Patents

Literature

86results about How to "Shorten pickling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

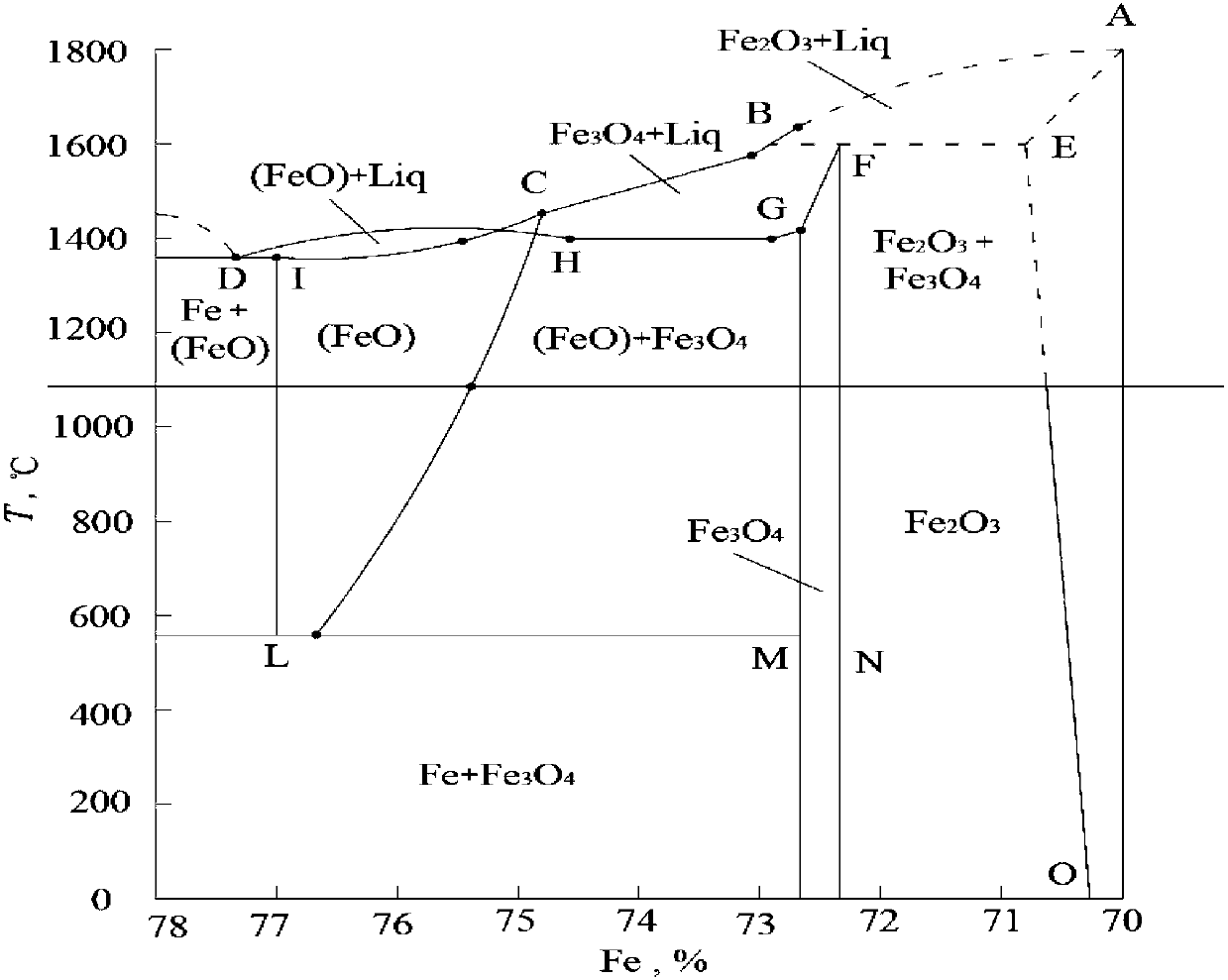

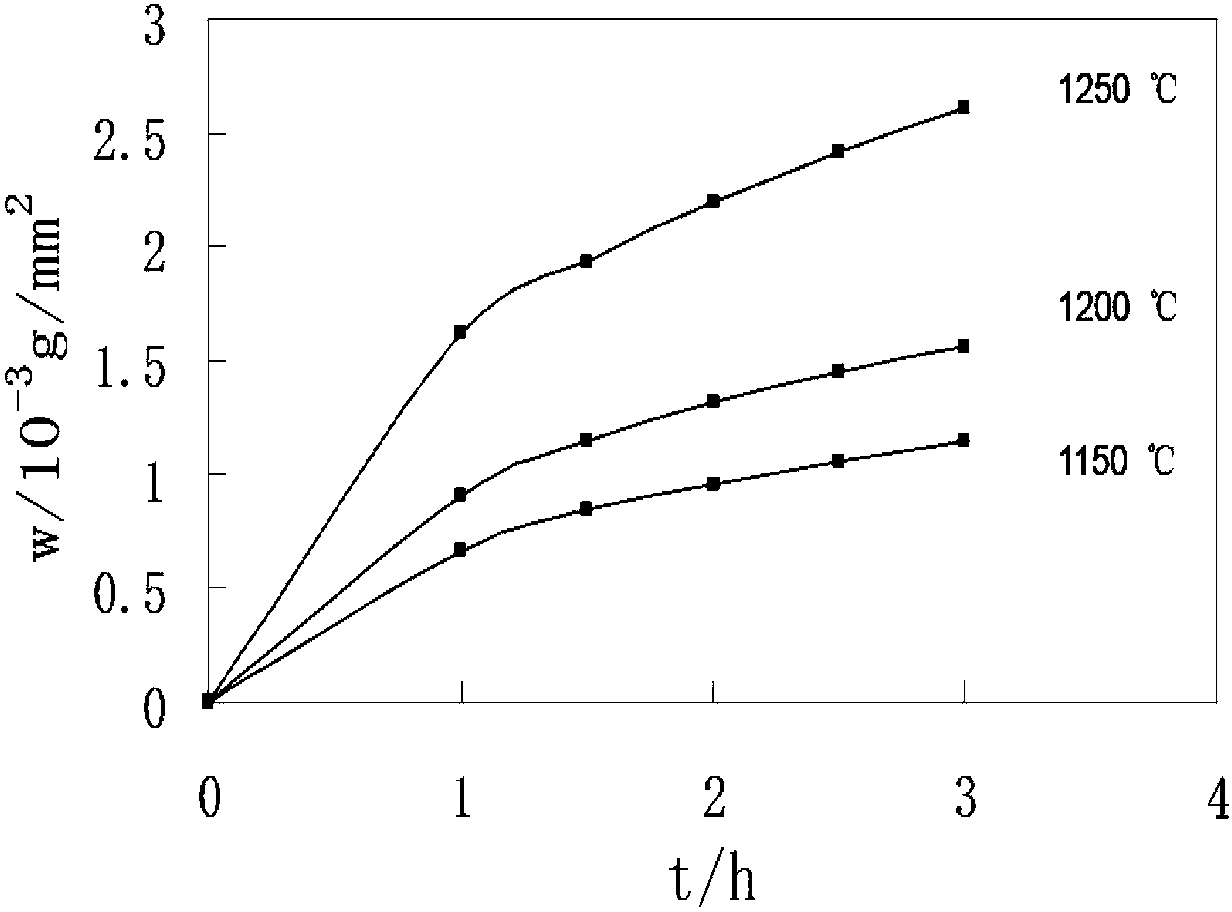

Method for reducing thickness of oxide scale on surface of hot-rolled steel sheet

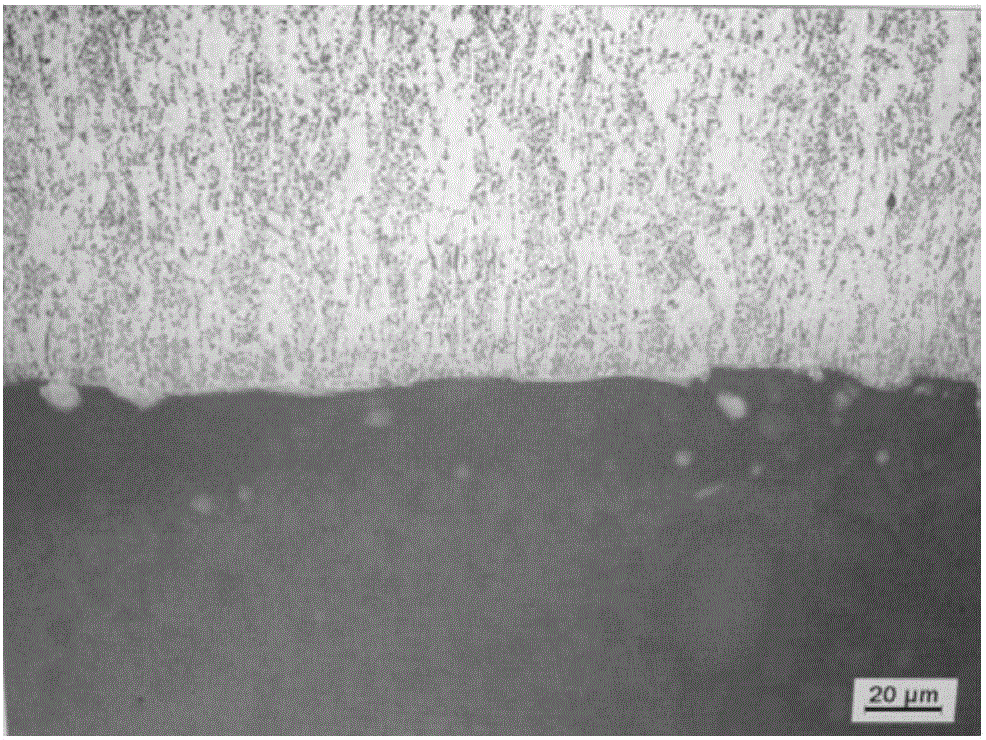

InactiveCN103341498ALess weight gainReduce thicknessTemperature control deviceMetal rolling arrangementsAustenite grainSheet steel

