Patents

Literature

34results about How to "No trimming required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

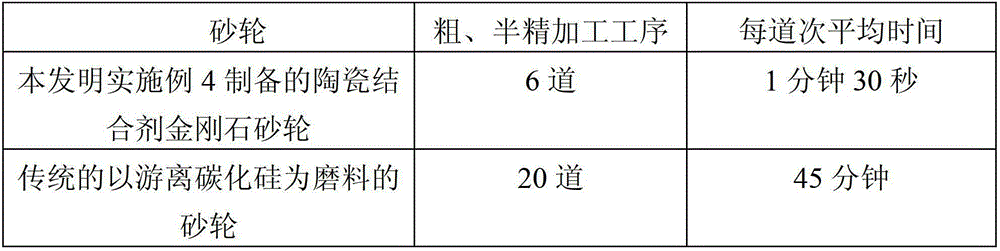

Diamond grinding wheel and preparation method thereof

ActiveCN102922436AImprove processing efficiencyLow costAbrasion apparatusGrinding devicesProcess systemsProcess efficiency

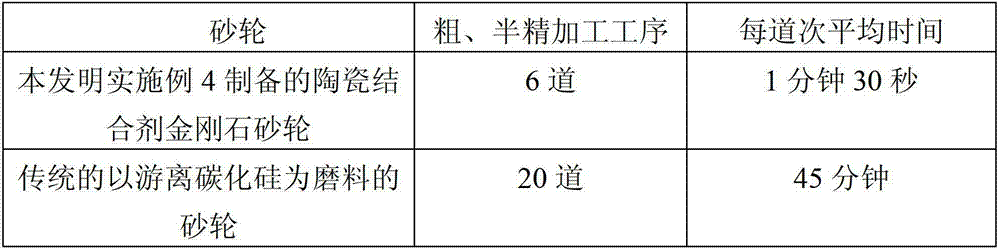

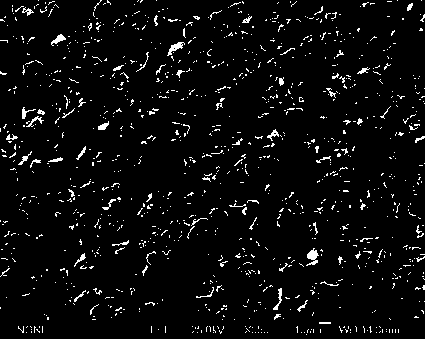

The invention belongs to the field of grinding tools, and discloses a diamond grinding wheel and a preparation method thereof. The diamond grinding wheel comprises a base body and an abrasion block, and a raw material of the abrasion block contains a ceramic binding agent made of the follow raw materials: SiO2 of 40-46wt%, Al2O3 of 8-13%, B2O3 of 18-22%, Na2O of 8-10%, CaF2 of 11-15 wt%, Li2O of 4-6wt% and TiO2 of 1-2wt%. The diamond grinding wheel can effectively improve processing efficiency of gorilla glass, reduce processing cost, reduce pollution to environment, and meets the requirements for grinding and processing the gorilla glass. In addition, according to the diamond grinding wheel, firing temperature of a binding agent is low, holding force on an abrasion material is strong, damage on diamond is greatly reduced under a process system, and the grinding wheel does not need to be repaired in the grinding process.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

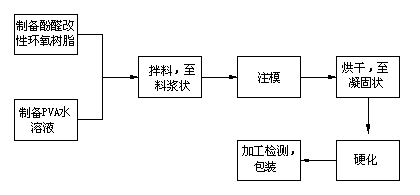

High-precision grinding consolidation flexible sand wheel and manufacturing method thereof

ActiveCN103481211AThe process method is scientific and reasonableFine abrasiveAbrasion apparatusPlane surface grinding machinesThermal insulationDefoaming Agents

A high-precision grinding consolidation flexible sand wheel comprises the raw materials in percentage by weight: 22-50wt% of silicon carbide abrasive or white corundum abrasive, 6-15wt% of phenolic aldehyde modified epoxy resin, 25-65wt% of poval PVA (polyvinyl acetate) aqueous solution, 5.5-11wt% of softening agent, coupling agent, defoaming agent, micropore agent and catalyst and 8-19wt% of water starch water dextrin binder. The manufacturing method comprises the steps of preparing the phenolic aldehyde modified epoxy resin and the PVA aqueous solution and placing the prepared materials in a mixer, sequentially adding the additives, and stirring to be slurry-shaped; pouring the well stirred materials to achieve the corresponding height of dies needed by sand wheels with different standards; drying the injection-molded materials to be solidified; moving the dried and solidified blank into a hardening furnace, heating, and performing thermal insulation to obtain the high-precision grinding consolidation flexible sand wheel. The sand wheel is fine in abrasive grain and good in binding agent flexibility, and solves the problems that the existing fine-grain sand wheel is large in rigidity and poor in flexibility and cannot meet the high-precision grinding machining demands.

Owner:FUZHOU SHUANGYI GRINDING WHEEL +1

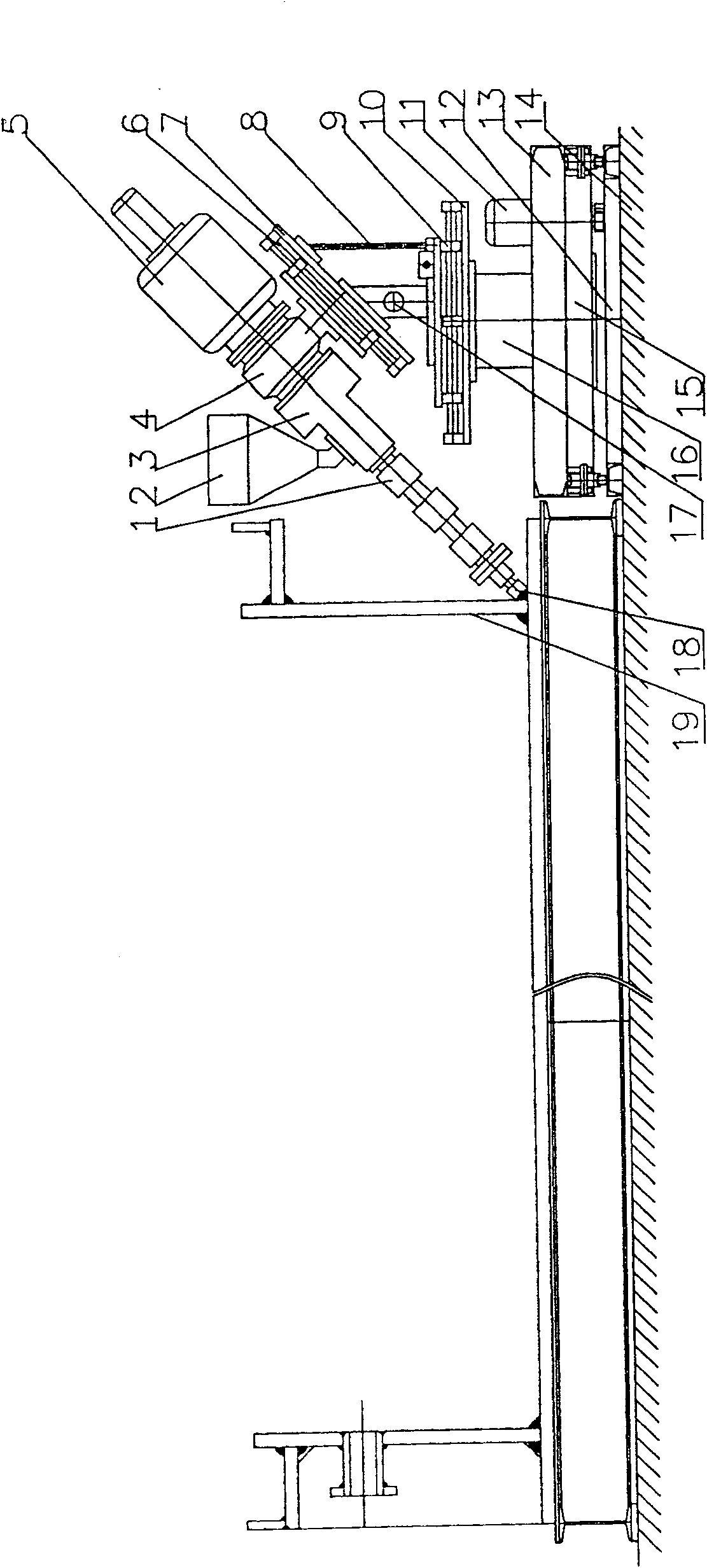

Turbine disc tongue-and-groove forming grinding machining device and use method thereof

ActiveCN109926894AHigh shape accuracyImprove machining accuracyGrinding machine componentsGrinding machinesNumerical controlEngineering

