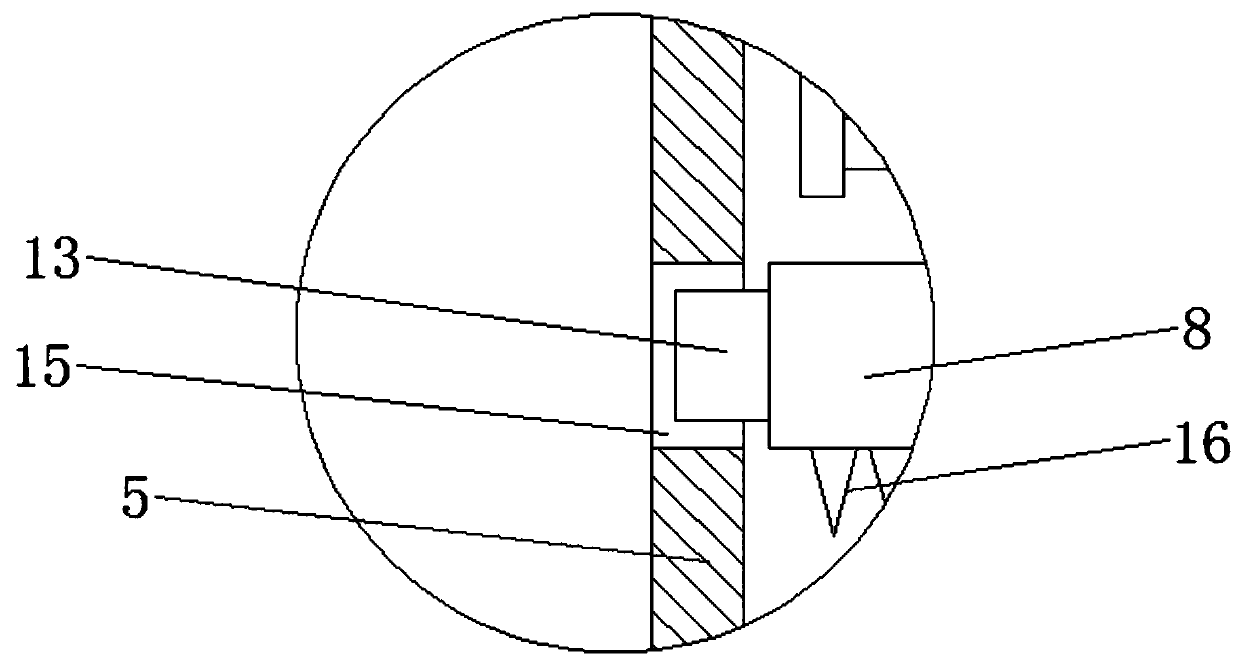

Novel purifier

PendingCN108019837AWide range of divergenceMaintain humidityGas treatmentMechanical apparatusEngineeringPollution

The invention provides a novel purifier. The purifier comprises a base and an upper cover; an air inlet is formed in the base, an air outlet is formed in the other end of the base, a groove is formedin the base, a humidifying device is arranged in the groove, and a filtering device, a suction device and a night lamp are further arranged on the base; and a fan and a negative ion generation deviceare arranged on the upper cover, the filtering device is divided into a first filtering mechanism and a second filtering mechanism arranged on the first filtering mechanism, the first filtering mechanism comprises an annular filter plate, wherein the annular filter plate is inclined downwards, and the second filtering mechanism is composed of two semi-annular filter screens. According to the novelpurifier, purifying and humidifying of air in a wide range are effectively achieved, the purification effect is better, bacteria can be killed through the purifier, secondary pollution can not be formed, and the novel purifier can be widely applied to the indoor life of people.

Owner:天津瑞祥千弘科技发展有限公司

Industrial waste gas treatment system

InactiveCN110013721AImprove processing efficiencyImprove processing qualityCombination devicesQuality assuranceMicromotor

The invention provides an industrial waste gas treatment system. The industrial waste gas treatment system comprises a main body, a fixed ring and a water pump, wherein a connecting valve is arrangedinside the upper part of the left side of the main body, the left side of the connecting valve is connected with an adapter, a micromotor is arranged inside the fixed ring, the fixed ring is located inside the adapter, fan blades are fixed to the left end of the micromotor, absorbent cotton and activated charcoal are separately arranged inside the upper end of the main body, a sealing cover is arranged above the absorbent cotton, a gas guide pipe is fixed to the internal left side of the main body, and an anchor ear is arranged at the middle part of the gas guide pipe. Compared with existing ordinary waste gas treatment systems, the industrial waste gas treatment system has the advantages that internal structures are reduced greatly while equipment functionality is kept, and workers can more simply and easily operate the system during use; and the system is used for carrying out complete treatment on waste gases through multiple layers of filtering structures, the treatment efficiencyof the waste gases and quality assurance are improved, and use requirements of people are effectively met.

Owner:郑州天狼实业有限公司

Landscaping maintenance device

InactiveCN112753683AIncrease temperatureImprove decomposition rateSpraying apparatusPressurised distribution of liquid fertiliserAgricultural scienceAgricultural engineering

The invention discloses a landscaping maintenance device which comprises a box body, a fertilizer box, a first storage box, a first bevel gear, a second bevel gear, a first driven rod and a motor used for driving the first bevel gear to rotate. A fertilizer is arranged in the fertilizer box; the first storage box is fixedly communicated with the fertilizer box; the second bevel gear is meshed with the first bevel gear; the second bevel gear is rotationally connected onto the first driven rod through a bearing; the first driven rod is provided with stirring blades; the stirring blades are arranged in the first storage box; an air cylinder is arranged in a box body; and the air cylinder is fixedly communicated with the first storage box and provided with a water spraying pipe communicated with the air cylinder. A motor is started, the first bevel gear rotates, the second bevel gear also rotates along with the first bevel gear to enable the first driven rod to rotate, and the stirring blades stir the fertilizer flowing into the first storage box in the first storage box. The fertilizer and water flow into the air cylinder and then are sprayed out through the water spraying pipe. The landscaping maintenance device provided by the invention can automatically spray the fertilizer and the water and dilute the fertilizer and the water at the same time.

Owner:吴跃

A kind of bamboo original chitosan functional dressing and preparation method thereof

ActiveCN104383590BPromote healingEffective bactericidal and antibacterial effectAbsorbent padsBandagesViscoseUltimate tensile strength

The invention relates to a bamboo chitosan functional dressing comprising bamboo fibers and chitosan, and a preparation technology for the dressing. The preparation technology comprises the following steps: (1) mixing and opening; (2) combing; (3) lapping; (4) pre-needling, wherein the pre-needling adopts oblique needling, and the needling angle of the oblique needling is 20-30 degrees; (5) needling of composite fiber net after the pre-needling to obtain dressing primary product; (6) pressing of the dressing primary product to obtain the dressing; (7) winding. The bamboo chitosan functional dressing adopts the bamboo fibers as a frame; the chitosan fibers are uniformly distributed on the frame; viscose fibers are utilized to strengthen adhesion; the component fibers form an integrative non-woven fabric structure without being layered by needling; the non-woven fabric structure is firmer, high in intensity and more durable; the chitosan fibers and the bamboo fibers are intersected complexly, and permeate mutually; the efficacy function of the fibers is more permanent; medicine smeared on the inner surface of a dressing in a conventional manner is easy to drop or be rubbed off; the dressing has no burr on edge.

Owner:ZHEJIANG AOLIN MEDICAL ARTICLES

Bamboo chitosan functional dressing and preparation method thereof

ActiveCN104383590ABroad-spectrum antibacterialBroad-spectrum hemostatic effectAbsorbent padsBandagesUltimate tensile strengthViscose fiber

The invention relates to a bamboo chitosan functional dressing comprising bamboo fibers and chitosan, and a preparation technology for the dressing. The preparation technology comprises the following steps: (1) mixing and opening; (2) combing; (3) lapping; (4) pre-needling, wherein the pre-needling adopts oblique needling, and the needling angle of the oblique needling is 20-30 degrees; (5) needling of composite fiber net after the pre-needling to obtain dressing primary product; (6) pressing of the dressing primary product to obtain the dressing; (7) winding. The bamboo chitosan functional dressing adopts the bamboo fibers as a frame; the chitosan fibers are uniformly distributed on the frame; viscose fibers are utilized to strengthen adhesion; the component fibers form an integrative non-woven fabric structure without being layered by needling; the non-woven fabric structure is firmer, high in intensity and more durable; the chitosan fibers and the bamboo fibers are intersected complexly, and permeate mutually; the efficacy function of the fibers is more permanent; medicine smeared on the inner surface of a dressing in a conventional manner is easy to drop or be rubbed off; the dressing has no burr on edge.

