Patents

Literature

52results about How to "Shorten the production and processing cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pummelo peel decoction pieces as well as processing method and application thereof

ActiveCN105726723ABeautiful appearanceUniform and beautiful appearanceRespiratory disorderPlant ingredientsBULK ACTIVE INGREDIENTActive ingredient

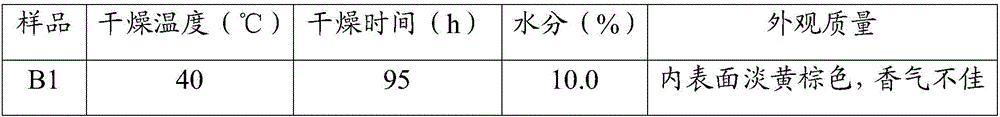

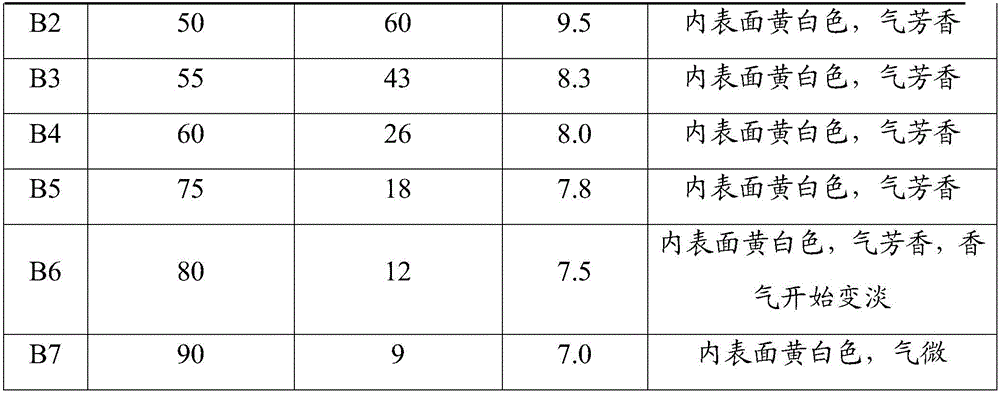

The invention relates to pummelo peel decoction pieces as well as a processing method and application thereof. The processing method of the pummelo peel decoction pieces comprises the following steps: (1) performing choosing, classification and impurity removal; (2) cleaning; (3) performing water removal and cutting; and (4) drying. The processing method provided by the invention shortens the production and processing cycle, improves the production efficiency, reduces the production cost, reduces the loss of active ingredients in medicinal materials at the same time, and improves the quality stability, and the decoction pieces are more beautiful and uniform in appearance.

Owner:GUANGZHOU XIANGXUE PHARMA CO LTD +1

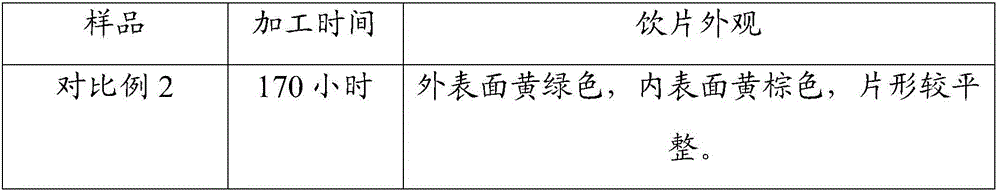

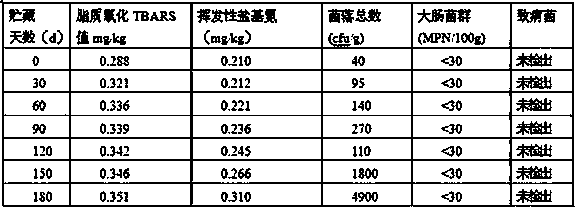

Processing method for improving quality of instant chicken feet by adopting ultrasonic combined with electron beam cold sterilization

The invention provides a processing method for improving the quality of instant chicken feet by ultrasonic combined with electron beam cold sterilization, and relates to the technical field of sterilization and freshness preservation of poultry machining and electronic accelerators. The processing method comprises the following steps of: thawing, trimming and washing chicken feet; bleaching and washing; boiling; ultrasonically pickling; and packaging and carrying out electron beam sterilization. According to the invention, a novel process of ultrasonic auxiliary pickling is added in a pickling process of the instant chicken feet; the processing method has the effect that by utilizing cavatition effect of ultrasonic waves, the speed of immersing pricking condiments into inner parts of tissues of the chicken feet is increased, the pickling time is shortened and the integral flavor of the chicken feet is improved; furthermore, the instant chicken feet are treated by the electron beam cold sterilization, and the processing method has the obvious advantages of short sterilization time, no temperature changes and low production cost, and can keep the original pickled flavor of the instant chicken feet to the greatest extent. Therefore, the method can improve the flavor quality of the instant chicken feet and can shorten the manufacturing and processing periods; the aims of rapidly sterilizing and prolonging the quality guarantee period of products are achieved; and finally, the instant chicken feet product with high quality is obtained.

