A fiberglass antenna cover cutting equipment

A cutting equipment and glass fiber reinforced plastic technology, which is applied in metal processing, smoke removal, cleaning methods and utensils, etc., can solve the problems of poor product accuracy, affecting the work efficiency of the assembly process, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the embodiments, but the protection scope of the present invention is not limited thereto.

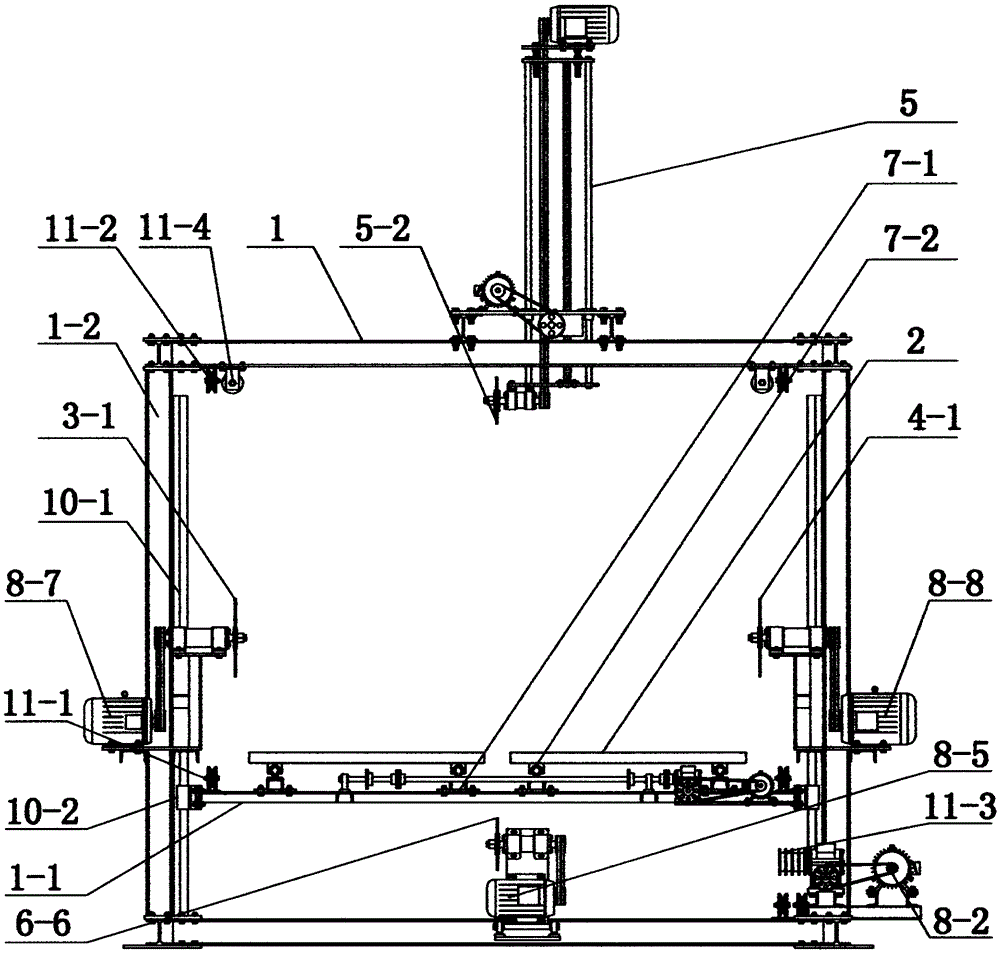

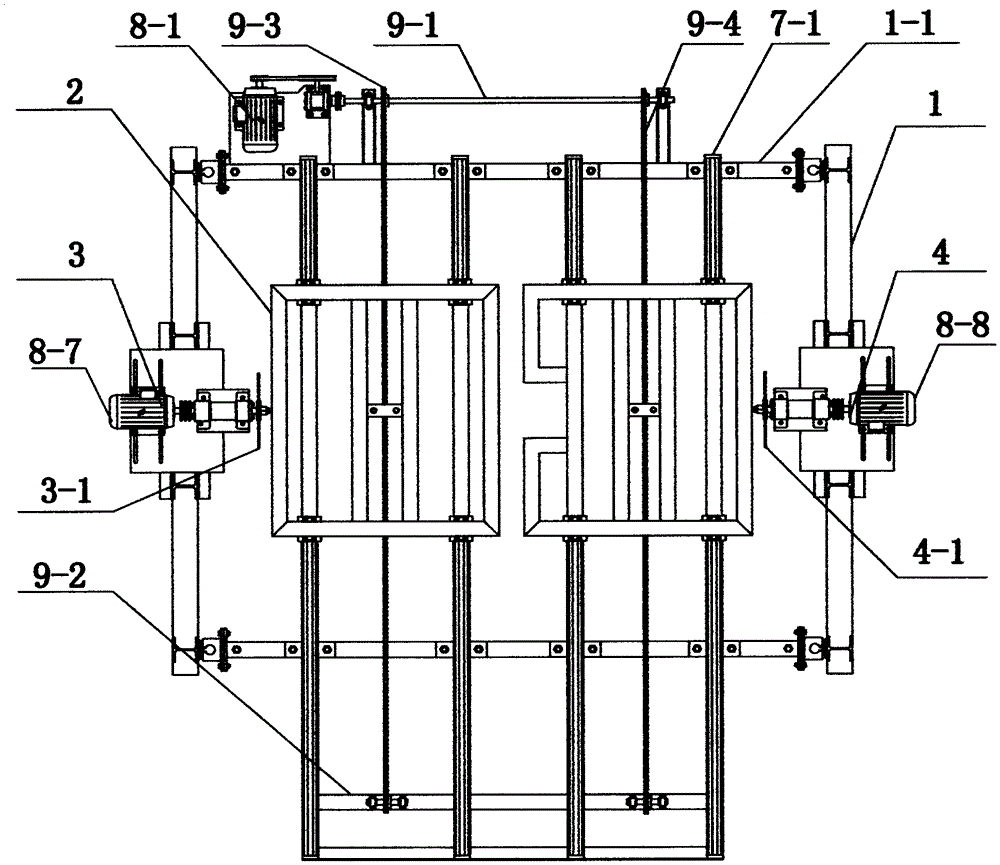

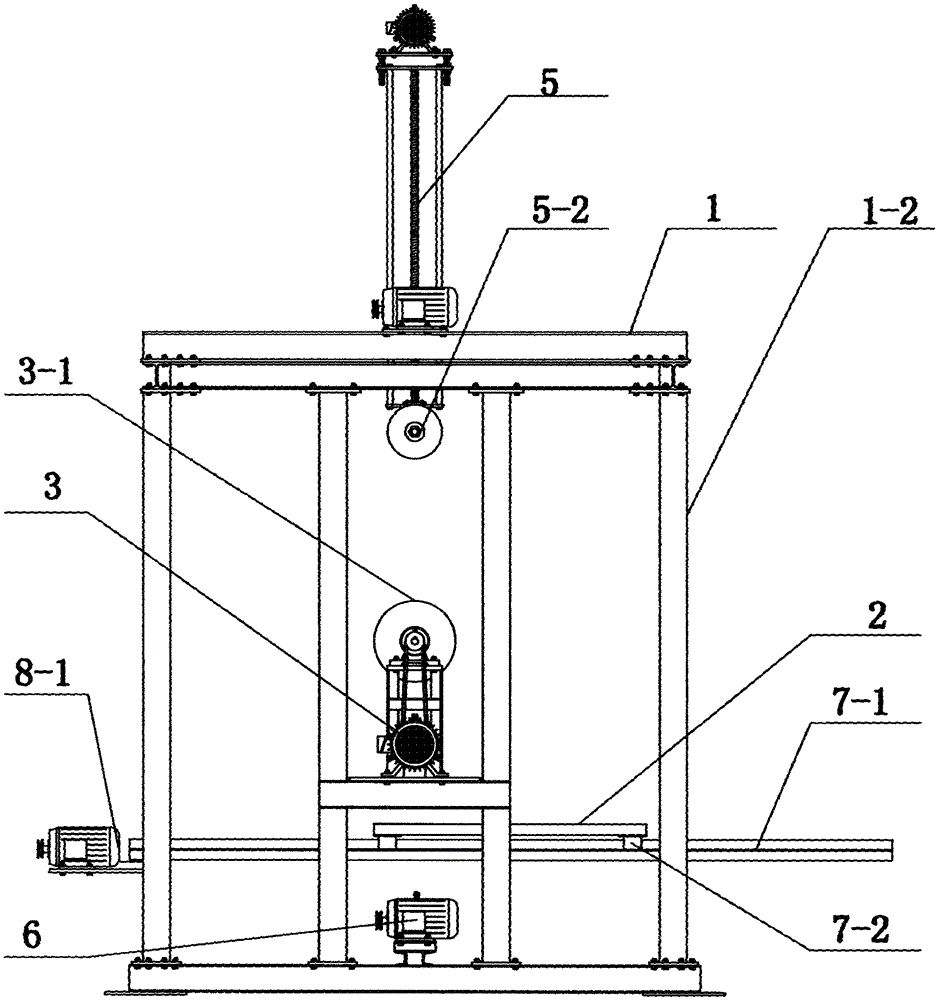

[0025]As shown in the figure, the present invention relates to a glass fiber reinforced plastic antenna cover cutting equipment, the cutting equipment includes a cutting base 1, and the cutting base 1 includes a transverse fixing rod 1-1 and a longitudinal fixing rod 1-2 arranged in cooperation, The horizontal fixing rod 1-1 and the longitudinal fixing rod 1-2 are matched with a working platform lifting mechanism; the lateral fixing rod 1-1 is provided with a working platform 2, and the working platform 2 passes through the horizontal set in the front and rear directions. The displacement mechanism is arranged in cooperation with the transverse fixing rod 1-1; the left and right sides of the cutting base 1 are respectively provided with a left cutting mechanism 3 and a right cutting mechanism 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com