Owner:ZHEJIANG AOLIN MEDICAL ARTICLES

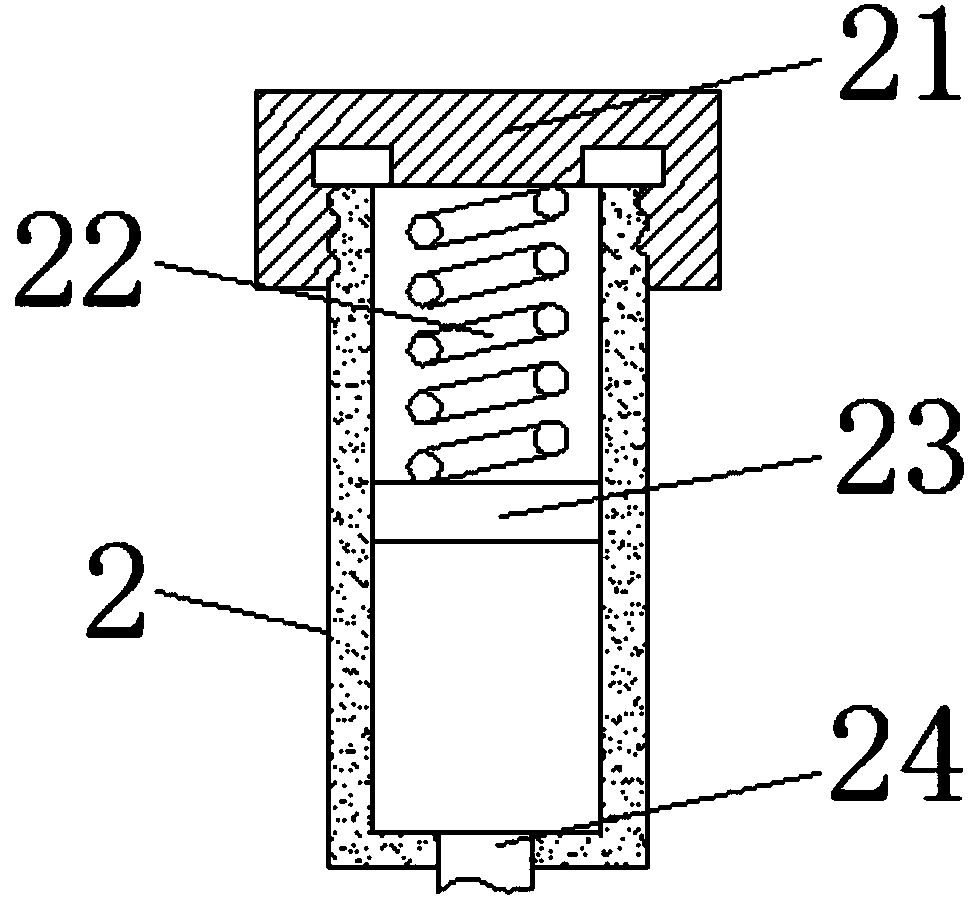

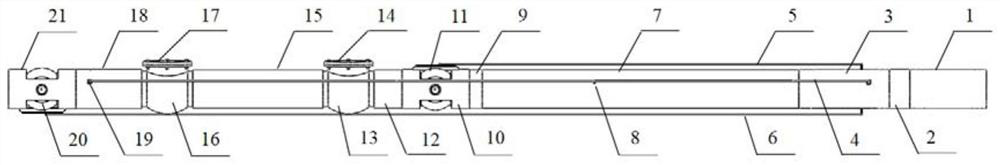

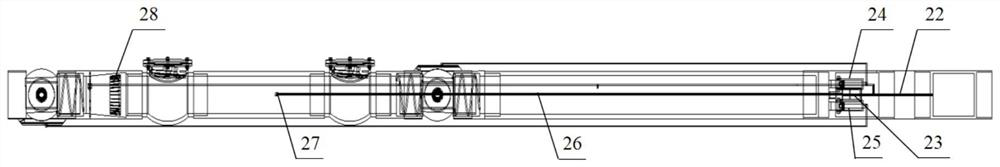

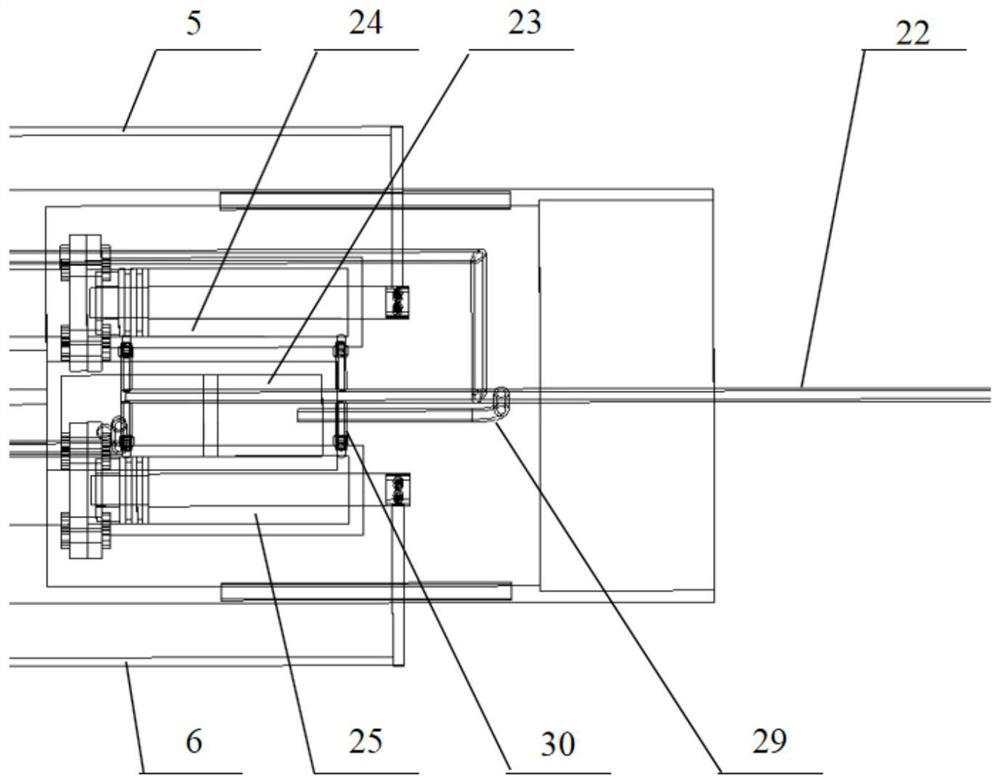

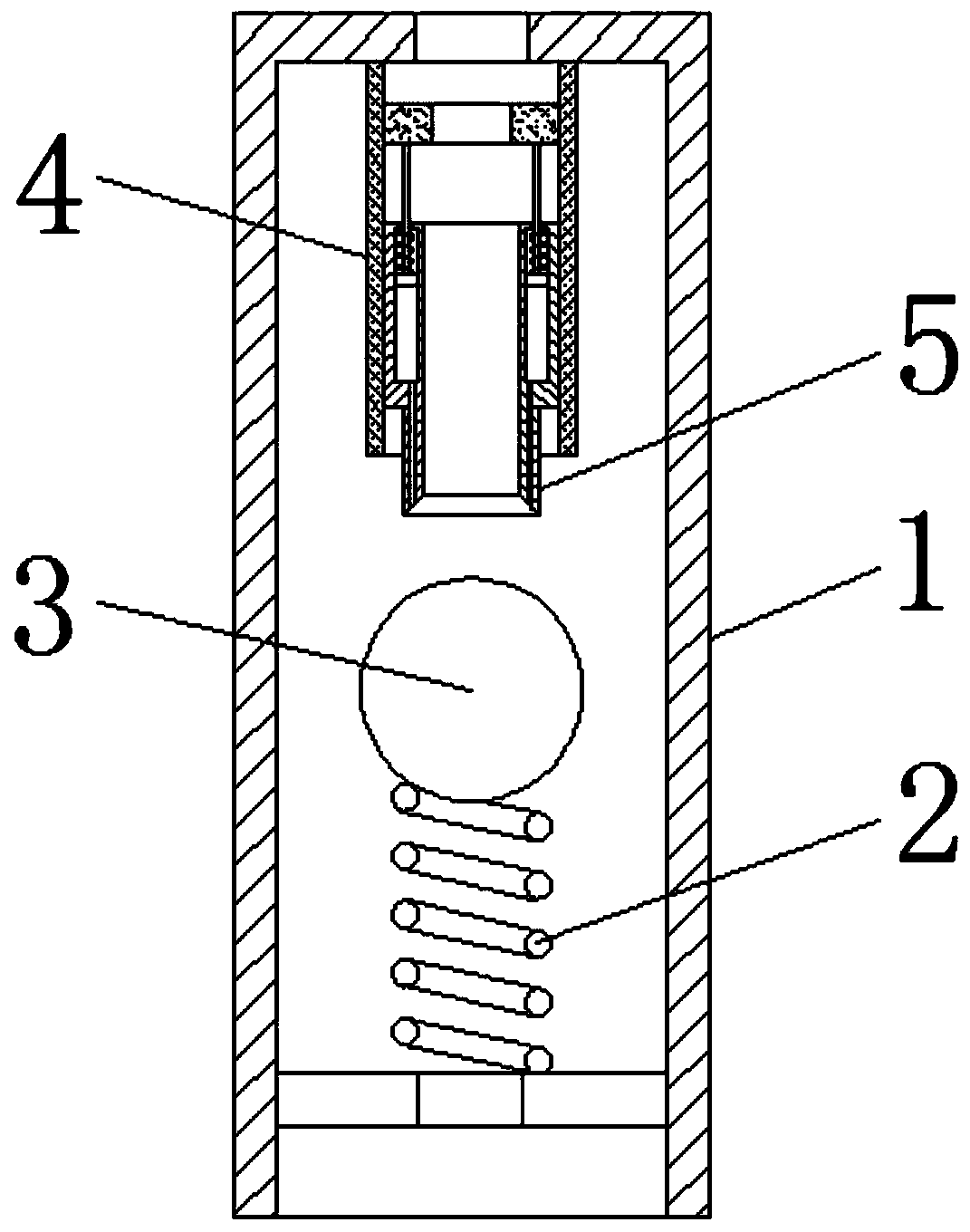

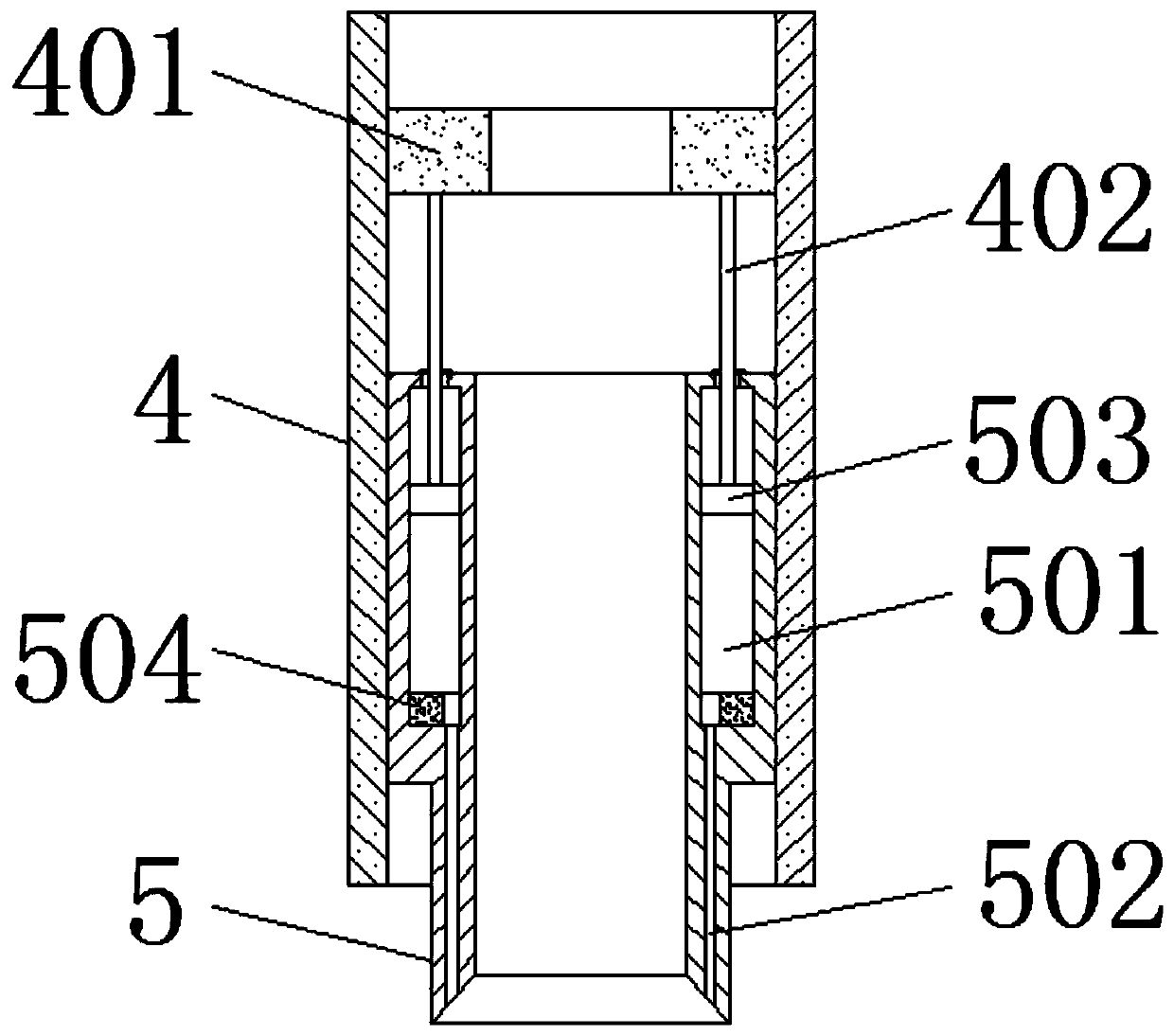

Horizontal well buried type continuous coring inner barrel assembly

The invention discloses a horizontal well buried type continuous coring inner barrel assembly. The coring inner barrel assembly comprises a control assembly, a pneumatic cylinder assembly, a high-pressure nitrogen chamber, a curing liquid chamber, a core storage barrel, a ball valve assembly, a check valve, a machining barrel, a core catcher and a high-pressure fluid pipeline, and the pneumatic cylinder assembly is used for controlling a sliding block valve rod to move to complete multiple times of opening and closing of a ball valve, so that continuous coring and sealing are achieved; the check valve is used for sealing the machining barrel and injecting curing liquid to realize burying and sealing of a rock core; the high-pressure nitrogen chamber is used for generating high-pressure nitrogen to impact the rock core to push away a check valve clack and enter the core storage barrel; and the control assembly is used for measuring, feeding back and adjusting the in-situ performance of the temperature and pressure of the core storage barrel, and the procedures are circulated to complete multi-point continuous fidelity coring operation. The coring inner barrel assembly drills down for one time to take out multiple sections of rock cores and conducts buried type sealing processing one by one, so that the coring inner barrel assembly has the characteristic of quality guarantee, nitrogen is filled into the core storage barrel to achieve a pressure maintaining effect, and a heat preservation coating is plated on the inner wall of the core storage barrel to achieve a heat preservation effect.