Owner:上海束能辐照技术有限公司 +1

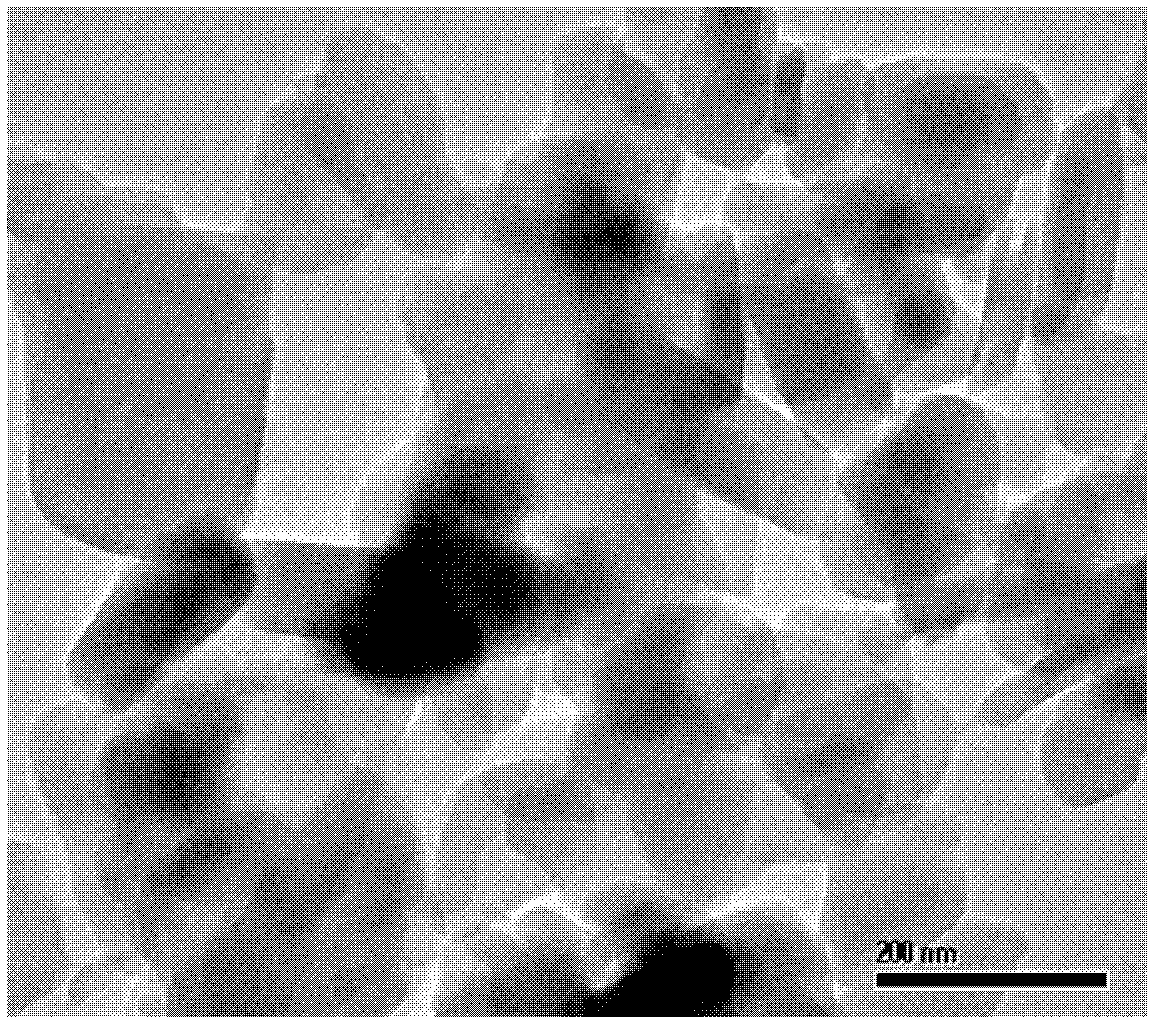

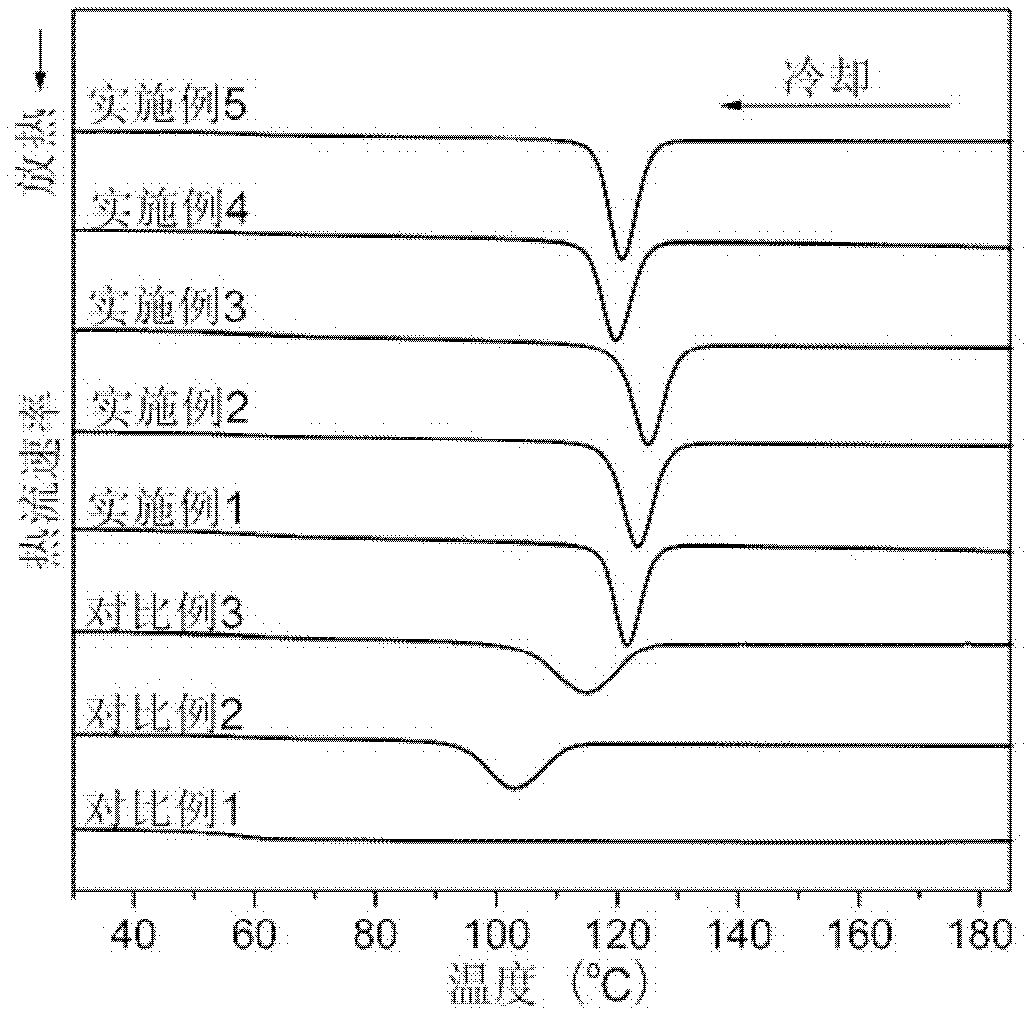

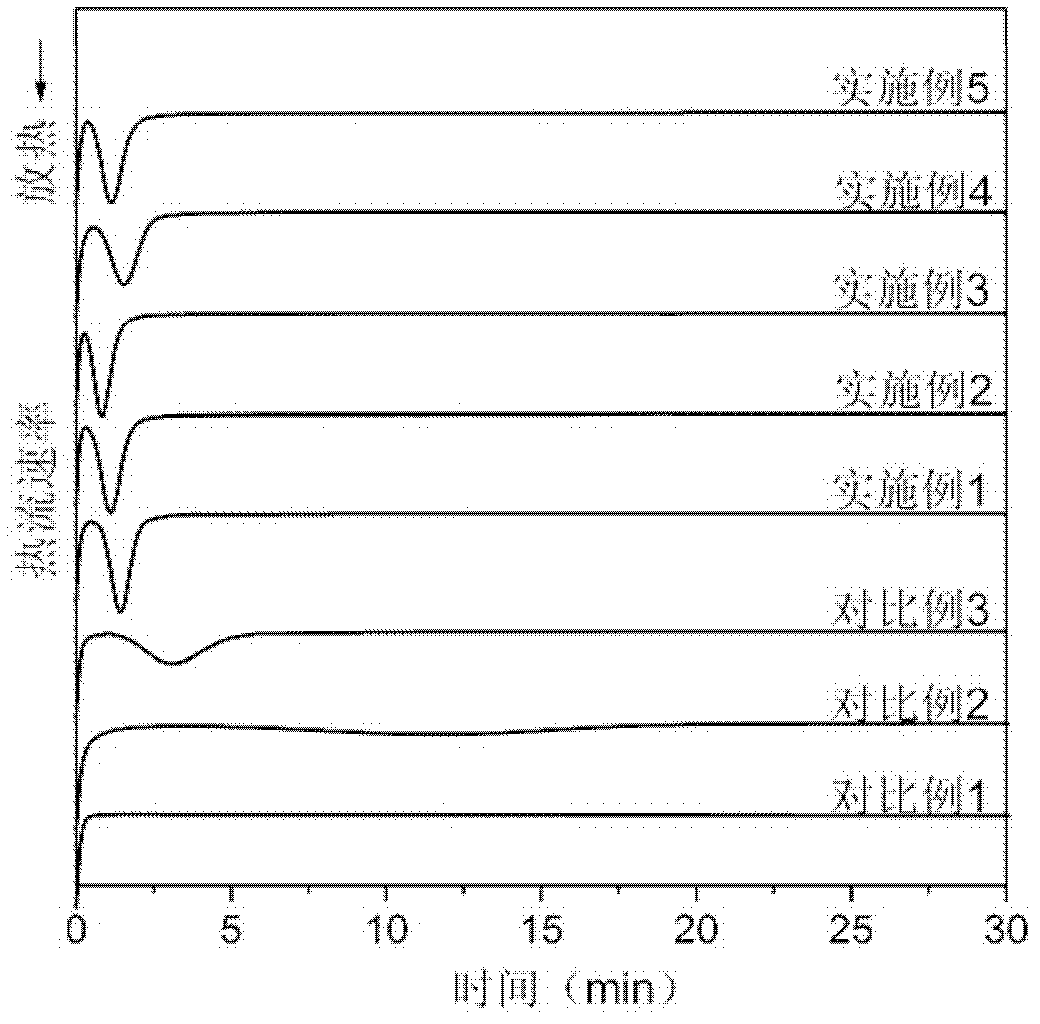

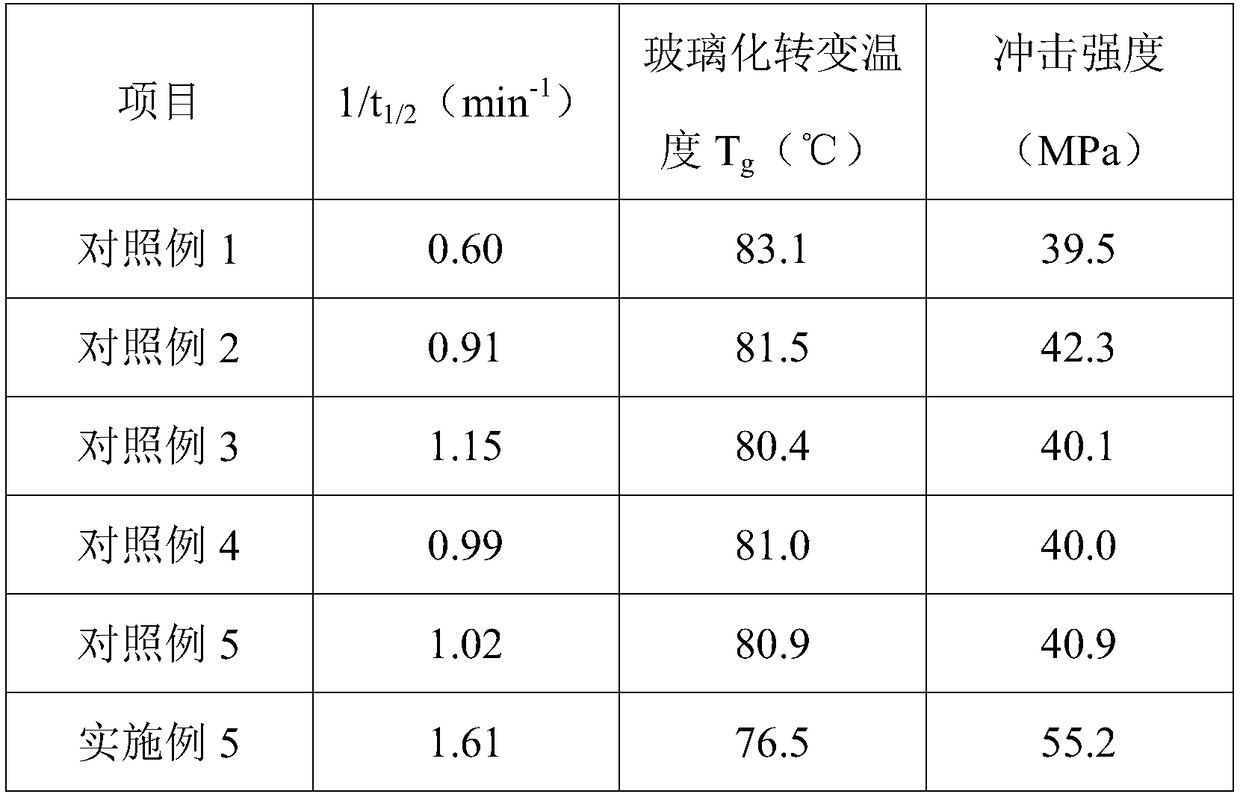

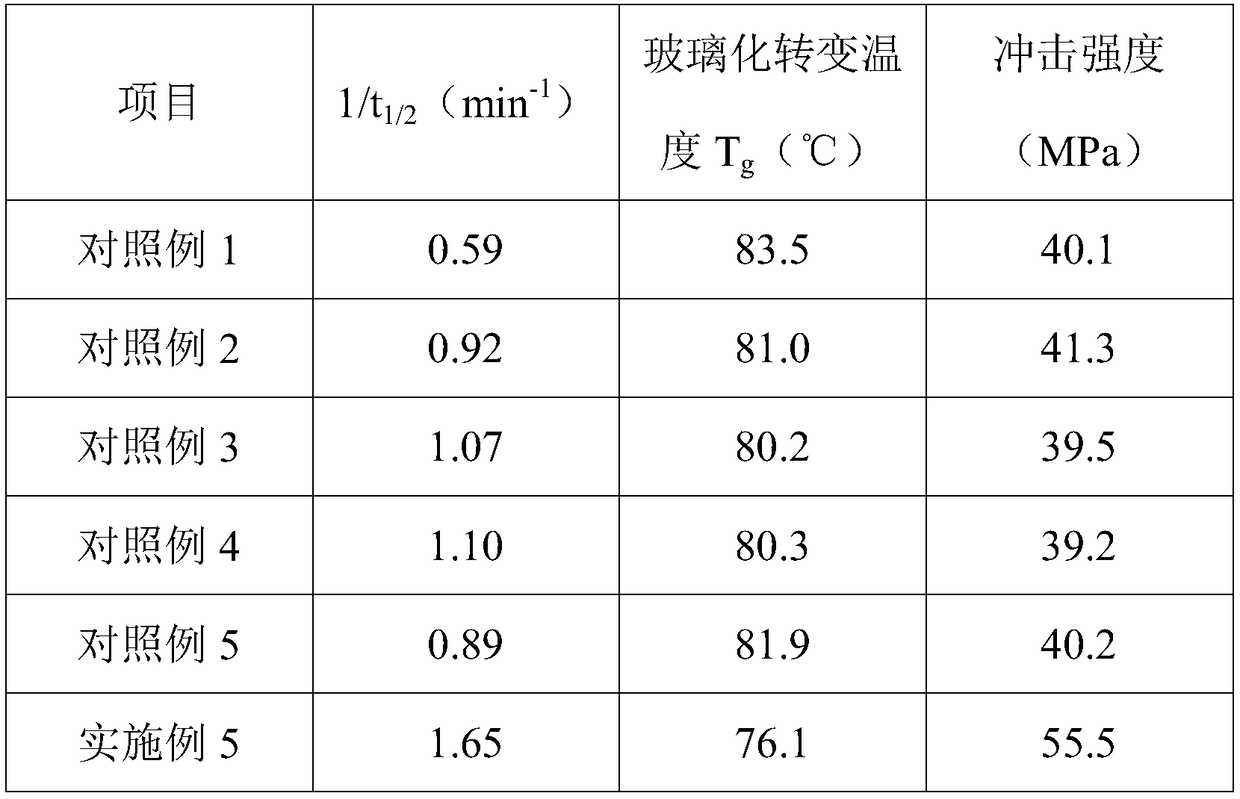

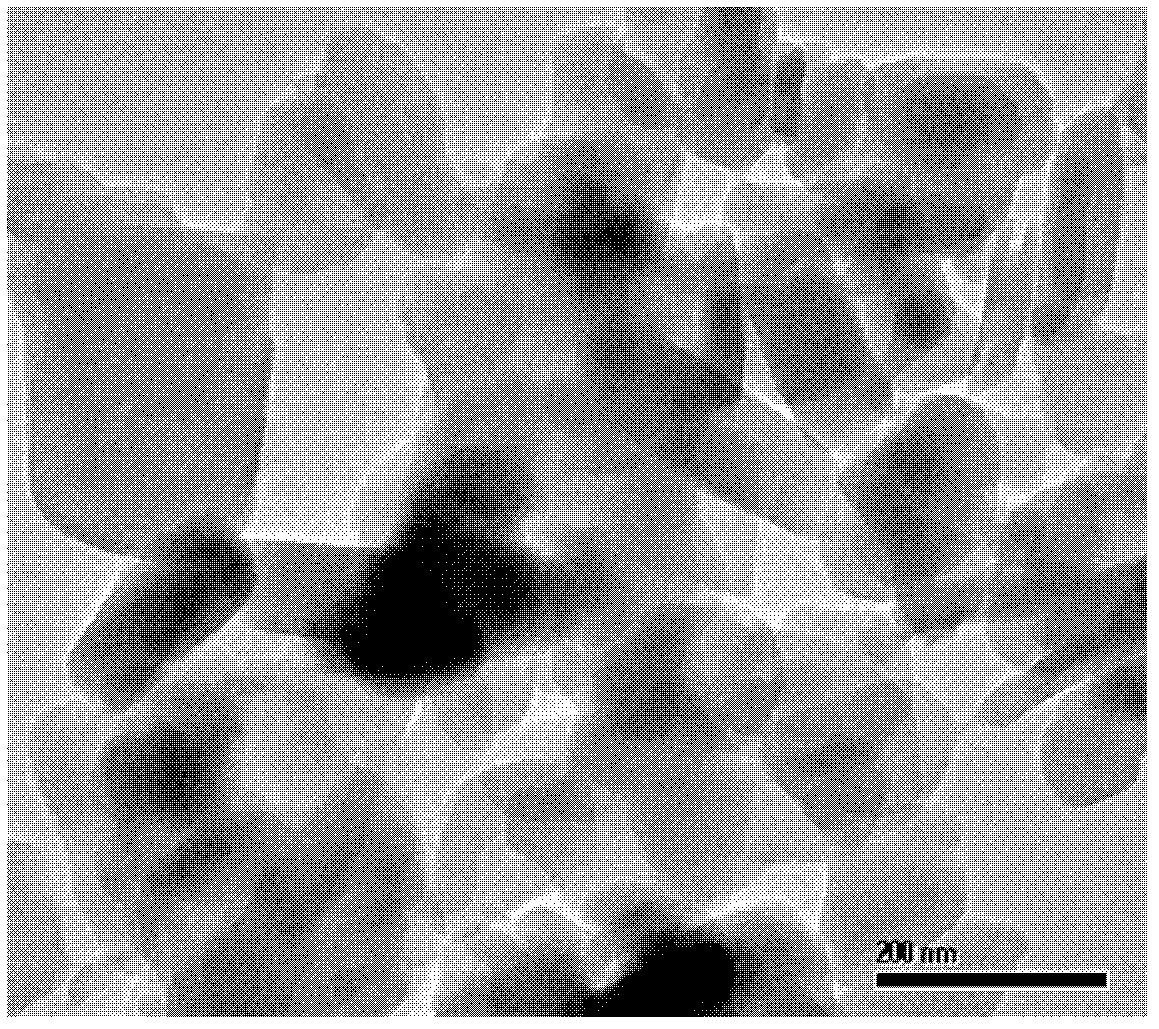

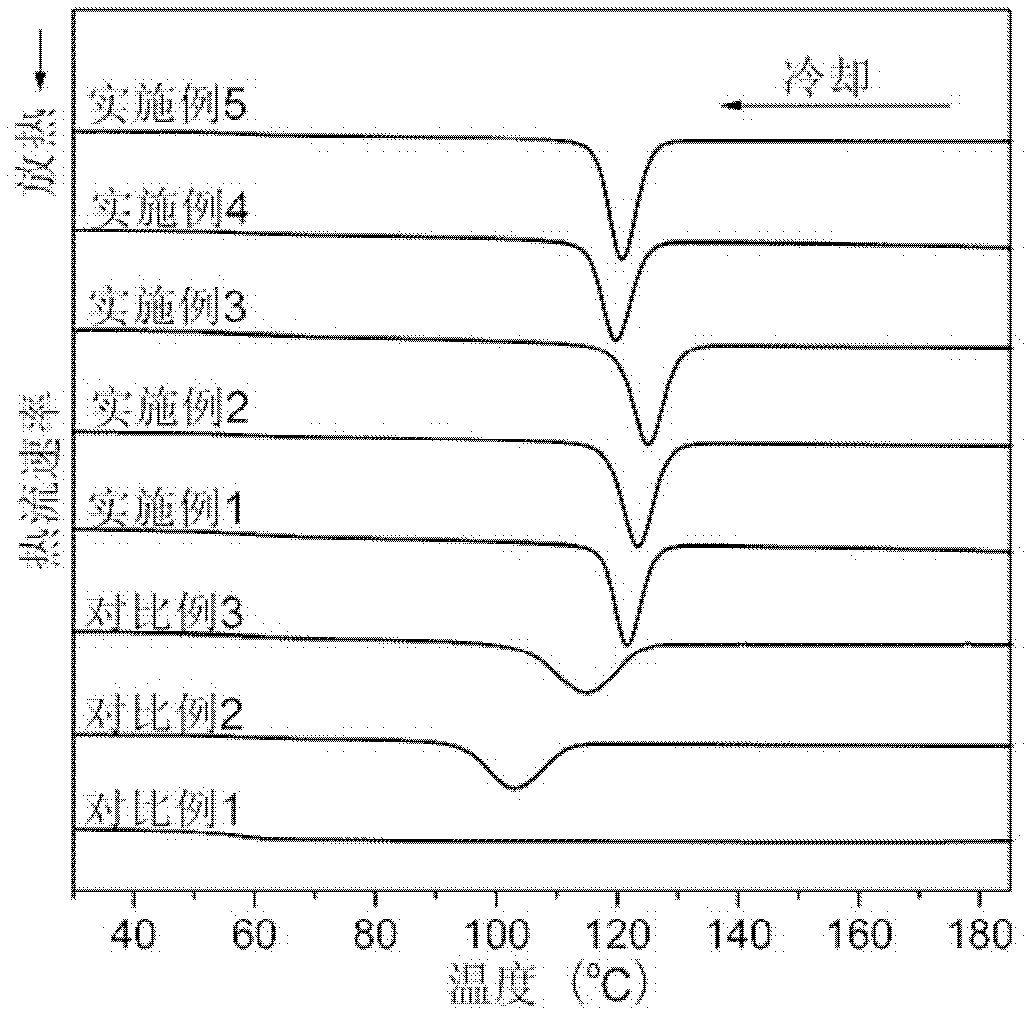

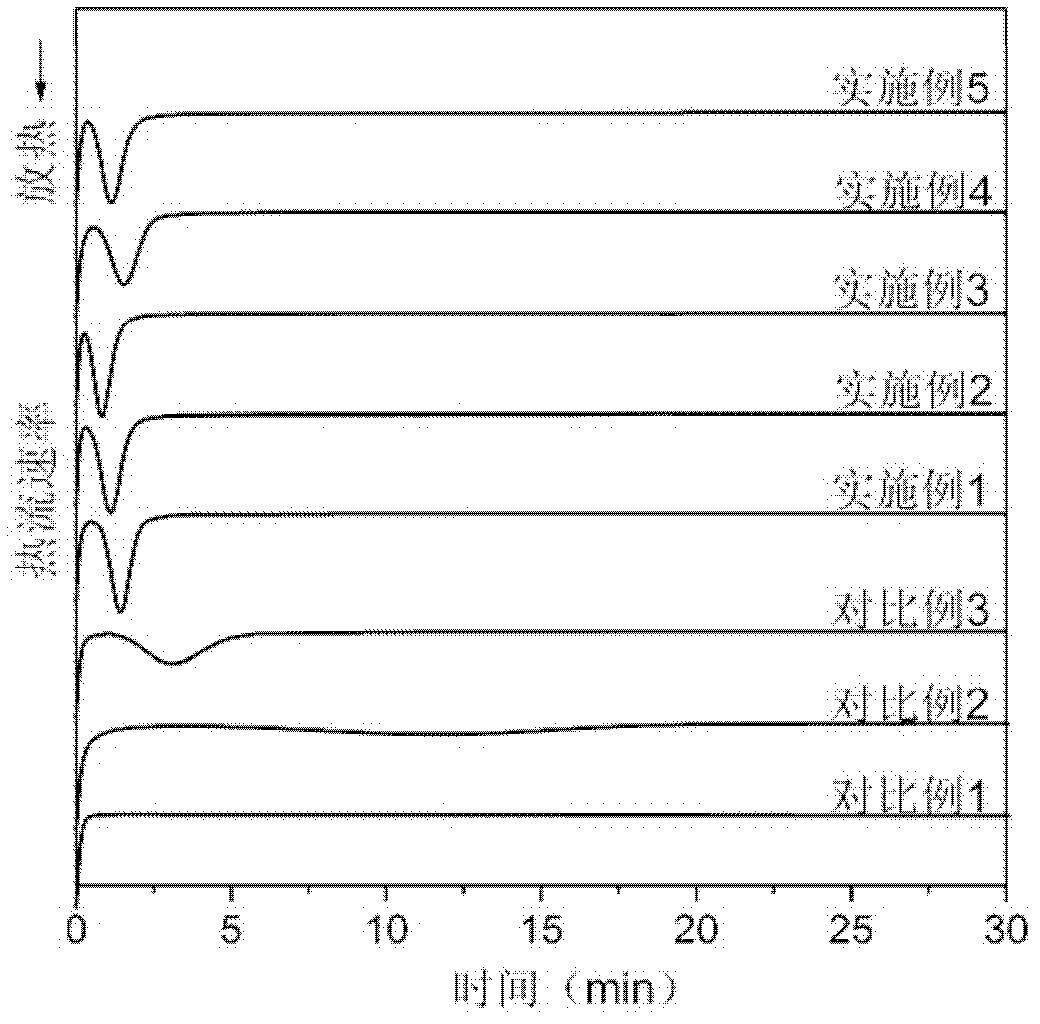

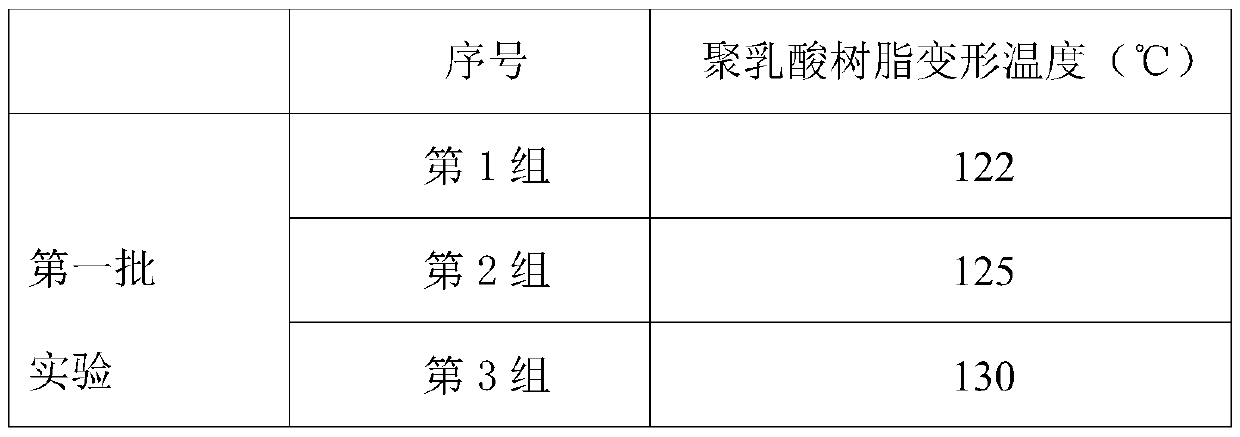

Efficient polylactic acid nucleating agent, and preparation method and application thereof

ActiveCN102584567AEasy to prepareImprove securityCarboxylic acid salt preparationCITRATE ESTERHeat resistance

The invention discloses an efficient polylactic acid nucleating agent, and a preparation method and application thereof and belongs to the technical field of crystallization and modification of polylactic acid. The prepared nucleating agent is a lamellar submicron zinc citrate complex, and is generated by heating zinc salt and citric acid in a mixed solution of water and ethanol and performing reflux reaction. A small amount of the nucleating agent and polylactic acid are mixed in advance and then are fused, blended and molded so as to obtain a polylactic acid product which is highly crystallized and has excellent heat resistance. The prepared nucleating agent has high safety for a human body and an obvious nucleating effect; and a process is simple and environment-friendly, the problems of low crystallization rate and heat resistance of the polylactic acid are solved, the forming processability of the polylactic acid product is improved, and a production cycle is shortened.

Owner:新倍斯(杭州)材料科技有限公司

Alpha linolenic acid cryogenic separation and purification method

InactiveCN102030629AChange concentrationComplete production processFatty acids production/refiningCarboxylic compound separation/purificationNemorensic acidAlpha-Linolenic acid

The invention discloses an alpha linolenic acid cryogenic separation and purification method, comprising the steps of: uniformly mixing oil rich in alpha linolenic acid and acetone or a methanol solvent according to a volume ratio of 1:(3-6), placing a container containing the mixed solution in an environment at (-30)-(-60) DEG C for refrigeration, separating and removing crystals at low temperature when the temperature reaches (-30)-(-60) DEG C, and desolventizing the solution to remove the solvent accounting for 20-30% of the total volume; repeating the steps of refrigeration, crystal removal and desolventization for 3-5 times for separating and removing the crystals; and after circularly removing the crystals for 3-5 times, repeating the steps of refrigeration and crystal removal once again when the volume ratio of the alpha linolenic acid to the solvent reaches 1:(2-3), and desolventizing the finally obtained mixed solution to obtain the alpha linolenic acid. The method is a pure physical cryogenic separation technology and can improve product quality and yield stability, and the concentration of the obtained alpha linolenic acid is above 80%.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

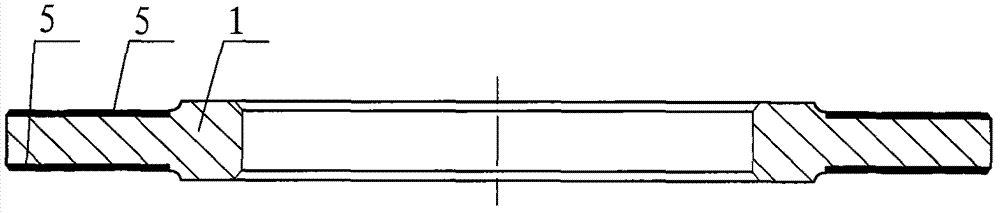

Solid solution sintering method of copper alloy steel piece and sintering of compressor swash plate

