Method for preparing high-purity quartz sand from kaolin tailings

A technology of kaolin tailings and high-purity quartz sand, which is applied in the direction of solid separation, recycling technology, mechanical material recovery, etc., can solve the problems of high processing cost, complicated operation, high roasting temperature, etc., and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

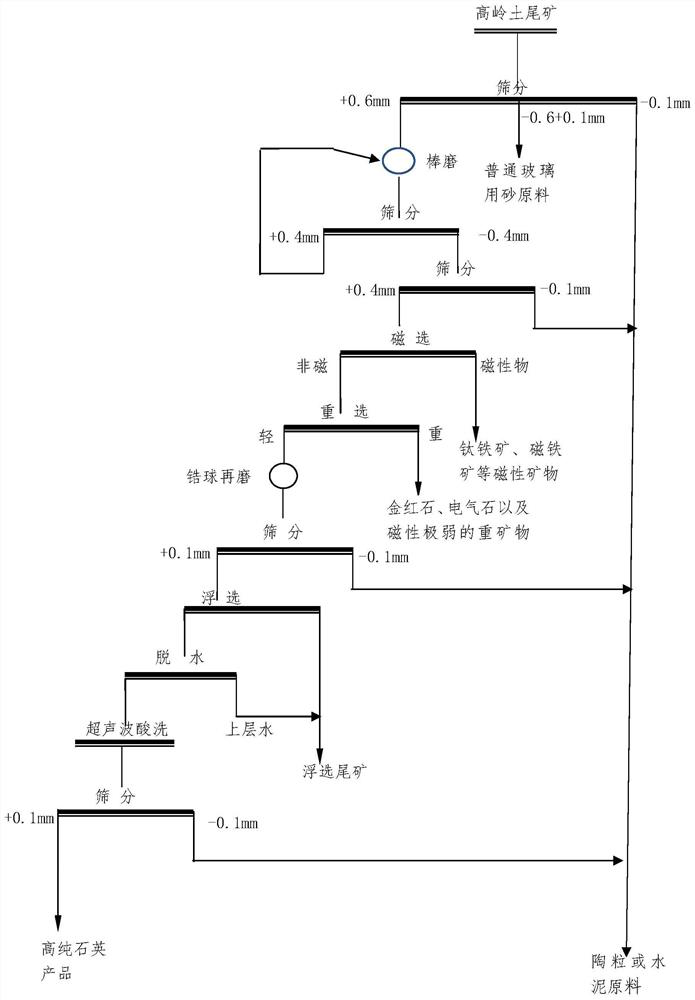

[0040] A kaolin tailings mine in Jiangxi, the main minerals are quartz, mica, feldspar, kaolinite, etc., and a small amount of minerals are rutile, tourmaline, etc. The analysis of the main elements of the ore is shown in Table 1. For the raw ore, it is stirred, scrubbed and classified first, and the +0.60mm particle size is separated, and the yield of +0.60mm particle size is 63.52%, which contains SiO 2 82.0%, Al 2 o 3 9.95%, Fe 2 o 3 0.73%. For the graded +0.6mm material, it is firstly ground with a rod mill, and then classified, and the +0.4mm material is returned to the mill to continue grinding. The -0.1mm material is thrown to make ceramsite or cement, and the 0.4mm-0.1mm material Enter high-gradient magnetic separators with field strengths of 0.8T and 1.2T for two magnetic separations to remove impurity minerals such as mica, magnetite, and ilmenite, and the non-magnetic materials after magnetic separation enter the two-stage spiral chute for gravity separation ...

Embodiment 2

[0050] A kaolin tailings in Jiangxi, the main minerals are quartz, mica, feldspar, diaspore, kaolinite, etc., and a small amount of minerals are rutile, tourmaline, zircon, etc. The main elements of the ore are analyzed in Table 4. For the raw ore, it is first stirred, scrubbed and classified, and the +0.60mm particle size is separated, and the yield of the +0.60mm particle size is 55.93%, which contains SiO 2 85.30%, Al 2 o 3 7.98%, Fe 2 o 3 0.51%. For the graded +0.6mm material, it is firstly ground with a rod mill, and then classified, and the +0.4mm material is returned to the mill to continue grinding. The -0.1mm material is thrown to make ceramsite or cement, and the 0.4mm-0.1mm material Enter high-gradient magnetic separators with field strengths of 0.8T and 1.2T for two magnetic separations to remove impurity minerals such as mica, magnetite, and ilmenite. Except for heavier minerals such as rutile, tourmaline and quartz intergrowth of weaker magnetic minerals, ...

