Horizontal well buried type continuous coring inner barrel assembly

A horizontal well and coring technology, which is used in the extraction of undisturbed core devices and earthwork drilling, etc., can solve problems such as difficulty in recovering physical properties, difficulty in ensuring core properties, and affecting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

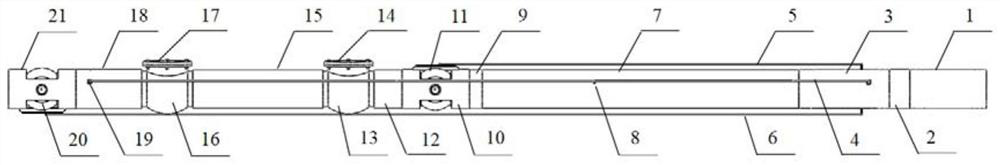

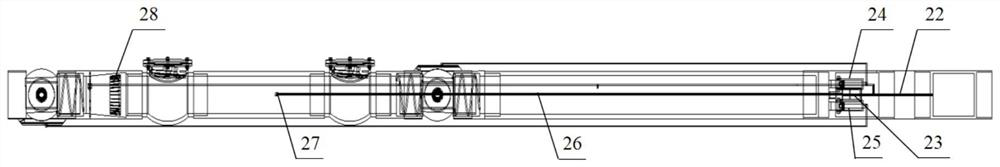

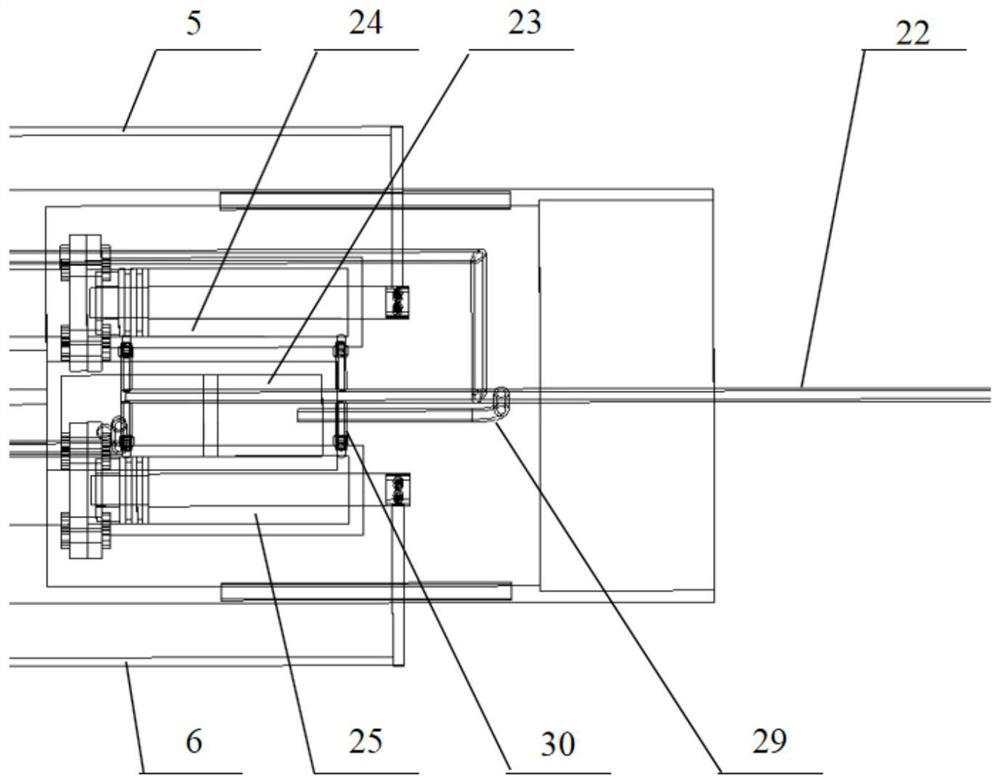

[0027] Depend on figure 1As shown, the high-pressure nitrogen chamber 1 is connected to the upper end of the control assembly 2 through threads, and the lower end of the control assembly 2 is connected to the upper end of the pneumatic cylinder seat 3 through threads. The pneumatic cylinder seat 3 is penetrated by the long rigid connecting rod 6 and the short rigid connecting rod 5, and the air pressure The lower end of the cylinder block 3 is threaded to the upper end of the storage cylinder 7, the cylinder wall of the storage cylinder 7 is provided with a storage cylinder air inlet 8, the lower end of the storage cylinder 7 is threaded to the upper end of the upper sealing ring 9, and the upper sealing ring 9 The lower end is threaded to the upper end of the upper ball valve seat 10, the upper ball valve seat 10 is connected to the upper ball valve 11 by bolts, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com