The invention discloses a solid solution sintering method of a copper alloy steel piece and sintering of a compressor swash tray and aims at providing the solid solution sintering method of the copper alloy steel piece and sintering of the compressor swash tray which are simple in process, high in production efficiency and easy to control in quality. The steel piece can be put in a die which is made of graphite. Copper alloyed powders can be covered and scattered on the surface of the steel piece of a copper alloy layer which needs sintering so that the surface of the steel piece of the copper alloy layer is covered with the copper alloyed powders. The graphite die which is provided with the copper alloy powders and the steel piece is put in a heating furnace for heating. The heating temperature is 1100 DEG C + / - 50 DEG C. The time of insulation is 2-3 hours. The copper alloy powders are completely melted. After cooling, the graphite die can be demoulded so that the firmly bonded copper alloy layer is formed on the surface of the steel piece, wherein the surface of the steel piece is covered with the copper alloyed powders. The method has the advantages of being high in bonding strength, simple in manufacturing process, high in production efficiency, low in manufacturing cost and good in product quality.

Owner:JIASHAN HONGDA COMPOSITE BEARING

Method for preparing hydrolyzed fish protein powder by utilizing electron beam irradiation and combining enzymolysis technology

InactiveCN106359844AImprove enzymatic hydrolysis efficiencyDelicate tasteAnimal proteins working-upHydrolysisFatty acid

The invention discloses a method for preparing hydrolyzed fish protein powder by utilizing electron beam irradiation and combining an enzymolysis technology, and belongs to the technical field of aquatic product deep processing. The main process of the method comprises the following steps: adding maltodextrin, emulsified starch and the like after washing and carrying out crushing by a meat grinder, electron beam irradiation and enzyme hydrolysis on (fresh, refrigerated or frozen) fish, and carrying out spray drying after emulsifying and homogenizing, thus finally obtaining the hydrolyzed fish protein powder. According to the method disclosed by the invention, electron beam irradiation treatment is carried out before enzyme hydrolysis of fish protein, so that the tissue structure of the fish protein can be loosened, the protein degradation during the enzyme hydrolysis of the fish protein is facilitated, and the efficiency of enzyme can be greatly increased; irradiation also realizes a sterilization effect, so that all kinds of microorganisms in raw materials can be effectively controlled, and a working procedure of cooling after heating during the enzyme hydrolysis is not needed; hydrolyzed fish protein liquid can be emulsified and homogenized before spray drying, the effect of carrying out microencapsulated embedding treatment on fatty acid grease in the raw materials of fish is obtained, the oxidization level of the fatty acid grease in a product processing and storing processes is reduced, and the product quality is enabled to be more stable.