Owner:NORTHEAST GASOLINEEUM UNIV

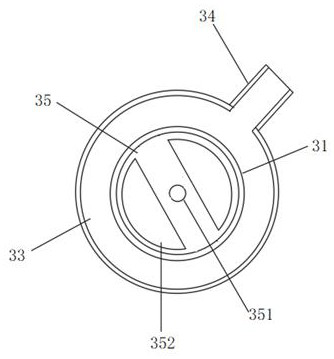

One-way ball valve for piston type grouting pump

ActiveCN110345283AWill not flow backEnsure grouting efficiencyPositive displacement pump componentsCheck valvesEngineeringSlurry

The invention relates to the field of grouting equipment, and discloses a one-way ball valve for a piston type grouting pump. The one-way ball valve comprises a valve tube, a spring, a valve ball anda flow guide tube, a casing tube is arranged outside the flow guide tube, the flow guide tube carries out longitudinal moving in the casing tube, the top of the casing tube is fixedly connected with the top of an inner cavity of the valve tube, and an upper cavity is formed in the top of the flow guide tube. According to the one-way ball valve for the piston type grouting pump, through the designthat the flow guide tube can move relative to the casing tube and a magnetic ring plug, when the grouting pump above the valve tube carries out slurry suction, the valve ball moves upwards and makes contact with the flow guide tube, the flow guide tube is driven to move upwards, the pressure intensity, below the magnetic ring plug, of the upper cavity of the flow guide tube is increased, gas flowor slurry carries out impact on the contact portion of the valve ball and the flow guide tube, a sticky solid stuck on the contact portion of the valve ball and the flow guide tube is flushed away, itis ensured that the valve ball is tightly attached to the flow guide tube, seal is effectively achieved, it is ensured that when the grouting pump works, slurry cannot flow back, amount of each-timegrouting is not reduced, and the grouting efficiency is effectively ensured.