The invention relates to a turbine disc tongue-and-groove forming grinding machining device and a use method thereof. A transmission device of the device enables a stepping motor for a turbine disc to be connected with the turbine disc, the turbine disc is fixed to a turbine disc clamp, an annular grinding wheel is used for forming grinding, the superhard abrasive grain grinding wheel is adopted,and is arranged on a machine tool spindle, direction converters and rocking wheels for controlling the turbine disc to axially and radially rotate are mounted on the free end and the fixed end of a horizontal supporting rod of the turbine disc clamp, the rocking wheels are driven by rocking wheel handles to rotate, after passing through the direction converters, the turbine disc is driven to do axial and radial rotation, during grinding, the annular grinding wheel does high-speed rotation in the vs direction, through the numerical control program, transverse feeding of the turbine disc and the grinding depth of the grinding wheel are controlled, then, in the feeding direction vw, the material is removed, through reciprocated grinding, grinding of one side of the turbine disc tongue-and-groove is finished, the turbine disc inverts by 180 degrees, and grinding of the other side of the turbine disc tongue-and-groove is finished. The traditional broaching machining or milling manner is changed into grinding forming machining of a large-size grinding wheel, and machining efficiency and precision of the turbine disc tongue-and-groove can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

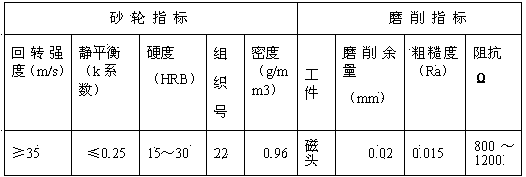

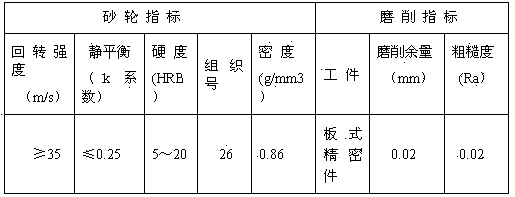

Grinding wheel applied to coaxiality grinding of ceramic ferrule and preparation method thereof

ActiveCN107717765ABoth shape retentionBoth sharpnessAbrasion apparatusGrinding devicesMicrosphereEthyl acetate

The invention relates to a preparation method of a grinding wheel applied to coaxiality grinding of a ceramic ferrule, and belongs to the technical field of ultra-precision machining of optical fiberconnecting material. The u preparation method comprises the following steps of 1, a diluted modified phenolic resin solution, a zirconium oxide hollow microsphere and calcium fluoride are added into ethyl acetate, and are stirred for 1 -3 hours at the temperature of 50-90 DEG C a sodium chloride solution is added, a mixture is heated for 45-90 minutes for at the temperature of 75-85 DEG C, a blockmixture is obtained, then modified polyimide resin is added, ball milling is carried out, and sieving is carried out to obtain a binding agent; 2, diamond and the binding agent prepared in the step 1are weighted according to the mass ratio of 1 to 3-8, sieving is carried out, pressing is carried out at the temperature of 280 DEG C with the pressure of 5 MPa to 15 MPa, the pressure maintaining time is 30-80 minutes, so that a grinding layer is obtained; 3, the grinding layer is bonded to fluorosilicone rubber, the fluorosilicone rubber is adhered to a grinding wheel base body to obtain a grinding wheel semi-finished product; and 4, feeding hole and the discharging hole chamfering of the semi-finished grinding wheel is carried out to obtain a finished product.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

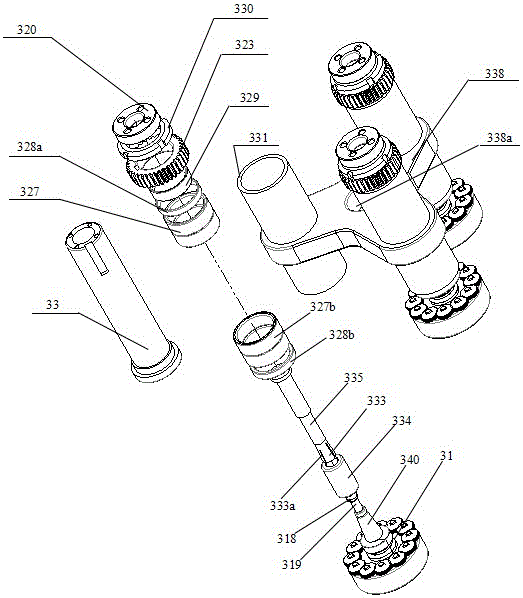

Diamond grinding and polishing method

ActiveCN104551974AEven consumptionExtended service lifeLapping machinesWork carriersCrystal orientationDiamond grinding

The invention discloses a diamond grinding and polishing method; while the surfaces of diamond particles are ground and polished by the high-speed rotation of a grinding plate, a clamping device for clamping the diamond particles is driven by a driving device to rotate by means of the vertical line of the grinding and polishing surface of the grinding plate as an axis. With adoption of the technical scheme in the diamond grinding and polishing method, a plurality of diamond particles are rotated for 360 degrees around the vertical line of the grinding and polishing surface of the grinding plate, so that the grinding plate is capable of grinding the diamond particles in each crystal orientation; on one hand, the step of determining the grinding crystal orientations of the diamond particles in the prior art is omitted and the working efficiency is improved effectively; on the other hand, the uniform consumption of the grinding plate can be maintained, so that the service life of the tool is prolonged without repairing.