Owner:SHANGHAI ACAD OF AGRI SCI +1

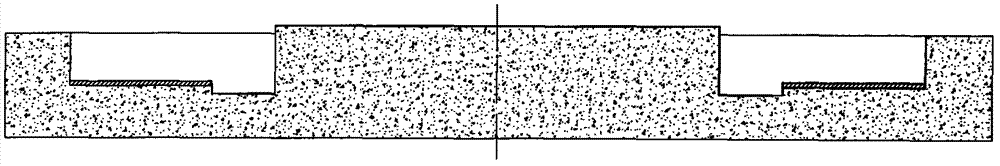

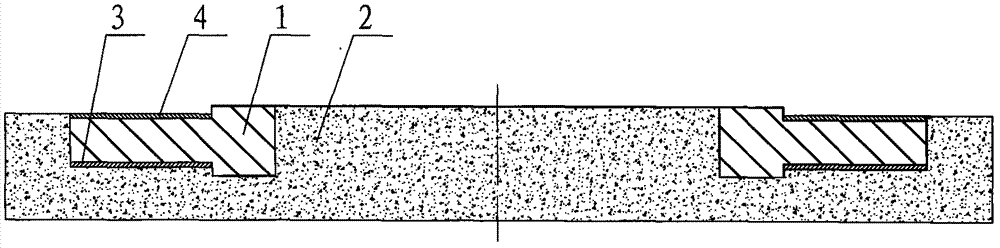

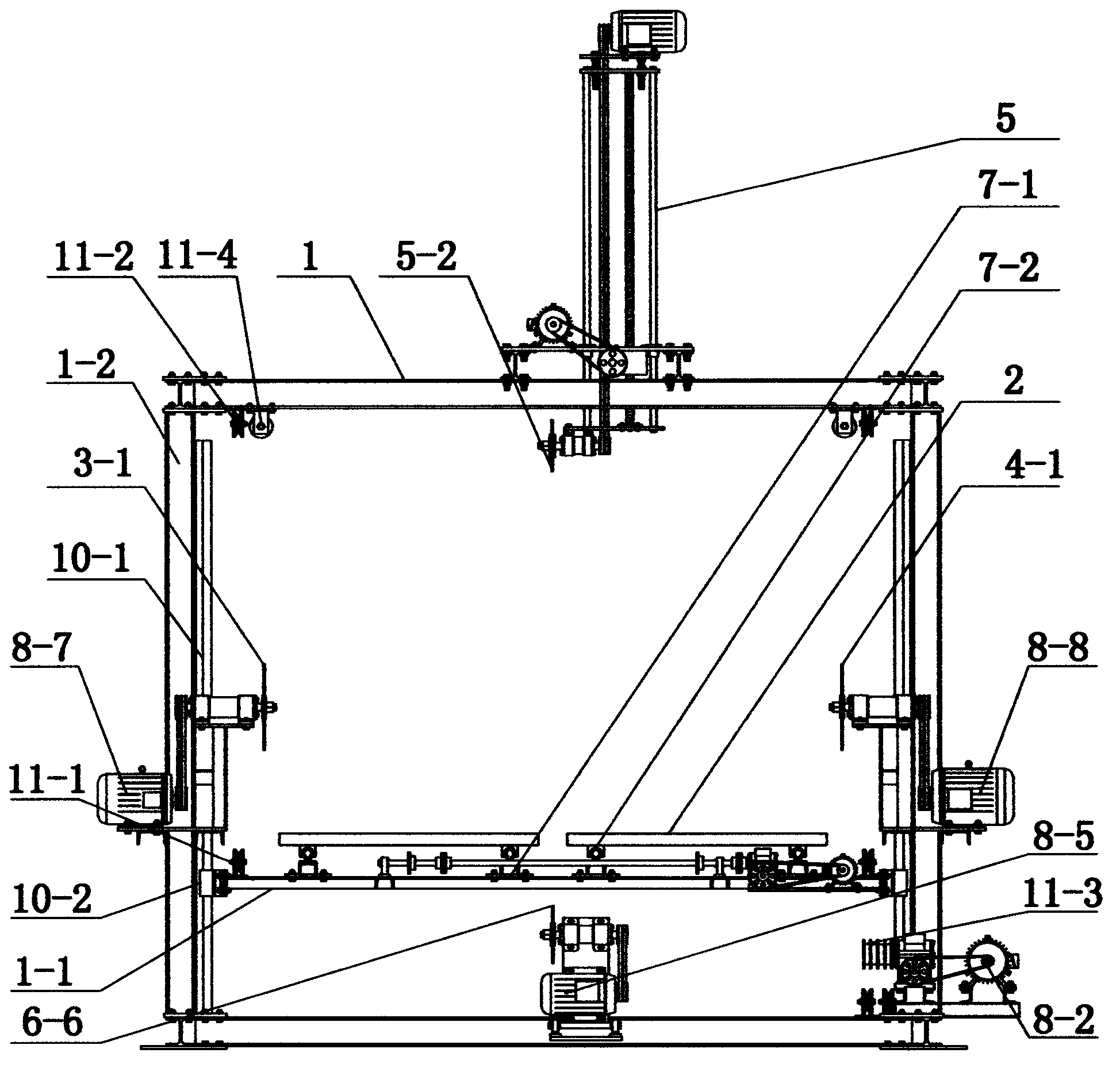

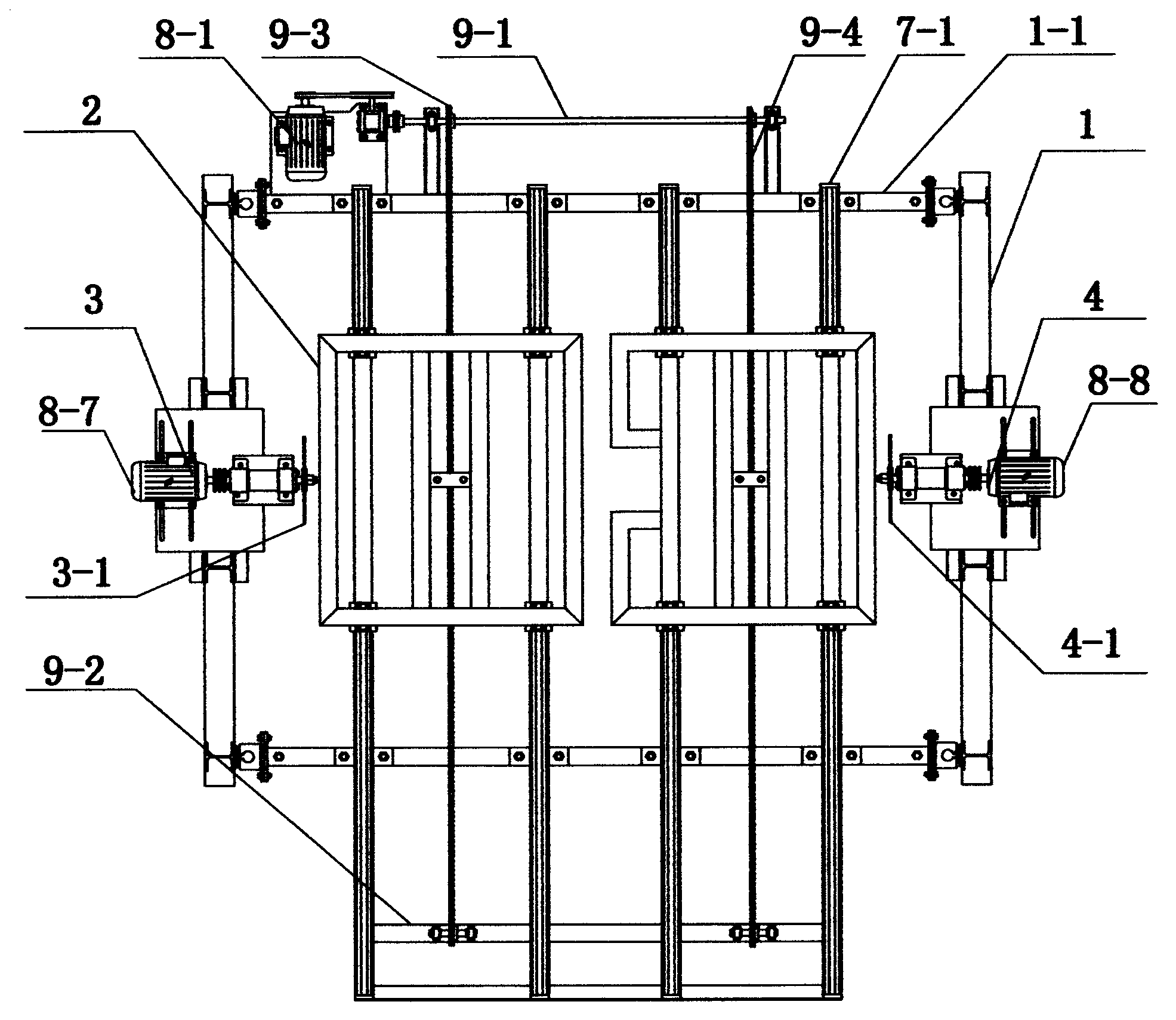

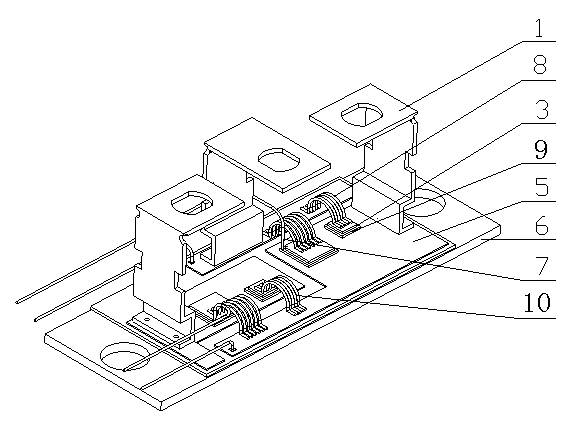

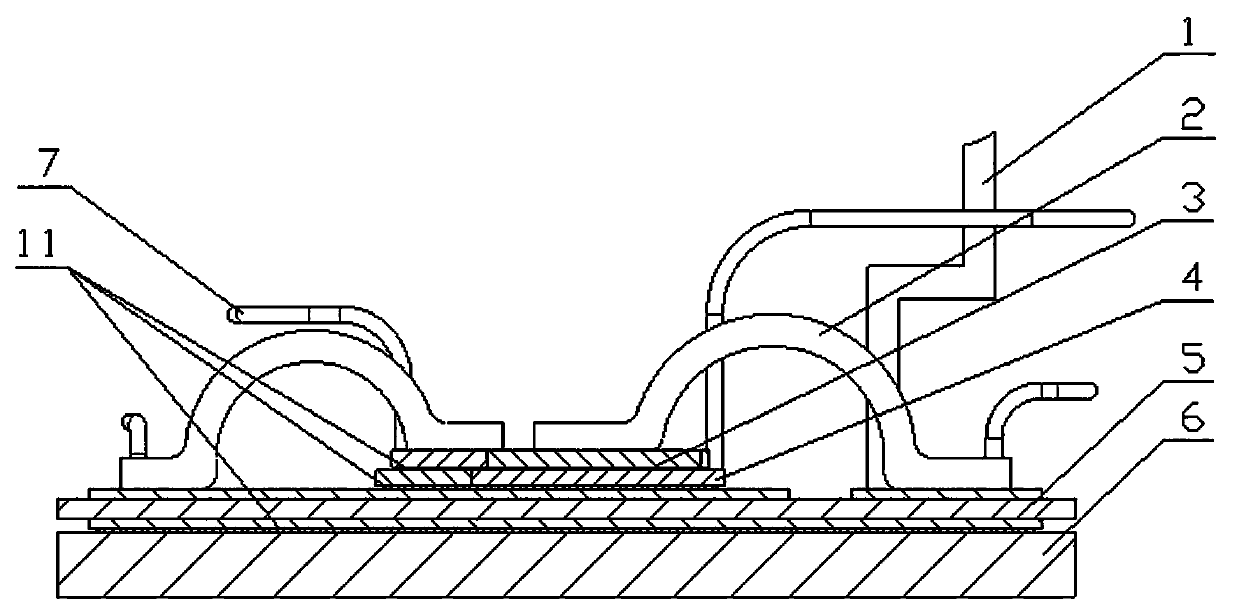

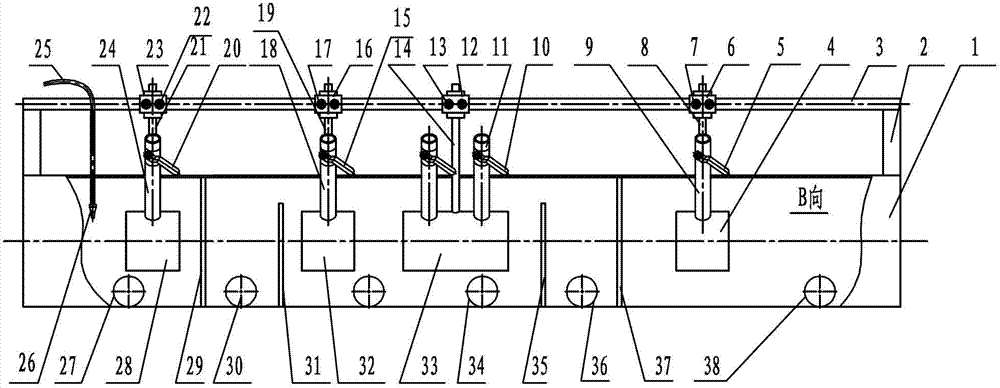

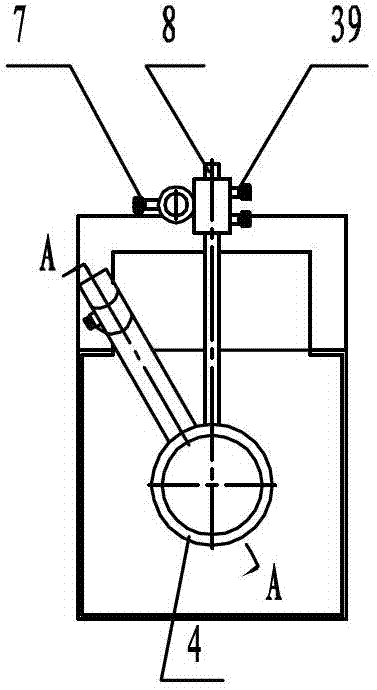

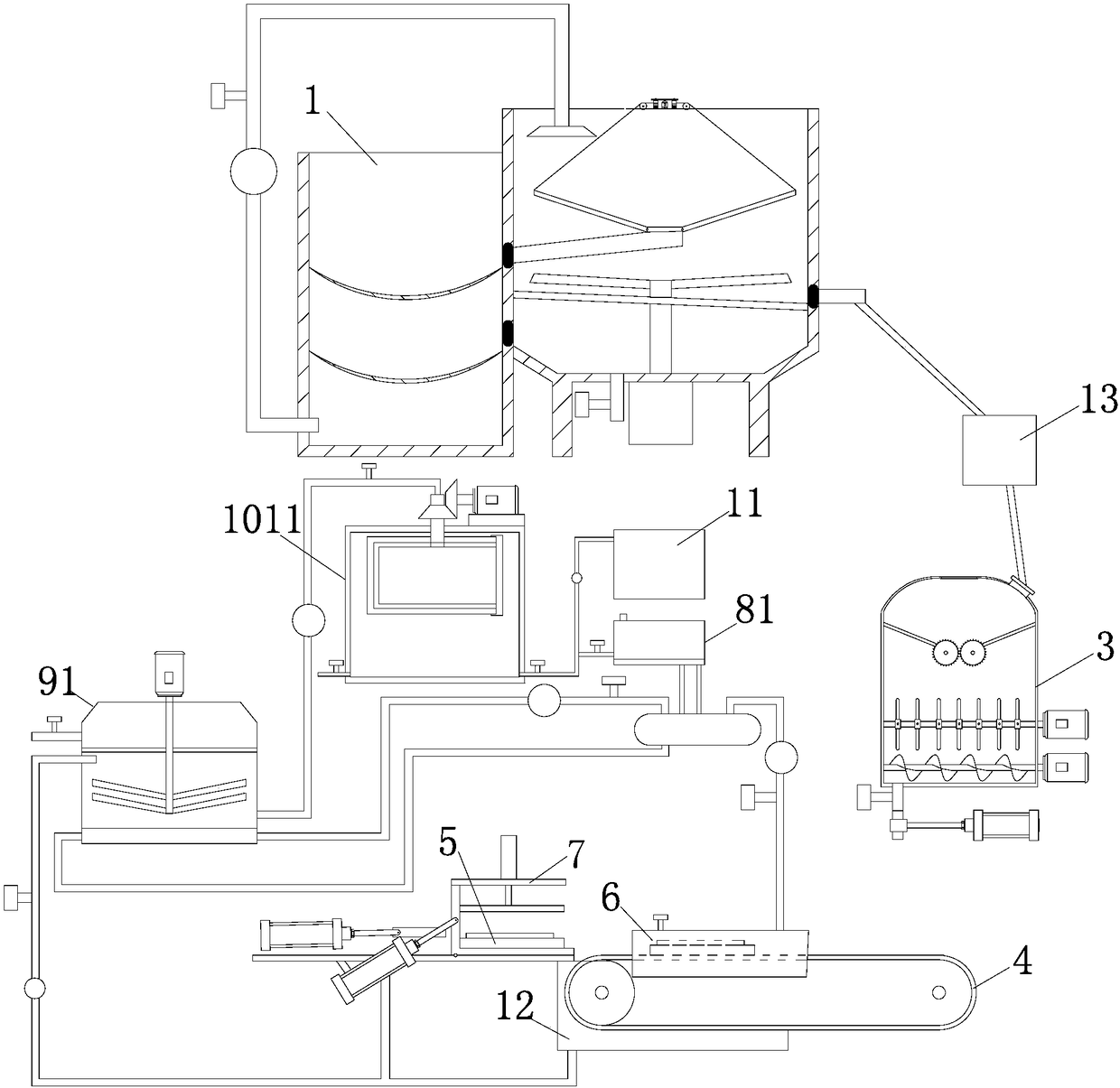

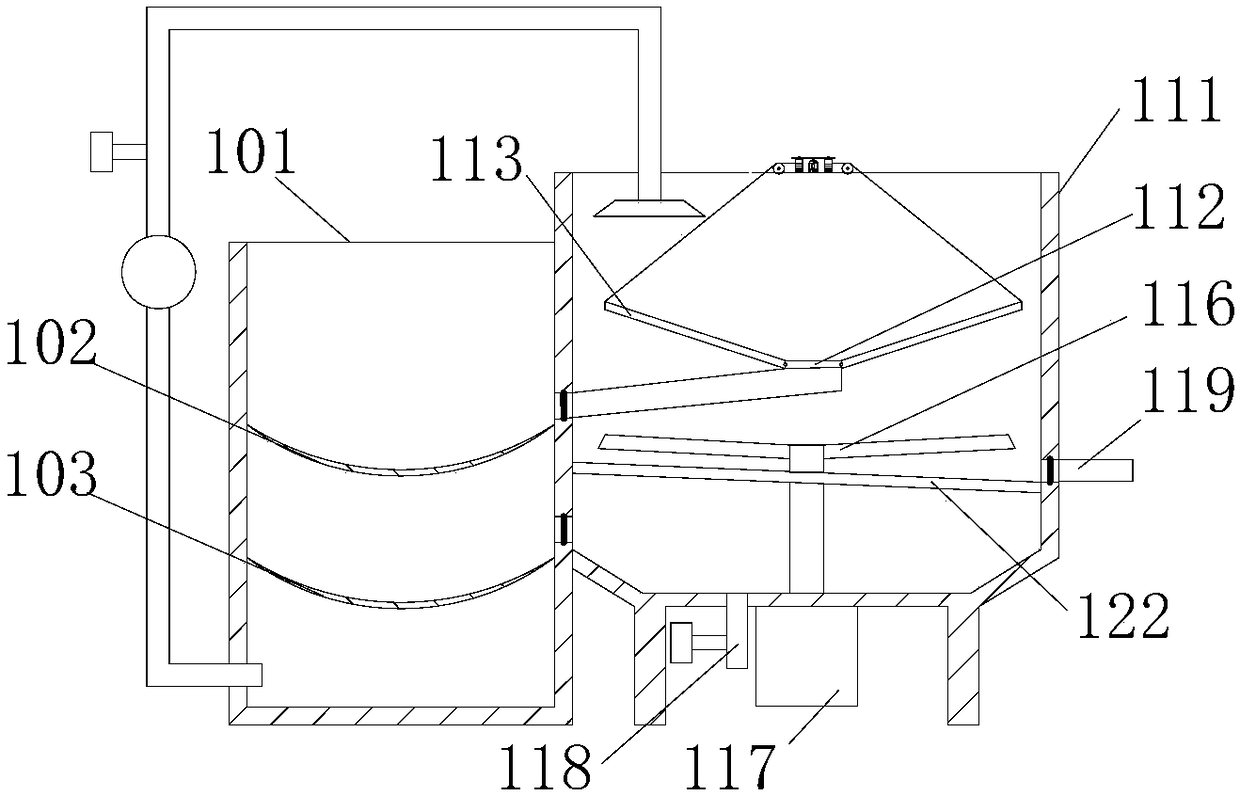

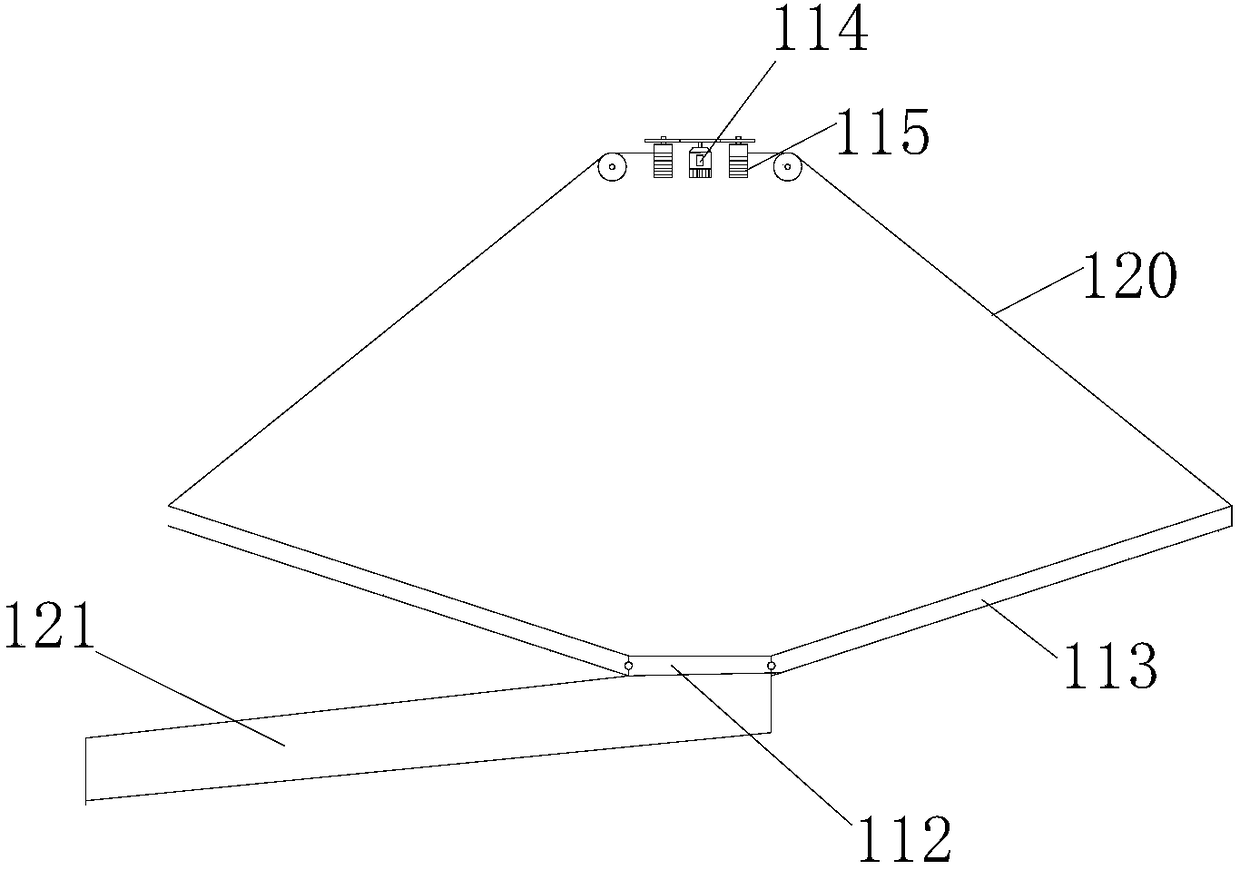

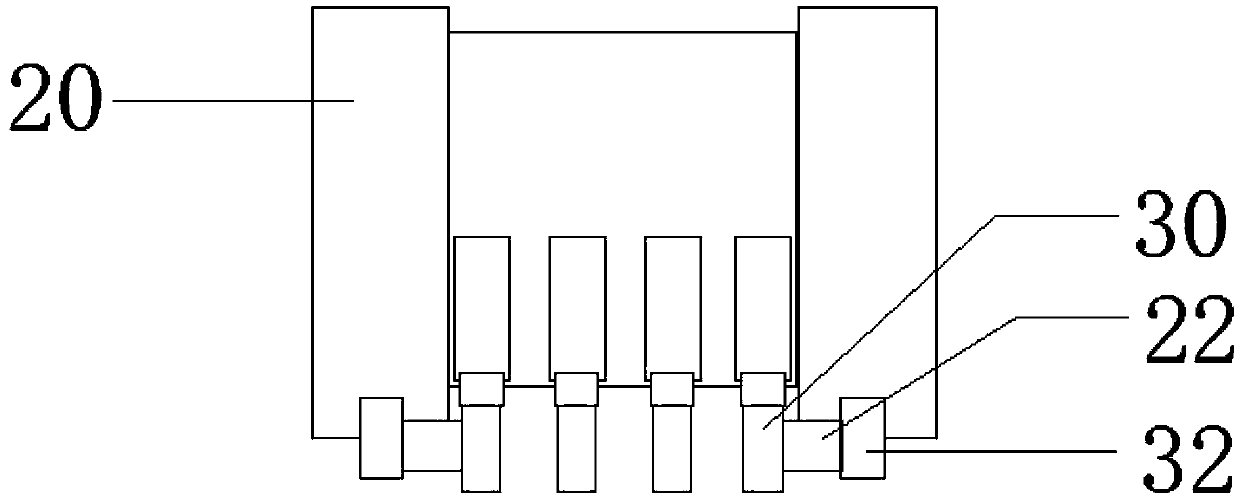

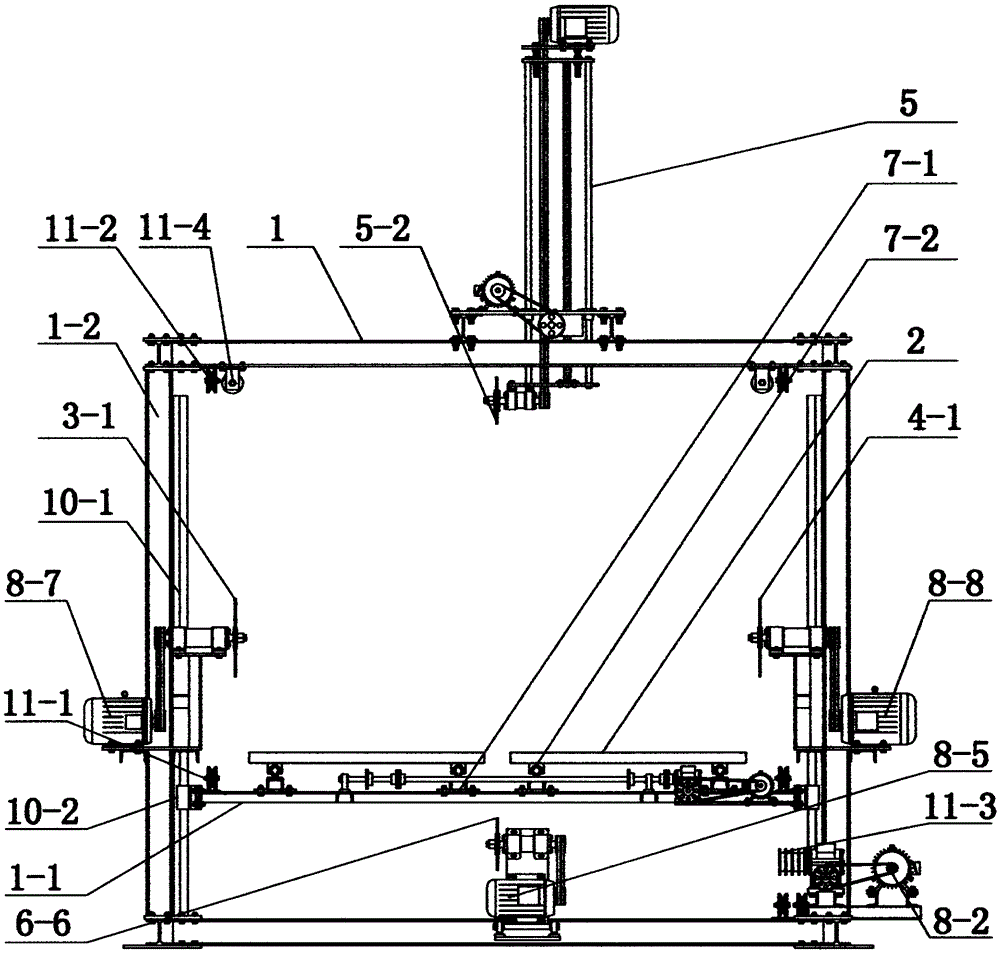

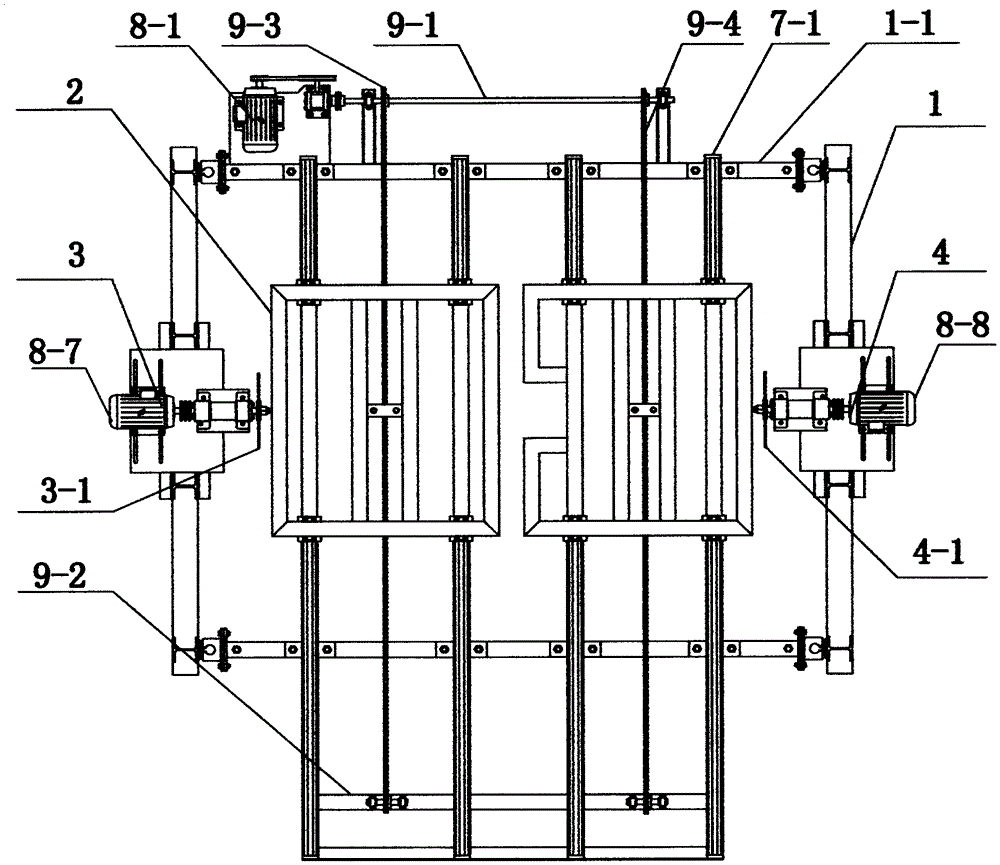

Outer hood cutting equipment for glass epoxy antenna

ActiveCN104354178AShorten the production and processing cycleKeep healthyDirt cleaningMetal working apparatusCutting glassEngineering

The invention relates to outer hood cutting equipment for a glass epoxy antenna. The equipment comprises a cutting base which is provided with a lateral fixing rod and a vertical fixing rod in a fit manner, wherein a working platform elevating mechanism is arranged on the lateral fixing rod and the vertical fixing rod in a fit manner, a working platform is arranged on the lateral fixing rod, and the working platform and the lateral fixing rod are arranged in a fit manner through a lateral displacement mechanism which is arranged in a direction of front to back; a left cutting mechanism and a right cutting mechanism which are arranged on the same lateral height are respectively arranged on the left side and the right side of the cutting base; an upper cutting mechanism and a lower cutting mechanism are correspondingly arranged at the top and the lower part of the cutting base; the working platform elevating mechanism, the lateral displacement mechanism, the left cutting mechanism, the right cutting mechanism, the upper cutting mechanism and the lower cutting mechanism are connected to a control mechanism. Through the adoption of the cutting equipment disclosed by the invention, the production and processing cycle of the outer hood of the glass epoxy antenna is shortened, the working efficiency is improved, the precision of products is improved, the probability that when an operator cuts the burrs of glass-reinforced plastics, particles are sucked in the body of the operator is reduced, the human body of the operator is guanrateed to be healthy, and the operating environment is clean and environmental-friendly.