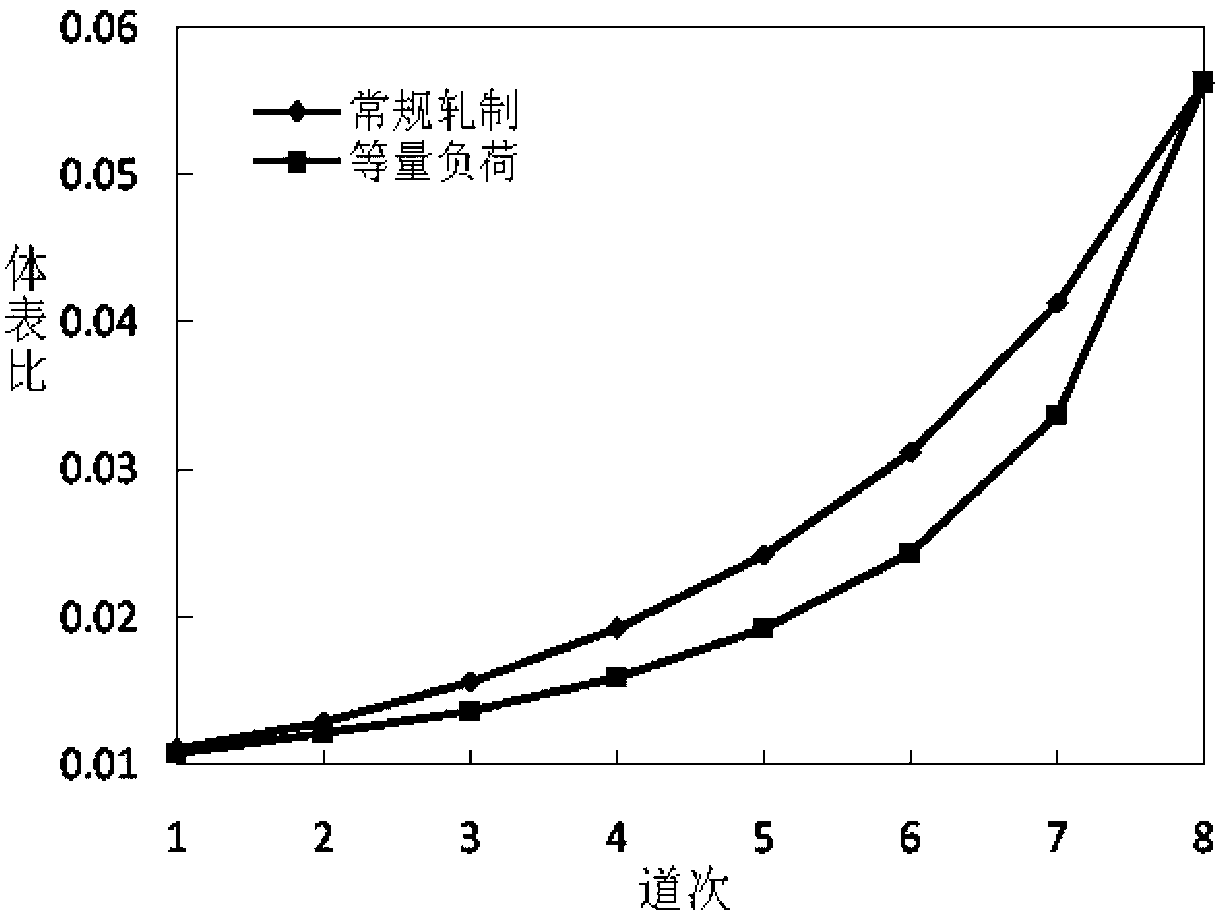

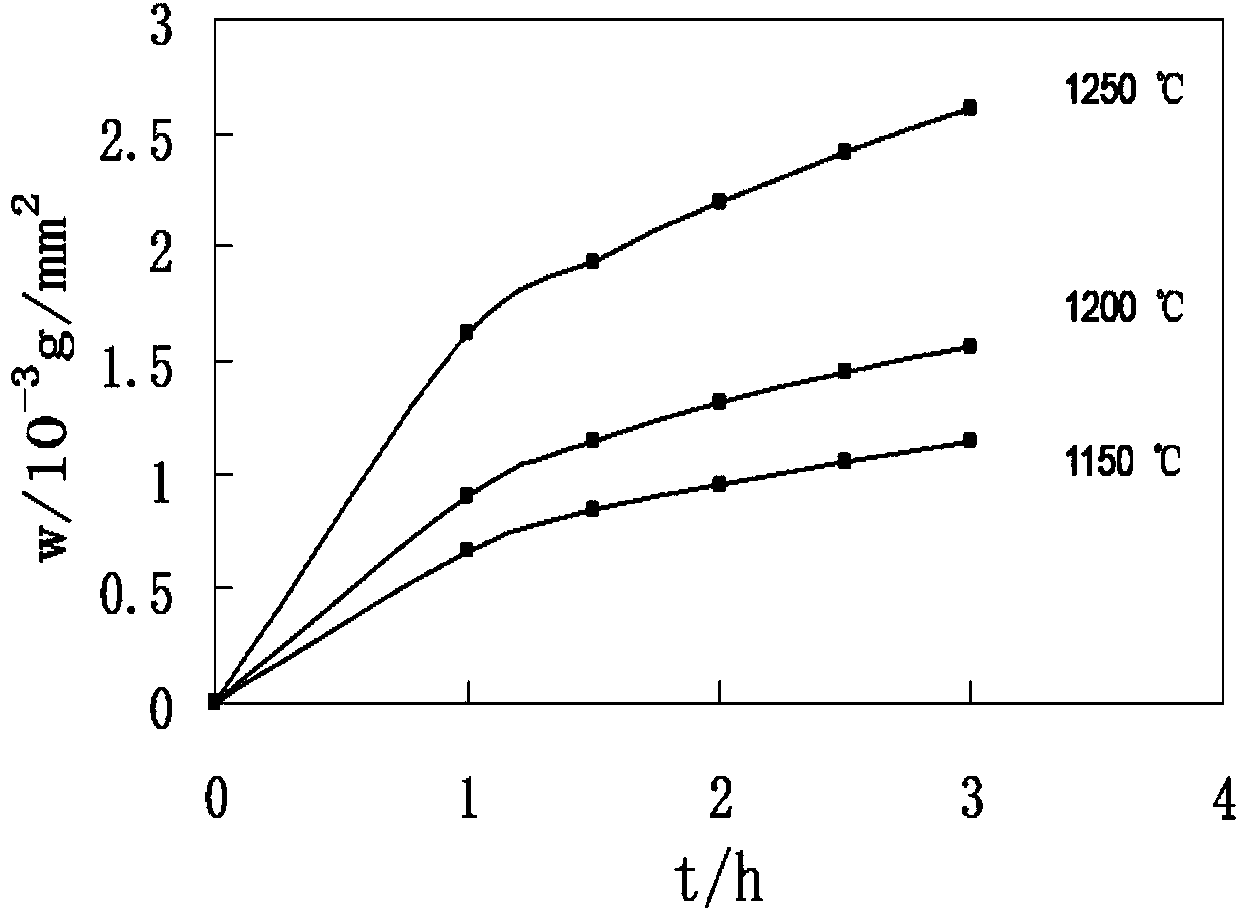

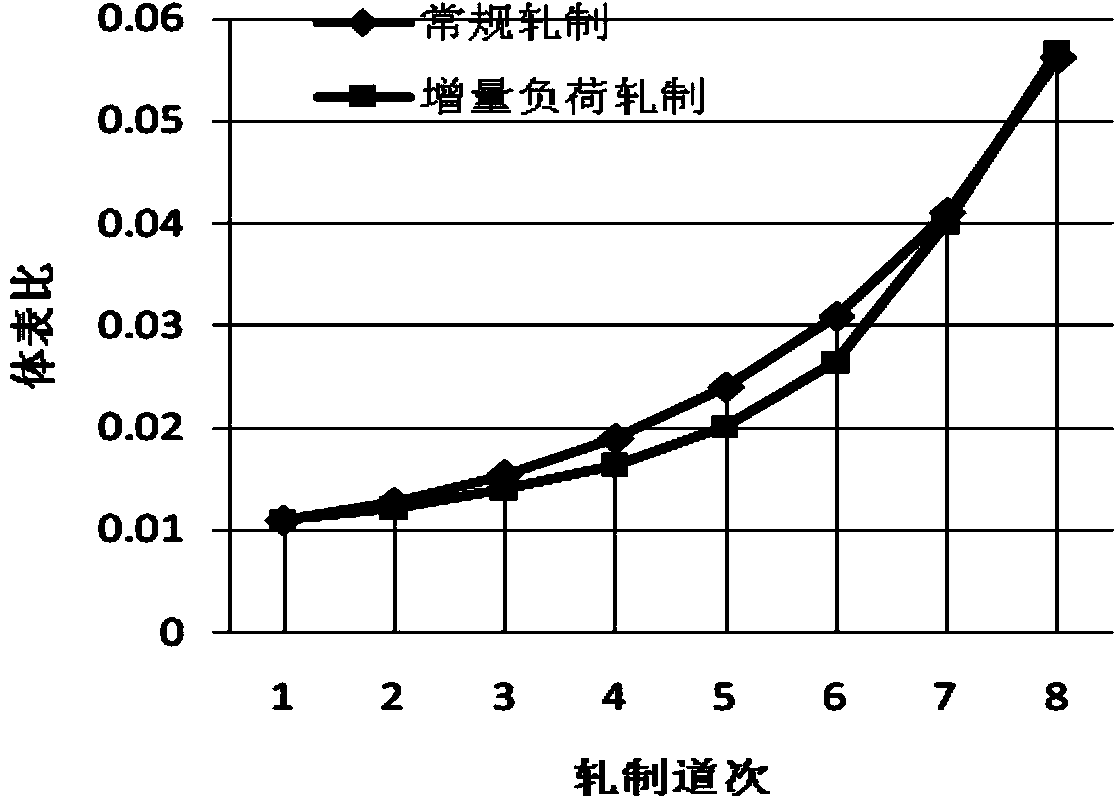

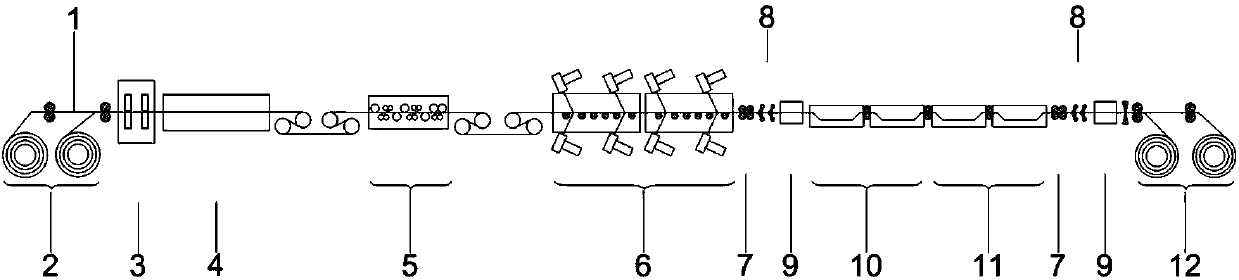

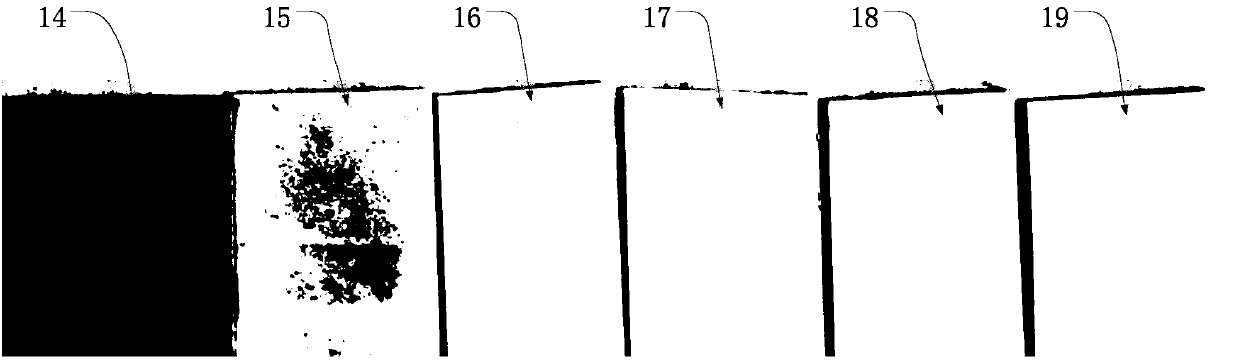

The invention discloses a method for reducing the thickness of oxide scale on the surface of a hot-rolled steel sheet. The method for reducing the thickness of the oxide scale on the surface of the hot-rolled steel sheet comprises the steps of dephosphorization before rough rolling of a continuous casting billet, and control over rough rolling, wherein the total deformation of the rough rolling is 70%-85%, and the rolling reduction of passes of the rough rolling is controlled to be equal. The process of rough rolling is controlled, the pass load is distributed again, the rolling reduction of the passes can be equal, and the body surface of a slab is gradually increased along with reduction of the temperature. The body surface ratio of the slab in each pass is smaller than that of a slab in a corresponding pass in a rolling method that the rolling reduction decreases pass by pass under the premise that the total deformation of the rough rolling is the same, thus, the purpose of reducing the thickness of the oxide scale and the purpose of pressing the oxide scale are achieved, the surface quality of the hot-rolled steel sheet is improved, the acid amount and the time for acid pickling in the follow-up working procedure are reduced, and production efficiency and metal yield are improved. When the method for reducing the thickness of the oxide scale on the surface of the hot-rolled steel sheet is adopted, the size of a recrystallized austenite grain can be reduced, and the method for reducing the thickness of the oxide scale on the surface of the hot-rolled steel sheet is beneficial to obtaining even microstructures, and improves strength, ductility and toughness of the hot-rolled steel sheet.

Owner:武汉钢铁有限公司

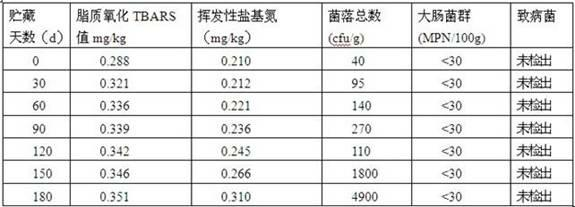

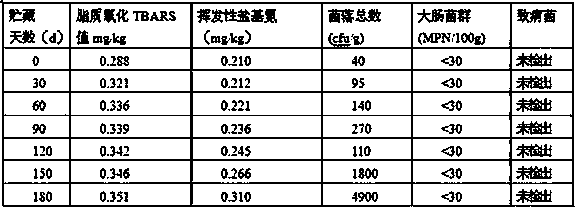

Processing method for improving quality of instant chicken feet by adopting ultrasonic combined with electron beam cold sterilization

The invention provides a processing method for improving the quality of instant chicken feet by ultrasonic combined with electron beam cold sterilization, and relates to the technical field of sterilization and freshness preservation of poultry machining and electronic accelerators. The processing method comprises the following steps of: thawing, trimming and washing chicken feet; bleaching and washing; boiling; ultrasonically pickling; and packaging and carrying out electron beam sterilization. According to the invention, a novel process of ultrasonic auxiliary pickling is added in a pickling process of the instant chicken feet; the processing method has the effect that by utilizing cavatition effect of ultrasonic waves, the speed of immersing pricking condiments into inner parts of tissues of the chicken feet is increased, the pickling time is shortened and the integral flavor of the chicken feet is improved; furthermore, the instant chicken feet are treated by the electron beam cold sterilization, and the processing method has the obvious advantages of short sterilization time, no temperature changes and low production cost, and can keep the original pickled flavor of the instant chicken feet to the greatest extent. Therefore, the method can improve the flavor quality of the instant chicken feet and can shorten the manufacturing and processing periods; the aims of rapidly sterilizing and prolonging the quality guarantee period of products are achieved; and finally, the instant chicken feet product with high quality is obtained.