Owner:BENSV VALVE CO LTD

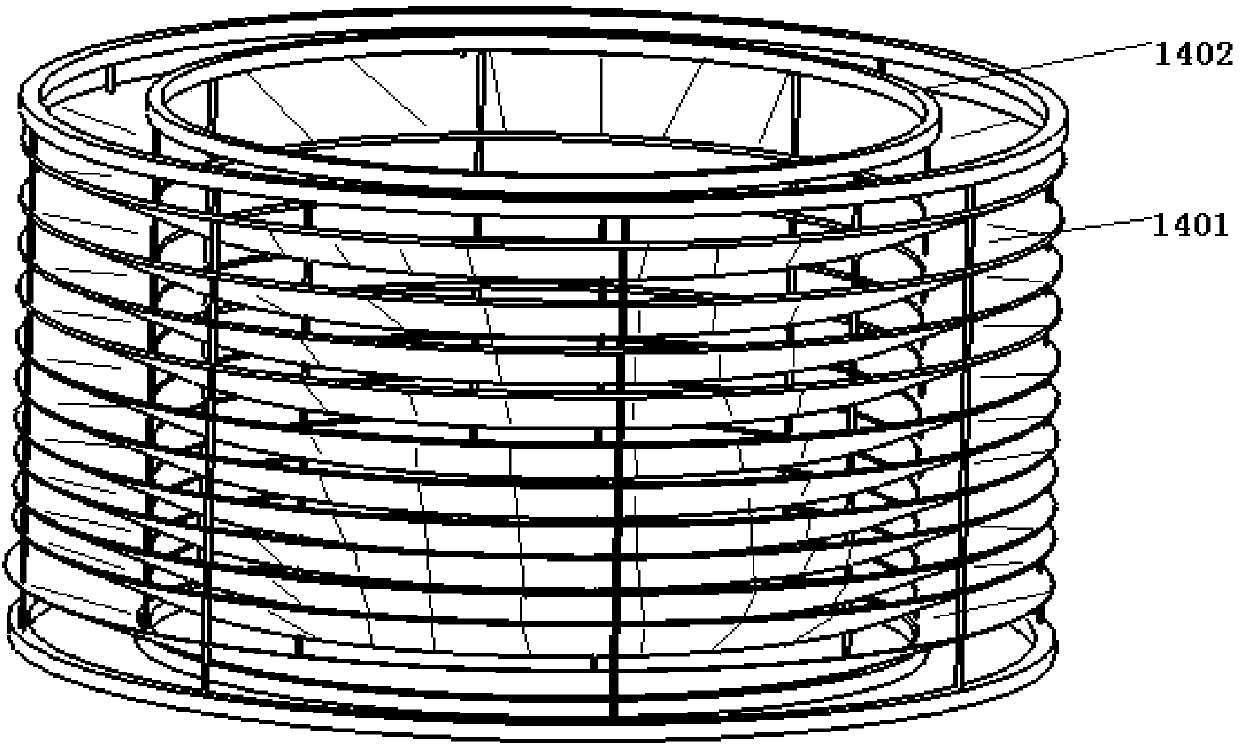

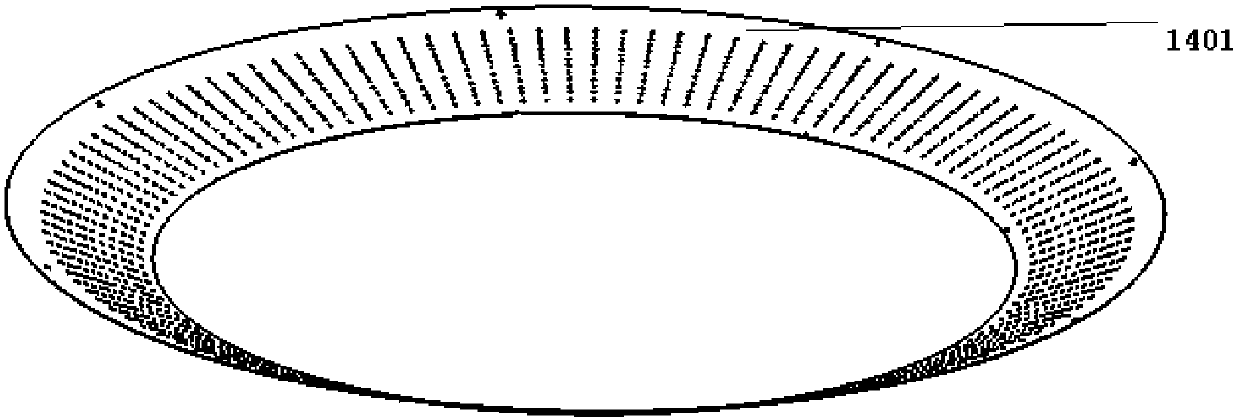

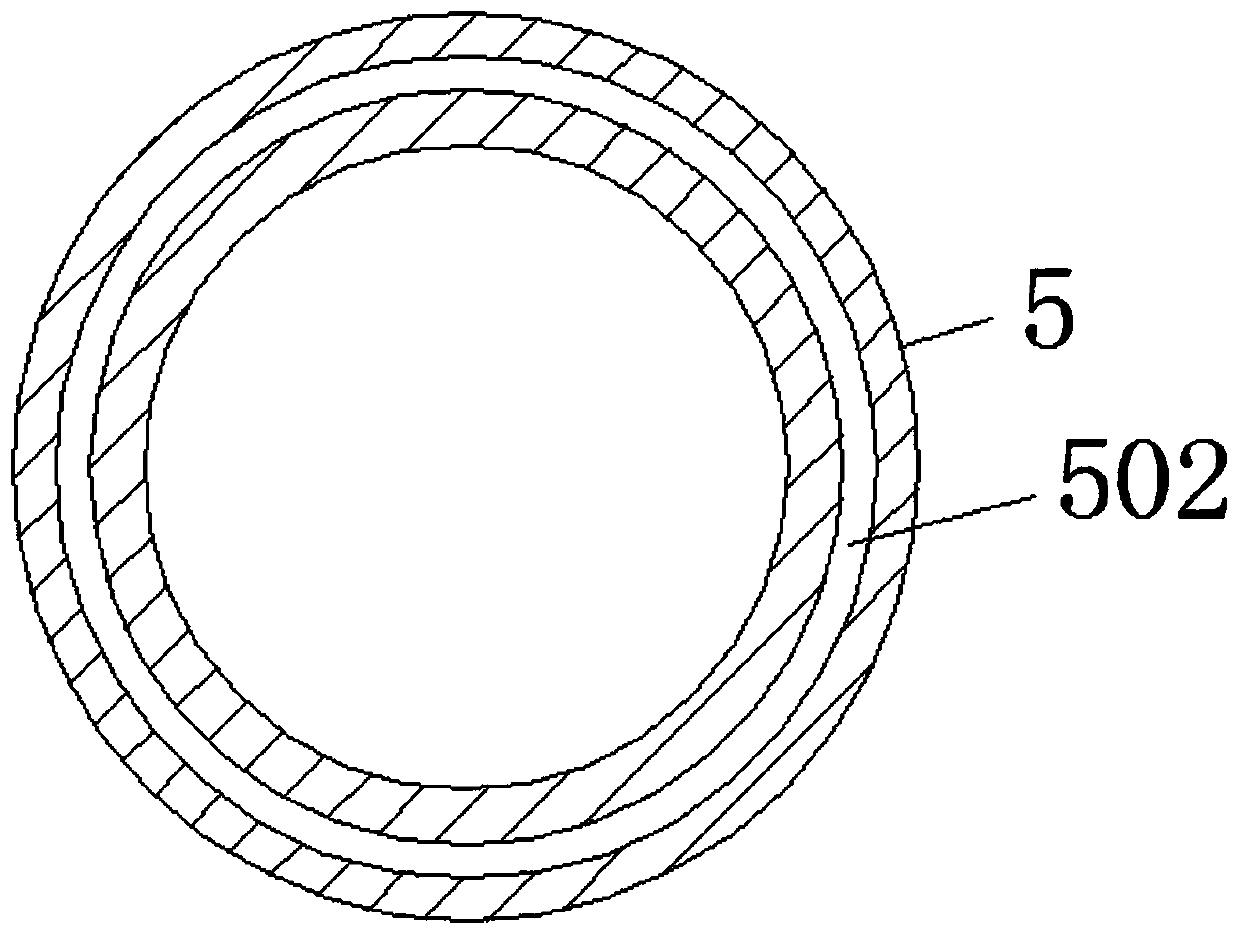

Large-scale hatching system and method for schizopygopsis younghusbandi regan eggs in Tibet

ActiveCN112293315ARoll up and down evenlyWill not flow backClimate change adaptationPisciculture and aquariaFisherySchizopygopsis younghusbandi

The invention provides a large-scale hatching system for schizopygopsis younghusbandi regan eggs in Tibet. The system comprises a production support and incubators, the production support is arrangedon the inclined ground, and a water outlet is formed at the lower side of the ground; a plurality of rows of incubators are placed on the production support, and a water outlet pipe with a valve is arranged above each incubator; and each incubator comprises an incubation barrel, an overflow groove, a flow guide groove and a water inlet pipe, the water inlet end of each water inlet pipe is connected with the corresponding water outlet pipe, the water outlet end of each water inlet pipe is inserted from an opening at the top of the corresponding incubation barrel, a water outlet is close to thebottom of each incubation barrel, and the overflow grooves surround the outer side walls of the upper ends of the incubation barrels. The hatching system is high in survival rate of hatched fish eggs,high in production efficiency and capable of achieving large-scale production in Tibet.