Owner:盐城新汇村镇建设发展有限公司

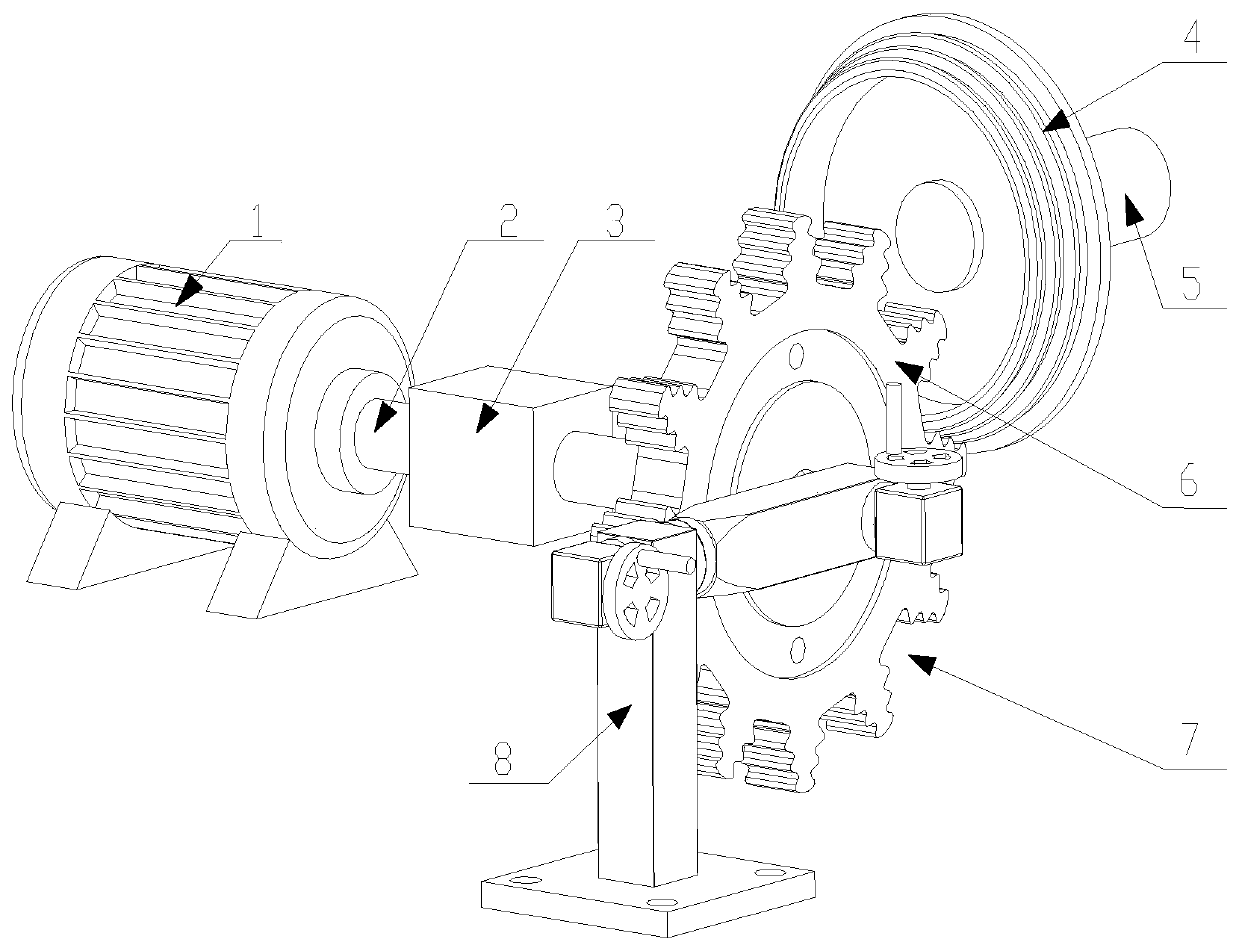

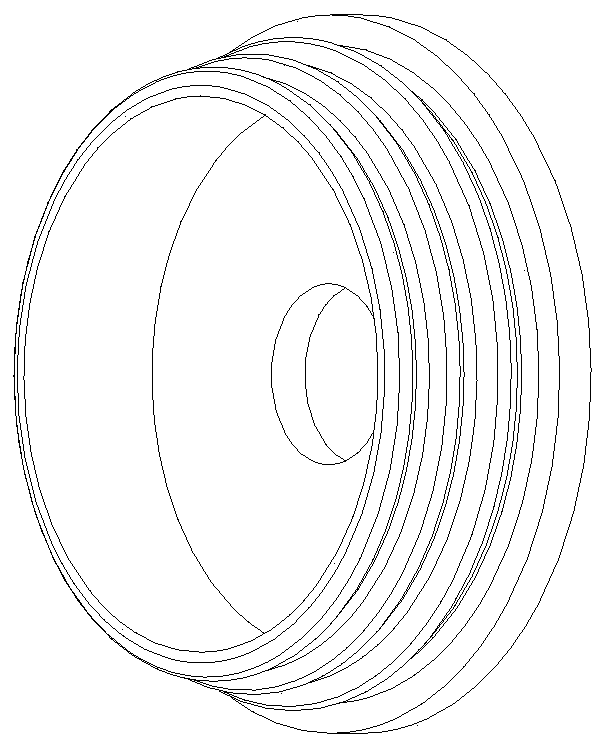

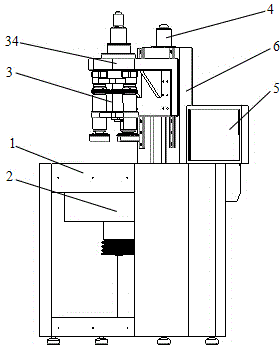

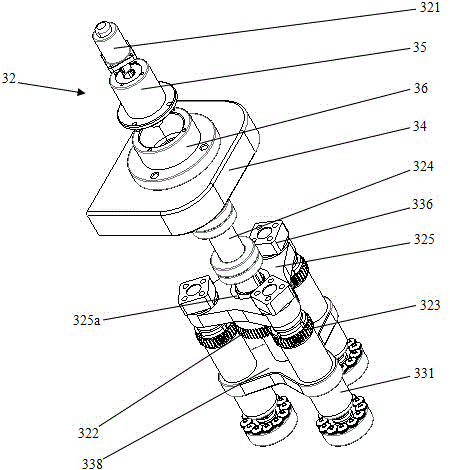

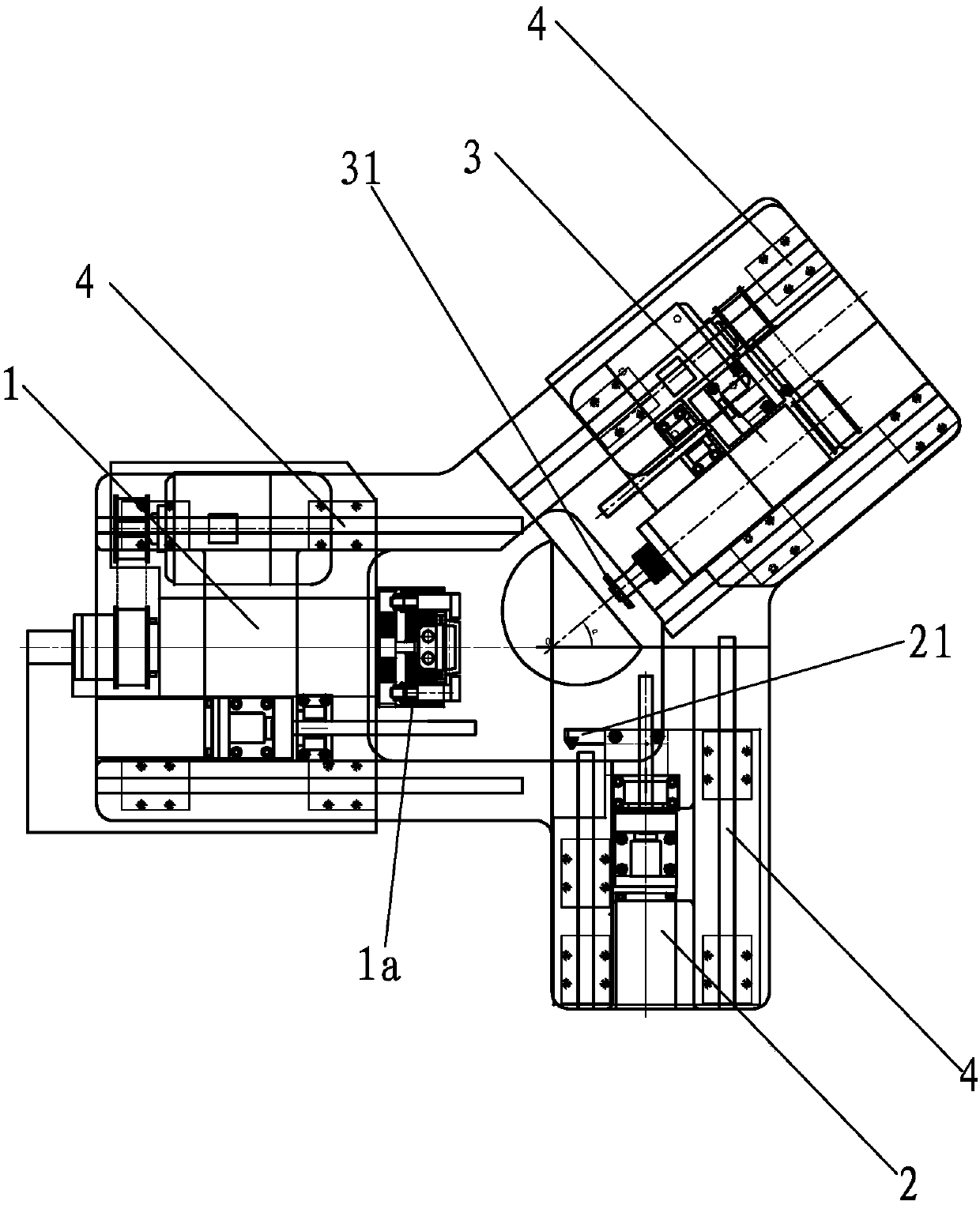

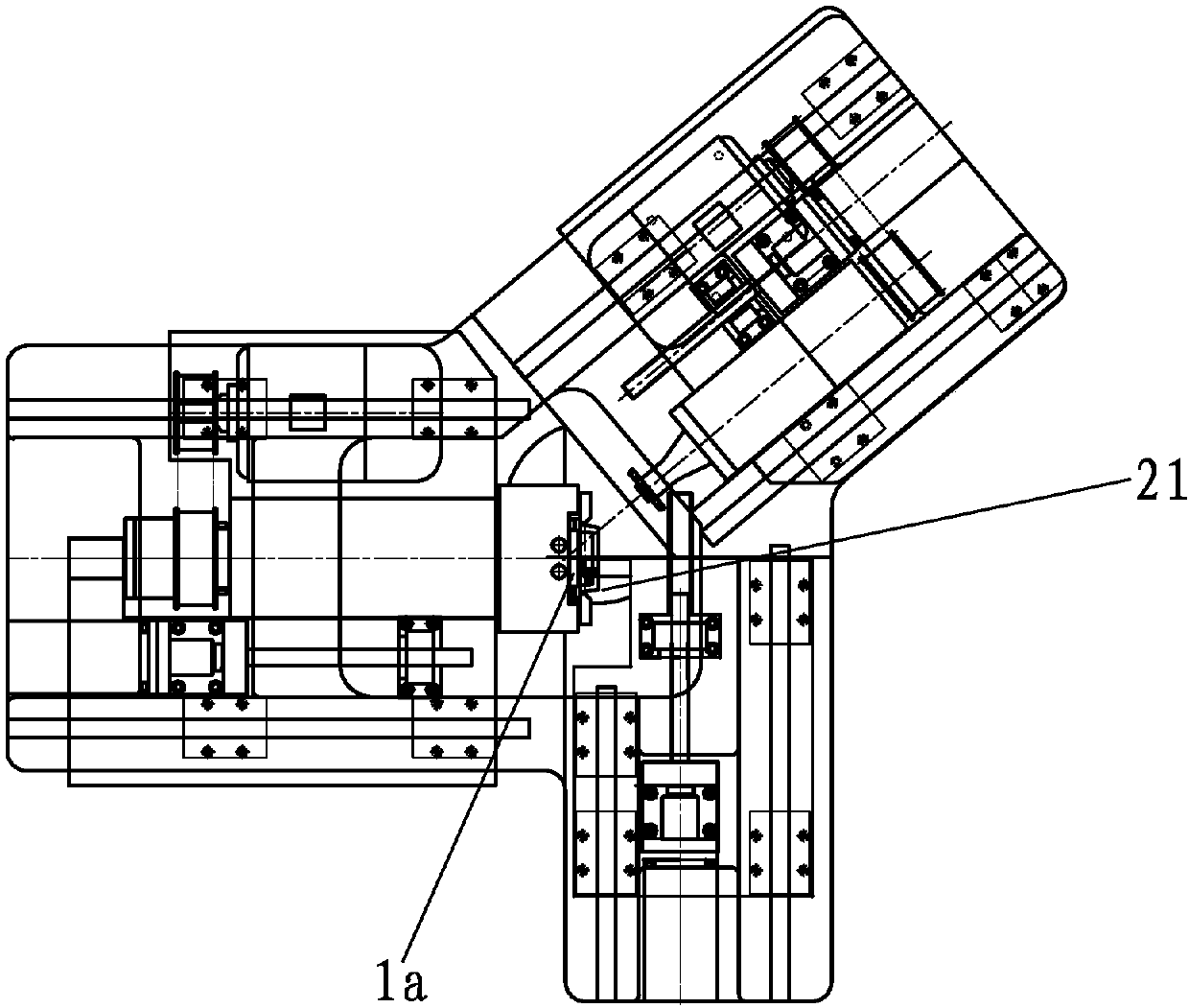

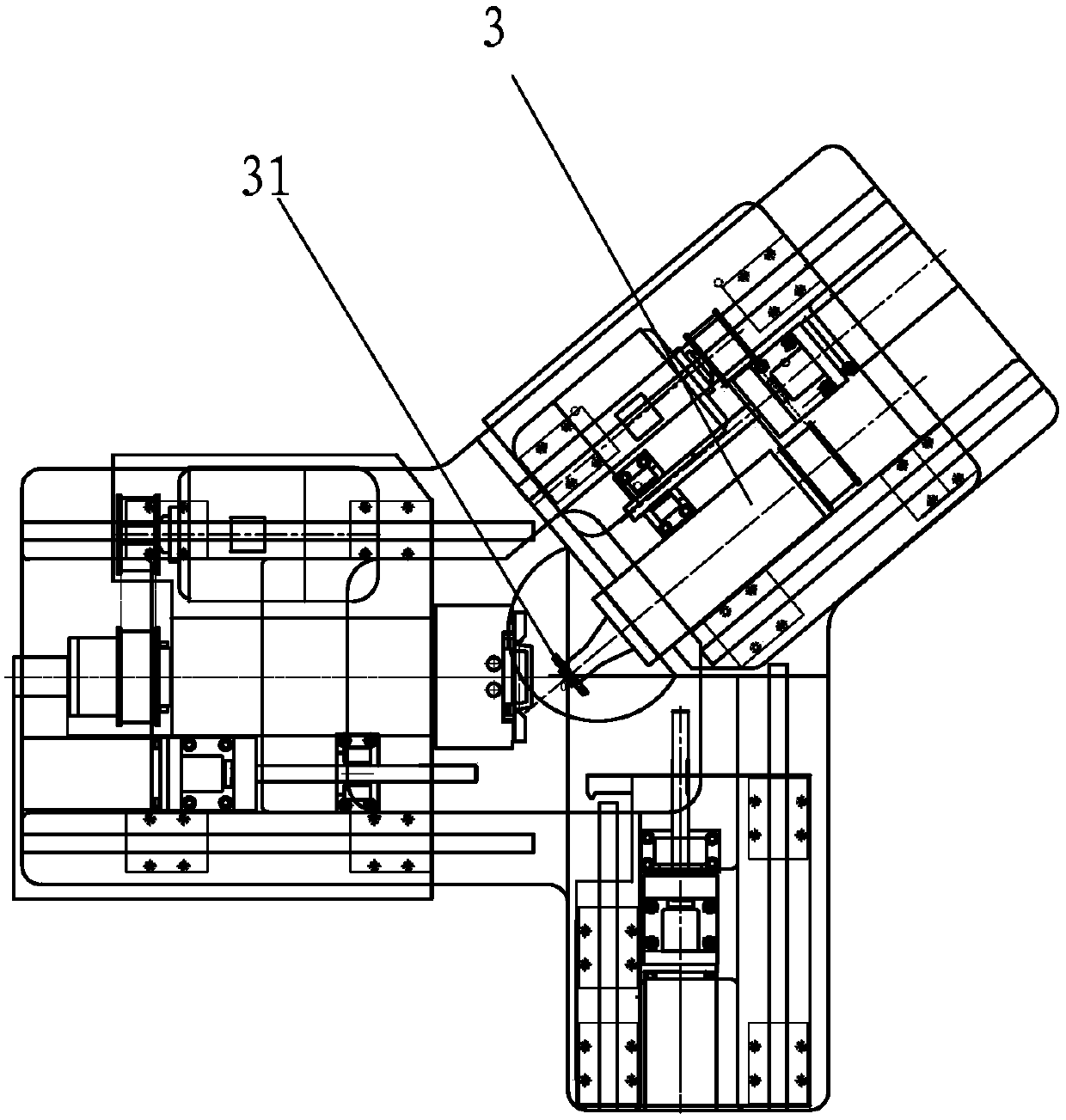

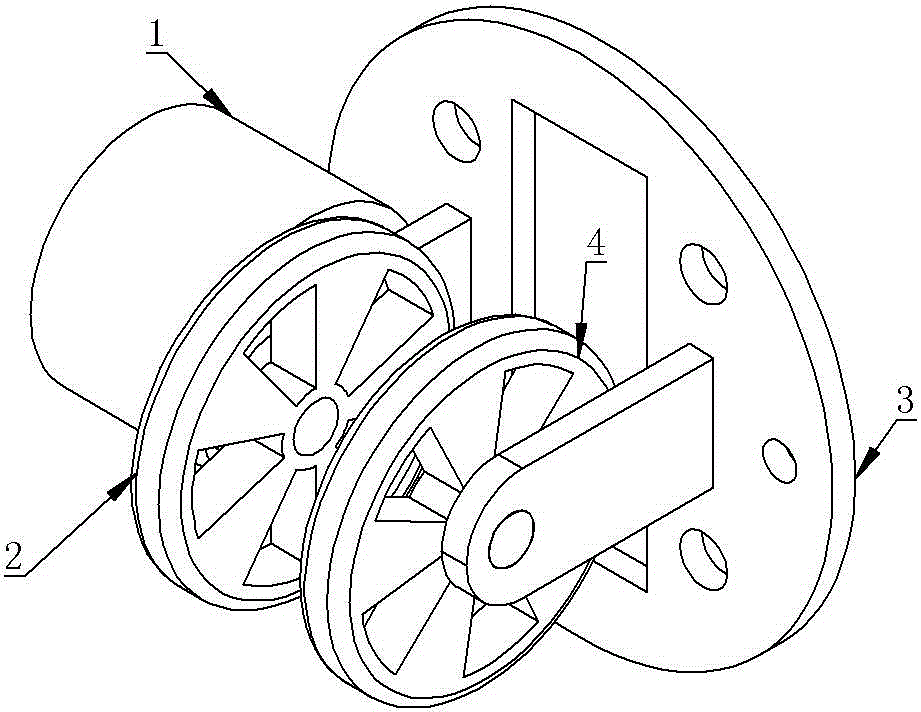

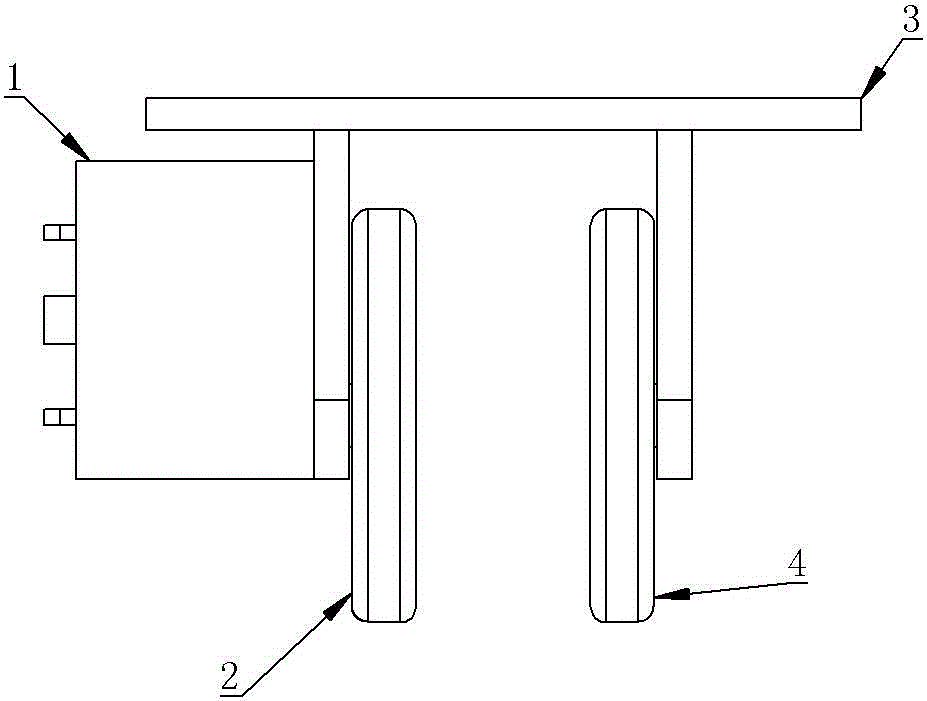

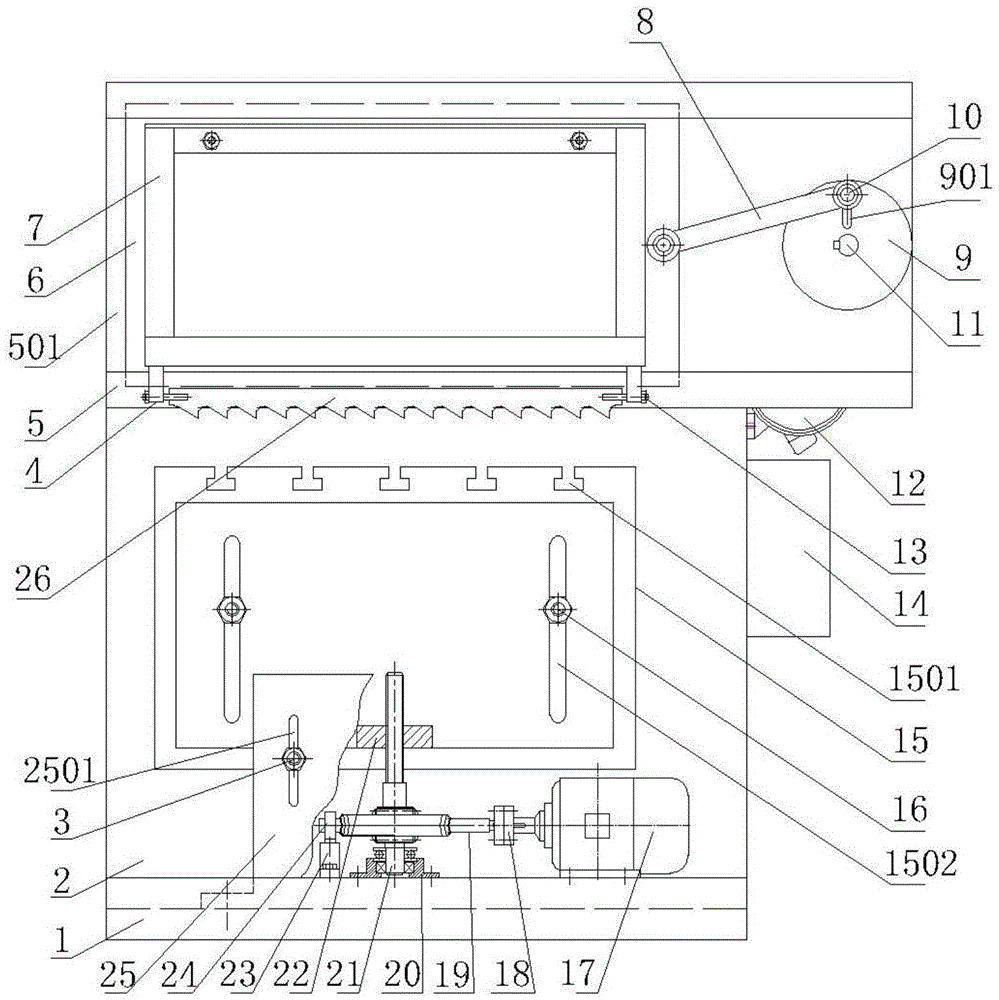

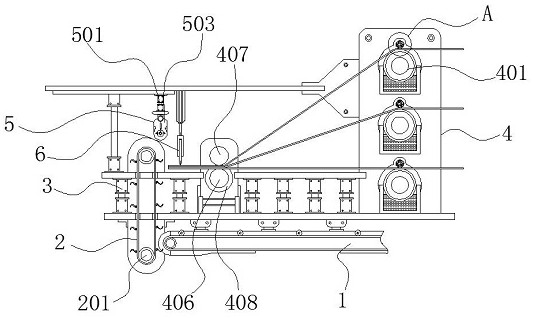

Milling and polishing machine

ActiveCN104526543AEven consumptionExtended service lifeLapping machinesWork carriersCrystal orientationMechanical engineering

The invention discloses a milling and polishing machine. The milling and polishing machine comprises a milling disc unit arranged on a rack, and a clamping unit arranged opposite to the milling and polishing face of a milling disc in the milling disc unit. The