Owner:ZHEJIANG E STRONG COMM TECH

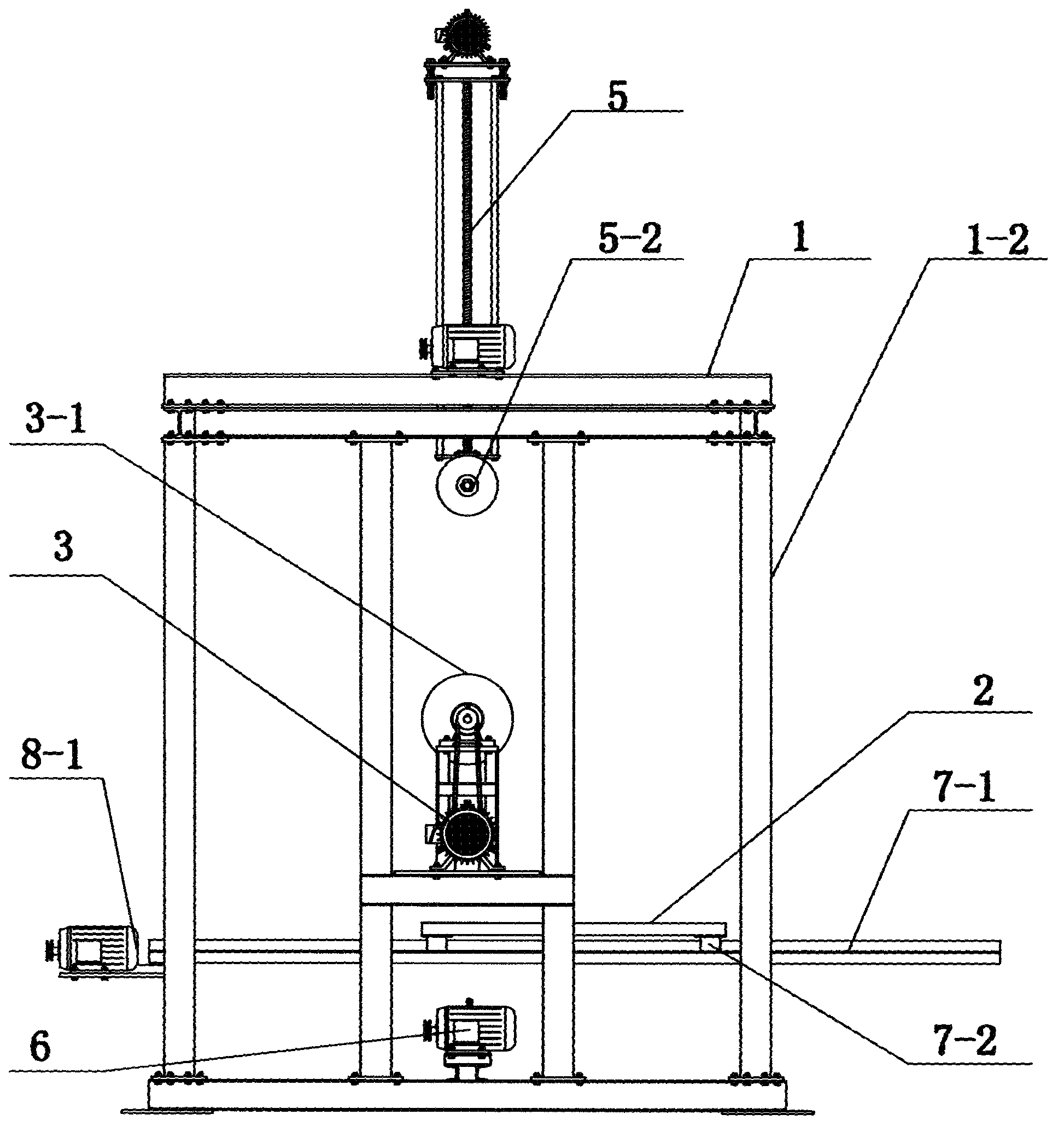

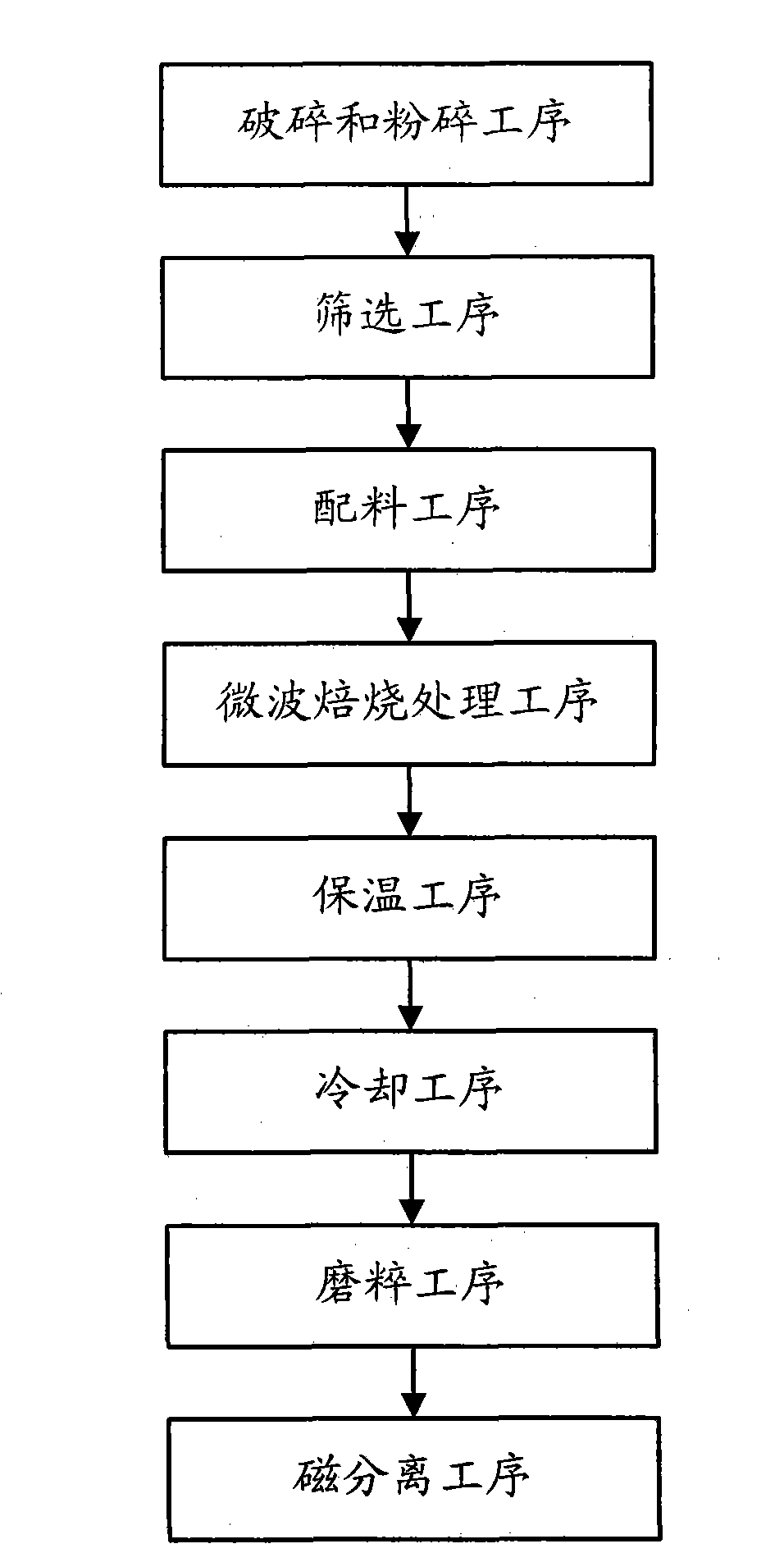

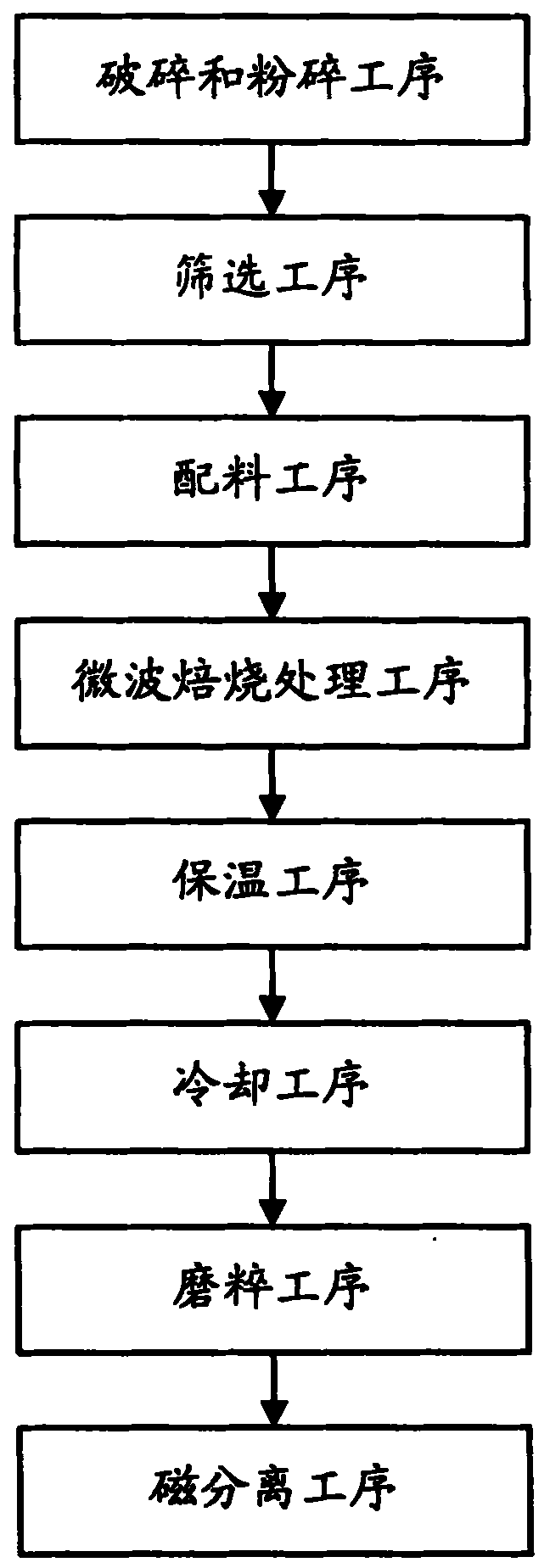

Method for converting natural non-magnetic iron ore into magnetite

InactiveCN102168170AIncrease profitComplete production processSievingScreeningMicrowave methodMagnetite

The invention discloses a method for converting natural non-magnetic iron ore into magnetite by a microwave method, and particularly relates to a method for converting non-magnetic iron ore such as natural limonite, hematite and siderite into the magnetite through processes of crushing, smashing, sieving, mixing, microwave roasting treatment, heat preservation, cooling, grinding, magnetic separation and the like. In the method, the production process is intact, the mechanization degree is high, production processing cycle is shortened, production processing speed is improved, the conversion rate of a magnetite powder product is high, and the continuous production can be realized; and the device simultaneously has the characteristics of energy conservation and high efficiency, and can improve the quality of products and the stability of the yield.

Owner:SHANGHAI MAIFENG MICROWAVE EQUIP

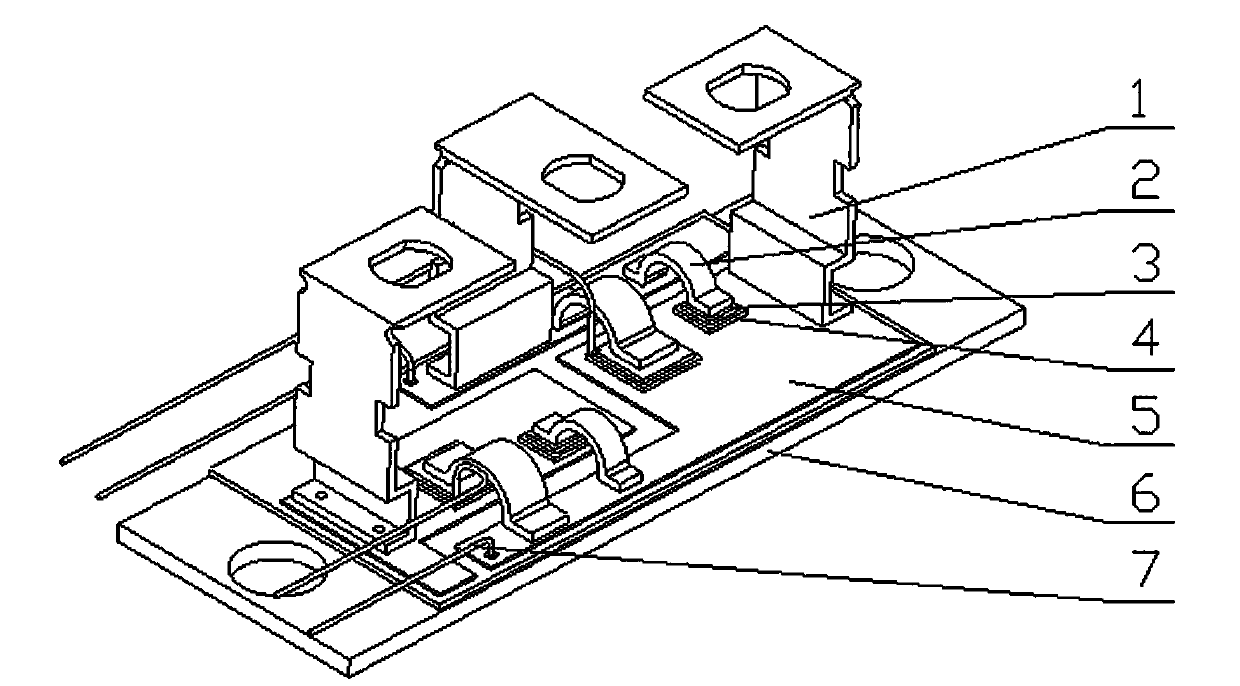

Busbar connection type high-performance IGBT (insulated gate bipolar transistor) module and manufacturing method thereof

ActiveCN104218031AIncrease contact areaImprove overload capacitySemiconductor/solid-state device detailsSolid-state devicesBusbarSemiconductor chip

The invention relates to a busbar connection type high-performance IGBT (insulated gate bipolar transistor) module and a manufacturing method thereof, belongs to the technical field of power semiconductor devices and power electronics and mainly solves the problems of low operational reliability of devices, poor surge current capacity and overload capacity of IGBT devices and small contact areas of chips and connection lines in aluminum wire bonding. The busbar connection type high-performance IGBT module is mainly characterized by comprising a shell, a bottom plate, electrodes, semiconductor chips, DBCs, busbars, molybdenum plates, soldering fluxes and the like. The semiconductor chips, the DBCs, the electrodes, the busbars, the molybdenum plates and the soldering fluxes are packaged in the shell, and the chips, the DBCs and the electrodes are connected through the busbars. A busbar connection method includes: sequentially assembling all the parts into a special tool, fastening and welding in a vacuum furnace. The busbar connection type high-performance IGBT module and the manufacturing method thereof are pretty applicable to high-frequency, high-power and high-reliability semiconductor devices and have the advantages that frequency characteristics of the IGBT devices can be remarkably improved to further improve switching performance of the devices. Compared with the prior art, the busbar connection type high-performance IGBT module and the manufacturing method thereof have the advantages that investment is saved, and production and processing cycle is shortened.

Owner:HUBEI TECH SEMICON

Method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes

ActiveCN102817038AGuaranteed StrengthSolve the mechanical propertiesFurnace typesHeat treatment furnacesInduction hardeningRebar

The invention relates to a method for production of high-strength threaded steel bar through on-line quenching and tempering, and heating blackening coating processes. The method includes the following steps of: subjecting a thread steel bar to multistage induction quenching heating, controlling the temperature of a quenching preheating zone at 700-850DEG C and the temperature of a quenching heat preservation zone at 820-950DEG C, and keeping the speed of quenching heating at 0.2-0.5m / min, then carrying out a quenching treatment, performing cooling at a cooling speed of 50-100DEG C / s, controlling the temperature of the thread steel bar released out of a spray ring cooling device at 60-100DEG C, then performing multistage induction tempering heating at a proceeding speed of 0.2-0.5m / min, controlling the tempering temperature at 500-650DEG C, delivering the tempered threaded steel bar to a surface coating zone to conduct heating blackening antiseptic treatment, implementing online packaging, and finally conducting offline storage. The technological method realizes on-line quenching and tempering, and heating blackening production of high-strength threaded steel bars, and has the characteristics of small deformation of workpieces, high production efficiency, energy saving, environmental protection, and less pollution, etc.

Owner:LIUZHOU OVM MASCH CO LTD

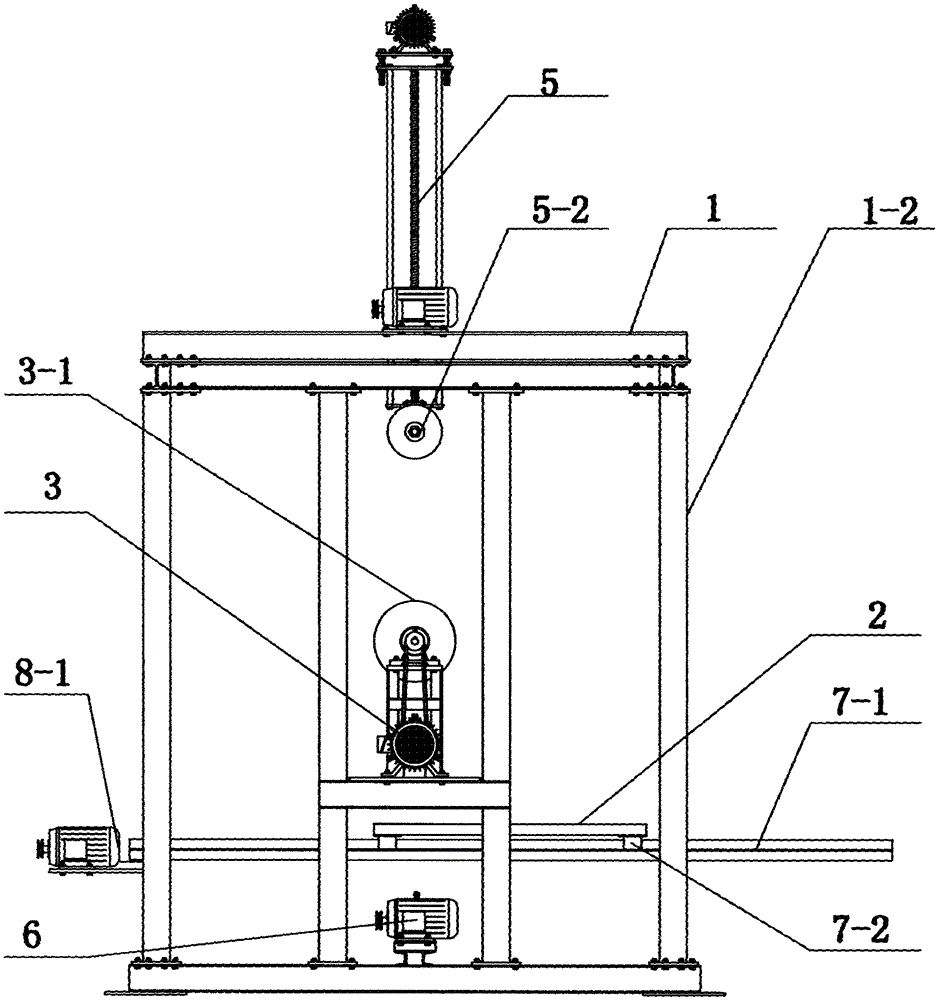

Environmentally friendly rotary multi-layer dry distillation, drying and carbonization integrated furnace

The invention belongs to the technical field of carbonization furnaces and provides an environment-friendly rotational type multi-layer dry-distillation, drying and carbonization integrated furnace. The furnace comprises an outer rotating cylinder, a middle rotating cylinder and an inner rotating cylinder which are arranged from outside to inside sequentially, wherein the outer rotating cylinder and the middle rotating cylinder are opened oppositely, and the outer rotating cylinder and the inner rotating cylinder are opened in the same direction; the outer rotating cylinder is arranged in a combustion chamber; a drying layer, a pre-carbonization layer, a carbonization layer which are communicated sequentially are arranged in the inner rotating cylinder, between the inner rotating cylinder and the middle rotating cylinder as well as between the outer rotating cylinder and the middle rotating cylinder; the inner rotating cylinder is connected with a feeding bin; a gas outlet is formed in one end of the outer rotating cylinder, and the other end is connected with a collecting tank; the gas outlet is connected with a flue gas recovery unit through a gas collecting device; guide plates are arranged on the outer rotating cylinder, the middle rotating cylinder and the inner rotating cylinder. The furnace is ingenious in conception, and solves the technical problems of simple design, lower heat energy utilization rate, high fuel consumption, long production cycle and unstable product quality of a single carbonization furnace in the prior art.

Owner:张启泰

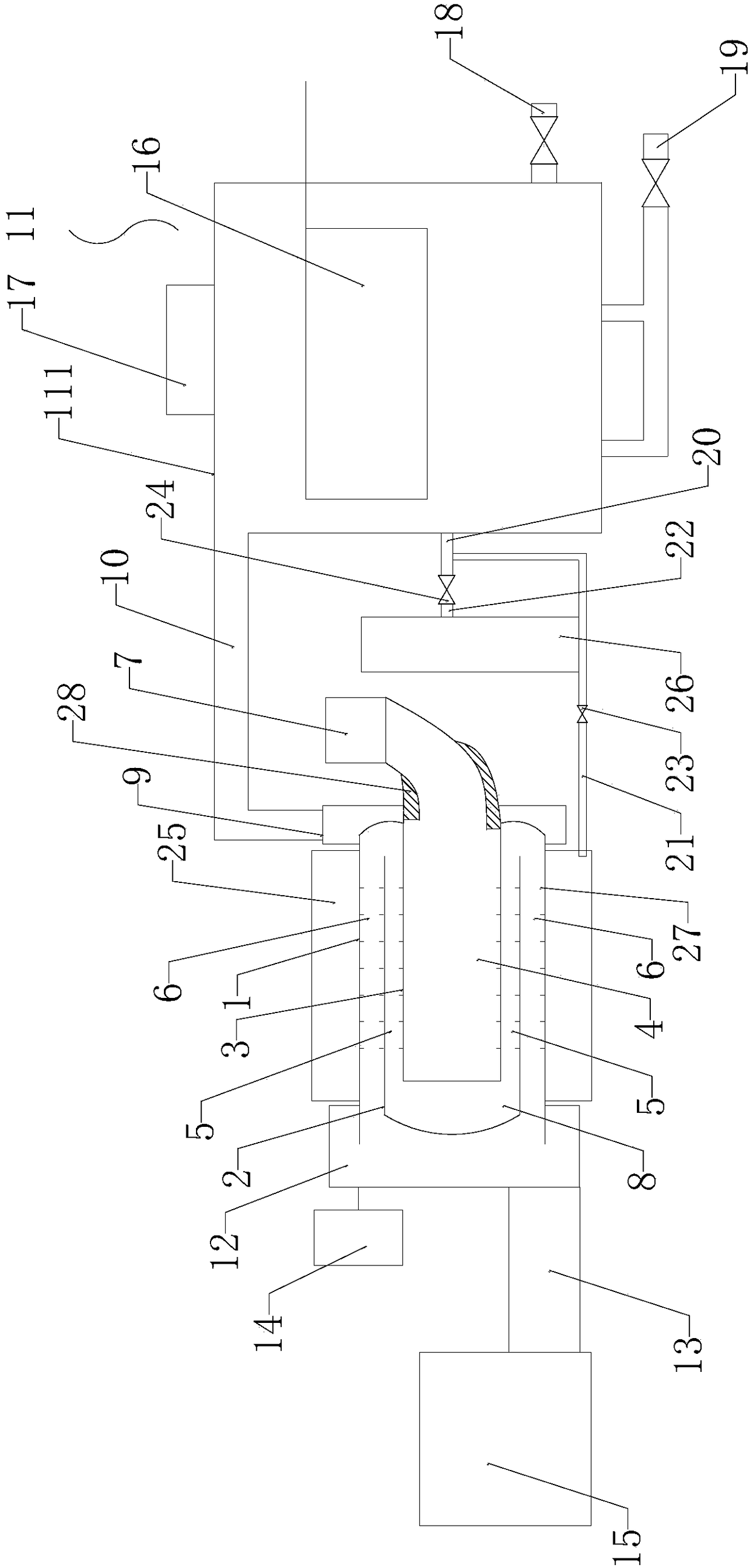

Pressing type efficient soybean oil production device

InactiveCN108410568AIncrease productivityEasy for production managementFatty-oils/fats refiningFatty-oils/fats productionOil waterPre treatment

The invention relates to a pressing type efficient soybean oil production device. The pressing type efficient soybean oil production device is characterized in a soybean preprocessing system comprisesa cleaning unit and a crushing unit, the cleaning unit is used for removing light impurities, gravels and dust mixed in soybeans, and the crushing unit is used for crushing the cleaned soybeans to obtain crushed soybeans; a soybean pressing system is used for pressing the crushed soybeans; a centrifugal separation system is used for performing oil-water separation on crude oil obtained after thepressing; the soybean pressing system comprises a primary pressing unit and a secondary pressing unit, a crushed-soybean feeding mechanism is arranged above the feed inlet of the secondary pressing unit, the crushed-soybean feeding mechanism comprises a feeding motor, a feeding screw and a slider, and the movement journey terminal of the slider is provided with a conveying belt. The pressing typeefficient soybean oil production device is high in process continuity, high in automation level, convenient in production management, high in soybean oil yield and high in soybean oil production efficiency.