Owner:西藏自治区农牧科学院水产科学研究所

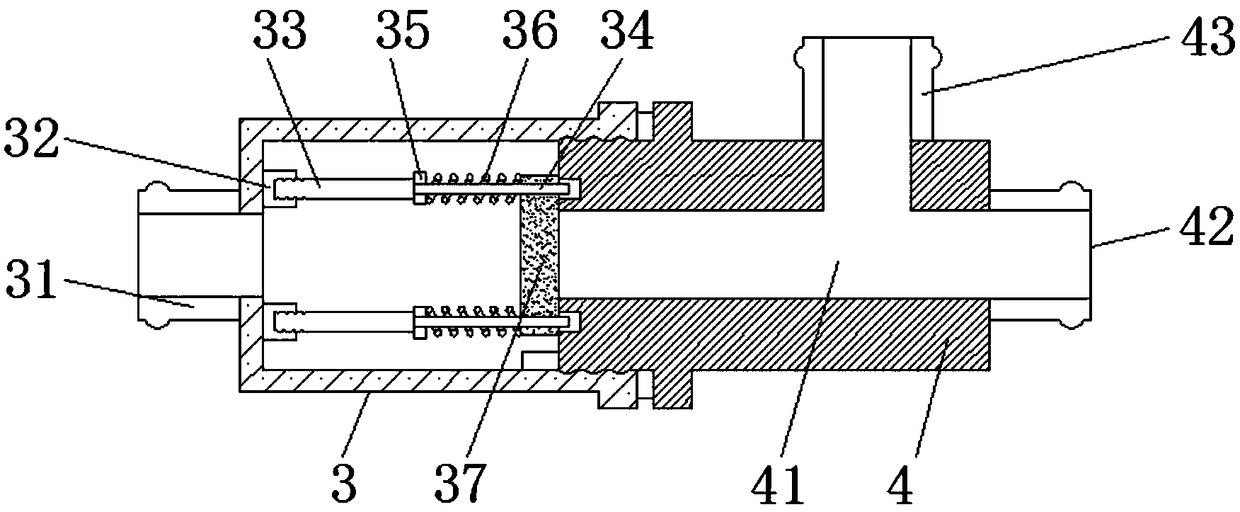

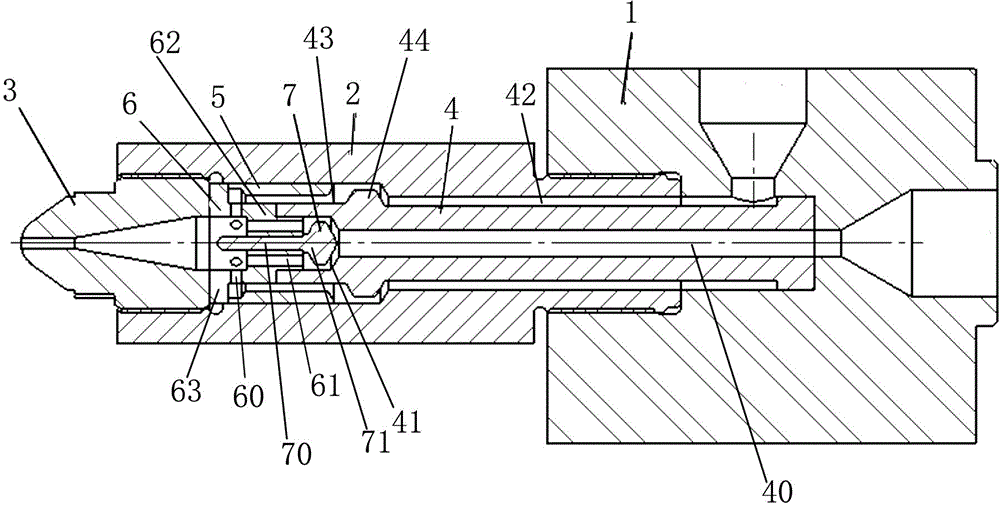

Double-colour injection nozzle for injection machine

The invention discloses a double-colour injection nozzle for an injection machine. The double-colour injection nozzle comprises a nozzle flange used for being fixedly connected with double adhesive-melting barrels of the injection machine, a sleeve and a nozzle body, wherein the interior of the sleeve is hollow, and the nozzle flange, the sleeve and the nozzle body form a nozzle housing with a cut-through interior; an adhesive-separating tube, an adhesive-passing ring, a distributor and a valve rod are further installed in the hollow interior of the sleeve; the distributor is installed between the nozzle and the adhesive-separating tube, and adhesive material inflowing holes communicated with an auxiliary runner and a main runner respectively are formed in the distributor; the adhesive-passing ring sleeves the outer wall of the junction of the distributor and the adhesive-separating tube, and a gap is formed in the outer wall of the junction of the distributor and the adhesive-separating tube and is capable of moving forwards and backwards to close the auxiliary runner; the valve rod comprises a connection leg and a head part, the connection leg is movably connected to the distributor in an insertion manner, and the head part is exposed out of the distributor, is accommodated in a valve rod chamber, and is capable of moving forwards and backwards to block the opening of the main runner. Melted adhesive materials in the main runner and the auxiliary runner of the double-colour injection nozzle disclosed by the invention cannot flow back; the double-colour injection nozzle is simple in structure and capable of achieving multi-way double-colour injection such as clear double-colour injection, mixed double-colour injection and interlayer injection.

Owner:佛山市宝捷精密机械有限公司

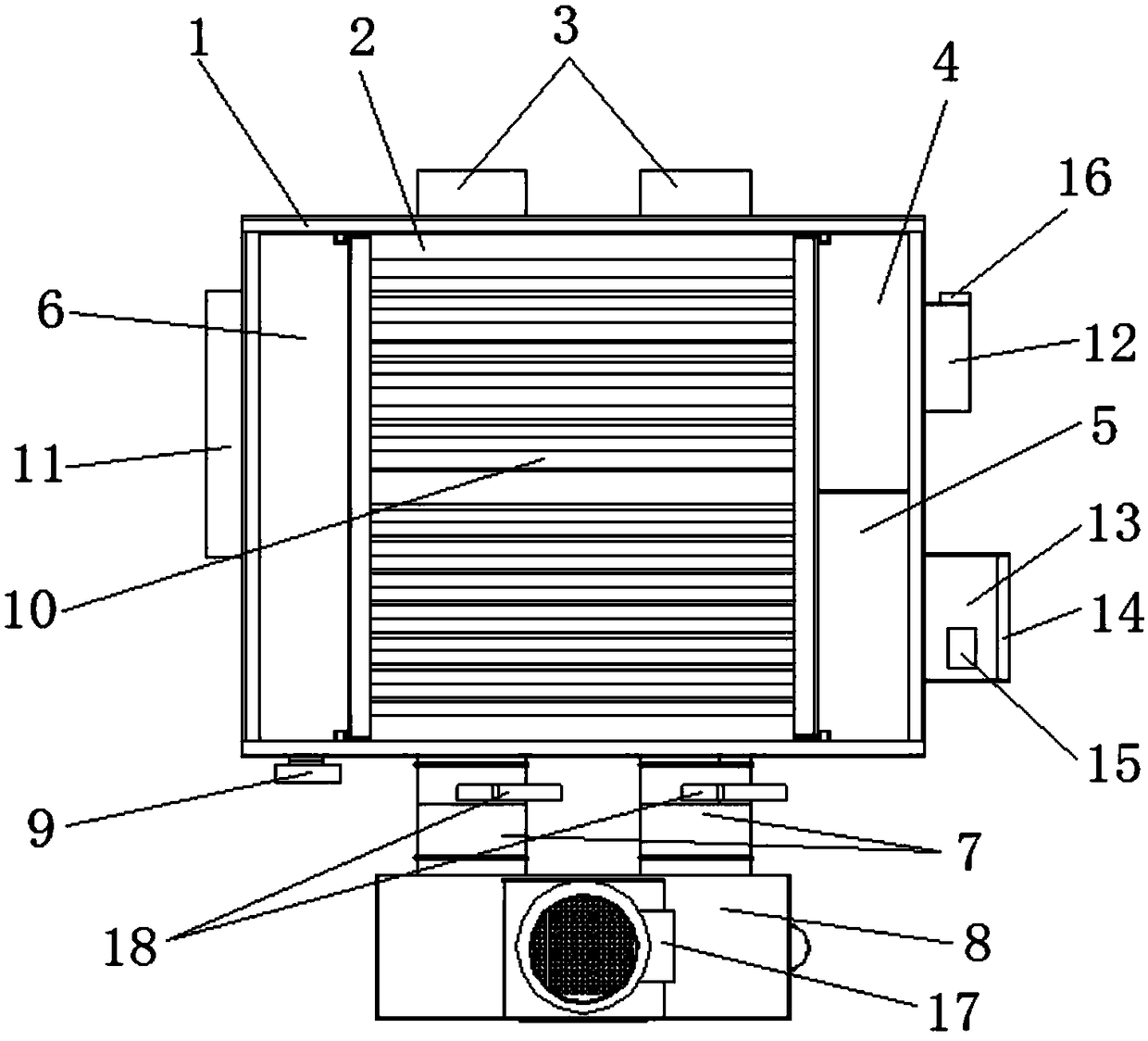

Industrial oven waste heat recovery equipment

InactiveCN109489353AGuaranteed uptimeWon't clogDrying solid materialsDrying machines with local agitationFlue gasProduct gas

The invention discloses industrial oven waste heat recovery equipment which comprises a box body and heat exchange pipes. The two opposite sides of the box body are provided with a waste heat gas inlet and a waste heat gas outlet correspondingly, and the waste heat gas outlet is provided with an oil contamination separation and collection device and a safety fire prevention device, a heat exchangecavity is arranged in the portion, between the waste heat gas inlet and the waste heat gas outlet, in the box body, the multiple heat exchange pipes are arranged in the heat exchange cavity, an air inlet cavity and an air outlet cavity are formed in one side of the heat exchange cavity in the box body, the other side of the heat exchange cavity is provided with a gas buffer cavity, a fresh air port and an automatic dust blowing device are arranged outside the air inlet cavity, a heat recovery air inlet is arranged outside the air outlet cavity, and the fresh air port communicates with the heat recovery air inlet through a heat exchange pipeline and the gas buffer cavity. A high pressure air blowing device is arranged outside the box body, and an air outlet of the high pressure air blowingdevice is arranged in the heat exchange cavity of the box body. By means of the industrial oven waste heat recovery device, waste heat in high-temperature waste heat flue gas can be sufficiently recovered and utilized to be converted into heat energy for reuse, and drying equipment such as an industrial oven can operate stably so as to reduce the cost.