clamping unit comprises a clamping part used for clamping a work-piece to be machined, and a drive part which drives the clamping part to rotate with the vertical line of the milling and polishing face of the milling disc as the axis. By the adoption of the technical scheme, the milling and polishing machine enables diamond particles to rotate around the vertical line of the milling and polishing face of the milling disc by 360 degrees in the milling and polishing process so that the milling disc can mill the diamond particles in all crystal orientations, on one hand, the step of needing to determine the milling crystal orientations of the diamond particles in the prior art is omitted, and the working efficiency is effectively improved; on the other hand, uniform consumption of the milling disc can be kept, finishing is not needed, and the service life of the milling and polishing machine is prolonged.

Owner:盐城新汇村镇建设发展有限公司

Gas guiding plate, preparation method and curing molding method of stiffened wall plate comprising gas guiding plate

The invention discloses a gas guiding plate, a preparation method and a curing molding method of a stiffened wall plate comprising the gas guiding plate and belongs to the technical field of composite molding. The preparation method of the gas guiding plate includes the steps that a blank gas guiding plate is manufactured through a hard porous material, and holes matched with the bottom faces of ribs in shape are formed in the blank gas guiding plate; and blind holes are formed in the blank gas guiding plate, and the gas guiding plate is obtained. The hard porous material can disengage after the stiffened wall plate is overall molded, and no scrap edge needs to be machined on the edges of the ribs.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