Owner:杨海萍 +5

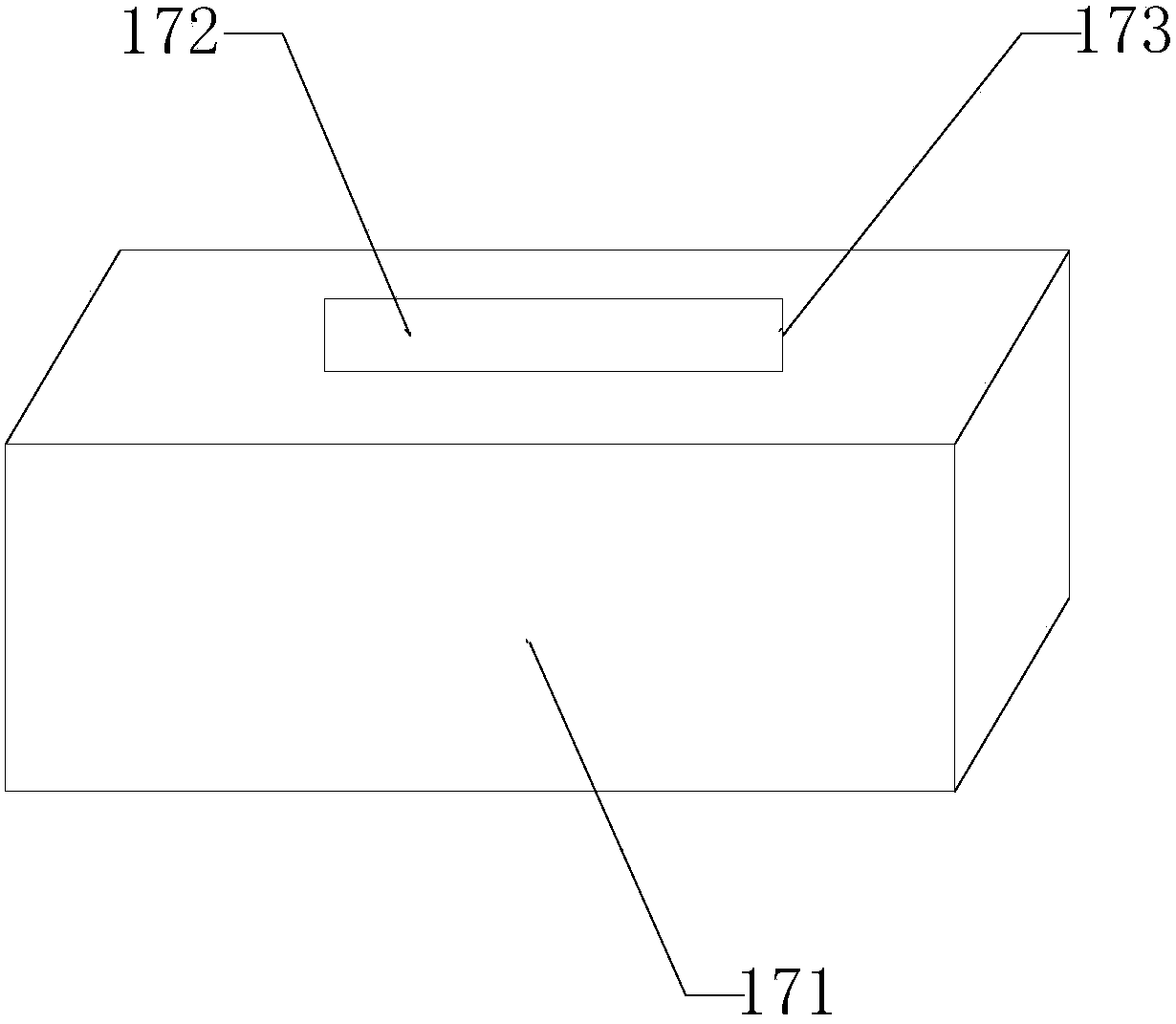

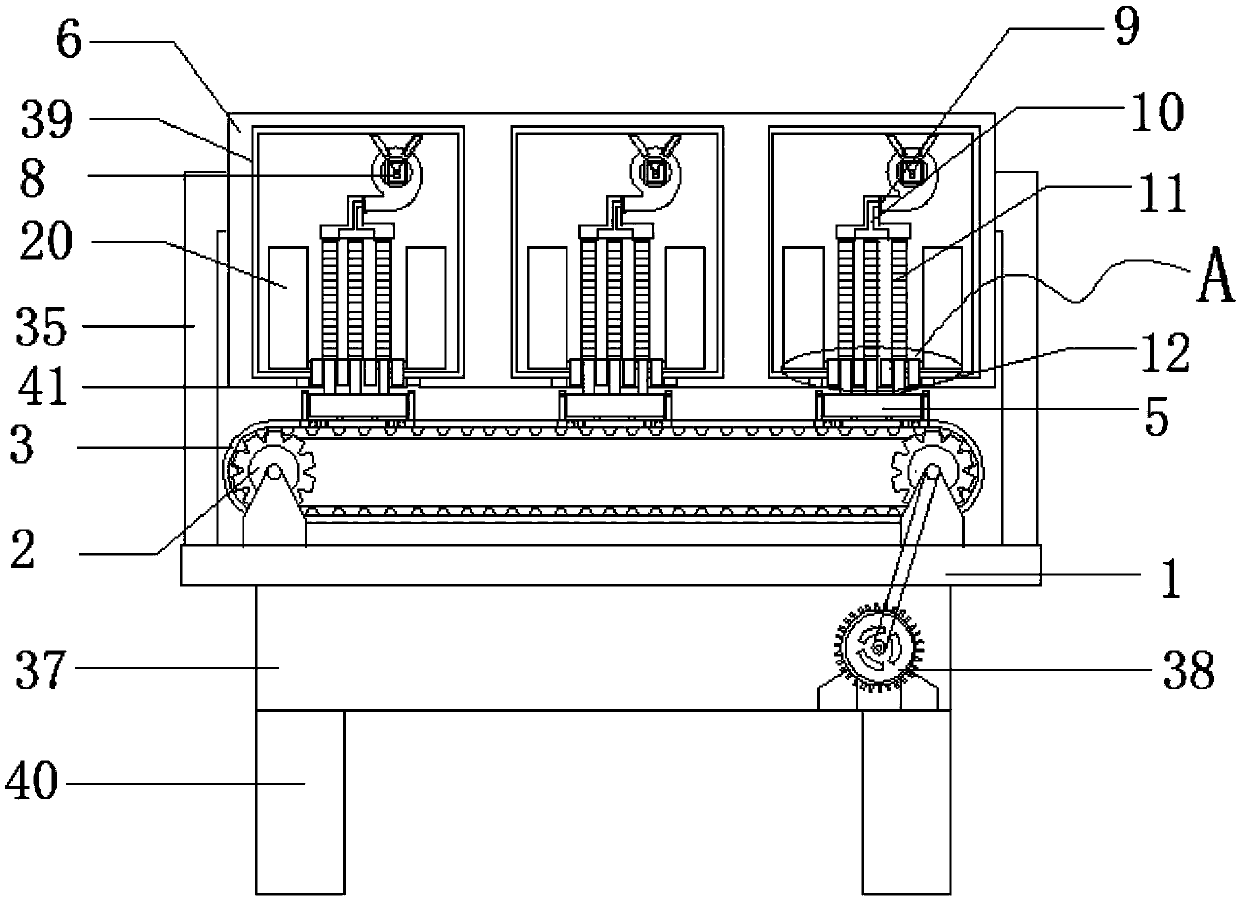

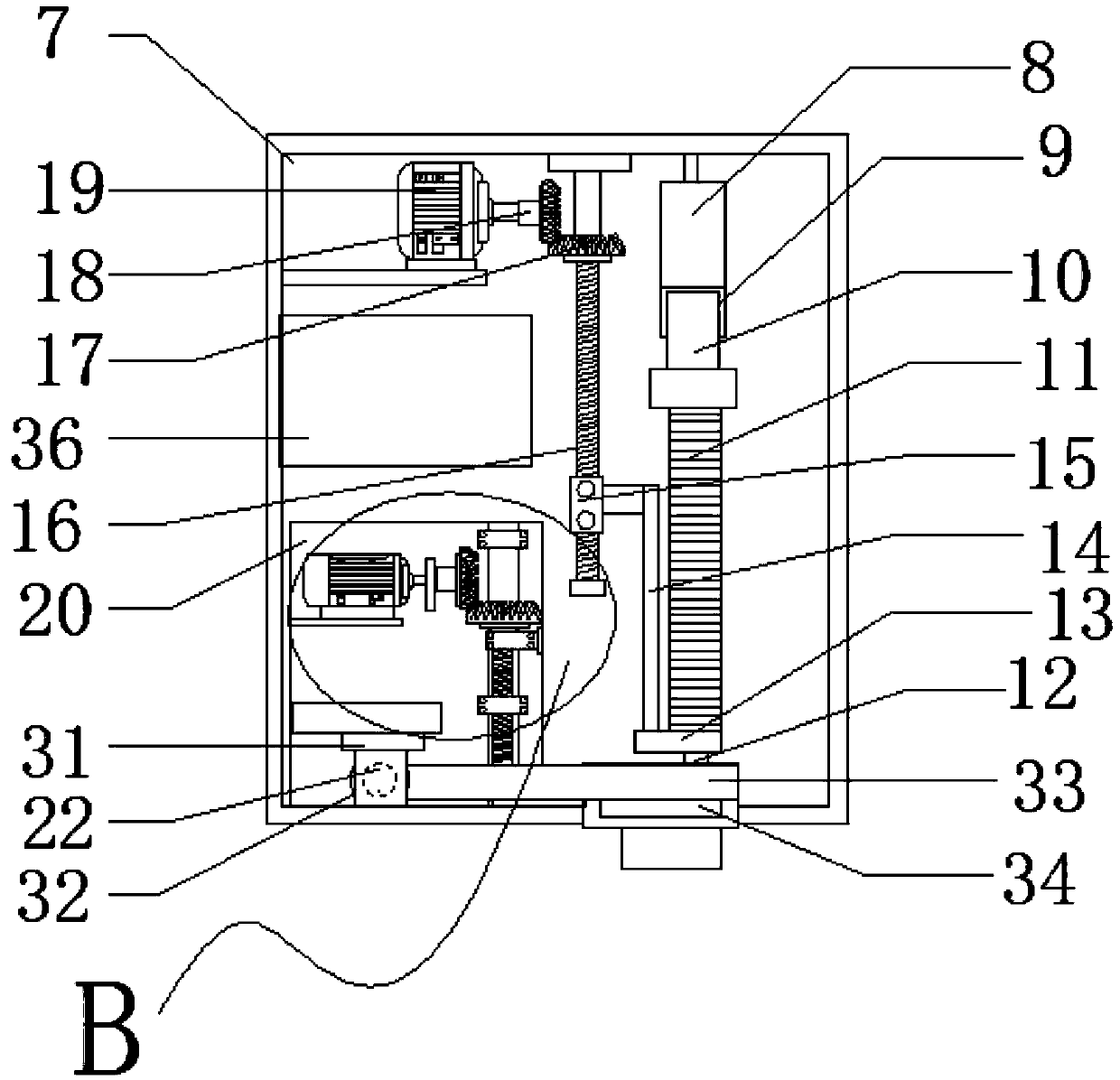

Fully-automatic vacuum packing device for drugs

ActiveCN108100351AHigh degree of automationShorten the production and processing cyclePackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringFully automatic

The invention discloses a fully-automatic vacuum packing device for drugs, and relates to the technical field of biology and new medicine. The fully-automatic vacuum packing device comprises a supporting platform, wherein the two sides of the top end of the supporting platform are fixedly connected with transmission gears through supporting devices, the peripheries of the transmission gears are inmeshed connection with a conveying caterpillar track, the outer walls of the two sides of the conveying caterpillar track are fixedly connected with fixing devices, and the fixing devices are fixedlyconnected with tablet packing aluminum foil; the outer walls of the two sides of the supporting platform are fixedly connected with a main working box through support fixators, and the inner walls ofthe two sides of the main working box are connected with vacuum packing boxes uniformly and fixedly; the inner wall of the top end of one side, close to the conveying caterpillar track, of each vacuum packing box is fixedly connected with a vacuum pump; and the bottom end of each vacuum pump communicates with an extraction opening. The fully-automatic vacuum packing device for the drugs improvesthe automation degree of drug vacuum packing, shortens the production and processing cycles of the drugs, improves the packing efficiency and meanwhile optimizes the vacuumizing effect.

Owner:亳州广源堂中药饮片有限公司

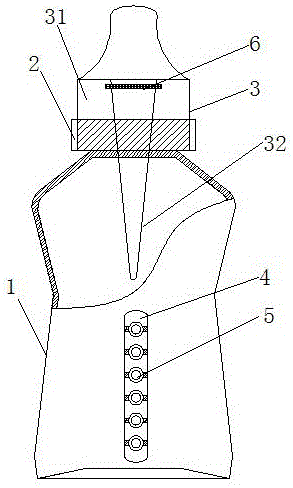

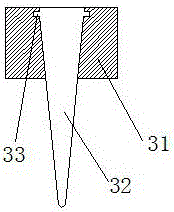

Novel high-strength and wear-resistant thermochromic glass milk bottle and preparation process thereof

PendingCN105997524AImprove cutting efficiency and effectShorten the production and processing cycleFeeding-bottlesGlass reforming apparatusChemistryBiotechnology

The invention discloses a novel high-strength and wear-resistant thermochromic glass milk bottle and a preparation process thereof. The milk bottle comprises a milk bottle body and a bottle cap, wherein the milk bottle body is in threaded and sealed connection with the bottle cap; a nipple connector in threaded and sealed connection with the bottom cap is arranged at the upper end of the bottle cap and is connected with a nipple in a sealed manner; a thermochromic groove is vertically formed in the milk bottle body, and a plurality of thermochromic parts are arranged in the thermochromic groove in parallel in the longitudinal direction. The milk bottle is simple in structure and can conveniently, quickly and accurately sense the temperature in the bottle milk, the safety is improved when a baby drinks milk in the milk bottle, and besides, the milk bottle prepared with the preparation process has high strength, high thermal resistance, good wear resistance and high production efficiency.

Owner:DANYANG SHUANGFENG GLASS

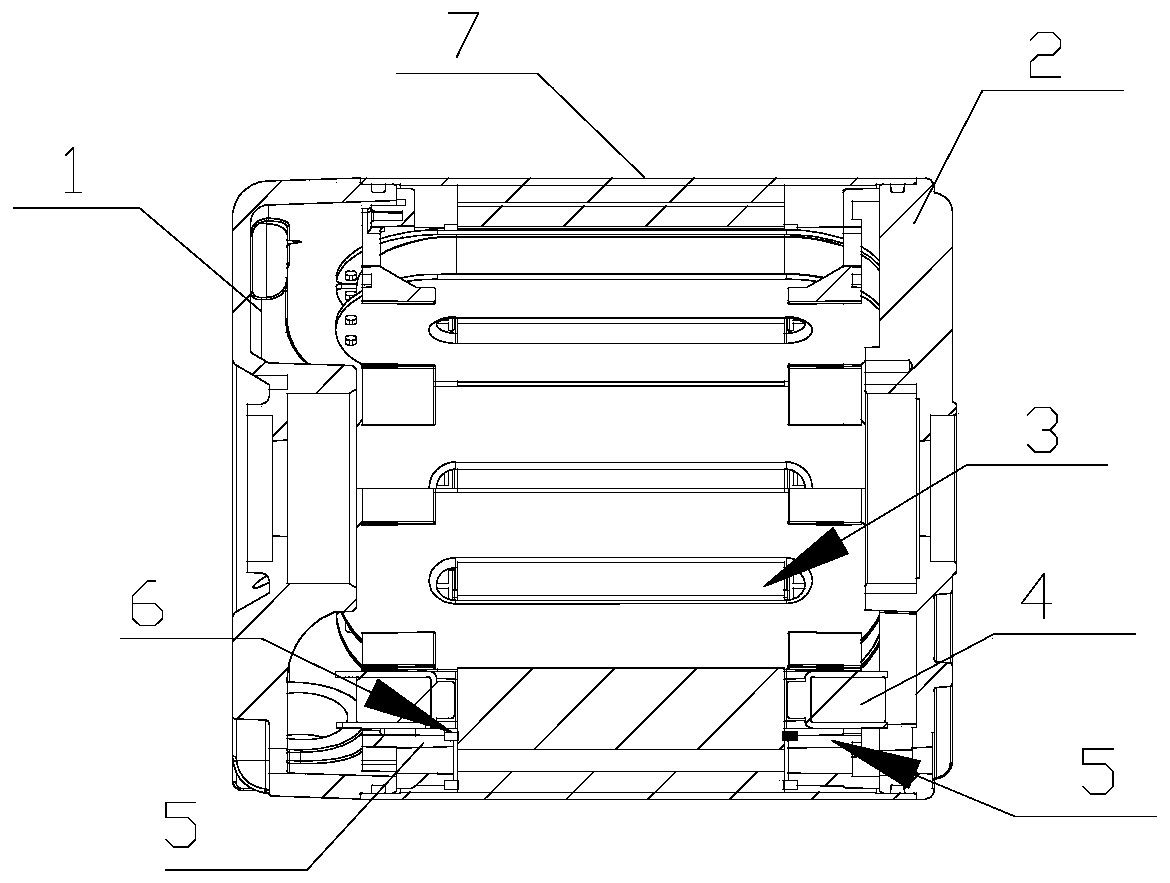

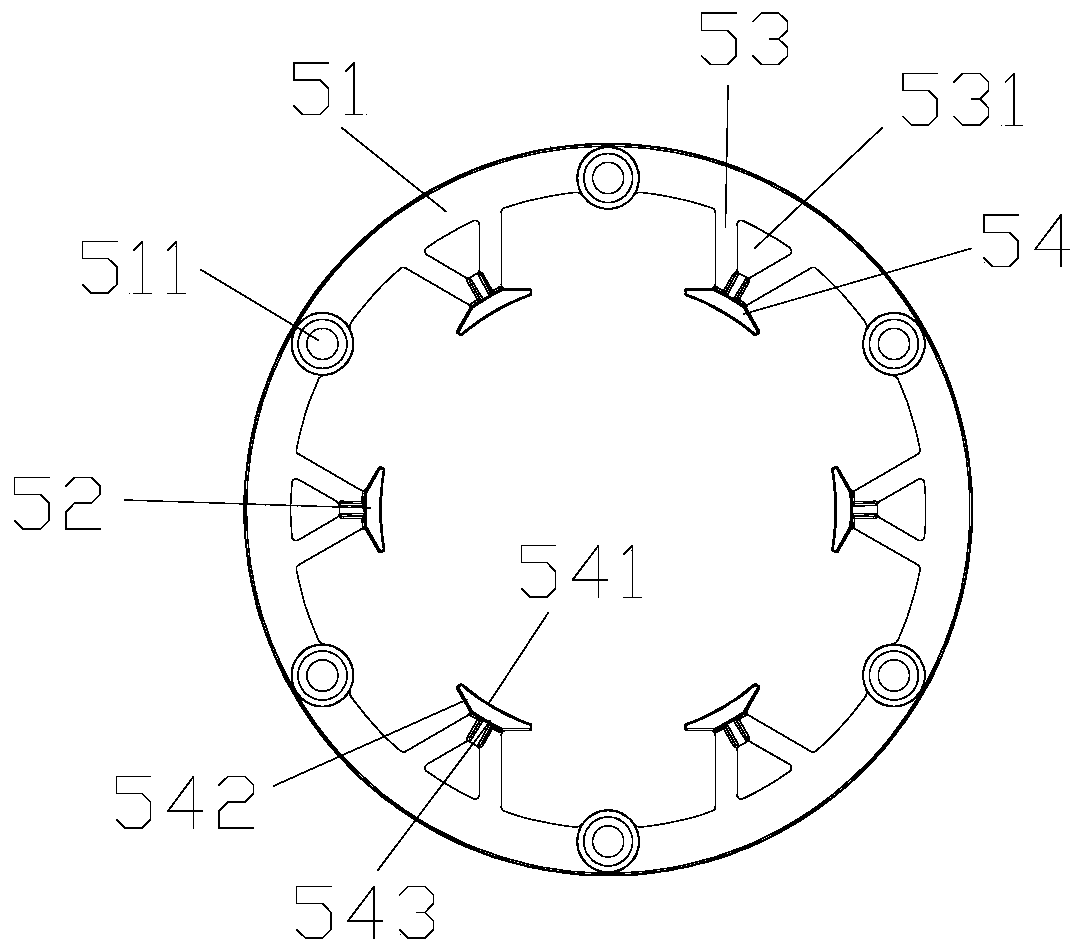

Centralized winding motor coil fixing structure and assembling method

ActiveCN111049286AImprove consistencyEasy to installWindingsMagnetic circuit stationary partsElectric machineStructural engineering

The invention discloses a centralized winding motor coil fixing structure and an assembling method. The centralized winding motor coil fixing structure comprises a stator iron core, centralized winding coils, end covers and supporting structural members; the supporting structural members are located between the stator iron core and the end covers on two sides; each supporting structural member comprises a fixing circular ring and coil positioning teeth with the same number as stator teeth; each coil positioning tooth comprises a triangular support and a lengthened fixing boot; the two isosceles sides of each triangular support is used for circumferentially limiting the coil of the corresponding centralized winding coil; and the two bottom surfaces of each lengthened fixing boot radially limit the frame plane of the corresponding centralized winding coil. According to the centralized winding motor coil fixing structure and the assembling method of the invention, the stator teeth are straight teeth, so that the batch winding of the centralized winding coils can be completed on the outer sides of the stator teeth; and the centralized winding coils are fixed in the radial direction andthe circumferential direction through the supporting structural members, and therefore, a pouring sealant can be omitted. Thus, a production period can be shortened by at least 20%, production efficiency can be improved by 65%, and production cost can be reduced by 25%.

