Treatment method for removing surface scale of hollow shaft through ultrasonic pickling

A treatment method, ultrasonic technology, is applied in the field of treatment for removing scale on the surface of hollow shafts by ultrasonic pickling, which can solve the problems of easy cracking of workpieces, long soaking time, high risk, etc., and achieve the effect of reducing the risk of hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

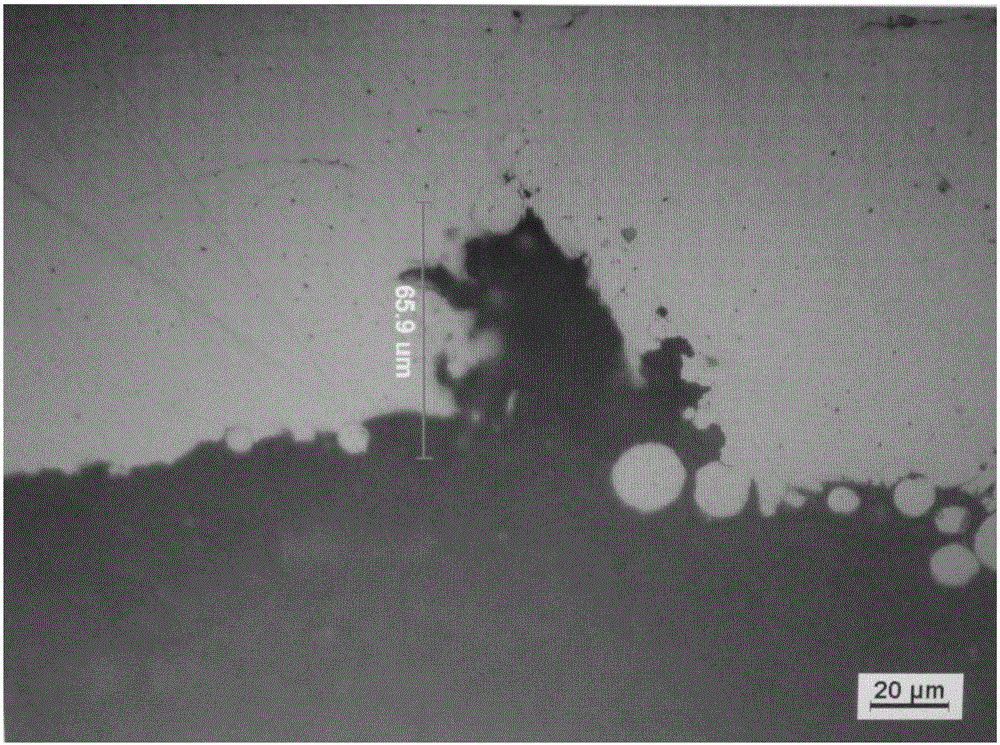

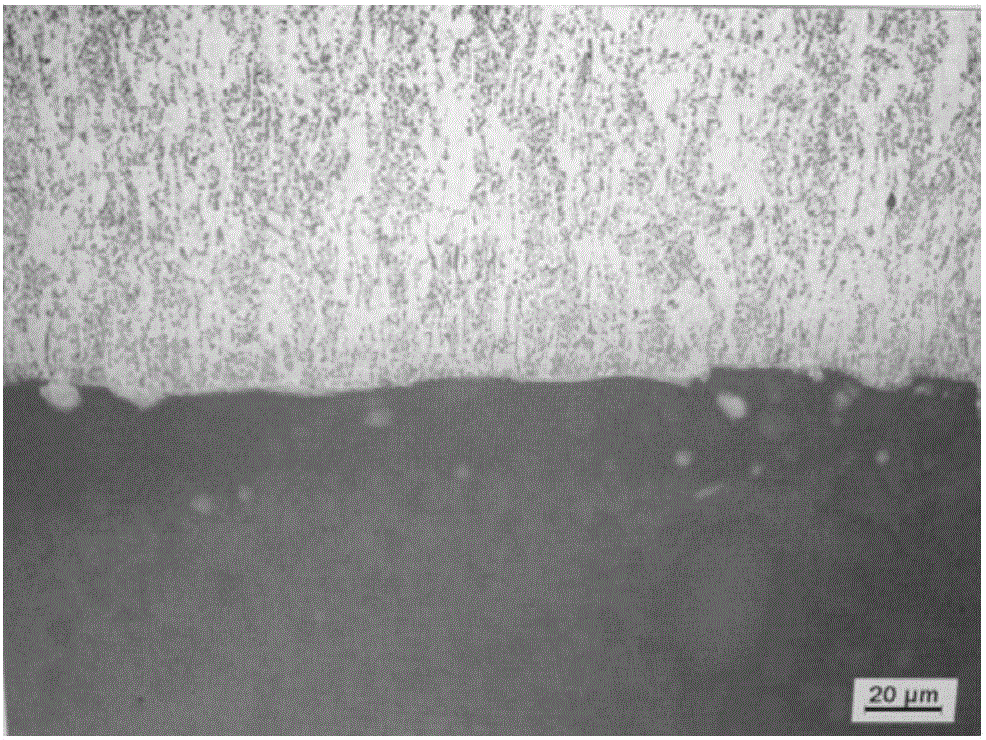

Image

Examples

Embodiment 1

[0023] Configure the pickling solution in the regularly cleaned acid tank, detect the sulfuric acid concentration and ferrous ion concentration in the acid solution, add sulfuric acid or water according to the sulfuric acid concentration and ferrous ion concentration, and control the free acid concentration in the acid solution at 16%— 18%, this free acid concentration can ensure the service life of the ultrasonic titanium plate in the pickling solution and the removal of scale on the surface of the hollow shaft. Under the same pickling treatment conditions, it is found through experiments that the mass concentration of ferrous ions > 1% can inhibit the pickling reaction, so the mass concentration of ferrous ions in the acid solution is ≤ 1%. ;

[0024] Turn on the ultrasonic transmitter, according to the acid volume 2M 3 , The quantity of material loaded is 50 pieces, estimate the required ultrasonic vibration energy, adjust the current of the ultrasonic generator at 4-5A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com