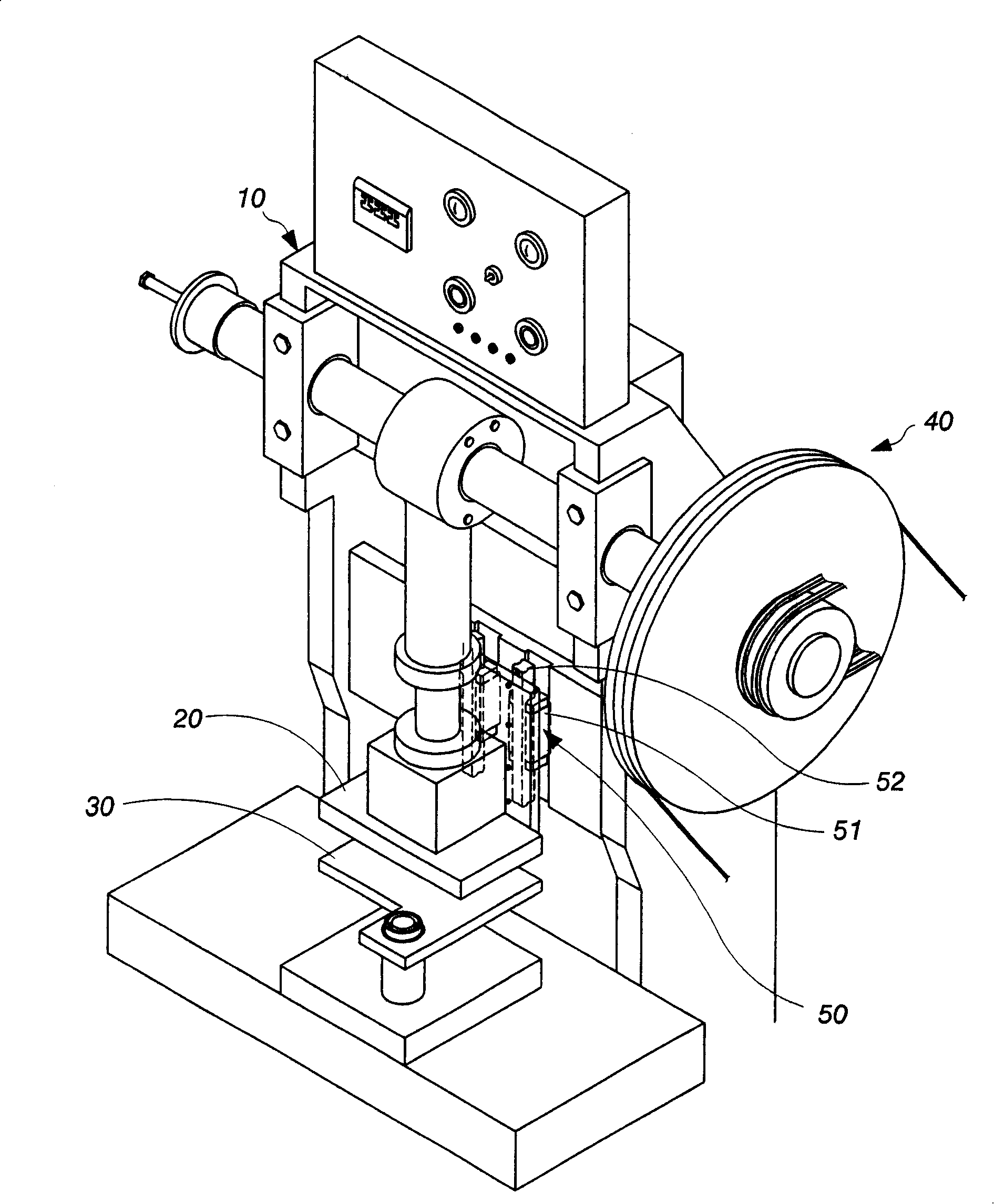

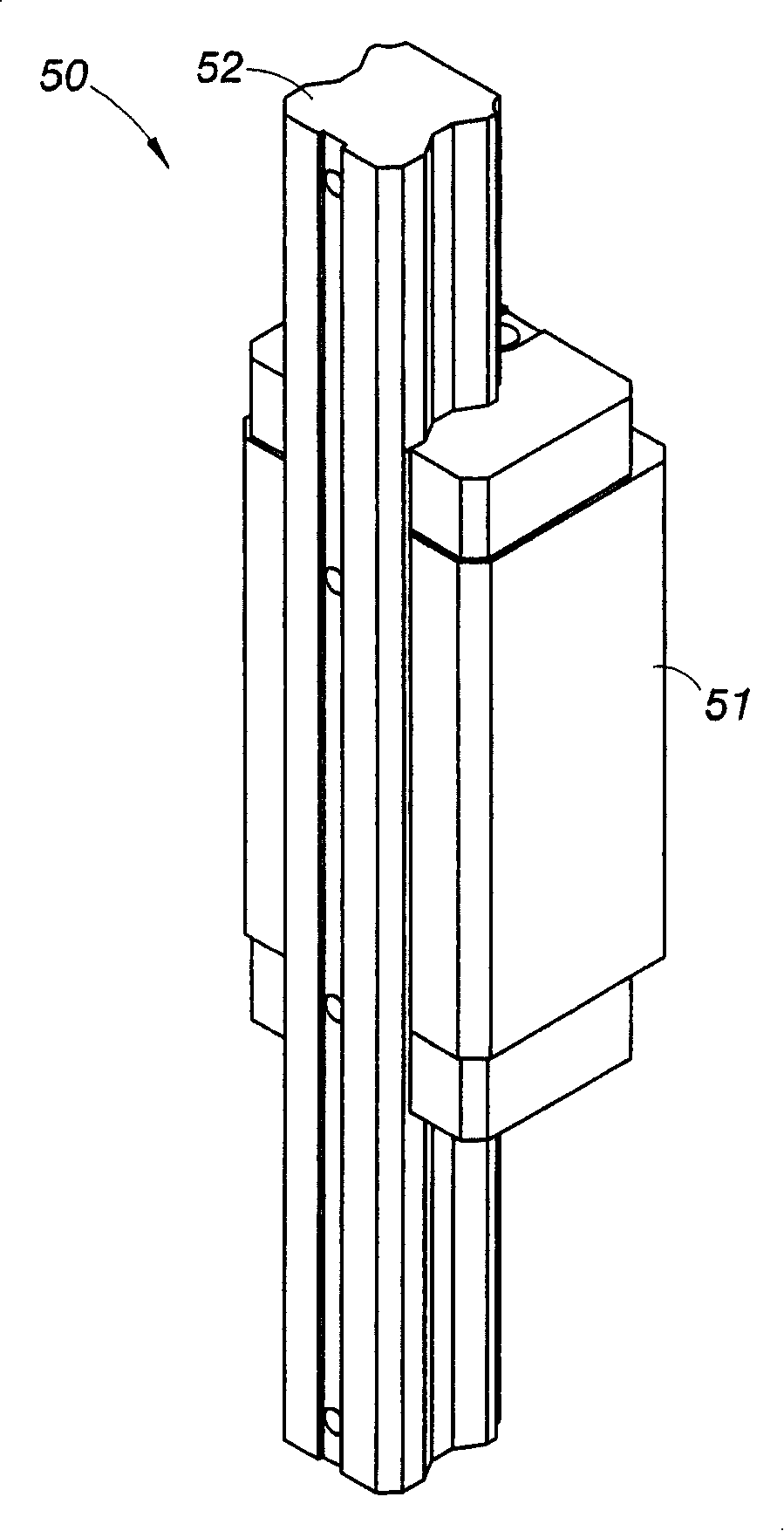

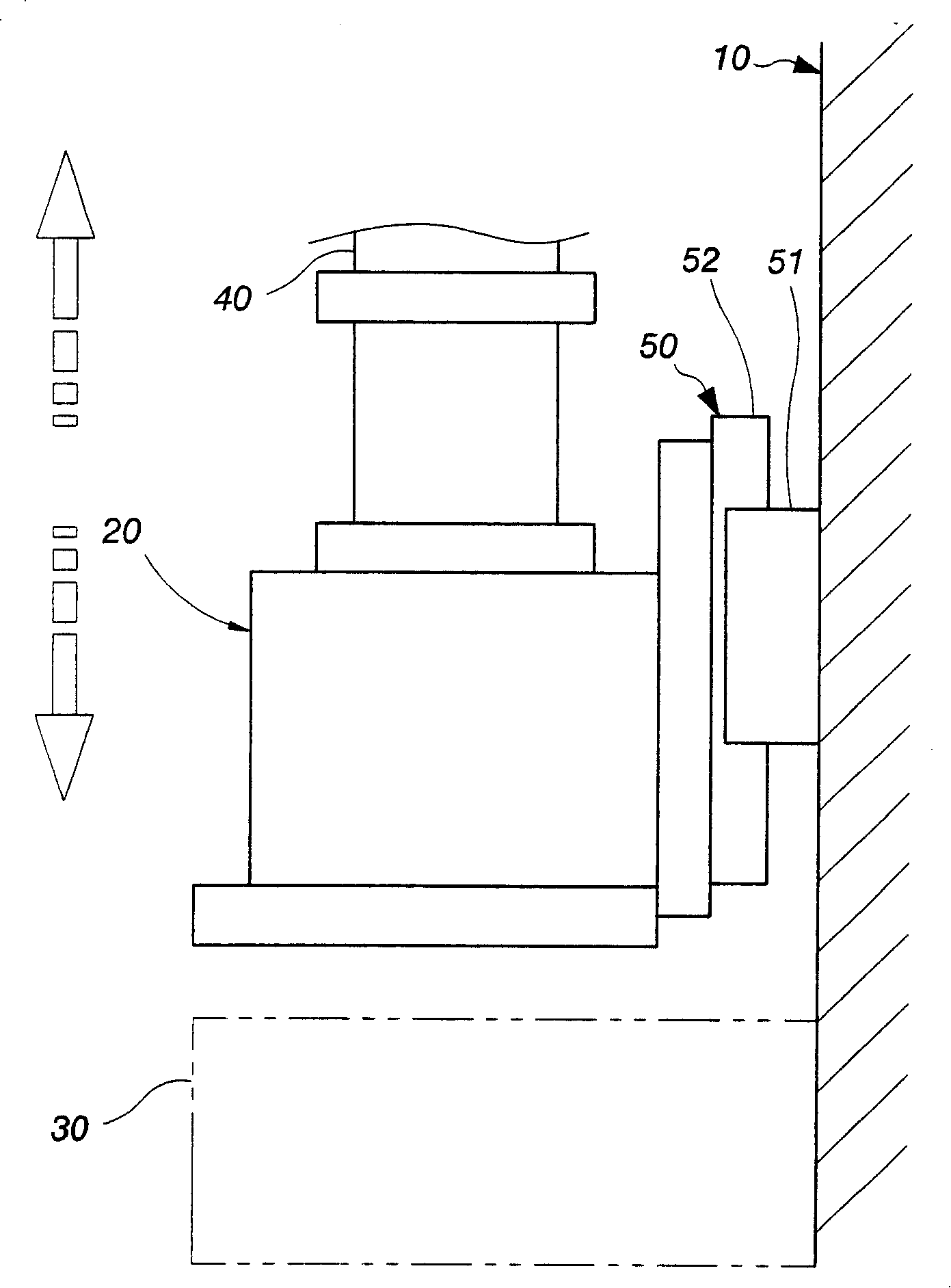

Punching machine

InactiveCN101161449AEasy to disassembleShorten production timePress ramPunch pressAgricultural engineering

The invention provides a punch, at least comprising one machine bench, an upper shoe on the machine bench, a lower shoe on the machine bench, a driving unit for driving the upper shoe, a linear slideway group with at least one vertical furnishings. The upper shoe is subjected to linear guide by linear slideway group to make the operation course of upper shoe more stably quickly and accurately. The setup amount of the linear slideway group can fluctuate as use require and can be set on the rear side or left side or right side, or the linear slideway group can be actualized using setting manner of multi-group and multi-side.

Owner:嵩亿工业股份有限公司

Method for machining inner spherical surface of bearing seat through movement forming

InactiveCN107717669AShape error reductionSmall shape errorSpherical surface grinding machinesGrinding feedersSpherical bearingGrinding wheel

The invention discloses a method for processing the inner spherical surface of a bearing seat through motion forming. The inner spherical surface of the bearing seat is ground with a diamond grinding wheel, which can be used for a long time without shaping and grinding, because the processing method of the present invention is formed by a motion The method of grinding the inner spherical surface adopts three numerical control feeding steps of diamond grinding wheel spherical center feeding, bearing seat spherical center feeding and diamond grinding wheel spherical diameter feeding, and uses the compound rotation circle of the bearing seat and the rotation circle of the diamond grinding wheel to form The ball is used to complete the grinding of the inner spherical surface of the bearing seat. The invention discloses a method for processing the inner spherical surface of the bearing seat through motion forming, without the need of correcting the grinding wheel, the grinding wheel has a long service life, and the processing accuracy and efficiency are high.