Owner:库珀环境技术(上海)有限公司

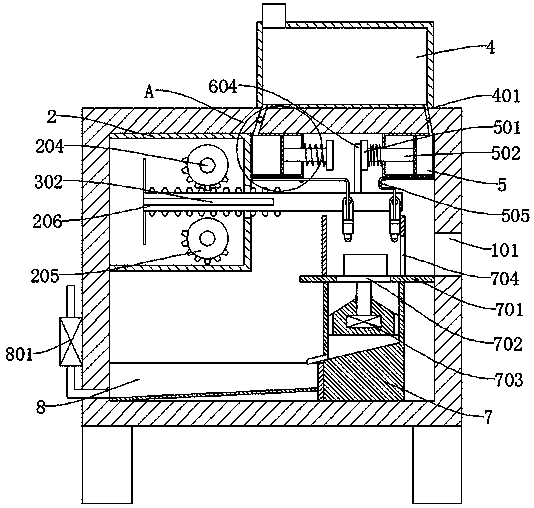

Anti-rust oil spraying device used for mechanical workpiece

InactiveCN110280417AGood spray effectReduce labor intensityLiquid spraying apparatusFuel tankEngineering

The invention discloses an anti-rust oil spraying device used for a mechanical workpiece and belongs to the technical field of spraying. The anti-rust oil spraying device used for the mechanical workpiece comprises a first box body, and the inner wall of the first box body is connected with a second box body and a sleeve; a rack plate is connected in the second box body in a sliding manner; the outer wall of the rack plate is rotationally connected with a spray head; the top of the first box body is connected with an oil storing box which communicates with the sleeve through a connection pipe; the outer wall of the sleeve is connected with a water spraying pipe; the end, away from the sleeve, of the water spraying pipe is connected with the spray head; a fixed table is further connected to the inner wall of the first box body; the top of the fixed table is connected with a top plate; a rotating disk is rotationally connected in the top plate; a part body is connected to the top of the rotating disk; and the outer wall of the rotating disk is provided with a concave hole. The anti-rust oil spraying device used for the mechanical workpiece is convenient to operate, manual operation is not needed, the labor intensity is lowered, the work efficiency is improved, and meanwhile the effect of spraying is better.

