Quartz sand pickling method and device

A quartz sand and pickling technology, which is applied in the field of quartz sand purification, can solve the problems of affecting the efficiency of quartz sand pickling, the quality of quartz sand purification, insufficient contact between acid solution and quartz sand, and the inability to mix acid solution and quartz sand. To achieve the effect of shortening the feeding time, shortening the cleaning time and improving the pickling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

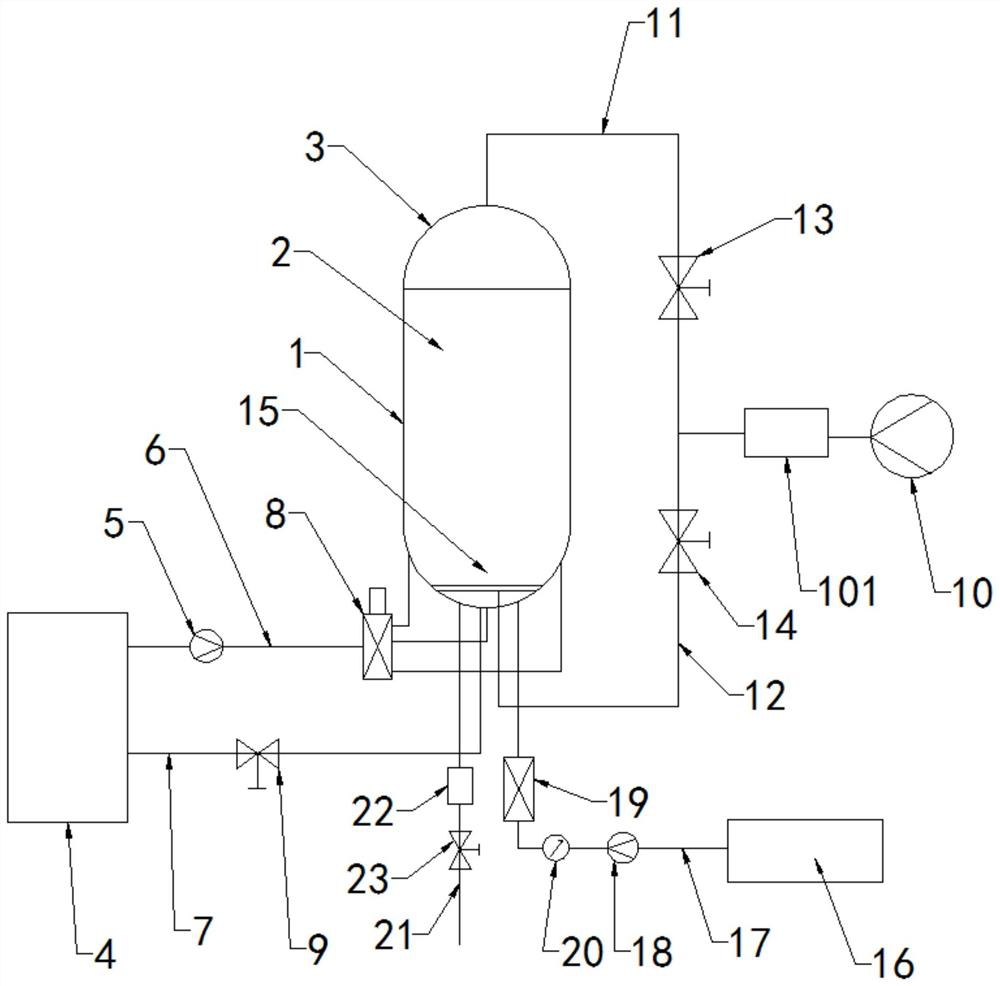

[0034] Such as Figure 1~3 As shown, the invention discloses a quartz sand pickling device. In a specific embodiment of the invention, it includes a pickling bed 1 with a cavity 2 for placing quartz sand, and the upper end of the pickling bed 1 is detachable. A sealing cover 3 that can seal the cavity 2 is connected; one side of the pickling bed 1 is provided with a pickling device for delivering acid liquid from the bottom of the cavity 2 to the bottom of the quartz sand and a device for delivering compressed air into the cavity 2 The gas supply device is used to supply gas from the upper or lower end of the pickling bed 1 to the cavity 2; it also includes a water supply device used to deliver pure water to the bottom of the quartz sand.