Embodiment 3

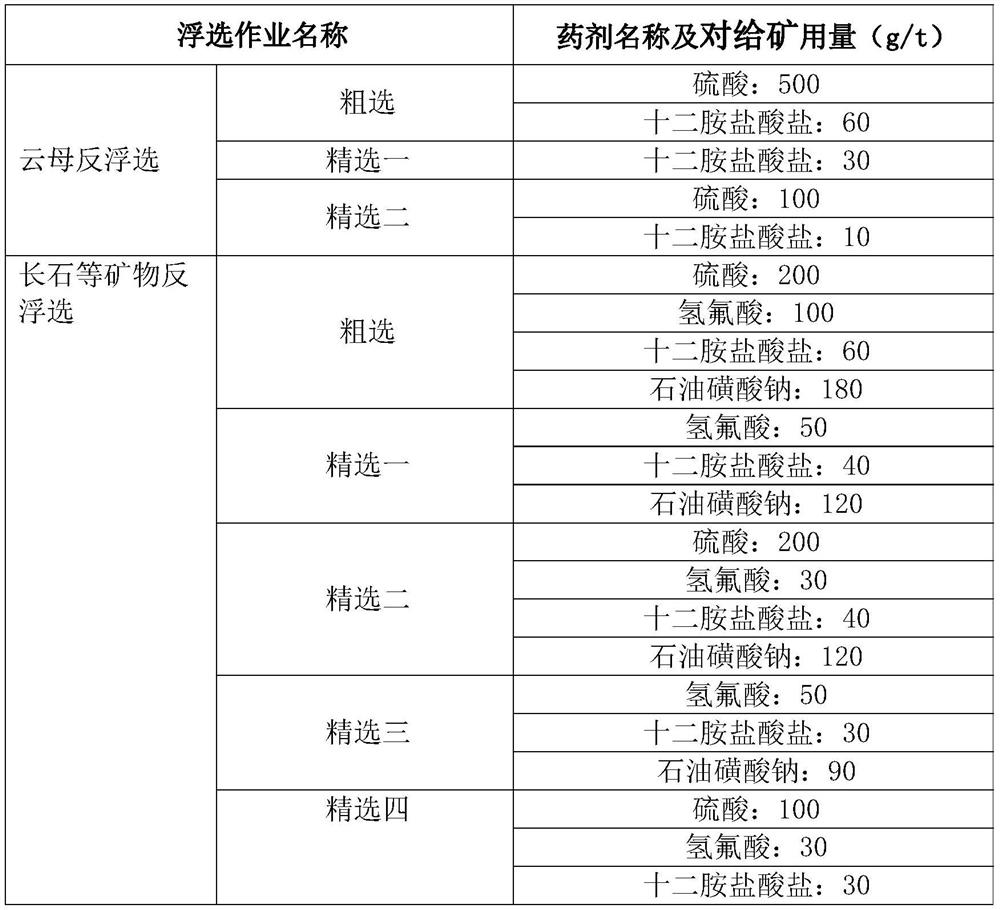

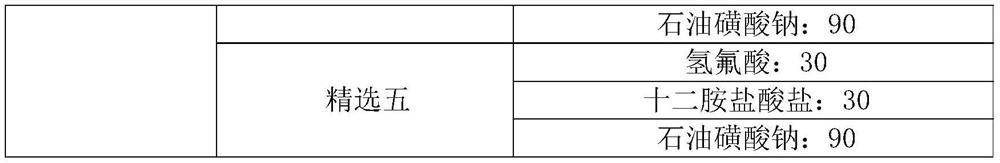

[0060] The present embodiment is basically the same as Example 1, the difference is that in step (3), the concentration of the flotation pulp is 45%, and in mica reverse flotation, adding sulfuric acid to adjust the pH is 5, adding sulfuric acid to adjust the pH to the minerals at the bottom of the tank is 4, and the flotation agents and their dosage are shown in Table 7.

[0061] Table 7 Flotation agent dosage

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com