Owner:上海束能辐照技术有限公司 +1

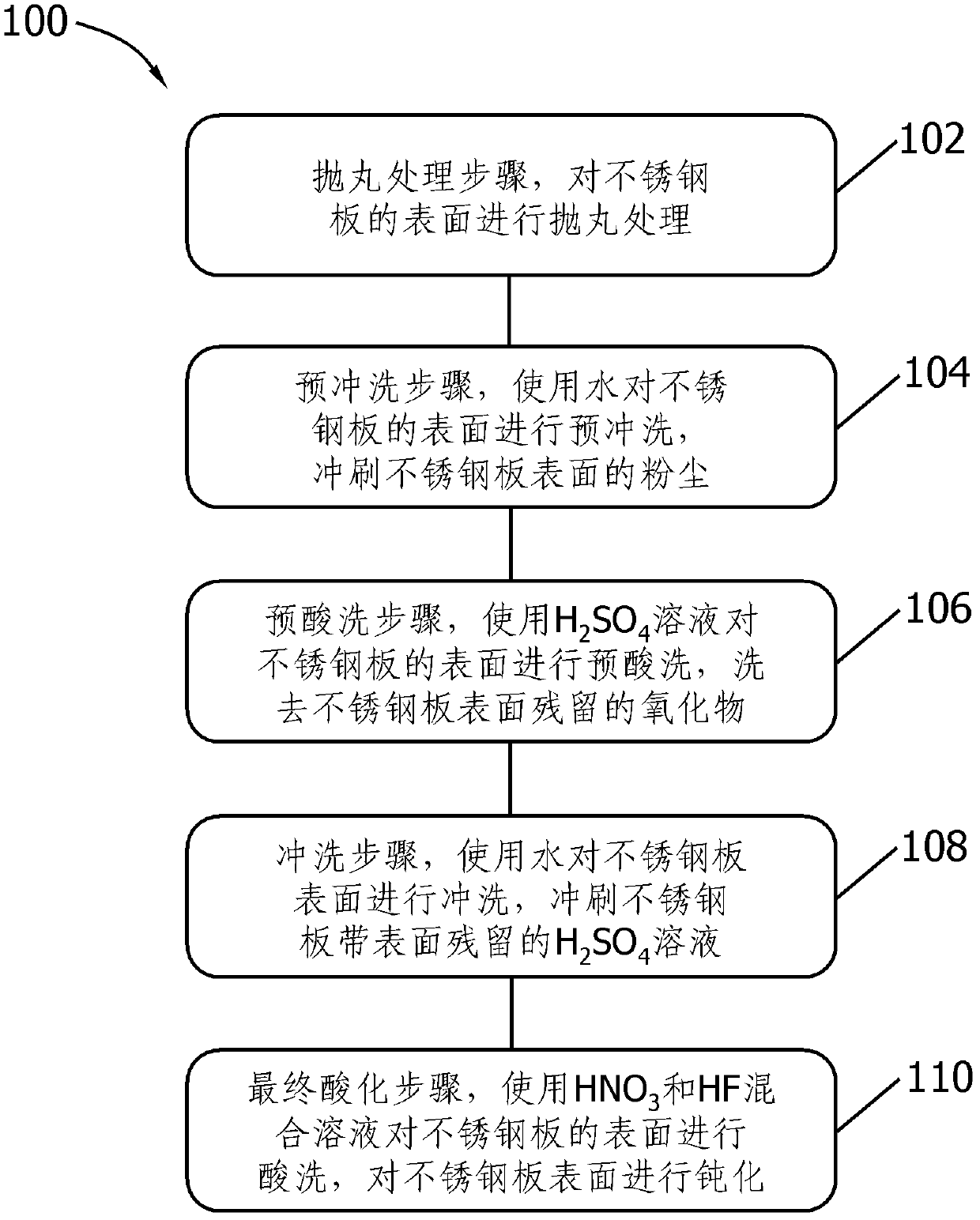

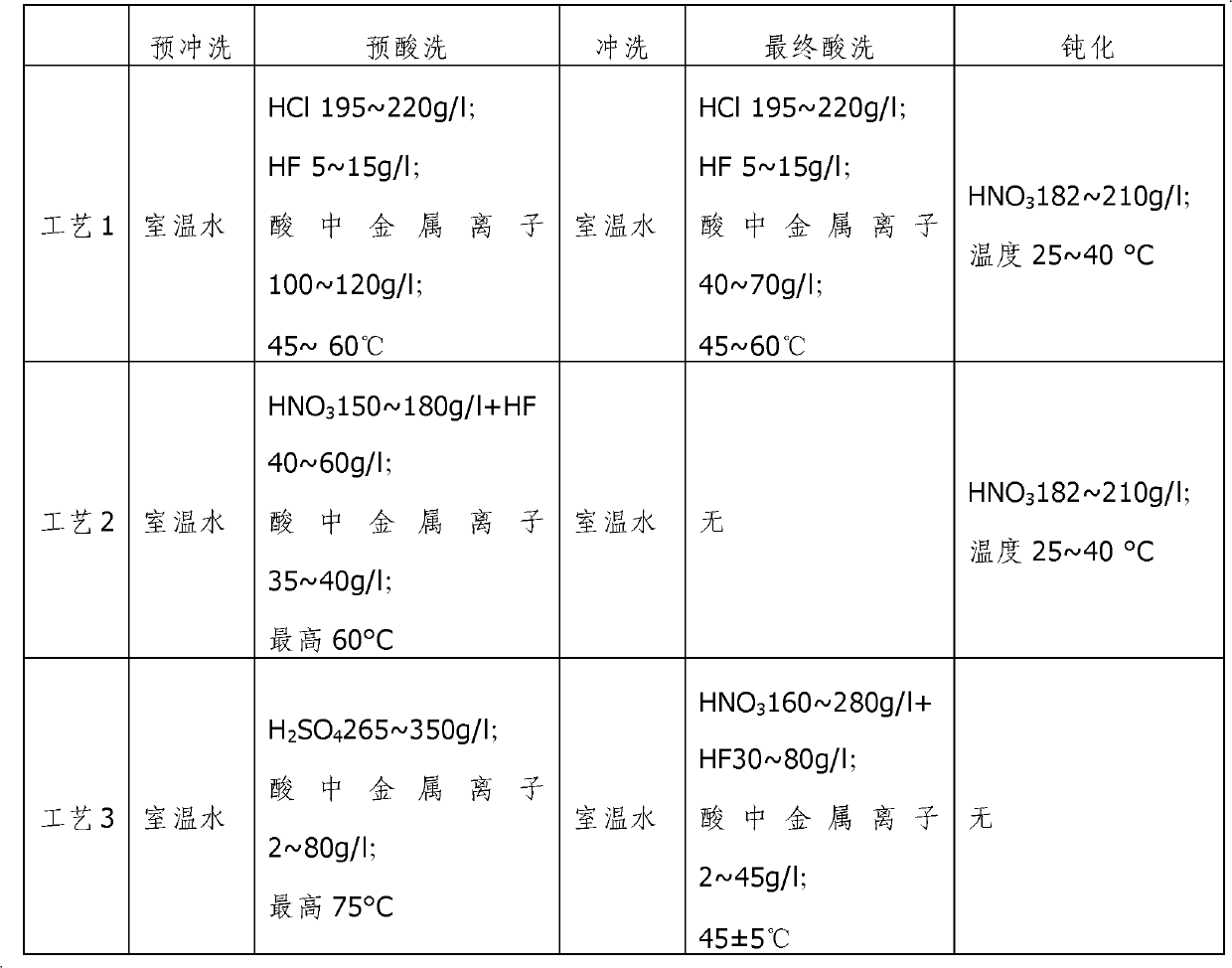

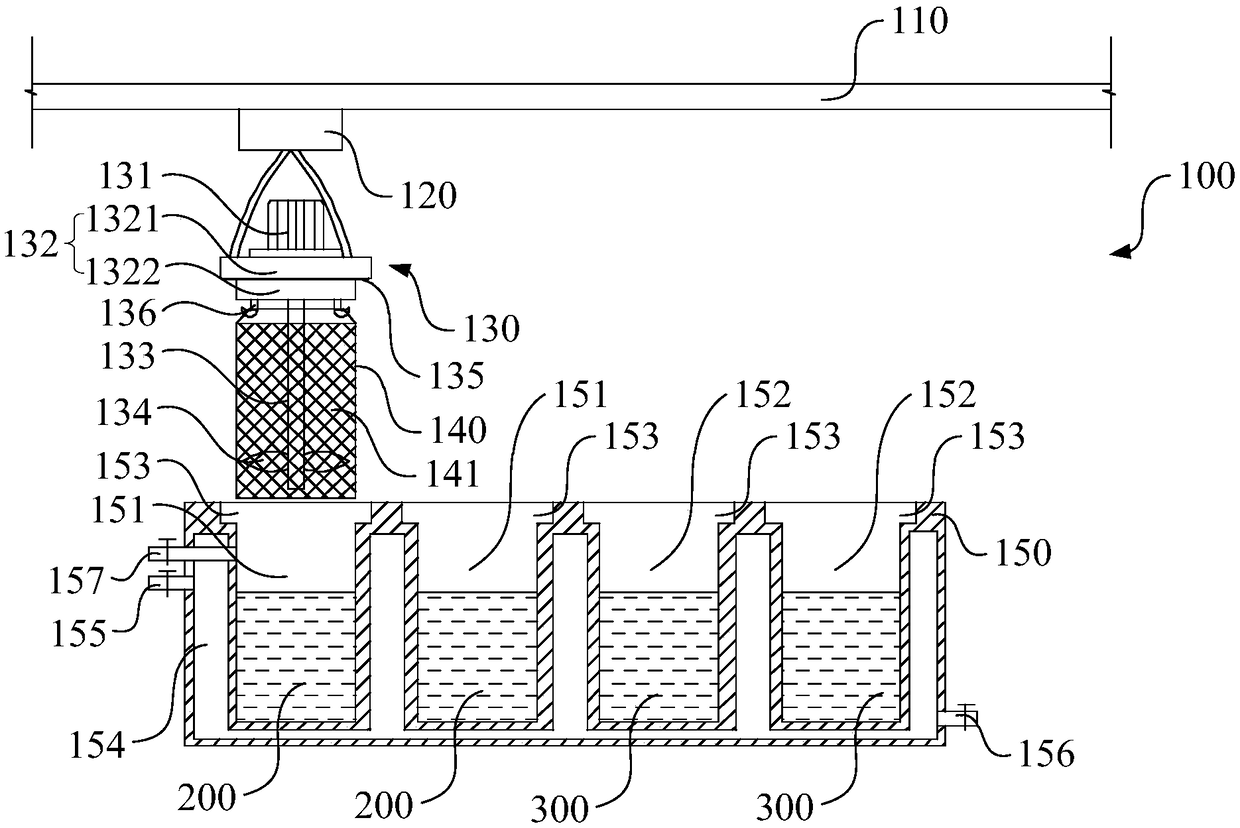

Plate strip temperature pickling process

The invention discloses a plate strip temperature pickling process, which includes: a shot blasting treatment step, in which shot blasting treatment is carried out on the surface of a stainless steel plate; a pre-washing step, in which water is employed to wash the surface of the stainless steel plate to wash out dust thereon; a pre-pickling step, in which an H2SO4 solution is taken to conduct pre-pickling on the surface of the stainless steel plate so as to wash off residual oxides on the surface of the stainless steel plate; a washing step, in which water is used to wash the surface of the stainless steel plate so as to scour the H2SO4 solution remaining thereon; and a final acidification step, in which a mixed solution of HNO3 and HF is used to carry out pickling on the surface of the stainless steel plate so as to passivate the surface of the stainless steel plate. The process provided in the invention can shorten the pickling time of each steel plate, improve the production efficiency by over 20%, and omits a special passivation treatment procedure, thus significantly reducing the production cost.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Pickling agent for stainless steel

The invention relates to a pickling agent for stainless steel. According to percentage by weight, the pickling agent consists of the following components: 23 to 30 percent of sulfuric acid; 4 to 6 percent of nitric acid; 7 to 14 percent of hydrochloric acid; 0.1 to 0.3 percent of corrosion inhibitor; 0.13 to 0.25 percent of additive; and the balance of water. The mass concentrations of the used acids are as follows: 95.0 to 98.0 percent of sulfuric acid; 65.0 to 68.0 percent of nitric acid; and 36.0 to 38.0 percent of hydrochloric acid. The components are uniformly mixed according to proportion. The corrosion inhibitor is hexamethylene tetramine, the additive is the mixture of sodium dodecyl sulfate and isooctyl phenol polyoxyethylene, the percentage by weight of the sodium dodecyl sulfate is 0.08 to 0.15 percent, the percentage by weight of the isooctyl phenol polyoxyethylene is 0.05 to 0.1 percent, and the effect is better when the temperature of each acid is 60 DEG C to 80 DEG C. The pickling efficiency of the pickling agent for stainless steel is increased by four to five times, the pickled surface is bright and clean, and the pickling agent for stainless steel is particularly suitable for pickling the surfaces of stainless steel with high Cr, Ni and Mo alloy contents to remove ferric oxide scales.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Quartz sand cleaning device

PendingCN109226033AGood for maintaining temperatureShorten pickling timeCleaning using liquidsAcid washingQuartz

The invention provides a quartz sand cleaning device, which comprises the following steps of: loading quartz sand to be treated into a cleaning frame, installing the cleaning frame on a stirring coverafter the quartz sand is loaded, placing the cleaning frame into a first cleaning tank through lifting equipment, starting a rotating motor, driving a stirring shaft to stir the quartz sand, liftingthe cleaning frame out of the first cleaning tank through lifting equipment after the reaction is complete, and then moving the lifting equipment, so that the cleaning frame can enter a second cleaning tank, and after entering the second cleaning tank, fully removing residual acid on the surface of the quartz sand through cleaning water, so that the quartz sand can enter the next working procedure. As the cleaning tank of this embodiment integrates the first cleaning tank and the second cleaning tank, the steps of acid washing and water washing can be directly completed in one set of equipment, thus avoiding quartz sand from being respectively carried out in two different equipment in the cleaning process, thus greatly improving the cleaning efficiency of quartz sand. Meanwhile, the equipment cost for quartz sand processing is also reduced.