Owner:NANJING AOLINGKE INTERNET OF THINGS TECH CO LTD

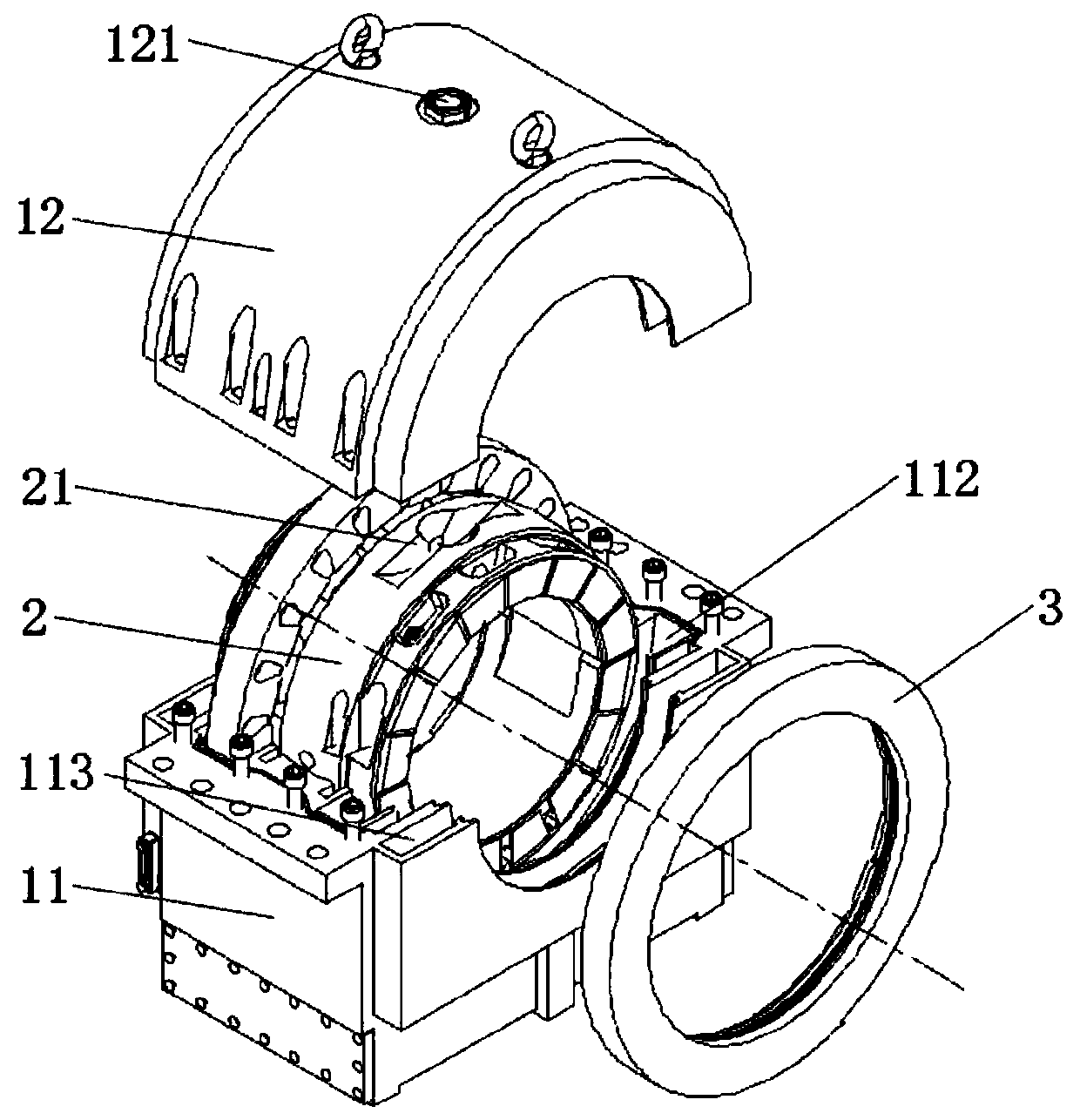

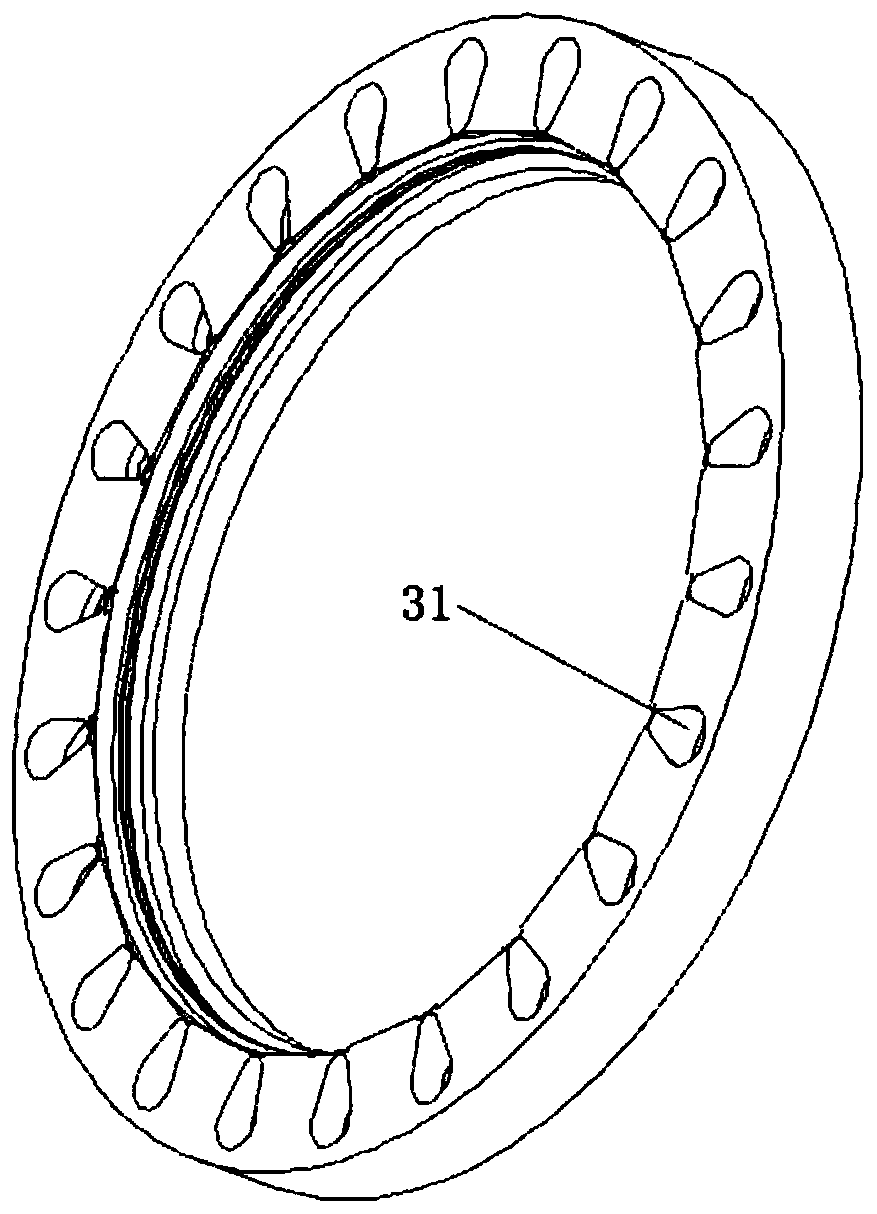

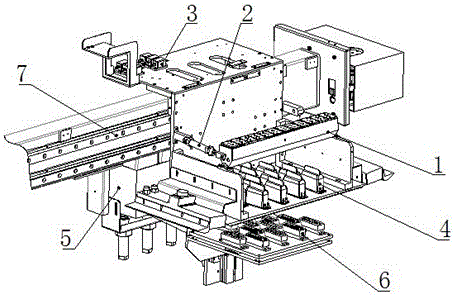

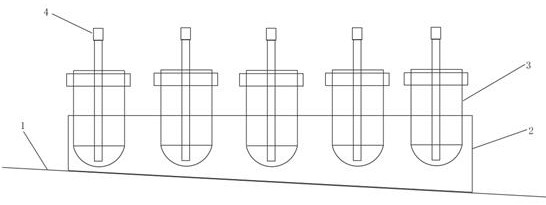

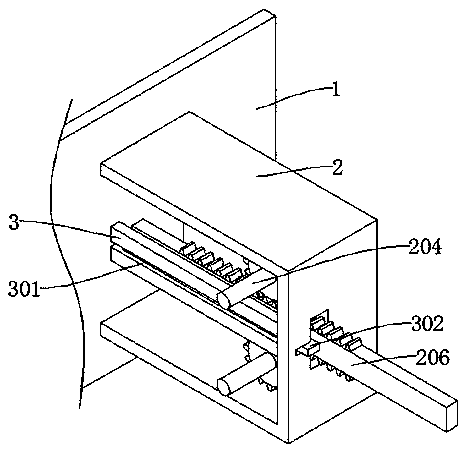

Automatic test tube washing equipment for laboratory medicine and urinary surgery

InactiveCN112642817AIncrease flow ratePromote circulationHollow article cleaningDrying gas arrangementsUrological surgeryTest tube

The invention provides automatic test tube washing equipment for laboratory medicine and urinary surgery. The equipment comprises a shell mechanism (1), a fixing mechanism (2), a centralizing mechanism (3), a driving mechanism (4) and an air blowing mechanism (5). The shell mechanism (1) comprises a shell (11). A plurality of second through holes (112) and third through holes (113) are formed in the lower surface of the shell (11). According to the equipment, by arranging a second pipeline, a third pipeline and a filtering frame, thus when liquid flows upwards in the second pipeline, the inner wall of a test tube can be washed, and liquid in the third pipeline can be driven to flow, so that the liquid of the exterior of the filtering frame flows into the interior of the test tube so as to promote circular flow of the liquid, and flushing to the inner wall of the test tube is achieved. Meanwhile, the centralizing mechanism is provided with a partition plate, a connecting pipe, a first one-way valve and other structures, one-way flowing of the liquid in the shell, the connecting pipe, a centralizing frame and the like can be achieved, thus the liquid can flow to the inner wall of the test tube in a one-way manner, and the effect of washing the inner wall of the test tube is remarkable.

Owner:CHENGDU GUANYU TECH

Quartz sand pickling method and device

The invention discloses a quartz sand pickling method and device. According to the technical scheme of the quartz sand pickling method and device, the quartz sand pickling device comprises a picklingbed with a cavity used for containing quartz sand, and a sealing cover capable of sealing the cavity is detachably connected to the upper end of the pickling bed; a pickling unit for conveying acid liquor to the bottom of the quartz sand from the lower part of the cavity and an air supply device for conveying compressed air into the cavity are arranged on one side of the pickling bed; the air supply device is used for supplying air into the cavity from the upper end or the lower end of the pickling bed; and the quartz sand pickling device also includes a water supply device used for conveyingpure water to the bottom of the quartz sand. The invention has the beneficial effects that acid liquor and quartz sand are fully mixed, the pickling effect is good, less cleaning water is used, the cleaning time is short, and the cost is reduced.

Owner:中建材衢州金格兰石英有限公司

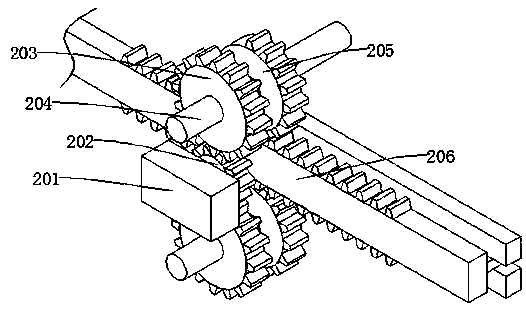

Ventilation and dust removal equipment for machine room of communication base station

ActiveCN111442442AImprove targetingWill not flow backDucting arrangementsMechanical apparatusTelecommunications engineeringDust control

The invention relates to the field of communication engineering, and particularly discloses ventilation and dust removal equipment for a machine room of a communication base station. The ventilation and dust removal equipment comprises a casing, a base, rolling wheels and a moving air inlet box; a dust removal chamber and a ventilation cooling chamber are symmetrically arranged at the two inner wall tops of the casing; toothed plates meshing with an intermittent gear intermittently are fixed to the opposite side surfaces of a first moving plate and a second moving plate; butt-jointing inlets communicating with the inside are formed in the top of the first moving plate and the bottom of the second moving plate; butt-jointing outlets extending outwards are formed in the left end of the firstmoving plate and the right end of the second moving plate; a dust removal cavity is arranged on the lower side of the dust removal chamber; a cooling cavity is arranged on the lower side of the ventilation cooling chamber; and an air draft cavity is arranged between the dust removal cavity and the cooling cavity. Dust removal and ventilation cooling are performed on air inside the machine room ofthe communication base station by the aid of the arranged dust removal chamber and ventilation cooling chamber, treatment is performed simultaneously, and one machine can have multiple purposes, so that the equipment is small in size and convenient to use.