Owner:JIANGSUSNGQI GROUP

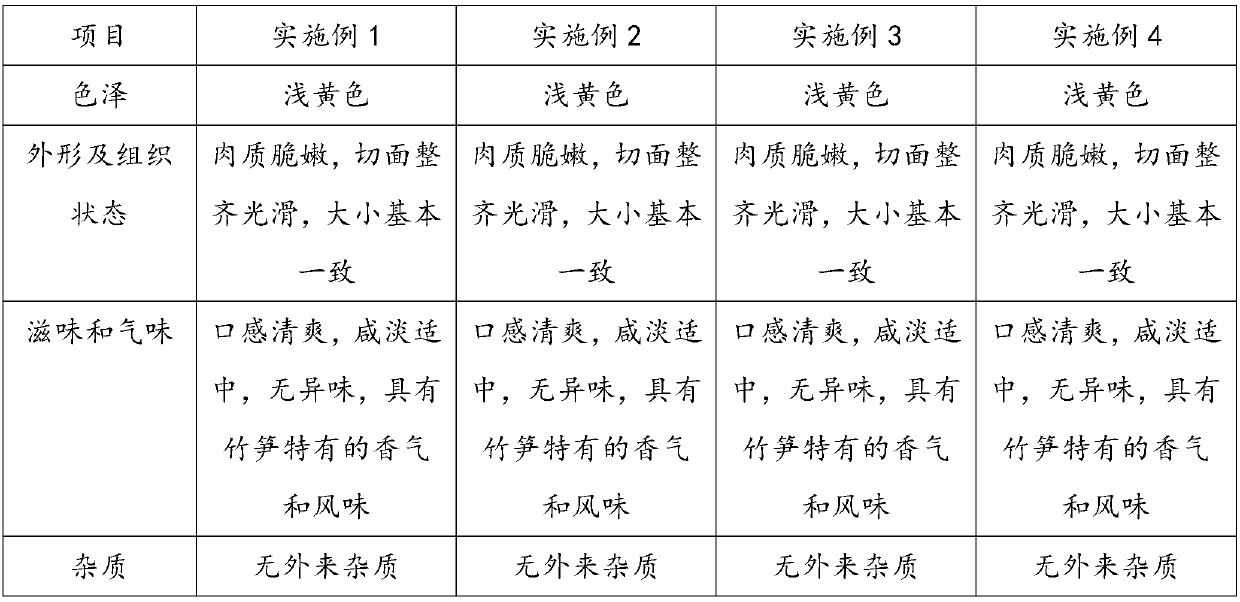

Preparation method for ready-to-eat bamboo shoots

InactiveCN110934270AShorten the production and processing cycleSimple processFood scienceEconomic benefitsPasteurization

The invention discloses a preparation method for ready-to-eat bamboo shoots, relates to the technical field of bamboo shoot processing, and solves the problems of a complicated preparation process anda long preparation period of current ready-to-eat bamboo shoots. The method includes the following steps: 1) pretreating raw materials: selecting the fresh healthy and strong bamboo shoots, performing peeling and leaving cores, and performing washing under running water; 2) performing boiling: adding a color protection agent and water into the bamboo shoots in the step 1), and performing boilingin boiling water; 3) performing soaking: adding a soaking solution into the cooled bamboo shoots after boiling, and performing soaking; 4) performing dehydration; 5) mixing materials; 6) performing inner packaging, and performing vacuumizing; 7) performing sterilization by using pasteurization; and 8) performing external packaging, performing inspection, and performing storage. The method has a simple process and short preparation time, shortens the production and processing cycle of the ready-to-eat bamboo shoots, and is conducive to improving the economic benefits of enterprises, and the prepared Sichuan-flavored ready-to-eat bamboo shoots meet the Agricultural Industry Standard of the People Republic of China: Green Food-Bamboo Shoots and Bamboo Shoot Products (NY / T 1048-2012).

Owner:SICHUAN PINPIN FOOD

Plastic material for beverage bottle

The invention discloses a plastic material for a beverage bottle. The plastic material is prepared from the following raw materials in parts by weight: 80 to 120 parts of polyethylene glycol terephthalate, 25 to 35 parts of fillers, 0.1 to 0.3 part of antioxidants, 1 to 3 parts of compatilizers, 2 to 4 parts of nucleating agents, 1 to 3 parts of plasticizers and 2 to 4 parts of lubricating agents,wherein the nucleating agents are Na-based montmorillonite, nanometer magnesia, sodium chloride and polyoxyethylene. The plastic material has the advantages that the crystallization speed is high; the crystallization time consumption is short; the anti-impact performance is good.

Owner:安徽洋龙塑业有限公司

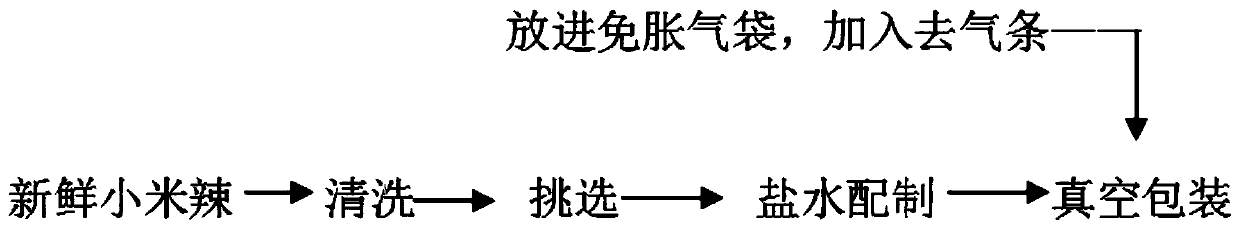

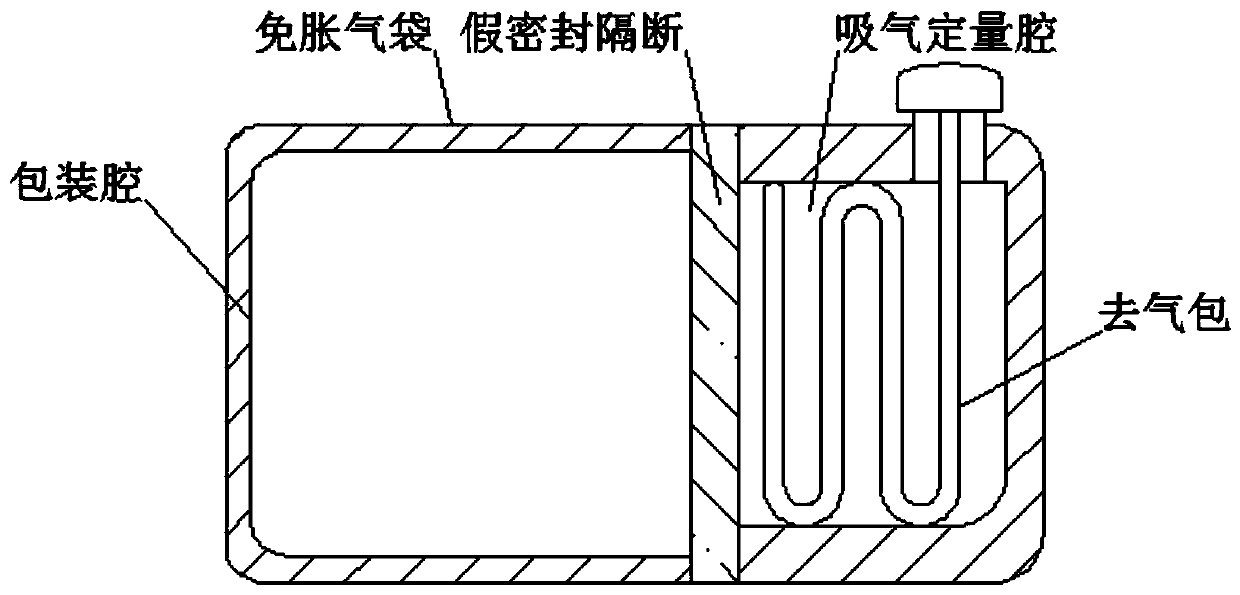

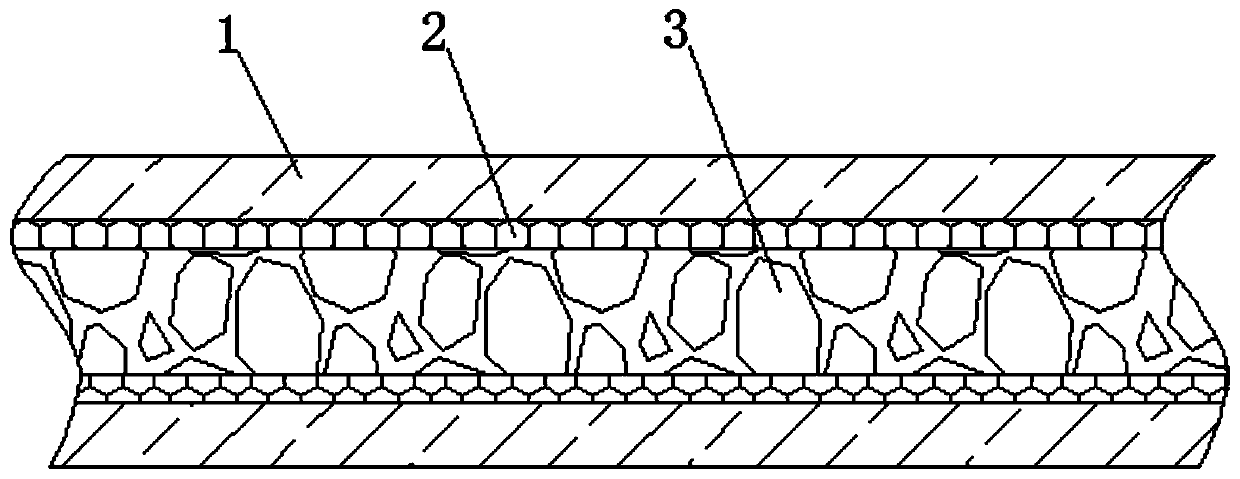

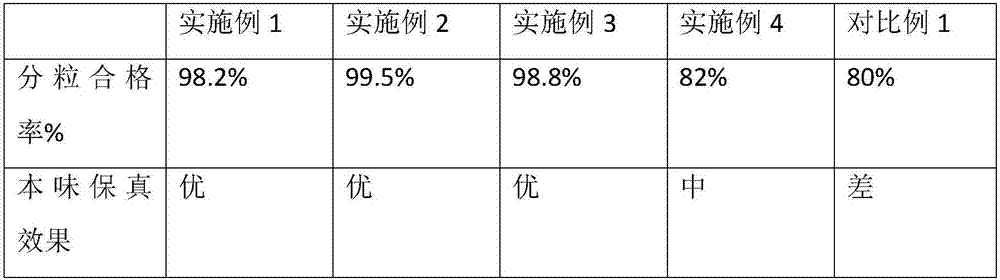

Salted bagged non-fermentation fresh capsicum frutescens production and processing method

ActiveCN110179078AEasy to take outAvoid flatulenceClimate change adaptationFood ingredientsSaline waterSalt water

The present invention discloses a salted bagged non-fermentation fresh capsicum frutescens production and processing method and belongs to the production field of fresh capsicum frutescens. The saltedbagged non-fermentation fresh capsicum frutescens production and processing method comprises the following steps: capsicum frutescens and salt water are directly sealed into a non-air-swelling bag, aprocess of fermentation in a salting pool is eliminated, production and processing cycle is shortened, an effect of purchasing, production and selling at the same time is achieved, a utilization rateof funds is improved, at the same time, the non-air-swelling bag is matched with an internal false seal partition, so that before opening, a degassing strip in an inhalation quantitative cavity can absorb carbon dioxide gas generated by the capsicum frutescens, thereby effectively reducing a phenomenon that the product produce air to swell the bag and ensuring product reliability, and after the opening, the inhalation quantitative cavity can be used as a transfer storage site for the capsicum frutescens, so as to achieve an effect of quantitative taking according to needs. Compared with existing packaging bags, the salted bagged non-fermentation fresh capsicum frutescens production and processing method effectively avoids a phenomenon that due to excessive taking and pouring back into thenon-air-swelling bag, the capsicum frutescens in the bag is contaminated, and improves food hygiene.

Owner:CHENGDU XINFAN FOOD

Sweet, fragrant, and light color tea beer and preparation method thereof

InactiveCN107881045AKeep active ingredientsSweet and refreshing tasteMicroorganism based processesBeer brewingGreen teaPurified water

The invention discloses a sweet, fragrant, and light color tea beer and a preparation method thereof. The tea beer comprises the following raw materials in parts by weight: 5 to 8 parts of green tea,8 to 12 parts of litchi honey, 2 to 3 parts of mint leaf, 3 to 5 parts of aloe, 3 to 5 parts of blueberry juice, 34 to 38 parts of barley malt, 0.3 to 0.4 part of Czech hop, 0.3 to 0.4 part of brewer's yeast, and 400 to 500 parts of purified water. The preparation method comprises the following steps: preparing tea essence, preparing a sweet and fragrant additive, grinding malt, carrying out gelatinization and saccharification, filtering wort, boiling, performing mixed fermentation, and carrying out sterilization and loading. The tea beer has unique fragrance and taste, and is welcomed by consumers, and the damage to the human body is reduced.

Owner:合肥福润茶业技术有限公司

Original flavor retaining technology of shade-dried cooked glutinous rice

The present invention discloses an original flavor retaining technology of shade-dried cooked glutinous rice in the field of food production processes. The technology comprises the following steps of: material selecting, cleaning, washing, soaking, steaming, shade-drying and granule separating, screening and finished product packaging. In the soaking, a pollution-free water source is used. In the shade-drying and granule separating, a rapid ventilation and dehumidification device consisting of a stainless steel exhaust pipe and an exhaust fan directly conducts dehumidification and ventilation in a low-temperature baking device. The cooked glutinous rice is subjected to low temperature baking in the baking device in which the temperature is 40-60 DEG C, ventilation is controlled to be conducted for about half an hour, the granule separating is conducted, then the natural shade-drying is conducted, two-stage shade-drying is used, and the technology shortens the shaping cycle and at the same time retains the product flavor. By improving the technology of the steps of the material selecting, washing, soaking, shade-drying and granule separating, etc. and by using a pollution-free soaking technology, a rapid ventilation and dehumidification technology and a temperature-varying time-controlled shade-drying technology to process and shape the shade-dried cooked glutinous rice, the original flavor retaining technology can realize large-scale production of the shade-dried cooked glutinous rice, at the same time maximally preserves traditional shapes and original flavor of the shade-dried cooked glutinous rice, so that the original flavor of the shade-dried cooked glutinous rice is retained with high fidelity, and the shade-dried cooked glutinous rice is good in quality and flavor.