Owner:新沂市磊晶石英材料有限公司

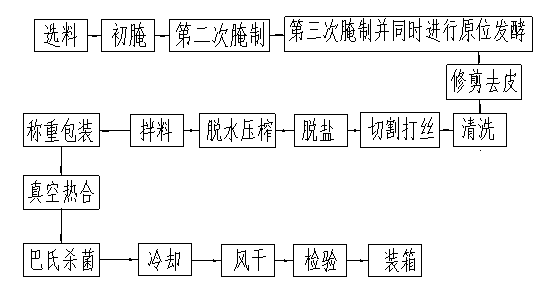

Method for employing in-situ fermentation technology to produce tuber mustard

The invention discloses a method for employing an in-situ fermentation technology to produce tuber mustard, and relates to a foodstuff processing method. The method comprises the following steps: selecting raw materials, performing first preserving, performing second preserving, performing third preserving and in-situ fermentation, trimming and peeling, cleaning, cutting and forming strips, desalinating, dewatering and squeezing, blending with materials, weighing, performing vacuum packaging, performing pasteurization, cooling, performing air drying, examining and cartonning. Compared with the prior art and methods, the preserving time of the tuber mustard produced by employing the in-situ fermentation technology is shortened to about 5.5-6.5 months from original about 6-9 months, and the produced tuber mustard is relatively mellow and pure in flavor and relatively good in quality, and is fresh, fragrant, crisp and tender.

Owner:NANXI SANJIANG FOOD

Stainless steel acid pickling technology

InactiveCN104404551AGuaranteed passivation protection treatmentAddress macular defectsUltimate tensile strengthContamination

The invention discloses a stainless steel acid pickling technology which comprises steps as follows: (1) completely immersing a workpiece in an acid pickling tank at the temperature of 30-55 DEG C for 3-5 min; (2) washing the workpiece with clear water; (3) performing acid pickling with an HNO3 and HF mixed solution used as an acid pickling solution, wherein the content of HNO3 is in a range of 180-290 g / l, the content of HF is in a range of 26-60 g / l, the content of metal ions is in a range of 5-45 g / l, and the temperature of the acid pickling solution is in a range of 55-65 DEG C. With the adoption of the stainless steel acid pickling technology, the corrosion resistance of stainless steel is improved effectively, the fingerprint contamination resistance of the stainless steel is improved, and the surface decoration property of stainless steel products is guaranteed; the technology has the characteristics of simplicity, low production cost, low environmental pollution, easiness in operation, low labor intensity, low energy consumption and high efficiency; the defects that the stainless steel cannot be drawn to be fine and is brittle and easy to break are overcome.

Owner:QINGDAO DUANYI METAL

Silicon steel pickling promoter and preparation method thereof

The invention specifically relates to a silicon steel pickling promoter and a preparation method thereof. According to a technical scheme in the invention, the silicon steel pickling promoter is prepared from 0.1 to 5.0 wt% of a corrosion inhibitor, 10.0 to 50.0 wt% of an inorganic salt reducing agent, 0.1 to 5.0 wt% of an emulsifier, 5.0 to 20.0 wt% of an organic metal ion chelating agent, 0.1 to 5.0 wt% of a defoaming agent, 0.1 to 5.0 wt% of a synergist and 20.0 to 80.0 wt% of water through uniform mixing at normal temperature with stirring. The silicon steel pickling promoter provided by the invention has the characteristics of convenience in usage, high pickling efficiency, low cost, environment friendliness, a good corrosion inhibition effect, etc.

Owner:WUHAN UNIV OF SCI & TECH

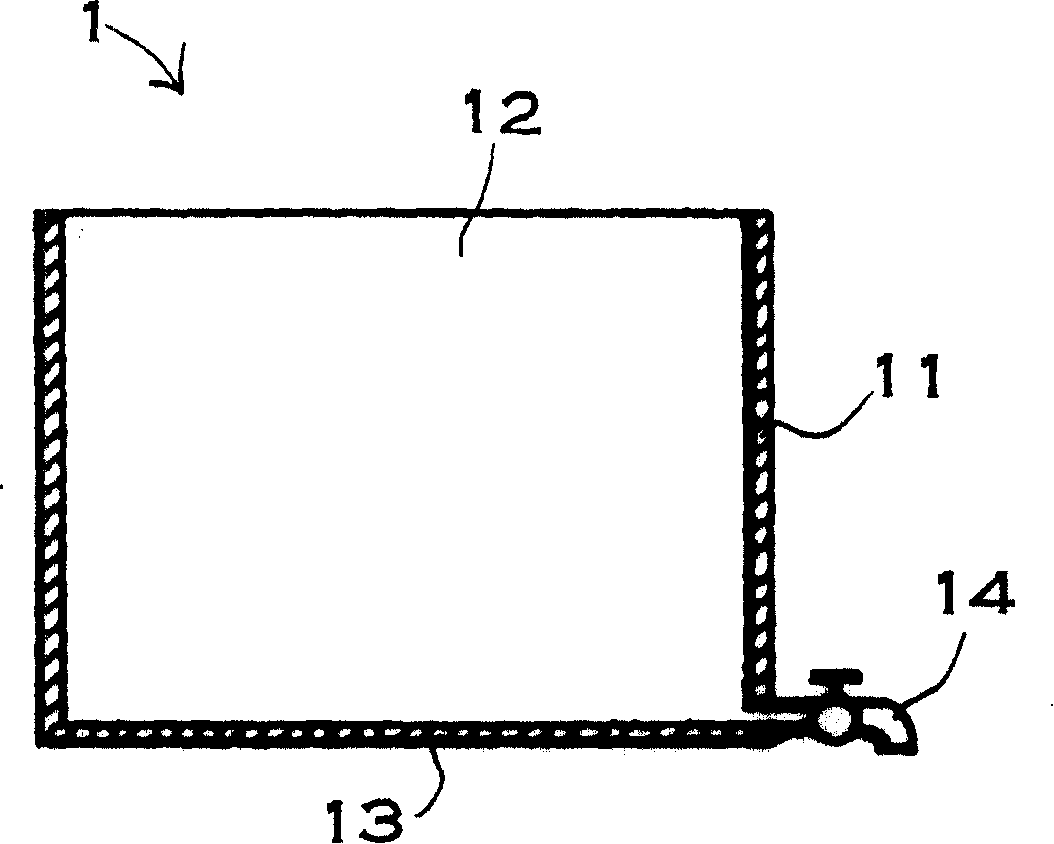

Method for restoring plant green or preserving plant green

The present invention relates to a method for restoring a green color of a plant and keeping the plant in the green color, capable of preventing deterioration of quality of the plant caused by heat. The method for restoring the green color of the plant and keeping the plant in the green color comprises contacting the plant with yeast, wherein a yeast solution contains at least one kind of ion of zinc, copper, iron, and magnesium, so that the yeast solution is contacted with the plant in a time of 10 days or more. The plant is soaked in the yeast solution in such a state that the plant has the green color. The plant is preferably contacted with the yeast in an unheated state in a container which is so formed and structured that an inner surface of the container has an exposed ground metal of an alloy containing the copper and / or the zinc. A green and yellow vegetable, a citrus fruit, a vegetable for pickles, or a fruit therefor is preferably used as the plant. Further, the method preferably includes a step for heating the plant at 60 to 100 DEG C for a time of 1 min or more.

Owner:株式会社佐藤运送

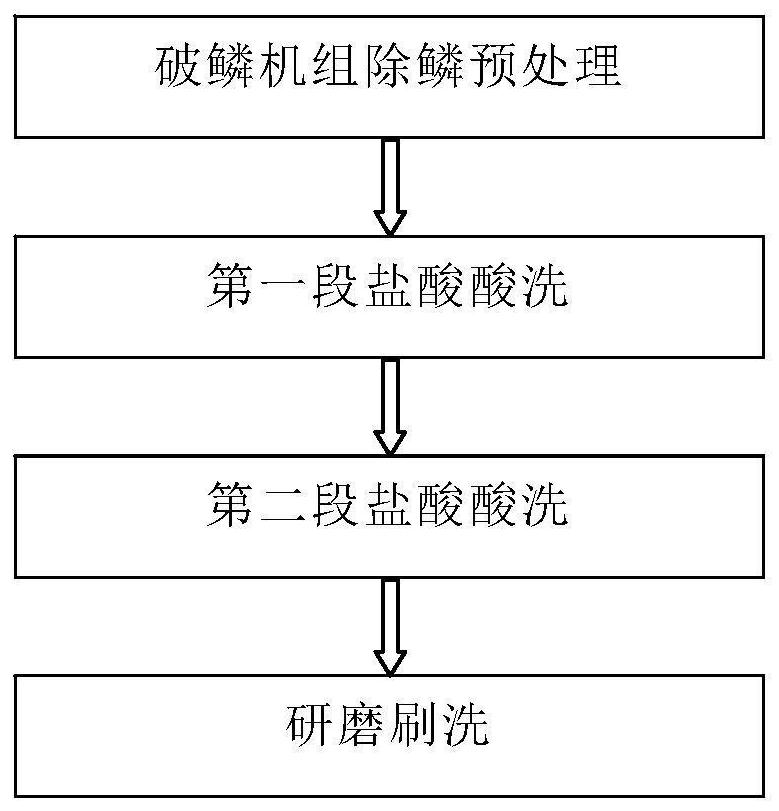

Stainless steel hot rolling strip steel acid pickling process

InactiveCN111604786AImprove surface qualityImprove pickling effectGrinding drivesGrinding machinesCarbide siliconStrip steel

The invention relates to a stainless steel hot rolling strip steel acid pickling process. The process comprises the steps of scale breaking unit scale removal pretreatment, wherein the total extensionrate of strip steel is controlled to be larger than or equal to 3.0%; first-segment hydrochloric acid acid pickling, wherein the strip steel is immersed in first-segment hydrochloric acid acid pickling liquid to be subjected to first-segment hydrochloric acid acid pickling, the hydrochloric acid concentration of the first-segment hydrochloric acid acid pickling liquid is controlled to 50 to 300 g / L, the iron ion concentration is controlled to 5 to 100 g / L, the temperature is controlled to 60 to 80 DEG C, and the acid pickling time is controlled to 25 s to 50 s; second-segment hydrochloric acid acid pickling, wherein the strip steel is immersed in second-segment hydrochloric acid acid pickling liquid to be subjected to second-segment hydrochloric acid acid pickling, the hydrochloric acid concentration of the second-segment hydrochloric acid acid pickling liquid is controlled to 50 to 250 g / L, the iron ion concentration is controlled to 5 to 100 g / L, the temperature is controlled to 50to 75 DEG C, and the acid pickling time is controlled to 25 s to 50 s; grinding scrubbing, wherein the strip steel is subjected to grinding scrubbing, the diameter of roller brush bristles is controlled to 0.7 to 1 mm, the bristles contain silicon carbide abrasives with meshes being 170 to 200 meshes, the rotating speed of a roller brush motor is controlled to 600 to 1000 rpm, and the current of the roller brush motor is controlled to 100 to 200 A.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