Owner:王大庆

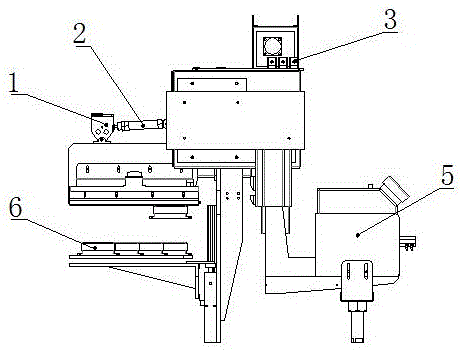

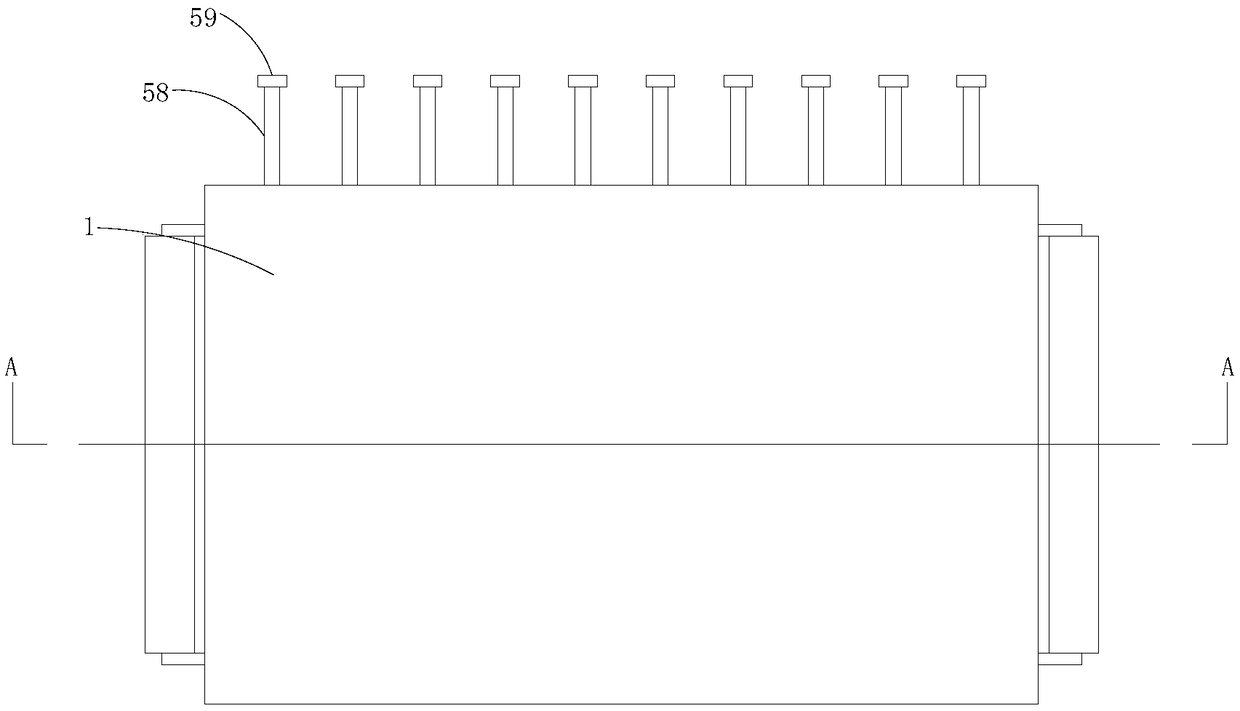

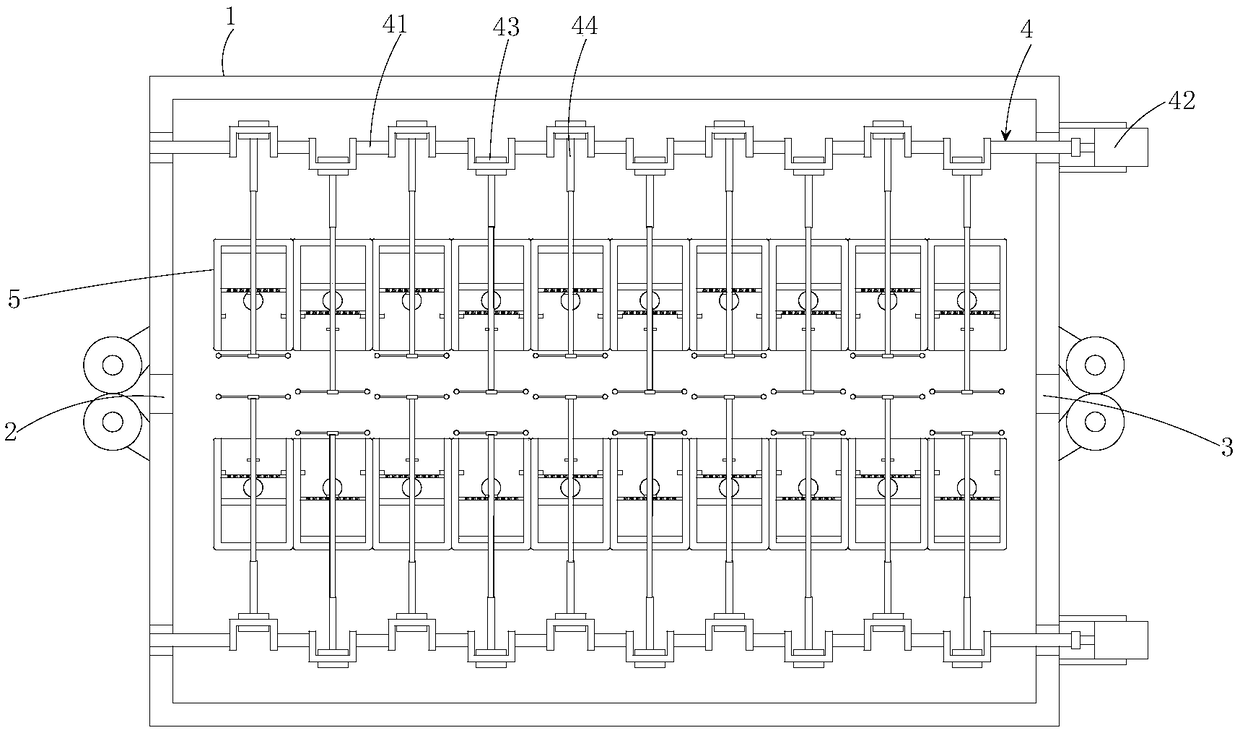

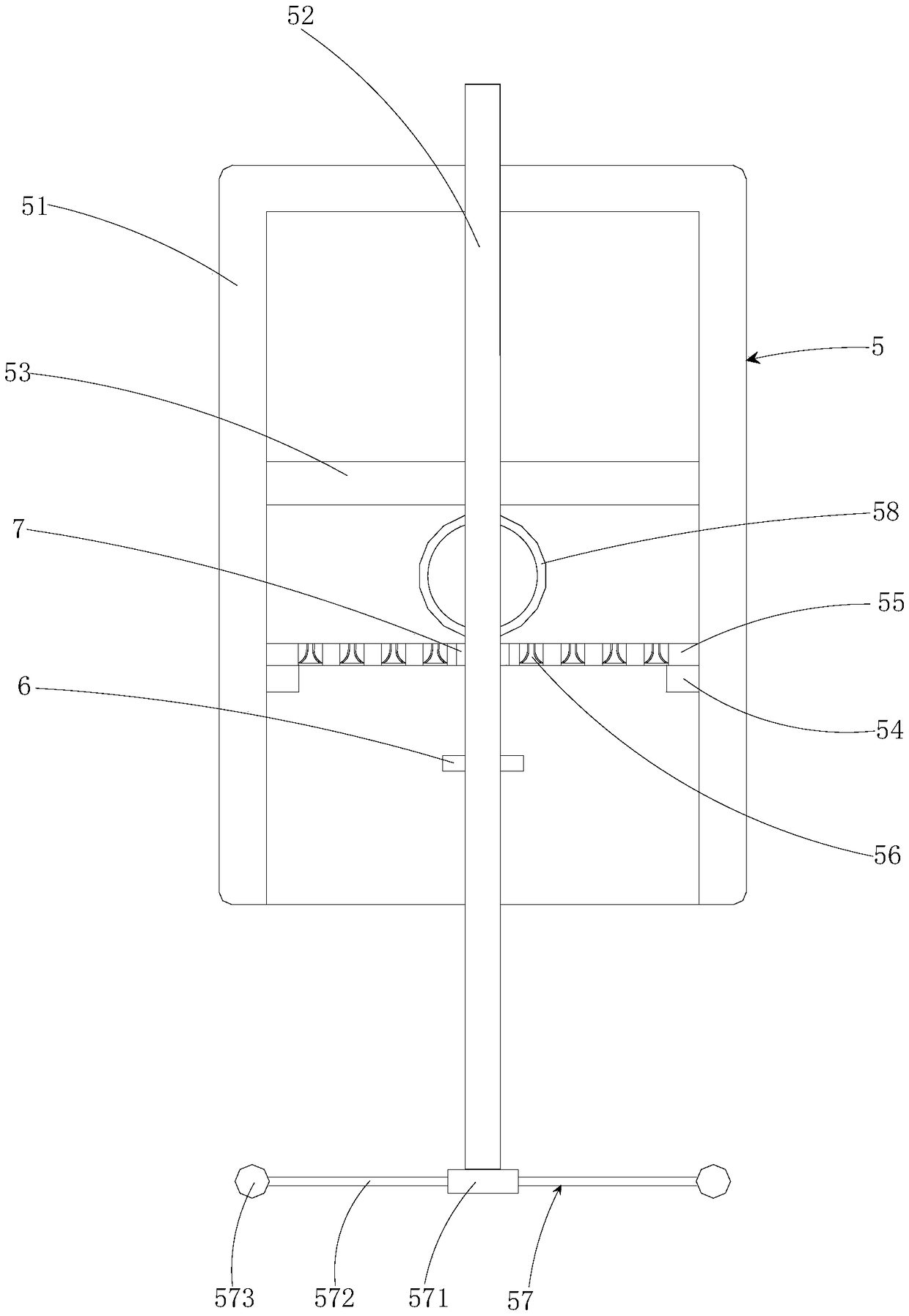

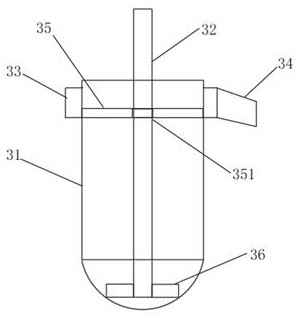

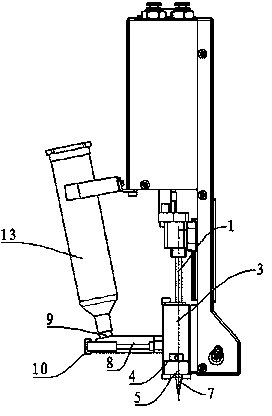

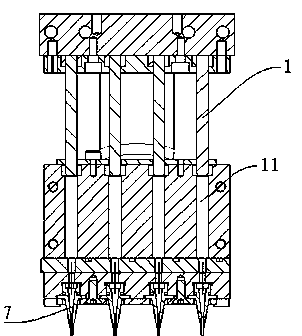

Multi-array glue dispensing device

InactiveCN103386389AWill not flow backSo as not to damageLiquid surface applicatorsCoatingsMulti-valveEngineering

The invention discloses a multi-array glue dispensing device which comprises a liquid feeding mechanism and a glue dispensing mechanism fixedly connected with the liquid feeding mechanism, wherein the glue dispensing mechanism comprises glue dispensing valves and glue dispensing needles (7); a plurality of cavities (11) are formed in valve bodies (3) of the glue dispensing valves; liquid outlets of the cavities (11) are connected with valve pins (4); the valve pins (4) are connected with a driving device in a transmission manner; liquid discharging blocks (5) are arranged at the lower ends of the valve pins (4) and are connected with the valve bodies (3) through screws; through holes corresponding to the cavities (11) are formed in the liquid discharging blocks (5) and are connected with the glue dispensing needles (7). The multi-array glue dispensing device dispenses glue simultaneously by adopting a multi-valve-rod injection mode; valve rods are driven by a stepping motor; the high-precision glue dispensing can be realized, and the production efficiency of light emitting diode (LED) product encapsulation is improved.

Owner:TONGLING FUSHI SANJIA MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com