Owner:福建省德源智能科技有限公司

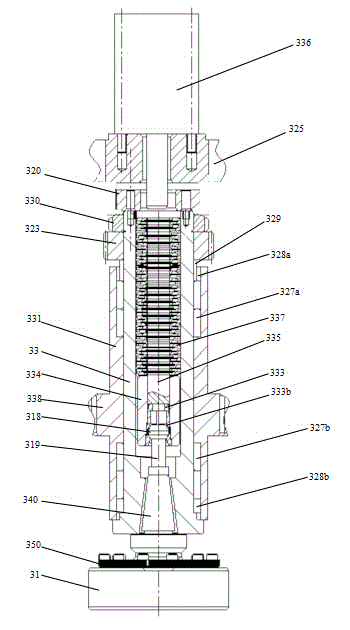

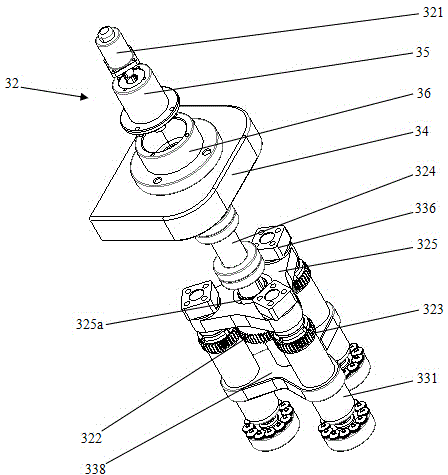

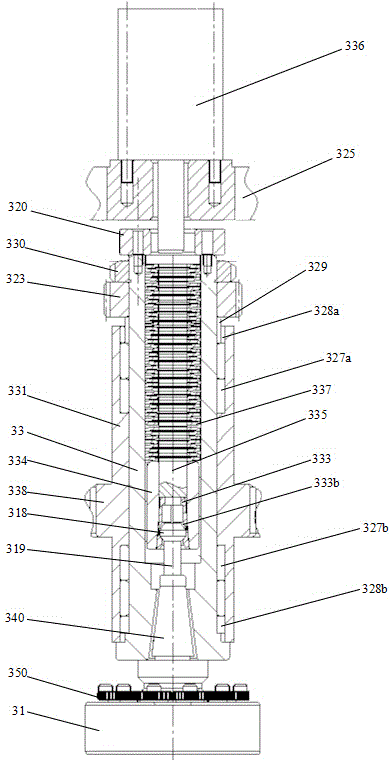

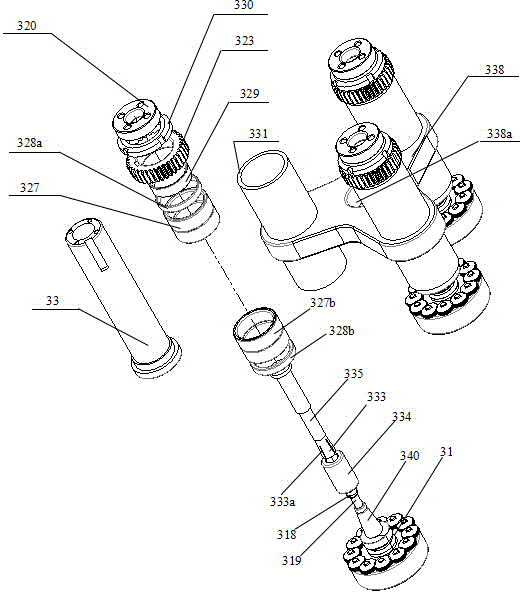

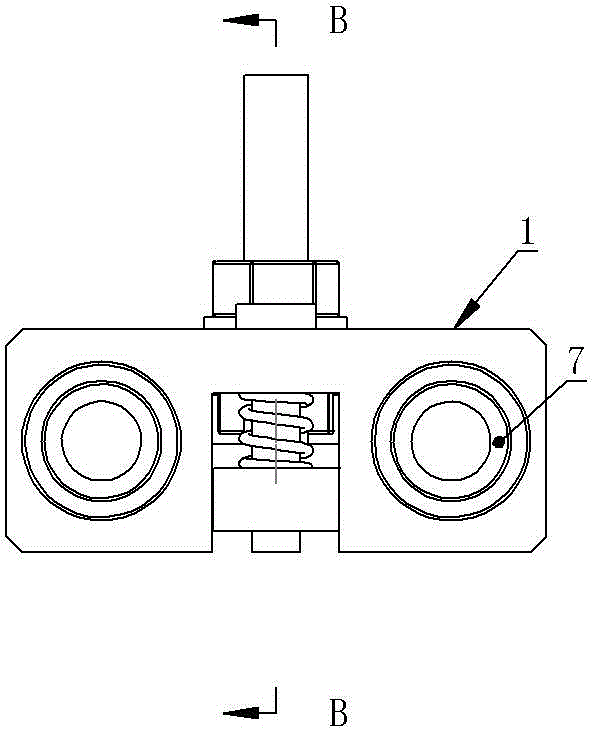

Roller type electric needle moving device

Owner:天津市宝坻区东亚光大地毯厂

A kind of preparation method of shadow carving ceramic product

The invention discloses a preparation method of a shadow-carving ceramic product, comprising the following technological steps: (1)making of a model: by a 3D Feifang making technology, a product model is drawn on a computer with the application of a shadow-carving technology, and the product model is printed by a 3D printing technology; (2) making of a mould: the mould is made according to the shape of the product model; mould testing and mould repairing: error-eliminating mould repairing is carried out on the mould according to the quality of a product made by the use of the mould; (4) making of porcelain clay; (5) moulding to prepare a ceramic blank; and (6) sintering: sintering temperature is 1220 DEG C-1350 DEG C, and sintering time is 10-15 h. The preparation method has simple technological processes, and the ceramic product prepared by the preparation method has good transmittance and stereoscopic effects.