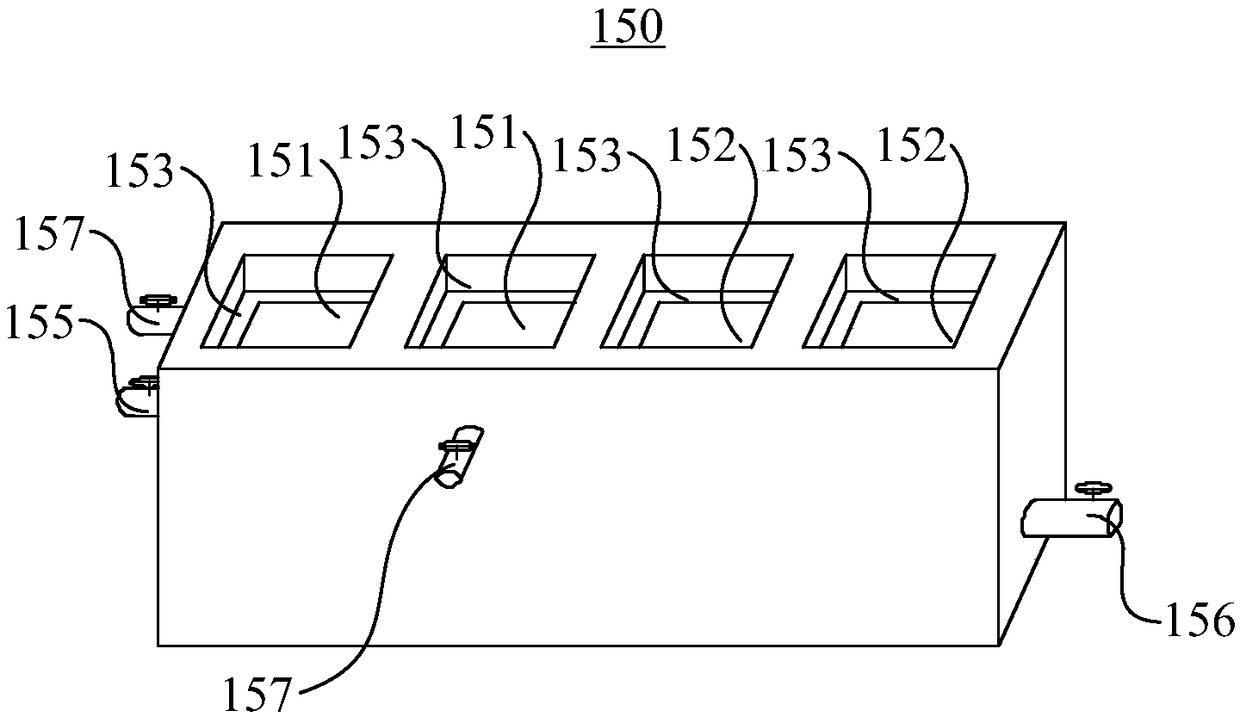

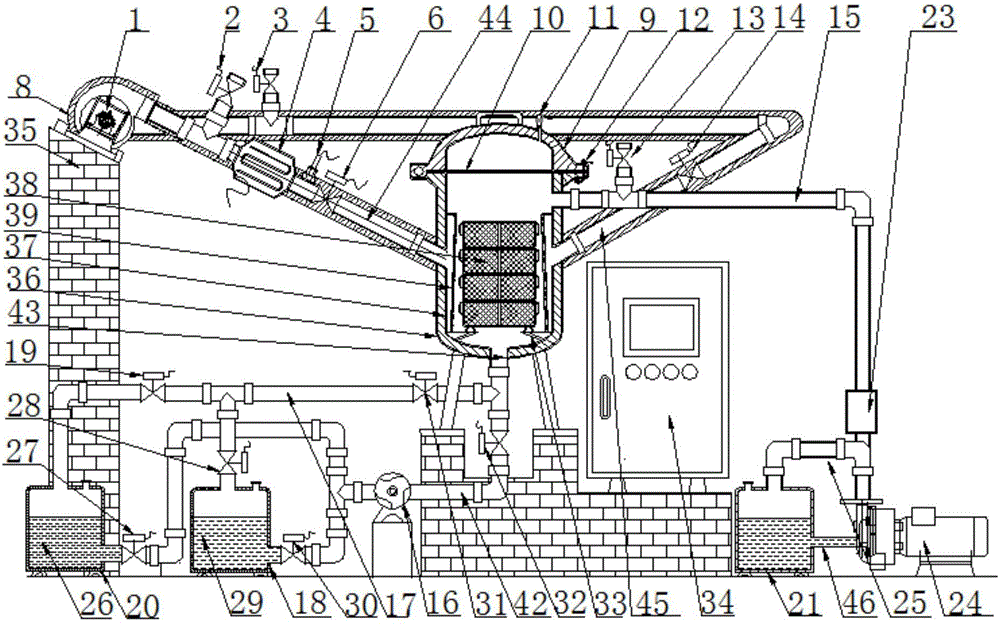

Fruit and vegetable vacuum pulsation pickling and hot-air drying integrated equipment

InactiveCN106615552AShorten pickling timeIncrease pickling rateConfectionerySweetmeatsAutomatic controlSolvent

The invention relates to fruit and vegetable vacuum pulsation pickling and hot-air drying integrated equipment. The fruit and vegetable vacuum pulsation pickling and hot-air drying integrated equipment comprises a material pickling system, a vacuum pulsation system, a material cleaning system, a hot air drying system and an automatic control system, and can realize high-efficient integration of vacuum pulsation pickling, cleaning solvents on surfaces of materials and drying, so that the problems that in the prior art, when pickling, cleaning and drying are respectively performed in various kinds of equipment, the equipment investment is high, the technology is complex, the renewed material distribution is high in consumption, and the labor intensity is high are solved, the processes of vacuum pulsation pickling, cleaning and drying are controlled by the automatic control system, the automation degree is high, the working efficiency is effectively improved, and human resources and material resources are saved. The equipment can be applied to high-efficient integral processing of sugar pickling foods, salt pickling foods and vinegar pickling foods.

Owner:SHAANXI UNIV OF SCI & TECH

Method for continuous annealing and pickling of stainless steel band

ActiveCN107312924AEfficient removalFulfil requirementsFurnace typesHeat treatment furnacesElectrolysisSilicic acid

The invention discloses a method for continuous annealing and pickling of a stainless steel band. The method mainly comprises the following steps that uncoiling is conducted; alkali wash is conducted, specifically, the temperature of alkali wash water is 42 DEG C-50 DEG C, and the PH value of the alkali wash water is 8.5-9.2; annealing is conducted, specifically, the temperature of an annealing furnace is set into eight sections, the temperature from an inlet to an outlet is sequentially and gradually increased from 820 DEG C to 960 DEG C, and the excessive oxygen concentration is sequentially increased from 3% to 5%; electrolysis is conducted, specifically, a electrolytic pickling solution comprises a neutral salt solution, silicic acid, nitric acid and one or more surfactant solutions; pickling is conducted, specifically, the pickling concentration is 150-170 g / L, the metal ion concentration is 50-60 g / L, and the temperature is 65-70 DEG C; first mixed pickling is conducted, specifically, the concentration of the nitric acid is 120-140 g / L, and the concentration of hydrofluoric acid is 35-50 g / L; second mixed pickling is conducted, specifically, the concentration of nitric acid is 130-140 g / L, and the concentration of hydrofluoric acid is 40-50 g / L; and wash cooling is conducted. By adoption of the method, iron oxides in an oxide skin can be effectively removed, the pickling time is greatly shortened, and the pickling effect is good.

Owner:SICHUAN TIANHONG STAINLESS STEEL

Titanizing method of reactor for sponge titanium production

InactiveCN104004987ATitanium infiltration effect is goodLess impuritiesSolid state diffusion coatingNonferrous metalTitanium tetrachloride

The invention belongs to the field of nonferrous metal chemical smelting, and particularly relates to a titanizing method of a reactor for sponge titanium production. The titanizing method of the reactor for sponge titanium production is shorter in consumed time and better in effect and is provided for solving technical problems. The titanizing method of the new reactor for sponge titanium production includes the following steps that 1 the new reactor is soaked by hot acid for 1-3 day and then is washed and dried; 2 the inner wall of the new reactor is coated with titanium scrap according to the inner wall surface area of 30-80 g / m<2>; 3 a right amount of titanium tetrachloride and a right amount of magnesium are added in the new reactor, and the temperature rises to 800-950 DEG C for titanizing, wherein the addition amount of the magnesium and the titanium tetrachloride is controlled to enable generated titanium and the wall of the new reactor to form a titanizing layer. The titanizing method is good in titanizing effect, impurities in sponge titanium generated by the reactor which undergoes titanizing are greatly reduced, damage, caused by high-temperature titanizing, to the new reactor is avoided, and the service life of the reactor after titanizing is prolonged.

Owner:SICHUAN HENGWEI TITANIUM TECH CO LTD

Method for preparing low-salt low-sodium dried salted duck through combination of ultrasonic waves and vacuum rolling

InactiveCN107821985AImprove permeabilityTo tenderize the meatInorganic compound food ingredientsMeat/fish preservation using chemicalsUltrasonic assistedSalt content

The invention discloses a method for preparing low-salt low-sodium dried salted duck through combination of ultrasonic waves and vacuum rolling. Through synergistic use of ultrasonic waves and a vacuum rolling technique, the condition that preserving liquid penetrates through duck meat is promoted, the preserving time is effectively shortened, and the preserving effect is increased; and in addition, calcium lactate and potassium chloride are added to the preserving liquid for replacing part of table salt, so that the usage amount of the table salt namely NaCl is reduced, the content of sodiumions in finished products of the dried salted duck is effectively reduced, the tender degree of muscle is improved, the negative effect of calcium chloride on meat quality is reduced, and the salt content and the sodium content in the dried salted duck are reduced efficiently.

Owner:ANHUI KANGLETAI AGRI TECH CO LTD

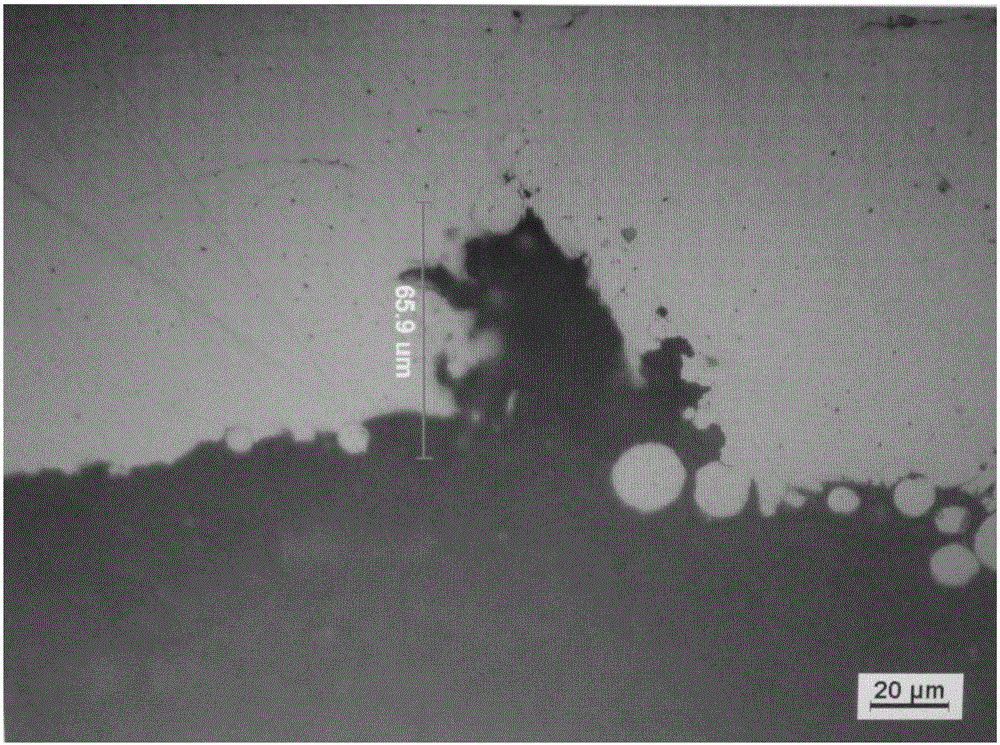

Treatment method for removing surface scale of hollow shaft through ultrasonic pickling

The invention provides a treatment method for removing scale on the surface of a hollow shaft by ultrasonic pickling. By adjusting the ultrasonic intensity, sulfuric acid concentration, pickling temperature and ferrous ion concentration in the acid solution, the hollow shaft can be removed after 10 minutes of ultrasonic pickling treatment. surface scale. The process of the invention is relatively simple, the equipment requirements are not high, the production cycle is shortened, and the production efficiency is improved. The surface of the hollow shaft parts after ultrasonic pickling has no oxide skin, and the color is uniform. The product has basically no acid etching phenomenon, the subsequent rotary forging process of the product is stable, and the product has no hydrogen embrittlement cracking.