[0035] In the present invention, the acid solution adopts mixed acid, and the components of the mixed acid are: 1-10% hydrofluoric acid, 1-15% hydrochloric acid, 1-15% nitric acid, and the reaction between hydrofluoric acid and quartz sand ...

Embodiment 2

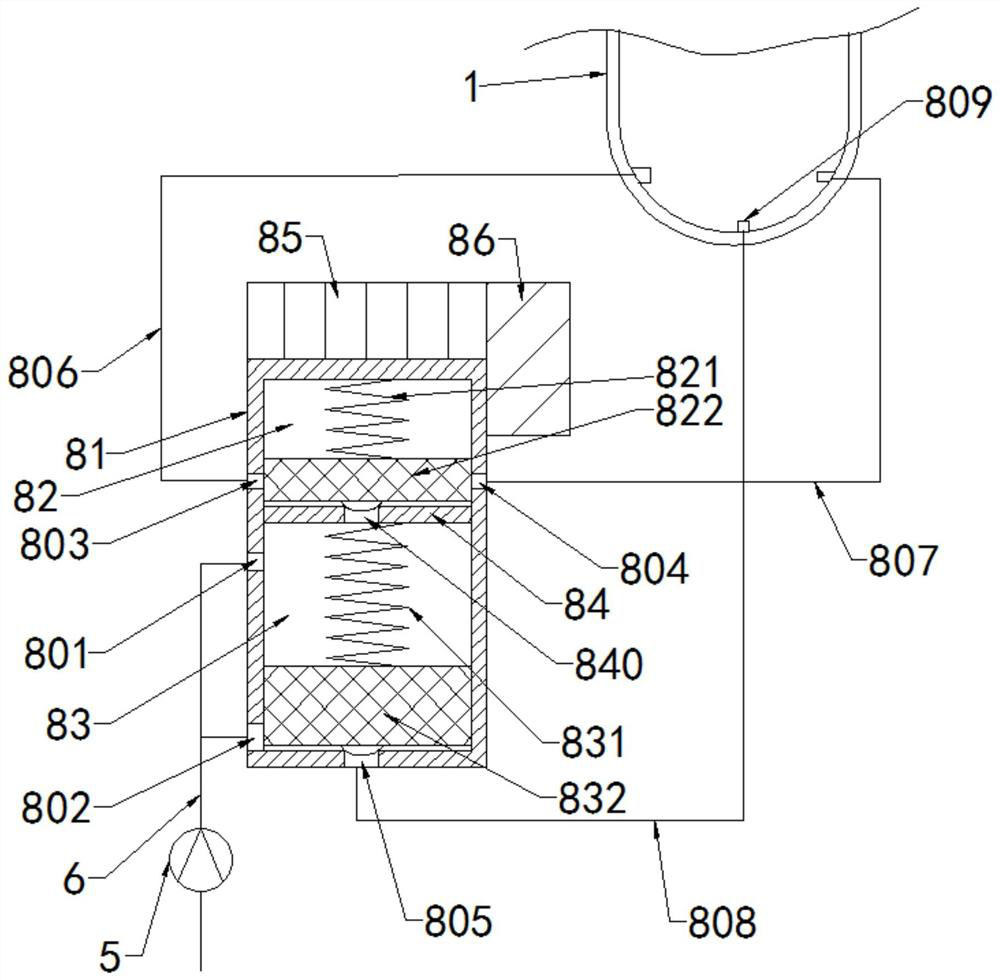

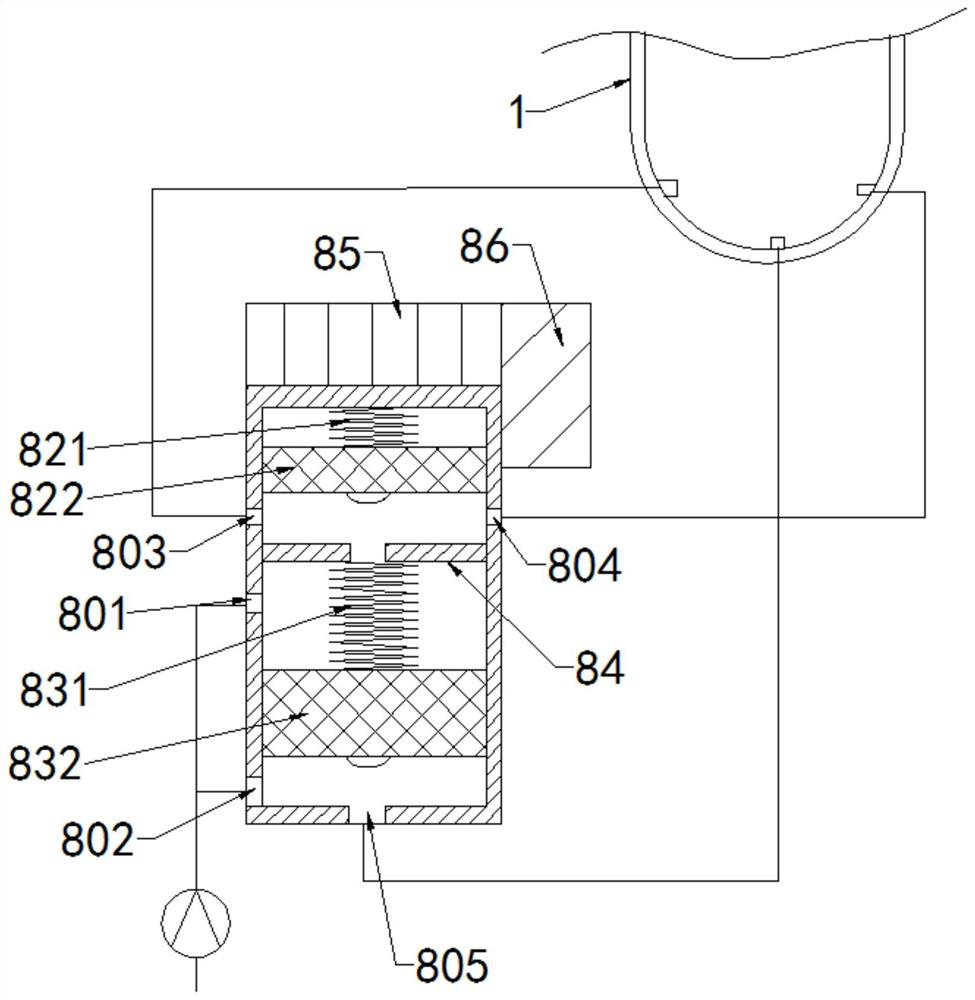

[0048] Such as Figure 4 and Figure 5 As shown, the difference between this embodiment and the above embodiment is that in this embodiment, a gas dispersion device 15 is provided at the bottom of the cavity 2 of the pickling bed 1, and the gas dispersion device 15 is connected to the second gas supply pipe 12, the gas dispersing device 15 includes a horizontal plate 151 horizontally arranged in the pickling bed 1 and several evenly arranged partition columns 152 arranged at the bottom of the cavity 2 of the pickling bed 1. The upper and lower sides of each partition column 152 The ends are fixedly connected with the horizontal plate 151 and the bottom wall of the pickling bed 1 respectively. The distance between the partition columns 152 is equal and an exhaust channel 153 is formed between the partition columns 152. The upper ends of the horizontal plates 151 are provided with exhaust channels at intervals. Plate 154, the exhaust plate 154 is fixed in the pickling bed 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com