Original flavor retaining technology of shade-dried cooked glutinous rice

A technology of yin rice and craftsmanship, which is applied in the field of yin rice original taste preservation technology, can solve the problems of losing the shape and taste of yin rice, achieve better color, less nutrient loss, and less fermented deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

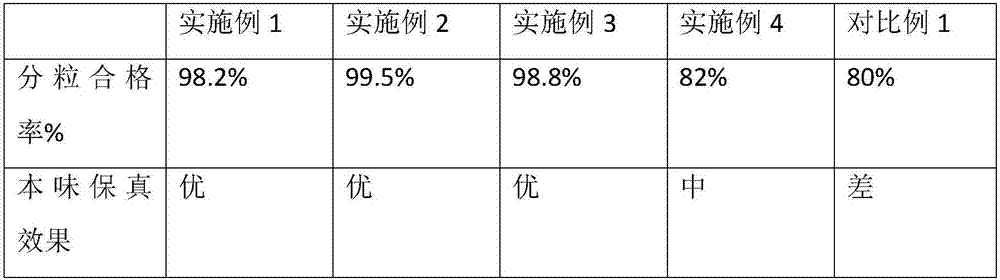

Examples

Embodiment 1

[0021] Embodiment 1, the preservation process of the original flavor of cloudy rice, comprises the following steps,

[0022] A, material selection, select white color, uniform particle size, no peculiar smell and the glutinous rice produced in the year with moisture lower than 14% as raw material;

[0023] B. Clean up, remove impurities and mildewed rice in the raw materials;

[0024] C, elutriation, the raw material is elutriated with water several times, and the ash and bran content are washed away until the water is clear;

[0025] D, soaking, soak the raw materials after elutriation with underground water, keep the water temperature at 6-9°C for 14-16 hours in winter, soak for 12-14 hours in spring and autumn, and soak for 10-12 hours in summer;

[0026] E, steamed, drain the soaked raw materials and then steamed. Steam in a wooden barrel with a diameter of 80 cm, steam for 50 minutes in summer, steam for 10 minutes after the steam mouth is full of air; steam for 55 minu...

Embodiment 2

[0030] Example 2, the difference between this example and Example 1 is that the internal temperature of the baking device is 50°C and the ventilation time is 30 minutes during the shade-drying and grading process; when the room temperature is below 20°C, it is dried in the shade for 48 hours Graining, when the room temperature is above 20°C, dry in the shade for 24 hours to classify.

Embodiment 3

[0031] Example 3, the difference between this example and Example 1 is that the internal temperature of the baking device is 60°C and the ventilation time is 35 minutes during shade drying and grading; during the shade drying and grading process, the shade is dried for 50 hours when the room temperature is below 20°C Graining, when the room temperature is above 20°C, dry in the shade for 26 hours to classify.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com