Owner:JIANGSU SUNWAY PRECISION FORGING

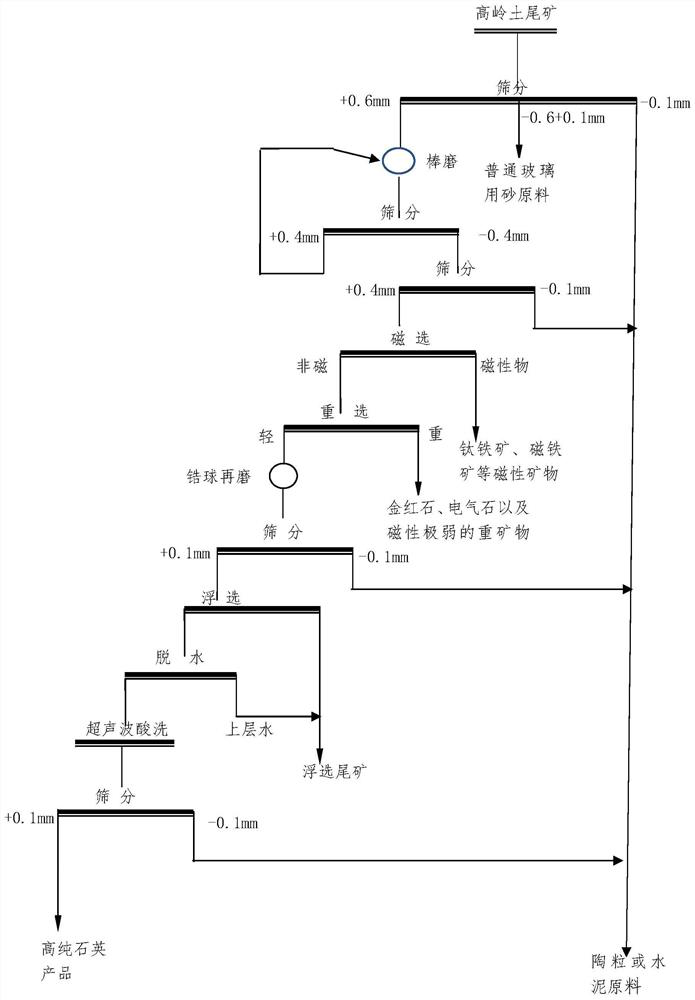

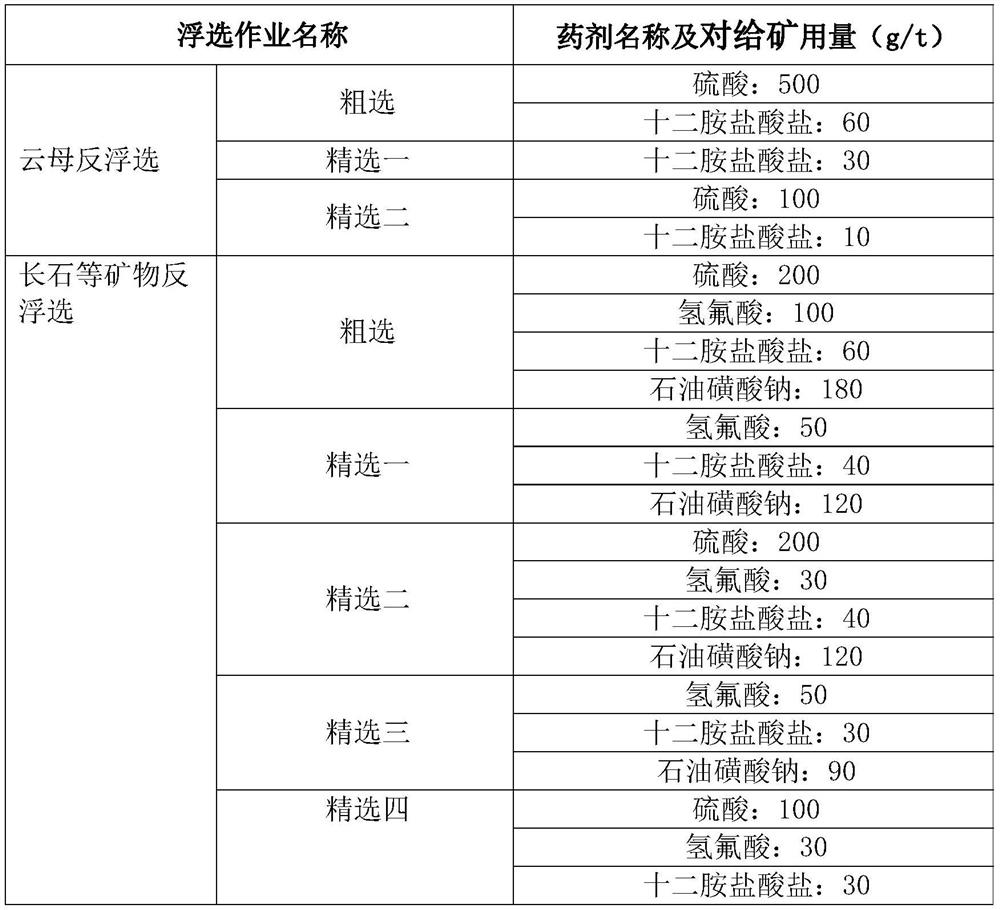

Method for preparing high-purity quartz sand from kaolin tailings

PendingCN113231193AEasy to operateLow costGlass recyclingSolid separationOre concentrateGravity separation

The invention provides a method for preparing high-purity quartz sand from kaolin tailings. The method comprises the following steps of stirring and scrubbing the kaolin tailings serving as raw ore, and screening to obtain materials with the particle size of +0.6 mm; conducting ore grinding on materials with the particle size of +0.6 mm, conducting grading, conducting magnetic separation operation on mineral aggregates with the particle size of 0.4 mm-0.1 mm to obtain magnetic materials and non-magnetic materials, conducting gravity separation operation on the non-magnetic materials to obtain gravity separation light minerals and gravity separation heavy minerals, and material regrinding operation and screening on the gravity separation light minerals to obtain minerals with the particle size of +0.1 mm ; and conducting flotation operation on the minerals with the particle size of +0.1 mm to obtain flotation concentrate, removing upper water from the flotation concentrate, conducting ultrasonic acid pickling, and screening to obtain coarse materials with the particle size of +0.1 mm, namely the high-purity quartz sand. By means of the method, the high-quality quartz concentrate product can be obtained, the processing time is short, the technological process is simple, energy consumption is low, and the obtained quartz concentrate is high in quality and can meet the quality requirement of high-purity quartz.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

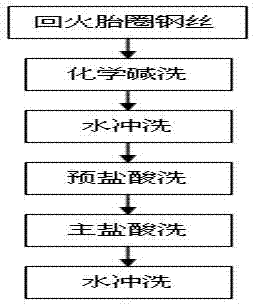

Method for pretreating magnesium-alloy waste material

InactiveUS20180010210A1Shorten pickling timeReduce lossesProcess efficiency improvementCleaning using liquidsPretreatment methodIngot

A method comprises sorting and removing impurities from magnesium alloy waste material, and cleaning and drying said material, the cleaning being high-pressure rinsing, pickling, and water washing, performed in sequence. The method employs high-pressure rinsing during the pretreatment of magnesium alloy waste material; the cleaning effectiveness is excellent, the effectiveness of the removal of impurities from the surface of the magnesium alloy waste material is much better than in conventional processes, and the amount of clean waste material can exceed 90% of the total amount of processed waste material; the clean magnesium alloy waste material obtained from the pretreatment method may be used as the entire raw materials for casting national-standard alloy ingots, the addition of costly high-purity magnesium is unnecessary, and the amount of alloy raw material that must be added is significantly reduced; during processing, little waste material is lost, costs are low, and efficiency is high.

Owner:HUNAN S R M SCI & TECH

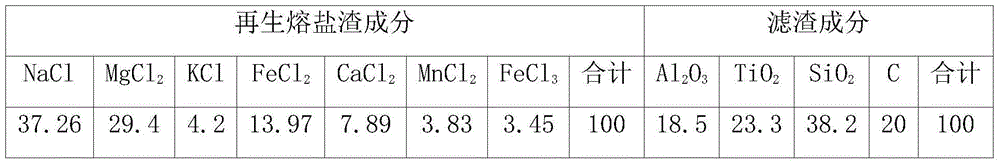

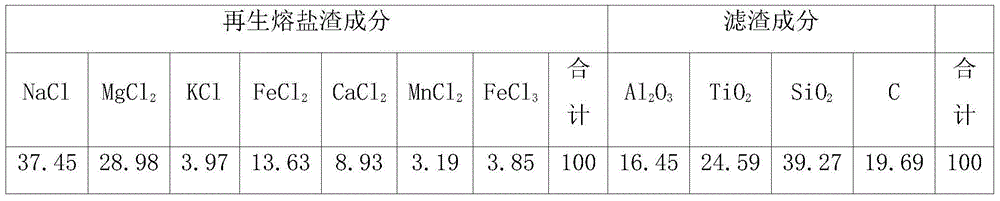

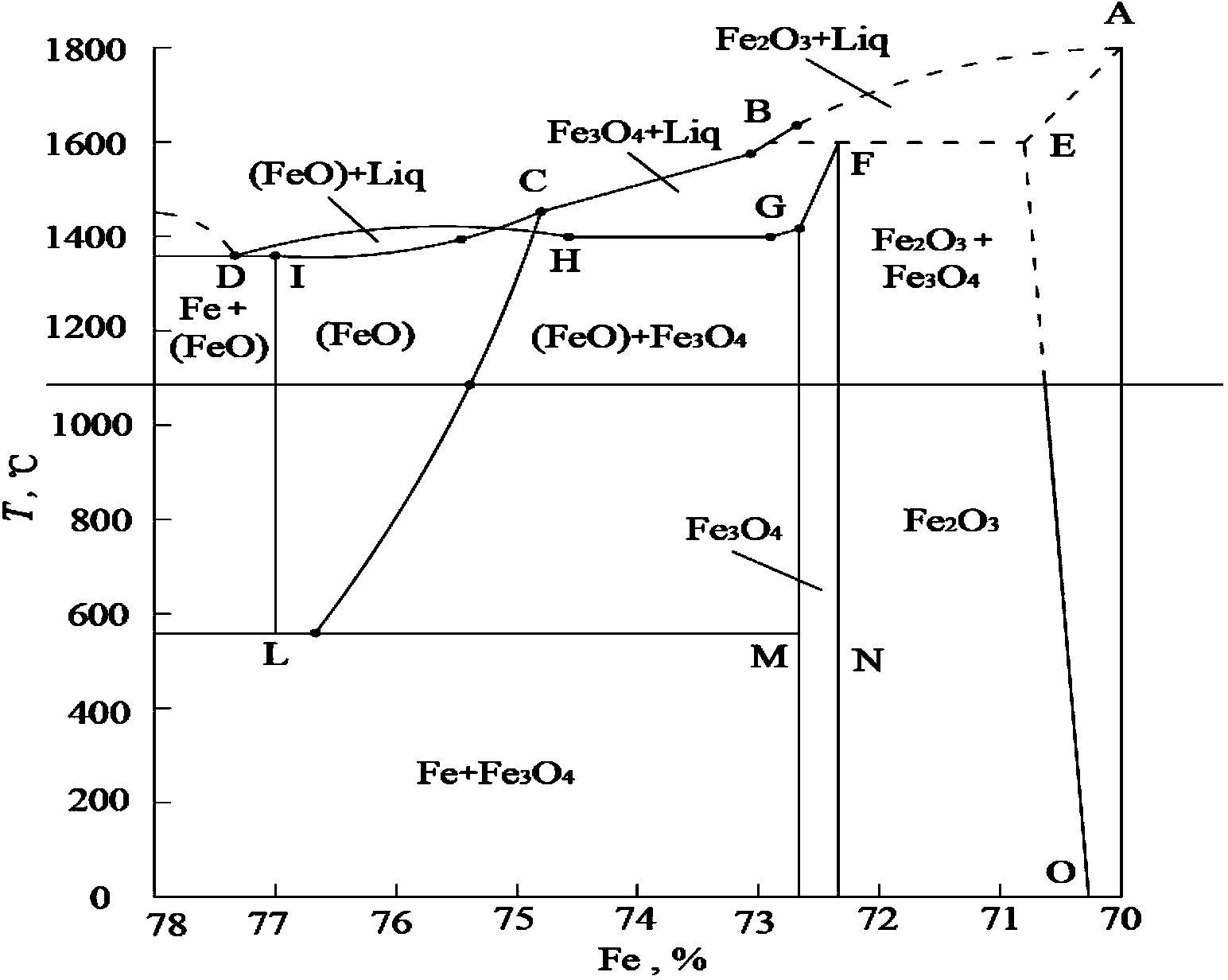

Method for recycling waste slag of fused salt chlorination

The invention relates to the method for recycling waste slag of fused salt chlorination and belongs to the field of resource recycling. The method for recycling the waste slag of fused salt chlorination comprises the following steps that a, the waste slag of fused salt chlorination is mixed with water, and filter liquor and filter residues are obtained after stirring and filtering, wherein the solid-to-liquid ratio of the waste slag of fused salt chlorination and the water is 1: (3-5) g / ml; b, recrystallization is carried out on the filter liquor to obtain regenerated fused salt slag, wherein the waste slag of fused salt chlorination is obtained during production of titanium sponge or titanium dioxide through a salt chlorination method. The invention further discloses application of the regenerated fused salt slag for improving the grade of artificial rutile. The method for recycling the waste slag of fused salt chlorination is simple in procedure and easy to operate, the obtained regenerated fused salt slag can be applied to production of the artificial rutile, and the grade of the artificial rutile can be improved by 3-6 percent.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Surface active agent in steel wire pickling solution

The invention discloses a surface active agent in steel wire pickling solution. The surface active agent comprises any or combination of two or more in alkylbenzene sulfonate, alkane sulfonate, alkyl glycoside, aliphatic alcohol phosphate, fatty alcohol-polyoxyethylene ether and alkylphenol polyoxyethylene, and the mass percent of the surface active agent is 0.01-2.5% in hydrochloric acid pickling solution. After being prepared into the pickling solution together with the hydrochloric acid, the surface active agent can be used for carrying out acid pickling on a steel wire; compared with the hydrochloric acid pickling solution which does not contain the surface active agent, the pickling solution containing the surface active agent obviously improves the pickling efficiency and saves the pickling time; after pickling, the oxide skin on the surface of the steel wire can be more thoroughly removed, and the surface of the steel wire is more uniform; after chemical planting, the bonding force between the steel wire and the rubber is higher.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Rolling method for optimizing surface quality of hot rolled steel plate

InactiveCN103406368ALess total weight gainReduce thicknessTension/compression control deviceSheet steelLoad distribution

The invention discloses a rolling method for optimizing the surface quality of a hot rolled steel plate, comprising phosphorus removal before continuous casting roughing and roughing control, wherein the total deformation of roughing is 70-85%, and rolling reduction of each pass in roughing control is in progressive increase. By taking the steel surface quality as the factor of influencing load distribution, a load distribution method in which the rolling reduction of each pass in roughing control is in progressive increase is adopted, so that oxide scale thickness is effectively reduced, possibilities of oxide scale press-in and red ironhide can be reduced, the surface quality of a hot rolled steel plate is improved, and steel plate components, tissue uniformity and mechanical property can be ensured while the oxide scale thickness is reduced. According to the method, the rolling power of a rolling mill can be fully utilized on the premise of not influencing the yield of energy consumption, and the method can be widely used in production of hot rolled steel plates. According to the method, additional facility and input are not increased, the investment is low, rapid effect is achieved and the operation is convenient.

