Stainless steel hot rolling strip steel acid pickling process

A technology of hot-rolled strip steel and stainless steel, which is applied in the direction of manufacturing tools, metal processing equipment, grinding machines, etc., can solve the problems of high one-time investment, high maintenance, high operating costs, and reduced production efficiency of shot blasting machines, so as to reduce surface roughness Degree and investment, reduced downtime for maintenance, and reduced waste water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

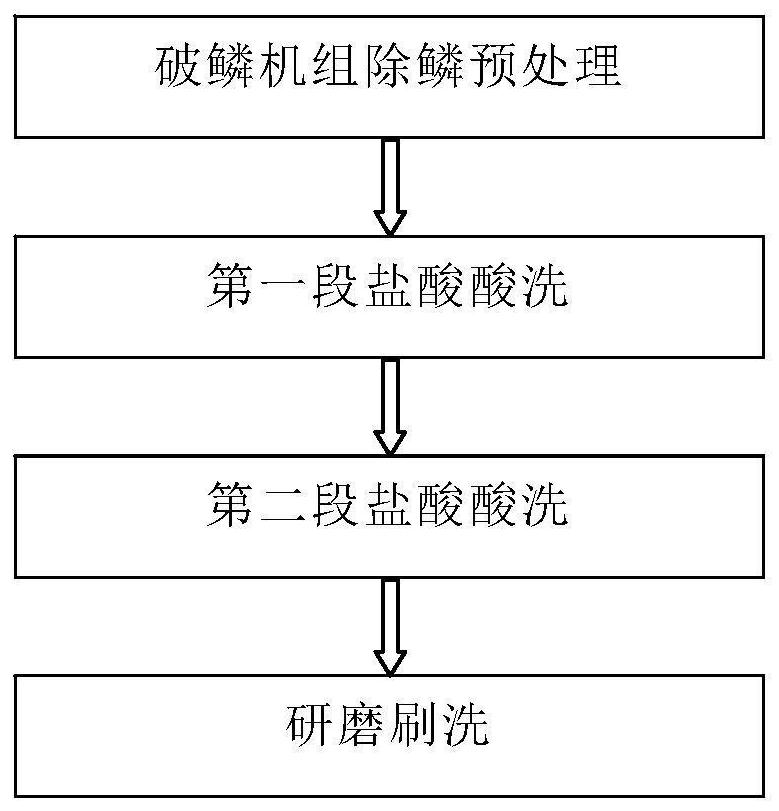

[0027]The stainless steel hot-rolled strip steel high surface environment-friendly pickling process of embodiment 1 is aimed at the strip steel to be treated is 430 ferritic stainless steel hot-rolled strip steel, and its thickness is 3.0mm, and this technique comprises the following steps:

[0028] (1) The 430 ferritic stainless steel hot-rolled strip enters the descaling unit in series from the entrance section through the entrance looper, the total elongation is controlled at 4.5%, and descaling pretreatment is carried out;

[0029] (2) Immerse the 430 ferritic stainless steel hot-rolled strip through the descaling pretreatment in the first stage hydrochloric acid pickling solution to carry out the first stage hydrochloric acid pickling, the hydrochloric acid concentration of the first stage hydrochloric acid pickling solution is 185g / L , The iron ion concentration is 20g / L, the temperature is 70°C, and the first hydrochloric acid pickling time is 30s;

[0030] (3) immerse ...

Embodiment 2

[0033] The stainless steel hot-rolled strip steel high surface environment-friendly pickling process of embodiment 2 is aimed at the strip steel to be treated is 441 ferritic stainless steel hot-rolled strip steel, and its thickness is 3.5mm, and this technique comprises the following steps:

[0034] (1) The 441 ferritic stainless steel hot-rolled strip enters the scale-breaking unit connected in series through the entrance loop through the entrance section, and the total elongation is controlled at 7%, and the scale-removing pretreatment is carried out;

[0035] (2) Immerse the 441 ferritic stainless steel hot-rolled strip through the descaling pretreatment in the first stage hydrochloric acid pickling solution to carry out the first stage hydrochloric acid pickling, the hydrochloric acid concentration of the first stage hydrochloric acid pickling solution is 220g / L , The iron ion concentration is 18g / L, the temperature is 75°C, and the first hydrochloric acid pickling time is...

Embodiment 3

[0039] The stainless steel hot-rolled strip steel high surface environment-friendly pickling process of embodiment 3 is aimed at the strip steel to be treated is 4Cr13 martensitic stainless steel hot-rolled steel strip steel, and its thickness is 3.0mm, and this technique comprises the following steps:

[0040] (1) The 4Cr13 martensitic stainless steel hot-rolled strip enters the scale-breaking unit connected in series through the entrance loop through the entrance section, and the total elongation is controlled at 4%, and the scale-removing pretreatment is carried out;

[0041] (2) Immerse the 4Cr13 martensitic stainless steel hot-rolled strip through the descaling pretreatment in the first stage hydrochloric acid pickling solution to carry out the first stage hydrochloric acid pickling, the hydrochloric acid concentration of the first stage hydrochloric acid pickling solution is 100g / L , The iron ion concentration is 15g / L, the temperature is 65°C, and the first hydrochloric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com