Organic nucleating agent for preparing heat resistant polylactic acid resin and preparation method thereof

A technology of polylactic acid resin and organic nucleating agent, applied in the field of polylactic acid resin preparation, can solve the problems of restricting the processing and application of polylactic acid resin products, unable to realize industrialized production, insufficient heat resistance of molded products, etc., so as to improve nucleation Efficiency, shortened production cycle, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The organic nucleating agent for preparing heat-resistant polylactic acid resin is prepared by the following method:

[0027] Step 1) Put 100 mL of thionyl chloride into the reaction vessel, divide 20 g of sodium terephthalate powder into several parts, and add 1 to 2 g in each part gradually to obtain a mixed solution; 0.2% butyl ammonium titanate or dibutyltin dilaurate or stannous chloride as a catalyst of phthalic acid metal salt, react to obtain terephthaloyl chloride;

[0028] Step 2) a certain proportion of alkylcyclohexylamine, ethyl acetate and DMF are mixed, and the mol ratio of alkylcyclohexylamine, ethyl acetate and DMF described in this embodiment is 4:1:1, and then the Terephthaloyl chloride is slowly added dropwise therein, and the said terephthaloyl chloride is controlled to be added dropwise within 0.5h, and component A is obtained after the reaction;

[0029] Step 3) Take polyethylene glycol with a weight fraction of 65% and heat it to 30° C., slowly ...

Embodiment 2

[0033] The organic nucleating agent for preparing heat-resistant polylactic acid resin is prepared by the following method:

[0034] Step 1) Put 110mL of phosphorus pentachloride into the reaction vessel, divide 28g of magnesium terephthalate powder into several parts, and add 1-2g of each part gradually to obtain a mixed solution; when heated to 120°C, add a mass fraction of Terephthalic acid metal salt 3% butyl ammonium titanate, dibutyltin dilaurate or stannous chloride are used as catalysts to react to obtain terephthaloyl chloride;

[0035] Step 2) a certain proportion of alkylcyclohexylamine, ethyl acetate and DMF are mixed, the mol ratio of alkylcyclohexylamine, ethyl acetate and DMF described in the present embodiment is 5:2:1, then described Terephthaloyl chloride is slowly added dropwise therein, and the described terephthaloyl chloride is controlled to be added dropwise within 1.5h, and component A is obtained after the reaction;

[0036] Step 3) Take polyethylene ...

Embodiment 3

[0039] The organic nucleating agent for preparing heat-resistant polylactic acid resin is prepared by the following method:

[0040] Step 1) Put 90mL of phosphorus trichloride into the reaction vessel, divide 15g of sodium terephthalate powder into multiple portions, and add 1-2g of each portion gradually to obtain a mixed solution; when heated to 110°C, add the mass fraction of 1% butyl ammonium titanate, dibutyltin dilaurate or tin protochloride as a catalyst to obtain terephthaloyl chloride;

[0041] Step 2) a certain proportion of alkylcyclohexylamine, ethyl acetate and DMF are mixed, and the mol ratio of alkylcyclohexylamine, ethyl acetate and DMF described in this embodiment is 4:2.5:1, and then described Terephthaloyl chloride is slowly added dropwise therein, and the described terephthaloyl chloride is controlled to be added dropwise within 1 hour, and component A is obtained after the reaction;

[0042] Step 3) Take polyethylene glycol with a weight fraction of 85% a...

PUM

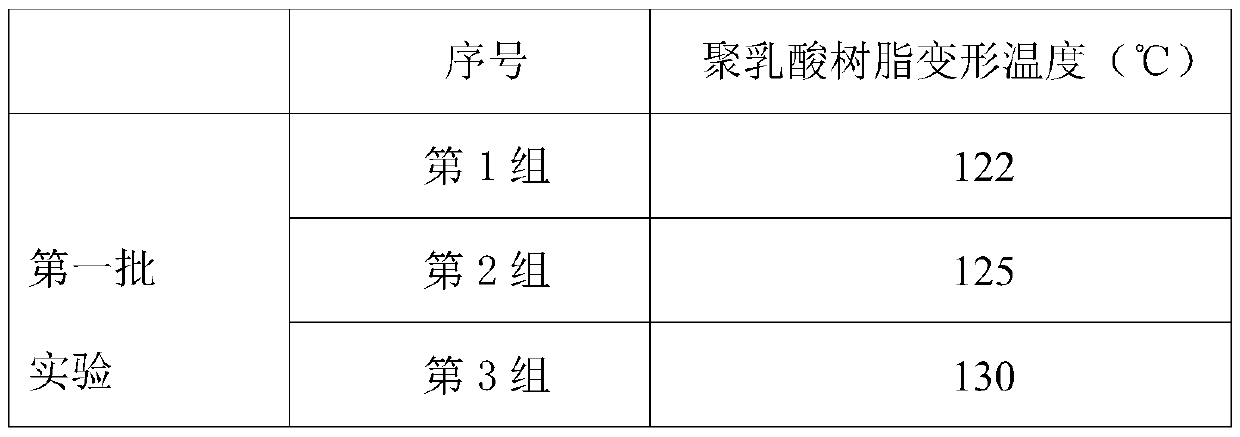

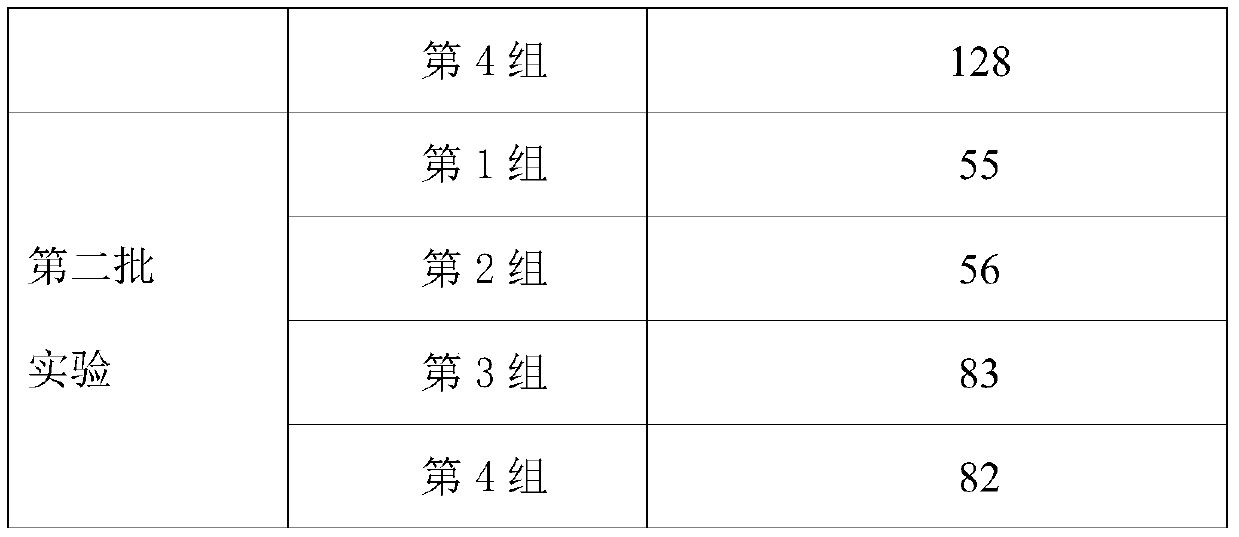

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com