Numerical-control modifying method for machine tool for rope groove processing

A technology for machine tools and rope grooves, which is applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of low precision at the transition joint, lack of smoothness at the transition joint, and high maintenance costs for machine tools, and achieves considerable economic benefits. , The effect of shortening the production and processing cycle and shortening the trial production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

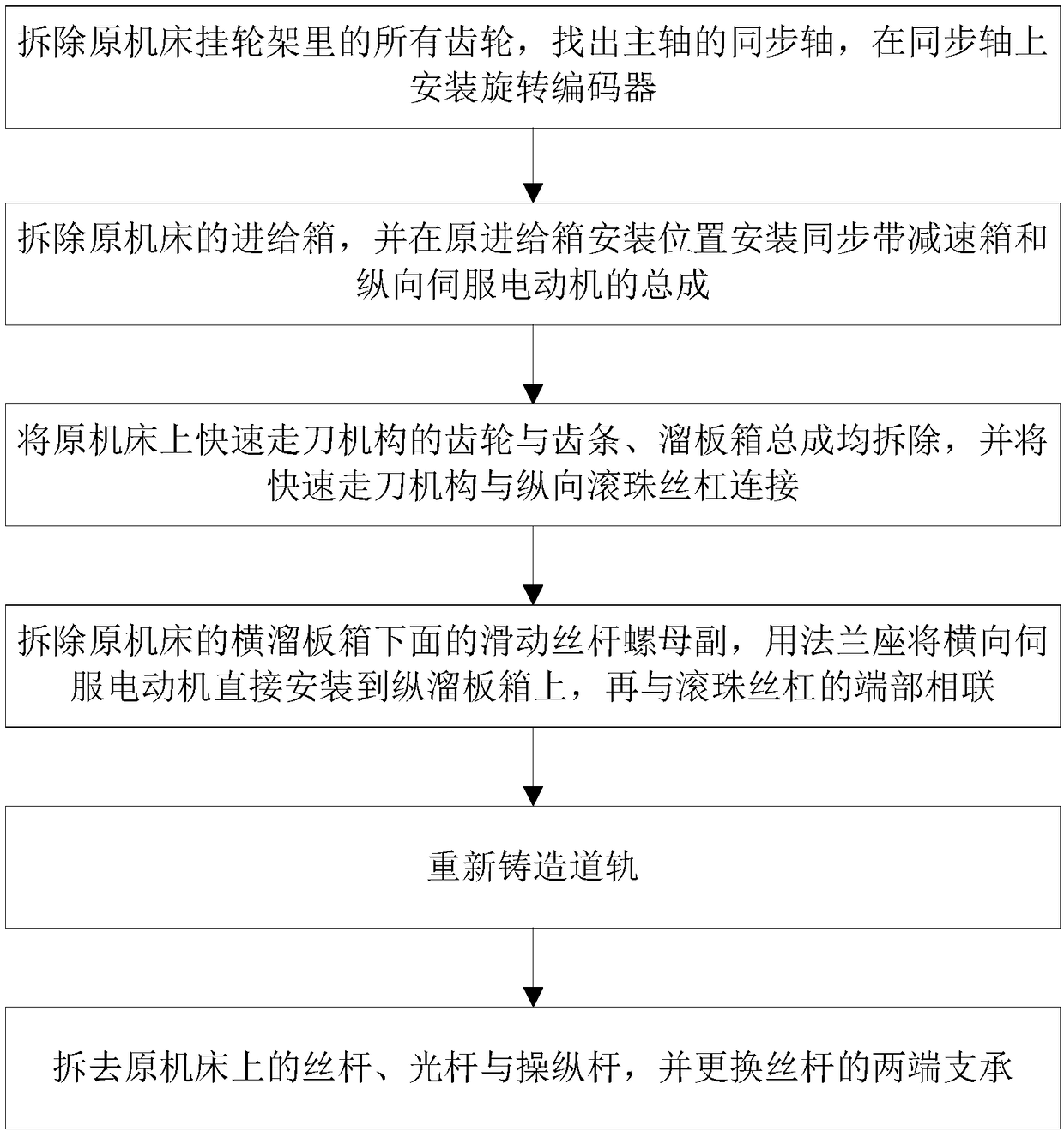

[0026] refer to figure 1 , the numerical control transformation method of a kind of rope groove processing machine tool that the present invention proposes, is used for transforming the traditional manually operated rope groove processing machine tool into a numerical control machine tool, and this method comprises the following steps.

[0027] S1. Remove all the gears in the hanger frame of the original machine tool, find out the synchronous shaft of the main shaft, and install the rotary encoder on the synchronous shaft.

[0028] The structural characteristics of the rope groove are similar to those of the screw thread, so the main shaft motor can be replaced by a servo motor, but the high-power servo motor is not economical and expensive, so in this embodiment, a rotary encoder is installed to detect the rotation angle of the main shaft, so that Complete the processing of the LEBUS rope groove. The rotary encoder is directly installed on the spindle, and rotates synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com