Owner:武汉钢铁有限公司

Anti-corrosion construction method for irregular steel structural part

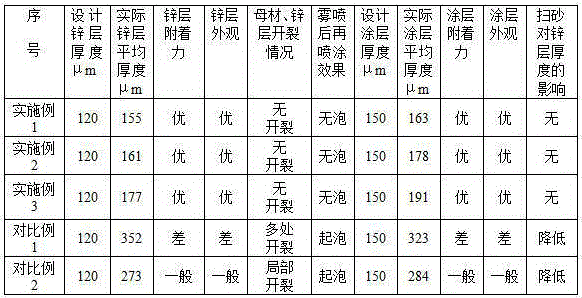

ActiveCN105349927AImprove adhesionQuality improvementHot-dipping/immersion processesHigh pressure waterSolvent

The invention provides an anti-corrosion construction method for an irregular steel structural part. The anti-corrosion construction method includes the steps of chamfering treatment, shot blasting, hot-dip galvanizing, alkaline washing, sand blasting, coating and the like. The anti-corrosion construction method for the irregular steel structural part has the advantages that shot blasting is carried out before hot-dip galvanizing to remove stains on the surface, the attaching force of a zinc layer is improved, the manufacturing residual stress of the part is lowered, and the acid pickling time is shortened; the temperature of a zinc pool, the dip plating time and the cooling mode are controlled in the hot-dip galvanizing process, the cracking risks of base metal and a zinc layer are effectively reduced, and the quality of the zinc layer is improved; passivation is not permitted after galvanizing to increase the adhesive force of a subsequent coating; the surface of the zinc layer is cleaned with strong alkali solvents and high-pressure water to reduce the possibility of oil stains left on the surface of the zinc layer; the sand blasting pressure, moving speed of a gun nozzle, the distance between the gun nozzle and the surface of the zinc layer and the included angle between the gun nozzle and the surface of the zinc layer are controlled, reasonable roughness is obtained, the adhesive force of the coating is improved, and it is guaranteed that the thickness of the zinc layer is not reduced; a first layer of connecting paint is sprayed in a mist mode, and defects of the coating are effectively reduced.

Owner:SHANGHAI CONSTR JIANGSU STEEL STRUCTURE CO LTD

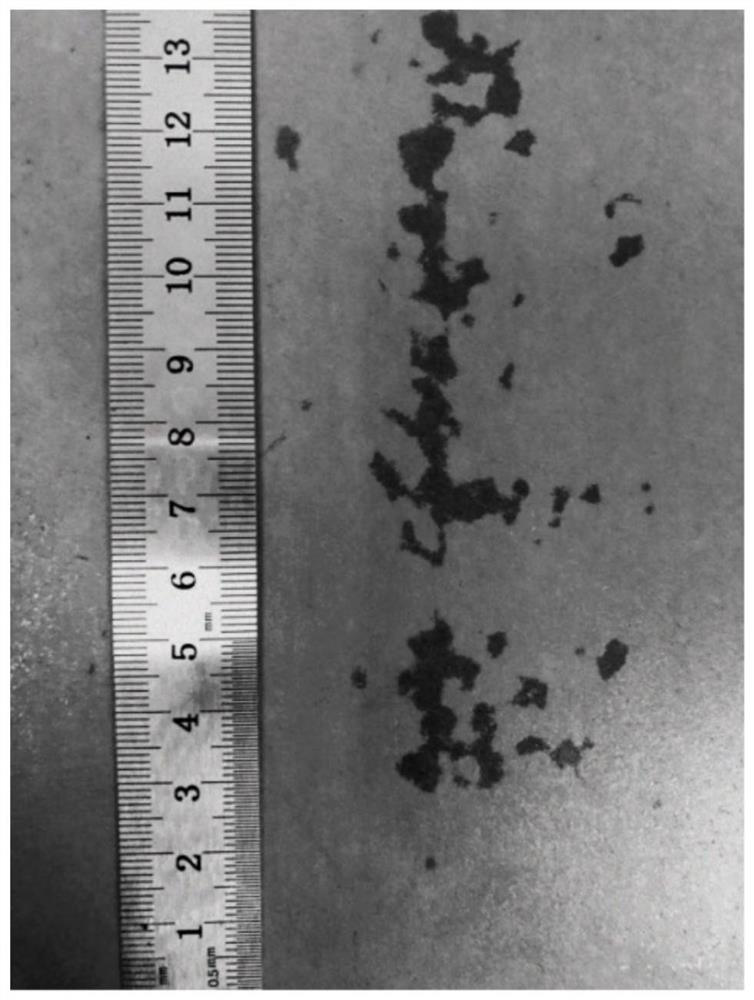

Method for preventing corrosion of high-manganese hot-formed steel after acid pickling

ActiveCN111659732AIncreased efficiency of iron or matrix iron actionReduce dosageMetal rolling arrangementsManganeseMetallic materials

The invention relates to the technical field of metal material processing, in particular to a method for preventing corrosion of high-manganese hot-formed steel after acid pickling. The method comprises the following steps that a plate blank of the high-manganese hot-formed steel is placed in a heating furnace and is heated to 1180-1210 DEG C, and heat preservation at the temperature is carried out for 25-40 minutes; rough rolling is conducted on the heated plate blank, the plate blank enters a finishing mill, the inlet temperature of the finishing mill is 1000-1010 DEG C, and coiling and uncoiling are conducted after finish rolling; the uncoiled plate blank enters a withdrawal and straightening machine, the insertion depth of a bending roller of the withdrawal and straightening machine iscontrolled to be 5-15 mm, and a hot-rolled coil obtained after withdrawal and straightening and descaling enters an acid pickling stage; and the hot-rolled coil is rinsed after taken out, wherein thechloride ion content of rinsing water is less than or equal to 10 mg / L, drying is carried out after rinsing, oiling is carried out, and then coiling is carried out to complete the method for preventing corrosion. According to the method for preventing corrosion of the high-manganese hot-formed steel after acid pickling, by controlling the components of the high-manganese hot-formed steel, the keytemperatures and processes of rough rolling and finish rolling, controlling the rolling rhythm, controlling the withdrawal and straightening parameter and operation in other aspects, occurrence of corrosion of the high-manganese hot-formed steel after acid pickling can be effectively prevented, and the method is simple, high in applicability and remarkable in effect.

Owner:SHOUGANG CORPORATION +1

Pickling method for 2205 duplex stainless steel coils

The invention relates to a pickling method for 2205 duplex stainless steel coils. The pickling method comprises the following steps that mechanical descaling is carried out on annealed steel coils; pre-pickling is carried out on descaled steel coil in the pickling stage; primary scrubbing is carried out after the pre-pickling; double-mixed acid pickling is carried out after the primary scrubbing;three-stage scrubbing is carried out after the double-mixed acid pickling; and a cleaning stage is entered after the three-stage scrubbing, and a drying stage is entered after cleaning. The pickling process is reasonable, complete and simple in step design; a high-concentration sulfuric acid solution and a low-concentration mixed acid solution are adopted, the metal ions is guaranteed, and the utilization efficiency of the acid liquid is guaranteed; and the solutions of the pre-pickling and other matched acid washing stages are reasonable proportioned, the pickling speed, the acid liquid concentration and the temperature are reasonable, so that the pickling time is shortened, the iron oxide scale on the surface of the duplex stainless steel coil is removed, and therefore the use requirements of NO.1 plate can be met.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

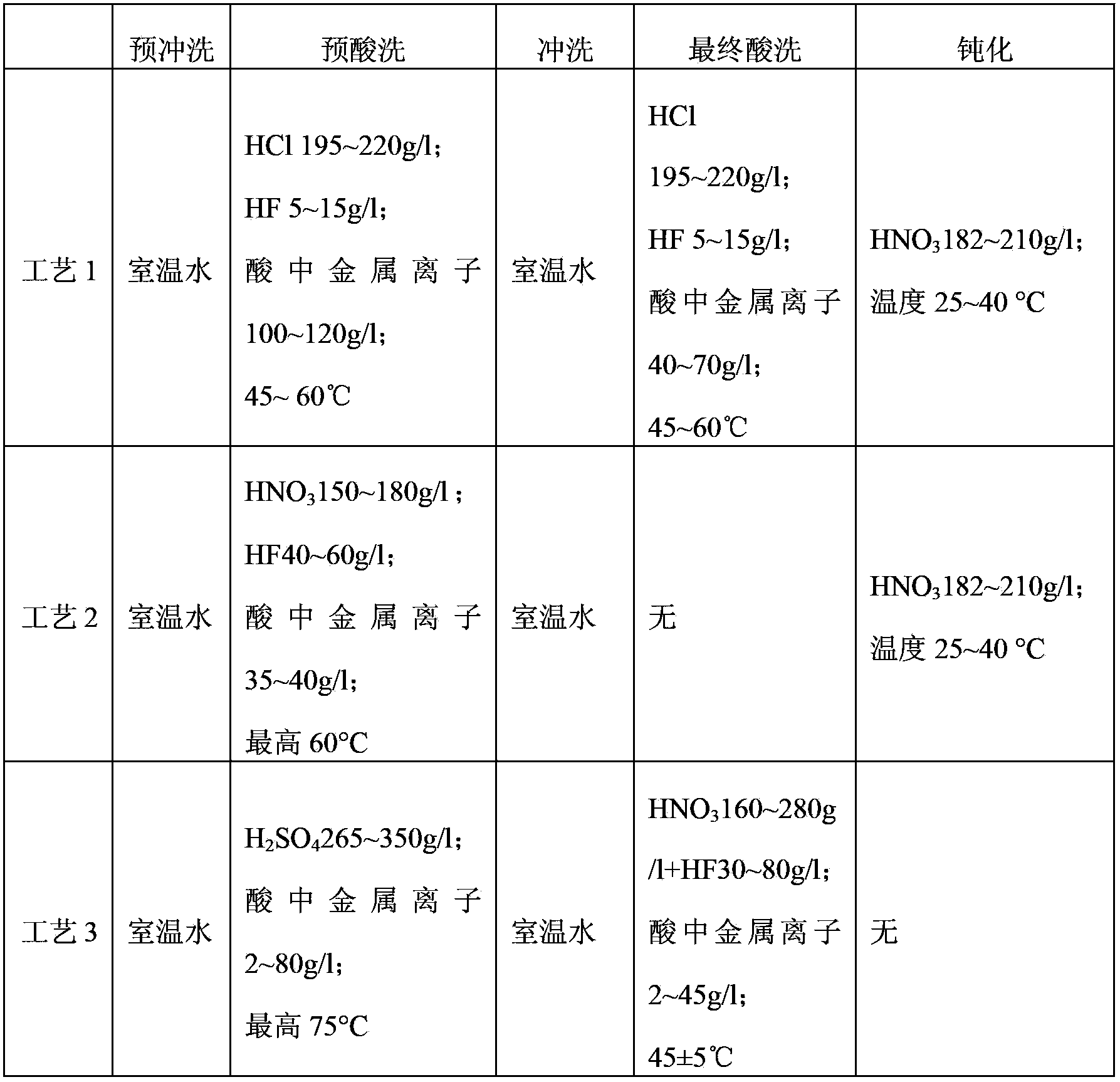

Plate with-temperature mixed-acid pickling process used for stainless steel plate

InactiveCN103447321AShorten pickling timeIncrease productivityWork treatment devicesMetal rolling arrangementsIonSteel plates

The invention provides a plate with-temperature mixed-acid pickling process used for a stainless steel plate. The process includes shot blasting, pre-flushing, pre-pickling, flushing and final pickling; flushing mediums in the pre-flushing process and the flushing process are water at 40-65 DEG C; the pre-pickling process adopts a mixed solution of HNO3 and HF as a pickling solution, content of HNO3 is 180-290g / l, the content of HF is 26-60g / l, the content of metal ions is 5-45g / l, temperature of the mixed solution is 35-50 DEG C, and operating speed of the stainless steel plate in the pre-pickling process is 0.6-4.5m / min; the final pickling process adopts a mixed solution of HNO3 and HF as a pickling solution, the content of HNO3 is 180-320g / l, the content of HF is 26-89g / l, the content of metal ions is 5-45g / l, the temperature of the mixed solution is 35-50 DEG C, and the operating speed of the stainless steel plate in the final pickling process is 0.6-3.5m / min. High-temperature water is adopted for flushing, shot blasting and pickling are performed on a same roller way continuous production line, and online quick continuous pickling of the stainless steel plate is realized. Compared with the prior art, the plate with-temperature mixed-acid pickling process has the advantage that pickling time is substantially reduced.

Owner:宝钢特钢有限公司

Wire rod processing process

The invention discloses a wire rod processing process which comprises the following process steps of: hot rolling, wherein a preheating section temperature during rolling is 600-900 DEG C, a soaking zone temperature is 1160-1280 DEG C and the soaking time is 1.8-3.5 hours; and air cooling after the rolling; solid solution, wherein a solid solution temperature is 1000-1060 DEG C and the solid solution time is 1.5-2.5 hours, and a cooling mode after the solid solution is water cooling; sanding or sand blasting, wherein iron oxide scale on the surface of a solid-solution wire rod is removed by virtue of sanding or sand blasting, the sand blasting speed is 3m / minute, the granularity of sand pills is 0.3-0.5mm, the mesh number of the sanding belt for sanding is 80-120; acid-pickling, wherein the acid-pickling process includes three process steps; polishing, wherein defects on the surface of the wire rod are removed by virtue of the polishing after acid-pickling; and wire-drawing or cold-drawing. According to the invention, the acid-pickling time can be shortened, the usage amount of an acid-pickling solution can be reduced, and the product surface quality can be improved.