Owner:重庆源源龙脉食品有限公司

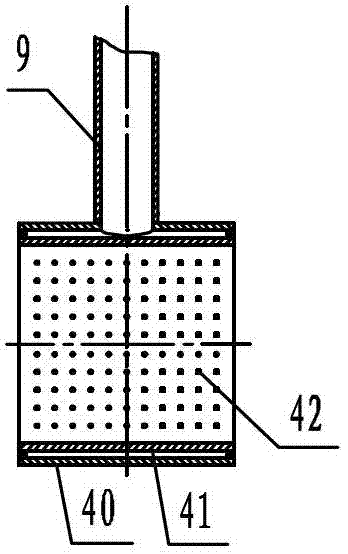

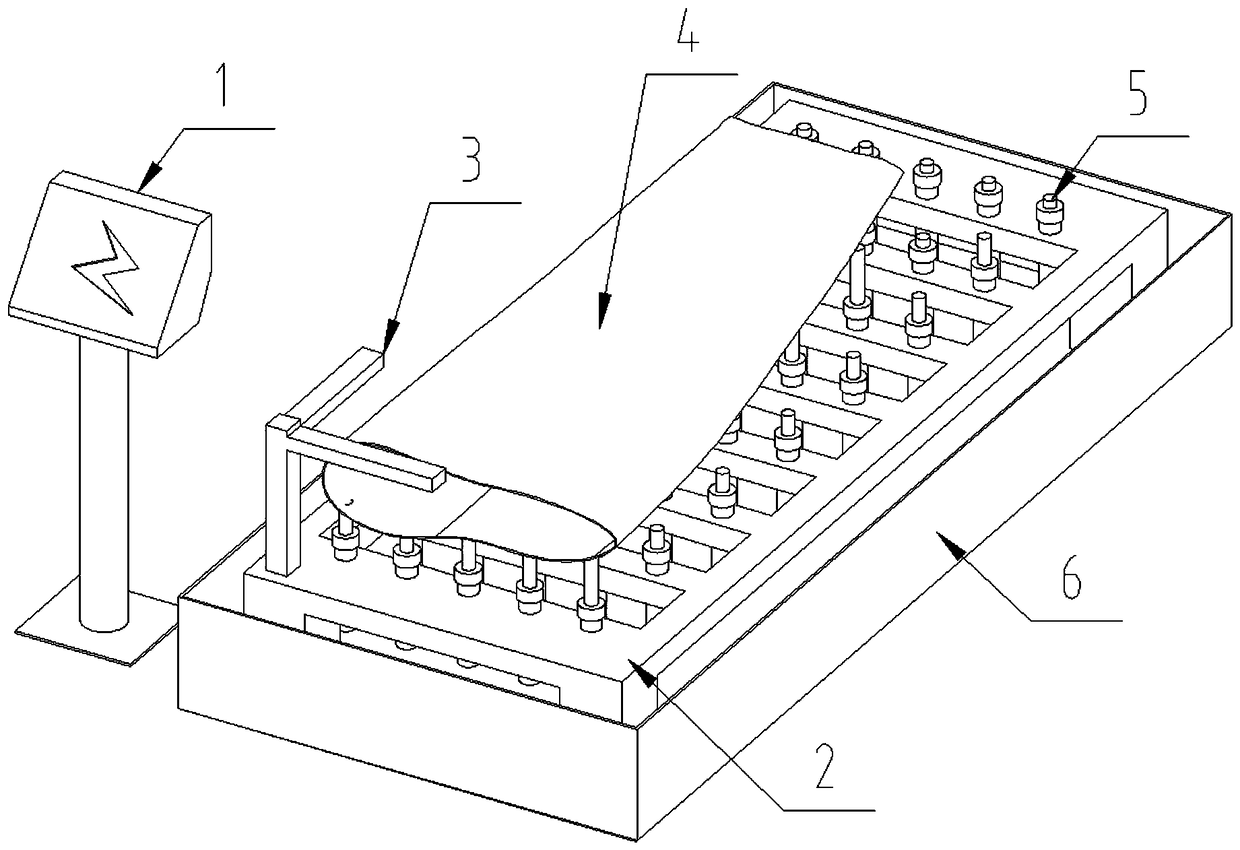

Numerical control workbench for ultra-high-pressure water cutting machining

PendingCN108544383AAccurate collectionEasy to clamp and positionAbrasive machine appurtenancesNumerical controlDot matrix

The invention discloses a numerical control workbench for ultra-high-pressure water cutting machining. The numerical control workbench comprises an electric control cabinet, a platform, a reference ruler, a plurality of electric cylinders and a water tank, and is characterized in that the water tank is horizontally arranged, the platform is arranged inside the water tank, the working surface of the platform is of a hollow shape, the plurality of electric cylinders are uniformly arranged on the platform in a dot matrix mode, and the electric cylinders are fixed by adopting a frame structure; the reference ruler is a support composed of three straight rods, wherein every two straight rods are perpendicular to each other, a grating ruler is arranged on each straight rod of the reference ruler, and the reference ruler is arranged at a set position of the working surface of the platform; and the electric control cabinet is arranged on the left side of the water tank. According to the numerical control workbench, clamping and positioning are convenient, the shape information of parts can be accurately collected, the universality is high, the research and development cost is reduced, theeconomic benefit is improved, and the numerical control workbench has a wide application prospect particularly in the field of machining special large-scale parts such as large aircraft wings.

Owner:沈阳奥拓福科技股份有限公司

Processing method for improving quality of instant chicken feet by adopting ultrasonic combined with electron beam cold sterilization

The invention provides a processing method for improving the quality of instant chicken feet by ultrasonic combined with electron beam cold sterilization, and relates to the technical field of sterilization and freshness preservation of poultry machining and electronic accelerators. The processing method comprises the following steps of: thawing, trimming and washing chicken feet; bleaching and washing; boiling; ultrasonically pickling; and packaging and carrying out electron beam sterilization. According to the invention, a novel process of ultrasonic auxiliary pickling is added in a pickling process of the instant chicken feet; the processing method has the effect that by utilizing cavatition effect of ultrasonic waves, the speed of immersing pricking condiments into inner parts of tissues of the chicken feet is increased, the pickling time is shortened and the integral flavor of the chicken feet is improved; furthermore, the instant chicken feet are treated by the electron beam cold sterilization, and the processing method has the obvious advantages of short sterilization time, no temperature changes and low production cost, and can keep the original pickled flavor of the instant chicken feet to the greatest extent. Therefore, the method can improve the flavor quality of the instant chicken feet and can shorten the manufacturing and processing periods; the aims of rapidly sterilizing and prolonging the quality guarantee period of products are achieved; and finally, the instant chicken feet product with high quality is obtained.

Owner:上海束能辐照技术有限公司 +1

PET material for beverage bottle caps

InactiveCN109467893AAvoid degradation of mechanical propertiesPromote crystallizationPolyethylene terephtalateSodium benzoate

The invention discloses a PET material for beverage bottle caps. The PET material comprises the following raw materials in parts by weight: 70-90 parts of polyethylene terephthalate, 10-20 parts of aPOE resin, 20-30 parts of a filler, 0.05-0.1 part of an antioxidant, 2-4 parts of a compatilizer, 1-3 parts of a nucleating agent, 1-1.5 parts of a plasticizer and 1-3 parts of a lubricant, wherein the nucleating agent is hydrotalcite, magnesium carbonate, sodium benzoate and PEG4000. The PET material is high in crystallization speed, short in crystallization time and high in impact resistance.

Owner:安徽洋龙塑业有限公司

Method for seamless welding of broken bridge aluminum door and window

InactiveCN112317988AImprove the finishImprove aestheticsWelding apparatusMaterials preparationRubber ring

The invention discloses a seamless welded broke bridge aluminum door and window. Materials such as a seamless welding machine, a broken bridge aluminum door and window and a sealing rubber ring are needed. The invention further discloses a method for seamless welding of the broken bridge aluminum door and window. The method comprises the following steps of material preparation, welding, compression, polishing and spray painting. The method for seamless welding of the broken bridge aluminum door and window has the beneficial effects that the finish degree and attractiveness of the broken bridgealuminum door and window are improved through multi-time polishing and spray painting of the seamless welding technology; the seamless welding technology is used for improving the sealing sound insulation performance of the door and window, and the problem of water seepage is solved; the seamless welding technology is used, so that the production and processing period of the whole die can be shortened, and time and labor are saved; and in the seamless welding process, it can be guaranteed that the aluminum door and window are more fixed through compression and are not prone to deformation.

Owner:湖南森云门窗有限公司

A fiberglass antenna cover cutting equipment

ActiveCN104354178BShorten the production and processing cycleKeep healthyDirt cleaningMetal working apparatusEnvironmental resistanceGlass fiber

The invention relates to outer hood cutting equipment for a glass epoxy antenna. The equipment comprises a cutting base which is provided with a lateral fixing rod and a vertical fixing rod in a fit manner, wherein a working platform elevating mechanism is arranged on the lateral fixing rod and the vertical fixing rod in a fit manner, a working platform is arranged on the lateral fixing rod, and the working platform and the lateral fixing rod are arranged in a fit manner through a lateral displacement mechanism which is arranged in a direction of front to back; a left cutting mechanism and a right cutting mechanism which are arranged on the same lateral height are respectively arranged on the left side and the right side of the cutting base; an upper cutting mechanism and a lower cutting mechanism are correspondingly arranged at the top and the lower part of the cutting base; the working platform elevating mechanism, the lateral displacement mechanism, the left cutting mechanism, the right cutting mechanism, the upper cutting mechanism and the lower cutting mechanism are connected to a control mechanism. Through the adoption of the cutting equipment disclosed by the invention, the production and processing cycle of the outer hood of the glass epoxy antenna is shortened, the working efficiency is improved, the precision of products is improved, the probability that when an operator cuts the burrs of glass-reinforced plastics, particles are sucked in the body of the operator is reduced, the human body of the operator is guanrateed to be healthy, and the operating environment is clean and environmental-friendly.

Owner:ZHEJIANG E STRONG COMM TECH

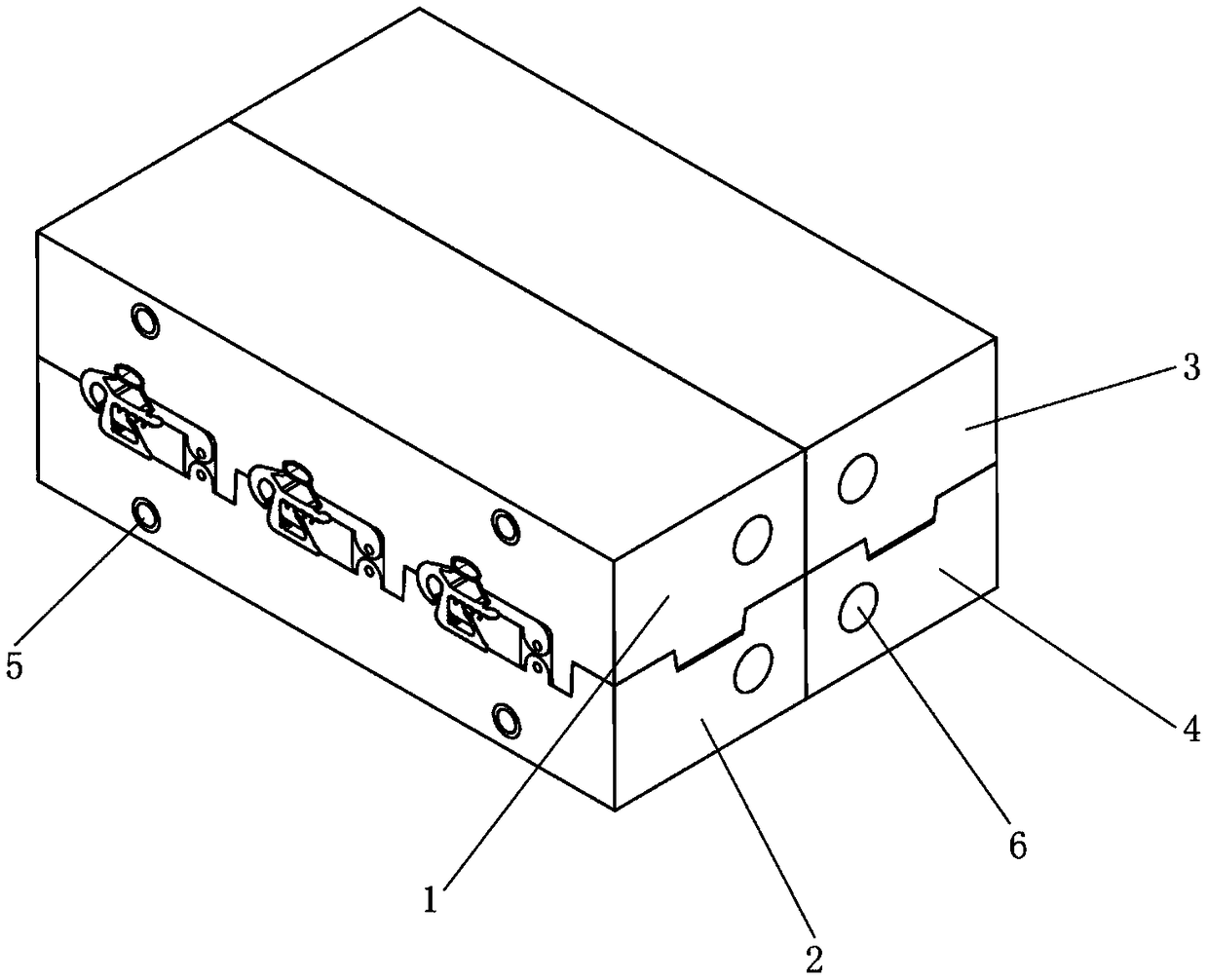

Trimming-free joint mold and application thereof

The invention discloses a trimming-free joint mold and application thereof. The trimming-free joint mold is formed by four molds in butt joint; after the joint surfaces of the four molds are in butt joint, a product has no need to be trimmed or deburred manually, so that the manpower is saved, and the productivity is improved; and by applying the trimming-free joint mold to jointing the product, the quality of the finished product is controllable, the production processing period is shortened, and the production efficiency is improved.

Owner:FOSHAN MEIRUN RUBBER TECH DEV CO LTD

Preparation method of Xiang-jian tea

InactiveCN109601658AKeep shapePreserve the tight, round and straight featuresPre-extraction tea treatmentGreen teaFermentation

The invention provides a preparation method of Xiang-jian tea, and belongs to the technical field of tea preparation. The preparation method of the Xiang-jian tea comprises the following steps: (1) blending raw dark green tea, and carrying out rehydration so as to obtain a rehydrated blend, wherein water content of the rehydrated blend is 21-26%; (2) steaming the rehydrated blend obtained in the step (1) so as to obtain a steamed material, wherein water content of the steamed material is 24-29%; (3) performing pile fermentation on the steamed material obtained in the step (2) so as to obtain afermented material, wherein duration of the pile fermentation is 39-49 hours; and (4) drying the fermented material obtained in the step (3) so as to obtain the Xiang-jian tea, wherein water contentof the Xiang-jian tea is 6-8%. The preparation method of the Xiang-jian tea provided by the invention is more conducive to ensuring quality of Xiang-jian tea; moreover, the preparation method is capable of shortening production and processing cycle as well as improving production and processing efficiency.

Owner:CHINATEA HUNAN ANHUA FIRST TEA FACTORY CO LTD

Efficient polylactic acid nucleating agent, and preparation method and application thereof

ActiveCN102584567BEasy to prepareImprove securityCarboxylic acid salt preparationCITRATE ESTERHeat resistance

The invention discloses an efficient polylactic acid nucleating agent, and a preparation method and application thereof and belongs to the technical field of crystallization and modification of polylactic acid. The prepared nucleating agent is a lamellar submicron zinc citrate complex, and is generated by heating zinc salt and citric acid in a mixed solution of water and ethanol and performing reflux reaction. A small amount of the nucleating agent and polylactic acid are mixed in advance and then are fused, blended and molded so as to obtain a polylactic acid product which is highly crystallized and has excellent heat resistance. The prepared nucleating agent has high safety for a human body and an obvious nucleating effect; and a process is simple and environment-friendly, the problems of low crystallization rate and heat resistance of the polylactic acid are solved, the forming processability of the polylactic acid product is improved, and a production cycle is shortened.

Owner:新倍斯(杭州)材料科技有限公司

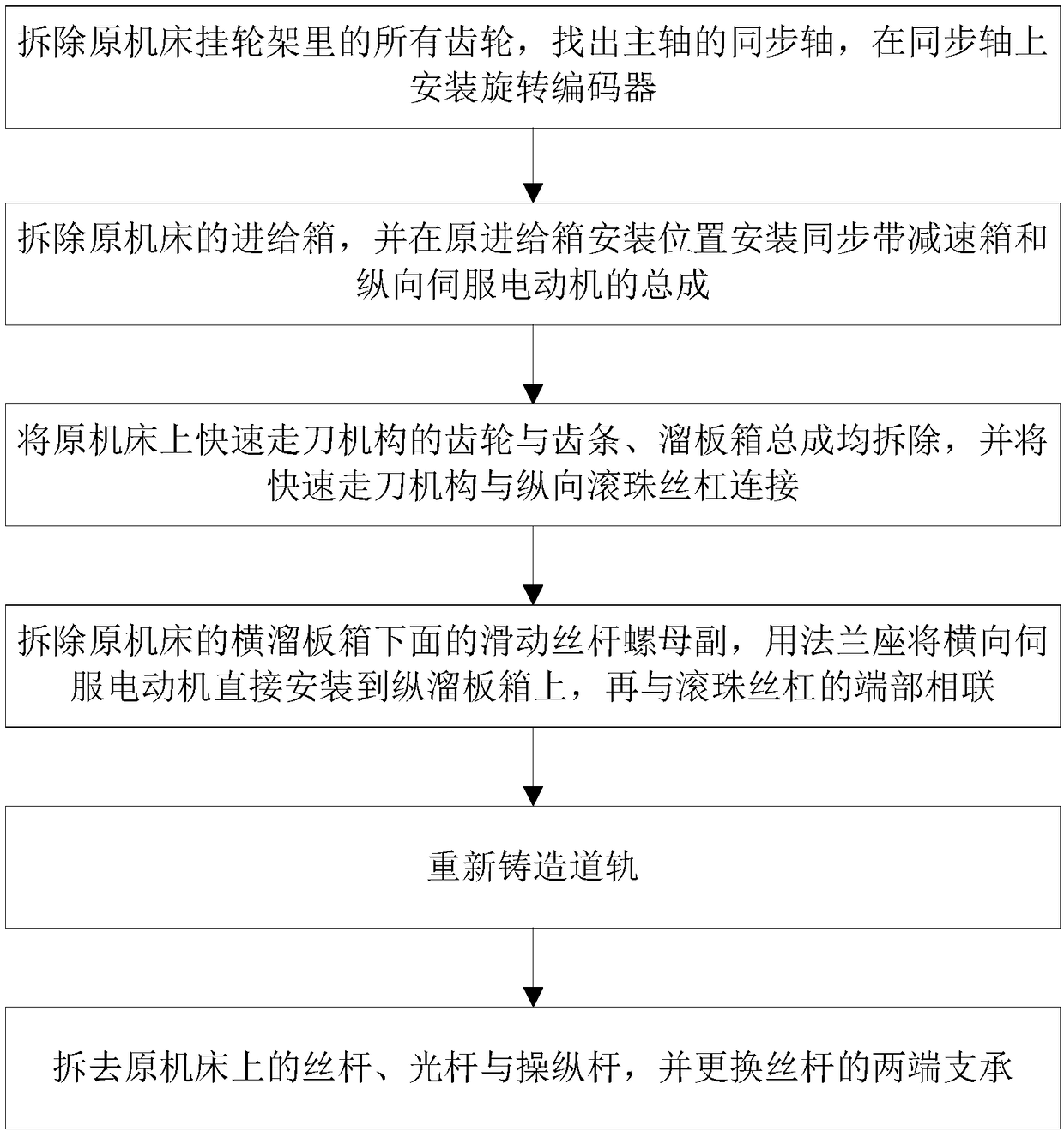

Numerical-control modifying method for machine tool for rope groove processing

InactiveCN108356578AImprove processing speedImprove processing qualityFeeding apparatusLarge fixed membersNumerical controlEconomic benefits

The invention discloses a numerical-control modifying method for a machine tool for rope groove processing. An existing common horizontal type lathe is refitted into a numerical-control lathe capableof processing a rope groove, so that the processing purpose of the rope groove can be completed. A C6031A type common lathe is a conventional horizontal lathe with an allowable maximum processing diameter of 3500 mm and maximum processing length of 6000 mm. When a double-broken-line rope groove is processed in the common C6031A type lathe, feeding of the machine tool cannot meet requirements of aspiral broken line; and after being modified in a numerical-control mode, the machine tool can process the double-broken-line rope groove, so that economic benefits are considerable. Through the numerical-control modifying method for the machine tool for rope groove processing disclosed by the invention, labor intensity of an operator is relieved, tooling times are reduced, a trial-production period and a producing and processing period for a novel product are also shortened, market needs can be timely responded quickly, and the like.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Organic nucleating agent for preparing heat resistant polylactic acid resin and preparation method thereof

The invention discloses an organic nucleating agent for preparing heat resistant polylactic acid resin and a preparation method thereof. The preparation method comprises following steps: (1) mixing terephthalate of metals and a chlorination agent to obtain a mixed solution, adding a catalyst, carrying out reactions to obtain terephthaloyl chloride; (2) mixing alkyl cyclohexane, ethyl acetate, andDMF according to a certain ratio, dropwise adding terephthaloyl chloride into the mixture, and carrying out reactions to obtain a component A; (3) heating polyethylene glycol with a weight percentageof 65-85% to a temperature of 30 to 75 DEG C, and slowly adding the component A into polyethylene glycol under stirring; and (4) adding disodium salicylate into the solution obtained in the step (3),and then mixing the solution with resin emulsion to obtain the nucleating agent. Terephthalate of metals and the chlorination agent are mixed to obtain the mixed solution, then disodium salicylate isadded, the heatproof property and moulding property of polylactic acid resin are improved, and the processing and production period is shortened.

Owner:BENGBU COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com