Owner:WUXI XINGCHENG HUAXIN STEEL

Nano additive used for steel pipe pickling solution and preparation method for nano additive

The invention discloses a nano additive used for a steel pipe pickling solution and a preparation method for the nano additive. The nano additive is chemically modified nano lanthanum borate emulsion or / and nano cerium borate emulsion. A chemical modification agent adopts oleic acid and a surfactant. The surfactant is selected from any one or more of alkylbenzene sulfonate, fatty alcohol-polyoxyethylene ether or alkylphenol ethoxylates. The pickling solution is prepared by the nano additive and hydrochloric acid. The nano additive accounts for 0.01-2.0 wt% of the pickling solution. Compared with a hydrochloric acid pickling solution which does not contain a nano additive, the hydrochloric acid pickling added with the chemically modified nano lanthanum borate emulsion or / and the nano cerium borate emulsion can significantly reduce acid mist, improve the pickling efficiency and save the pickling time. An oxide skin on the surface of a pickled steel pipe is thoroughly removed, and the surface is uniform.

Owner:SHANGHAI INST OF TECH

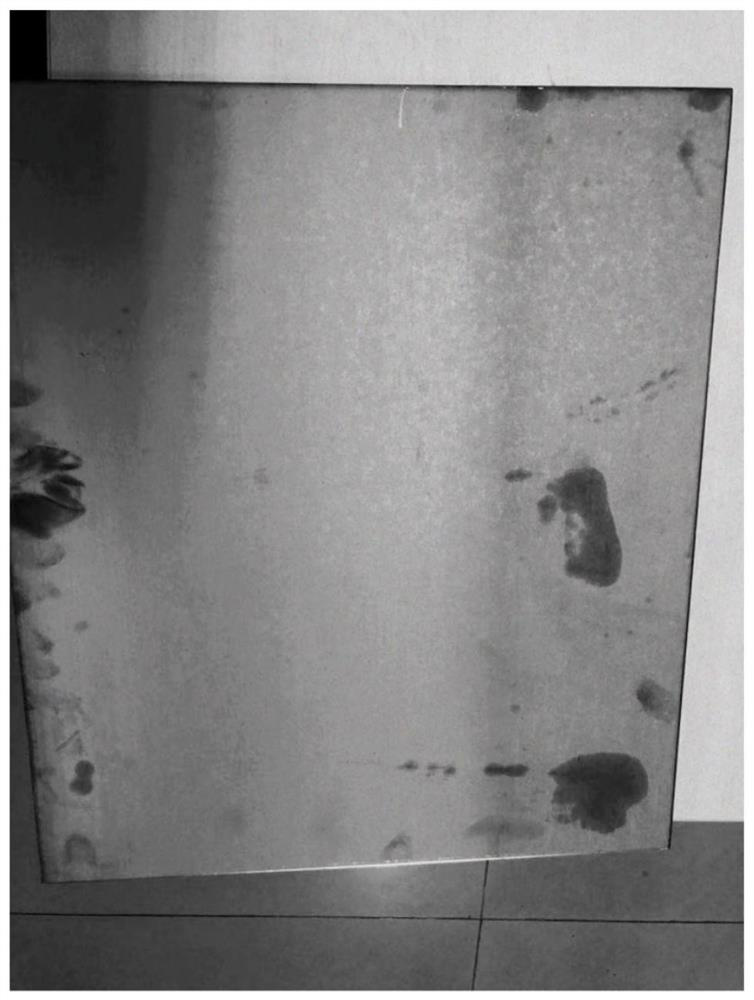

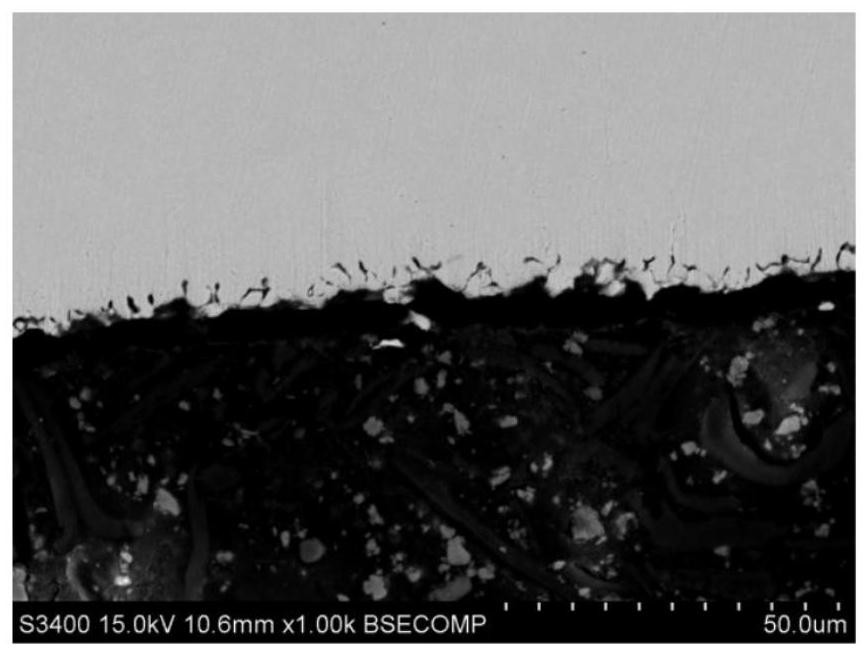

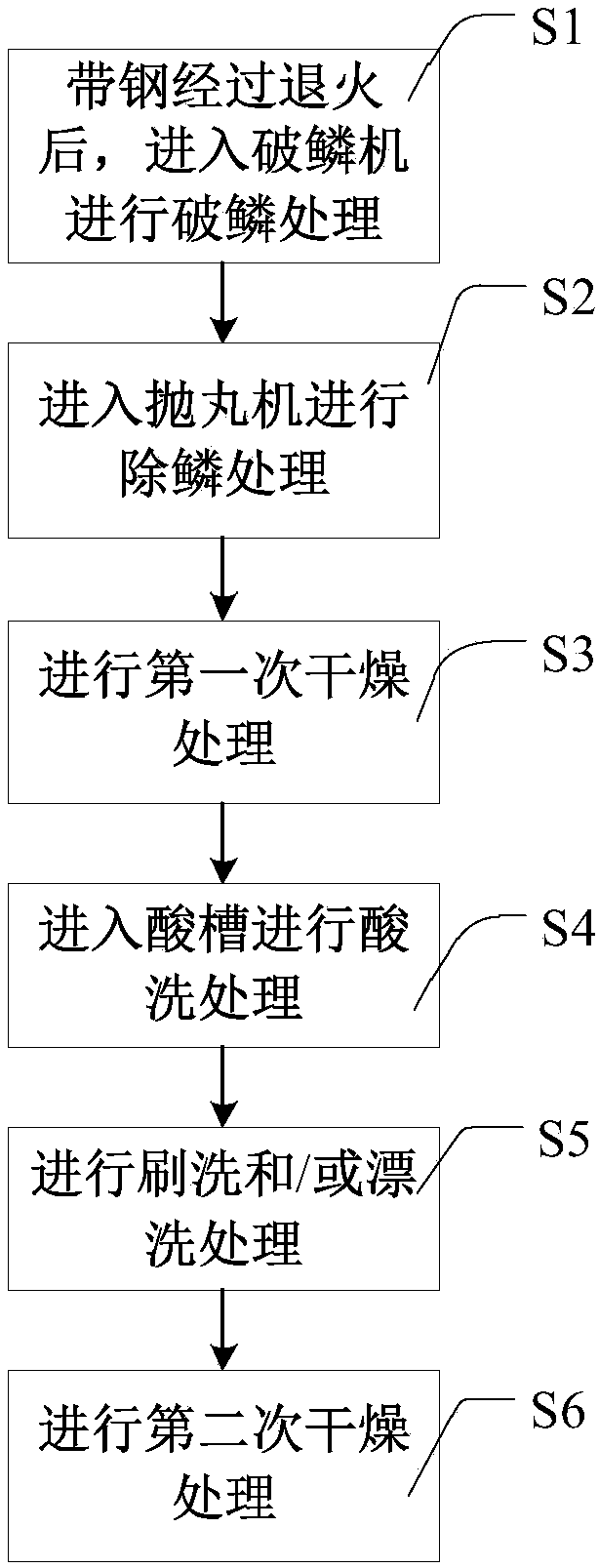

Strip steel surface descaling method and system

The invention provides a strip steel surface descaling method and system. The strip steel surface descaling method comprises the steps of carrying out scale breaking treatment, carrying out descalingtreatment, carrying out first drying treatment and carrying out acid pickling treatment, wherein an adopted descaling medium is mortar formed by mixing abrasive materials and water, an adopted acid pickling solution is a mixed solution of nitric acid with the concentration of 20-200 g / L and hydrofluoric acid with the concentration of 0.5-50 g / L, the temperature of the acid pickling solution is 40-65 DEG C, and the acid pickling time is 20-60 S. The strip steel surface descaling system is sequentially provided with a scale breaking machine for scale breaking treatment, a shot blasting machine used for descaling treatment, a first drying unit used for first drying treatment and an acid tank used for acid pickling in the movement direction of strip steel. The strip steel surface descaling method and system have the advantages that acid pickling of sulfuric acid is not needed, the concentration of the nitric acid and the hydrofluoric acid in the acid pickling solution can be decreased, theacid pickling time of the nitric acid and the hydrofluoric acid in the acid pickling solution can be shortened, and therefore the generation of pollutants such as waste acid and waste gas is reduced,the descaling efficiency is improved, and the equipment investment and the operation and maintenance cost are lowered.

Owner:CISDI RES & DEV CO LTD

High-stability paint processing technology

PendingCN112981424AImprove stabilityHigh hardnessCleaning using toolsMetallic material coating processesCleansing AgentsSlow cooling

The invention relates to the technical field of paint, and discloses a high-stability paint processing technology. The high-stability paint processing technology comprises the following steps that 1) a to-be-sprayed metal part with alkali liquor is cleaned, and greasy dirt on the surface of the to-be-sprayed metal part is removed through a brush. (1) Akali liquor is a metal cleaning agent solution, the metal cleaning agent is prepared into an aqueous solution with the concentration of 2-3% (mass percent), the metal cleaning agent can be used at room temperature, and the heating use effect is better; According to the high-stability paint processing technology, through plasticizing treatment, auxiliaries and low-molecular-weight polymers in paint can be removed through plasticizing, primer and a metal part act, the bonding strength is improved, the adhesive force of the primer is guaranteed, intermediate paint plays an indirect transition role, finish paint is smoother and smoother, and finally, a paint coating with considerable strength and high hardness can be obtained through slow cooling, so that the stability of the paint processing technology is further improved, and the effect of high stability is achieved.

Owner:云南万里化工制漆有限责任公司

Surface treatment method for iron wires used for civil engineering

InactiveCN106757079ALittle effortShorten pickling timeFurnace typesHeat treatment furnacesPhosphoric acidWater resources

The invention provides a surface treatment method for iron wires used for civil engineering and belongs to the field of metal surface treatment processes. The surface treatment method for the iron wires used for the civil engineering is used for solving the problems that pickling in the prior art is performed through hydrochloric acid, lots of water resources can be wasted easily, and water after cooling water washing cannot be reused. The surface treatment method includes the steps that after the whole bundle of iron wires are subjected to first time of pickling dirt removing, first time of water washing, heat treatment and cooling water washing, the whole bundle of iron wires are unfolded and pulled into a line shape to be subjected to second time of pickling, second time of water washing, first time of neutralizing water washing and anti-rusting water washing; pickling liquid adopted during the second time of pickling is composed of phosphoric acid and a BW-500P phosphoric acid fast pickling agent, the temperature of the pickling liquid is kept between 35 DEG C to 50 DEG C, an ultrasonic device is placed on the middle rear portion of a pickling pond, and ultrasonic pickling is kept for more than 20 seconds; and cooling water after cooling treatment is discharged into a first water washing pond corresponding to the first time of water washing, a second water washing pond corresponding to the second time of water washing, a third water washing pond corresponding to the first time of neutralizing water washing and an anti-rusting water washing pond corresponding to the anti-rusting water washing.

Owner:赵玉

Processing method for improving quality of instant chicken feet by adopting ultrasonic combined with electron beam cold sterilization

The invention provides a processing method for improving the quality of instant chicken feet by ultrasonic combined with electron beam cold sterilization, and relates to the technical field of sterilization and freshness preservation of poultry machining and electronic accelerators. The processing method comprises the following steps of: thawing, trimming and washing chicken feet; bleaching and washing; boiling; ultrasonically pickling; and packaging and carrying out electron beam sterilization. According to the invention, a novel process of ultrasonic auxiliary pickling is added in a pickling process of the instant chicken feet; the processing method has the effect that by utilizing cavatition effect of ultrasonic waves, the speed of immersing pricking condiments into inner parts of tissues of the chicken feet is increased, the pickling time is shortened and the integral flavor of the chicken feet is improved; furthermore, the instant chicken feet are treated by the electron beam cold sterilization, and the processing method has the obvious advantages of short sterilization time, no temperature changes and low production cost, and can keep the original pickled flavor of the instant chicken feet to the greatest extent. Therefore, the method can improve the flavor quality of the instant chicken feet and can shorten the manufacturing and processing periods; the aims of rapidly sterilizing and prolonging the quality guarantee period of products are achieved; and finally, the instant chicken feet product with high quality is obtained.

Owner:上海束能辐照技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com