Owner:吴冬娜

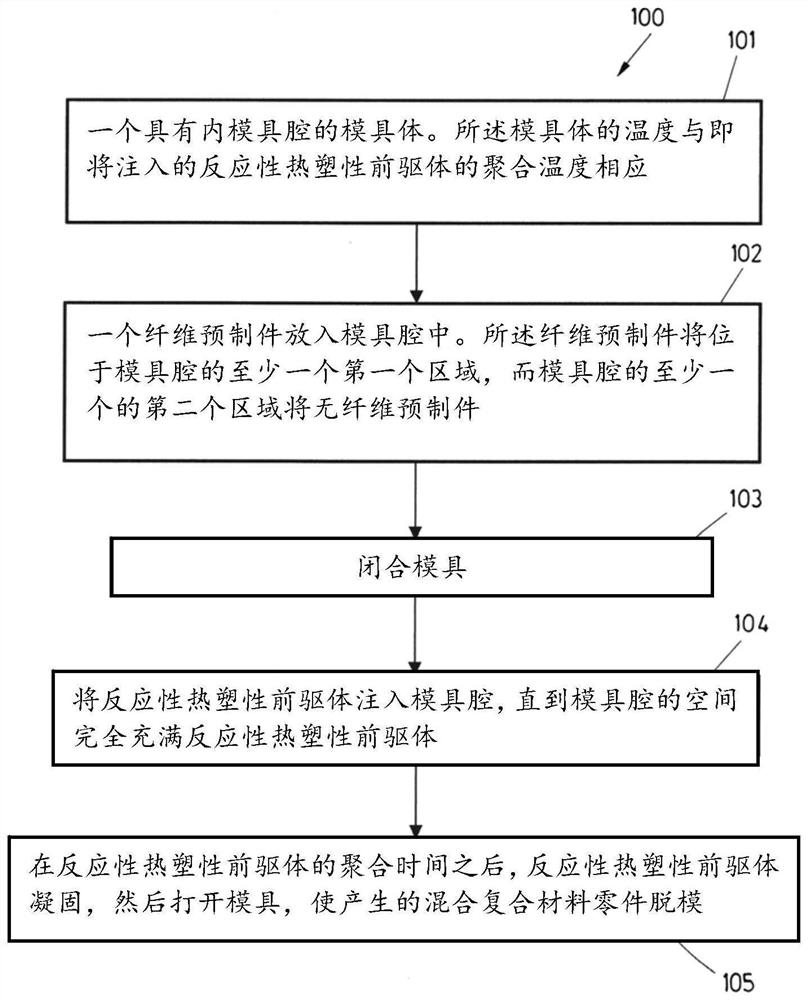

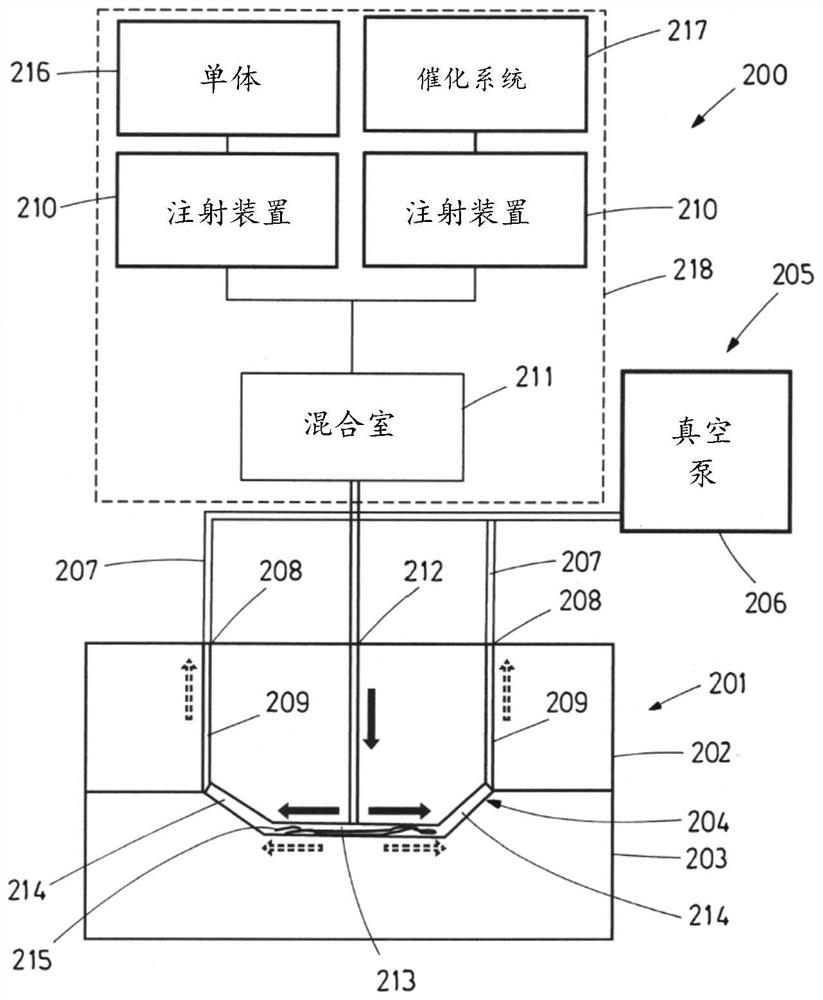

Method and system for producing hybrid composite parts

The invention describes a method and a system for producing hybrid composite parts,. Disclosed is a mould body provided with a mould cavity that has at least one male and one female portion. In this cavity, a fiber preform is placed, being located in at least one area of the mould cavity and leaving free at least other area of the mould cavity. This mould body, also, is at the polymerization temperature of a reactive thermoplastic precursor. After placing the preform into the mould cavity, the mould body is closed. At this point, the reactive thermoplastic precursor is injected into the mould cavity. When the mould cavity is completely filled and the reactive thermoplastic precursor polymerized, the resulting hybrid composite part is demoulded.

Owner:FUNDACION TECNALIA RES & INNOVATION

Rubber forming equipment for petroleum product processing

The invention relates to forming equipment, in particular to rubber forming equipment for petroleum product processing. The rubber forming equipment for petroleum product processing aims at achieving the technical effects that manpower can be saved, and the forming efficiency can be improved. Rubber forming equipment for petroleum product processing comprises a rack and a supporting frame, and the supporting frame is arranged on one side of the rack; the first air cylinder is arranged on the supporting frame; the compaction assembly is connected between the rack and the first air cylinder; the molding die is arranged on the compaction assembly part in a sliding manner; and the shaking mechanism is arranged between the compaction assembly part and the rack. Through cooperation between the discharging assembly and the self-starting switch assembly, the first air cylinder can be automatically started.

Owner:深圳市争先科技有限公司

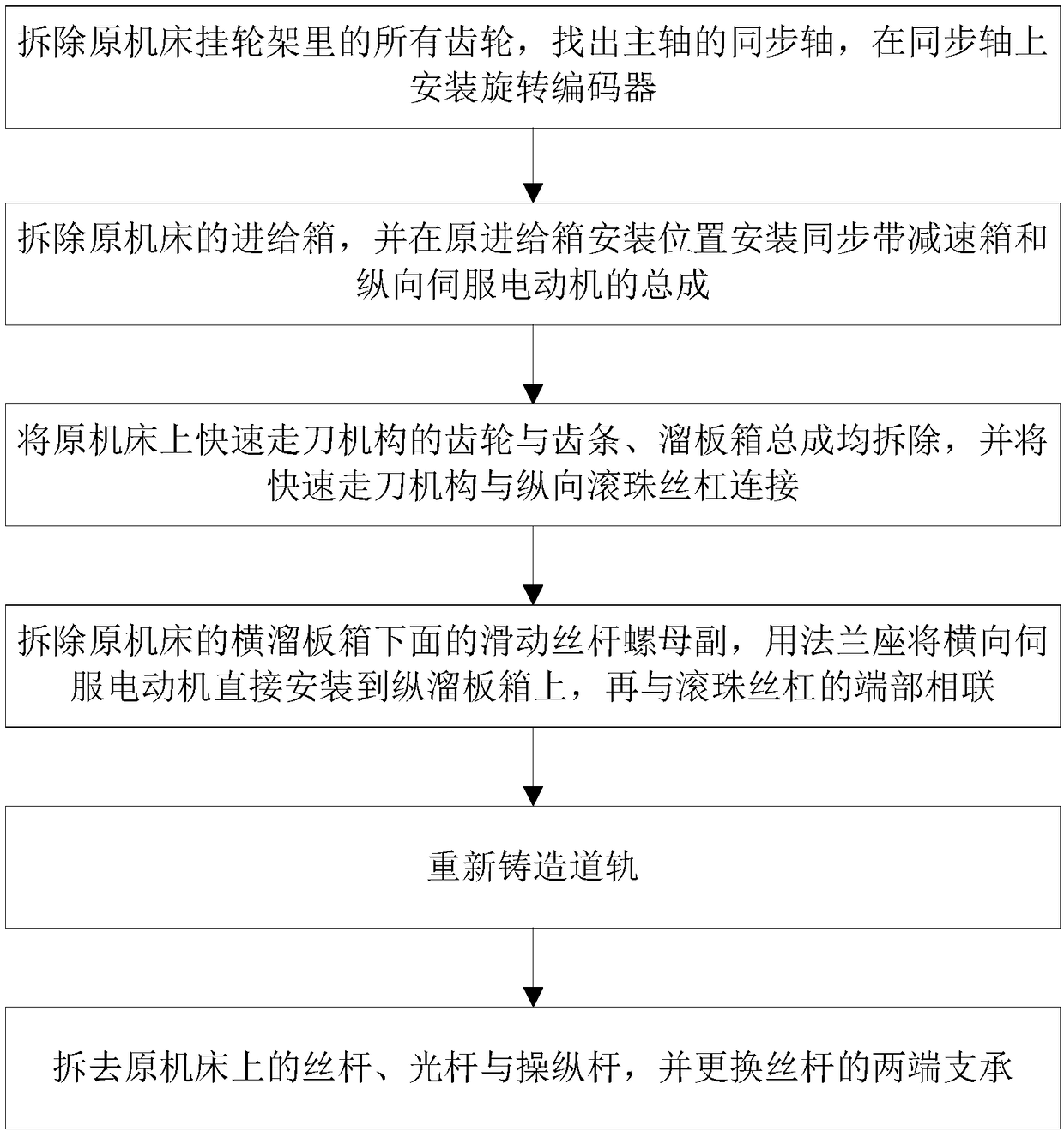

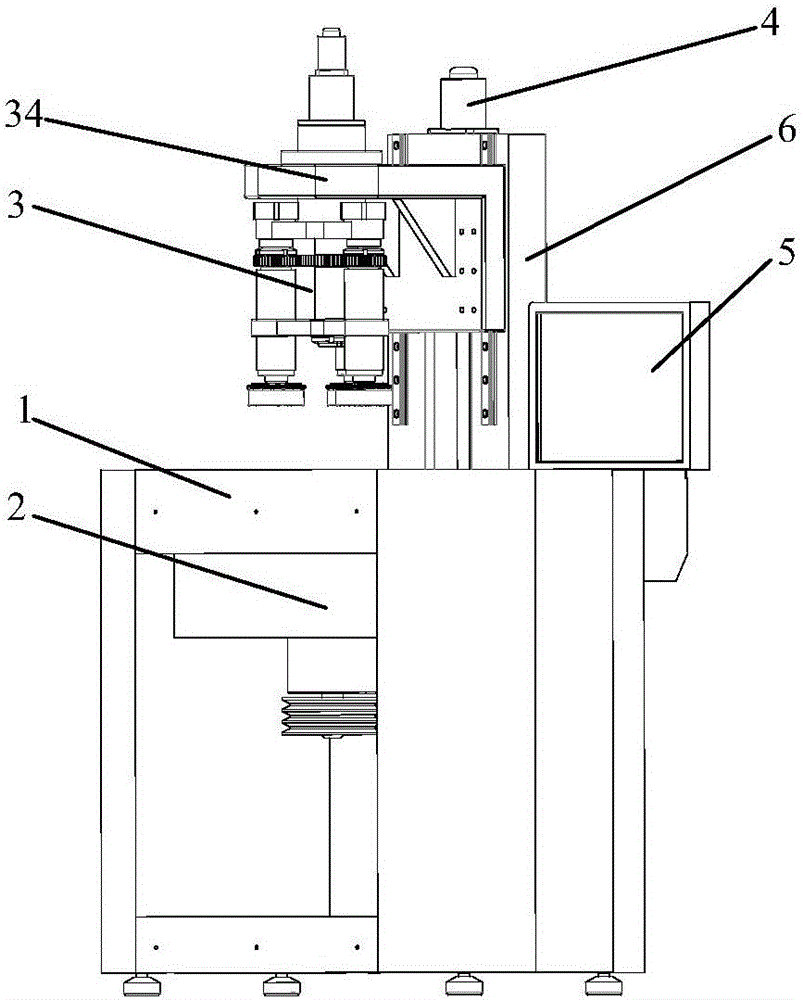

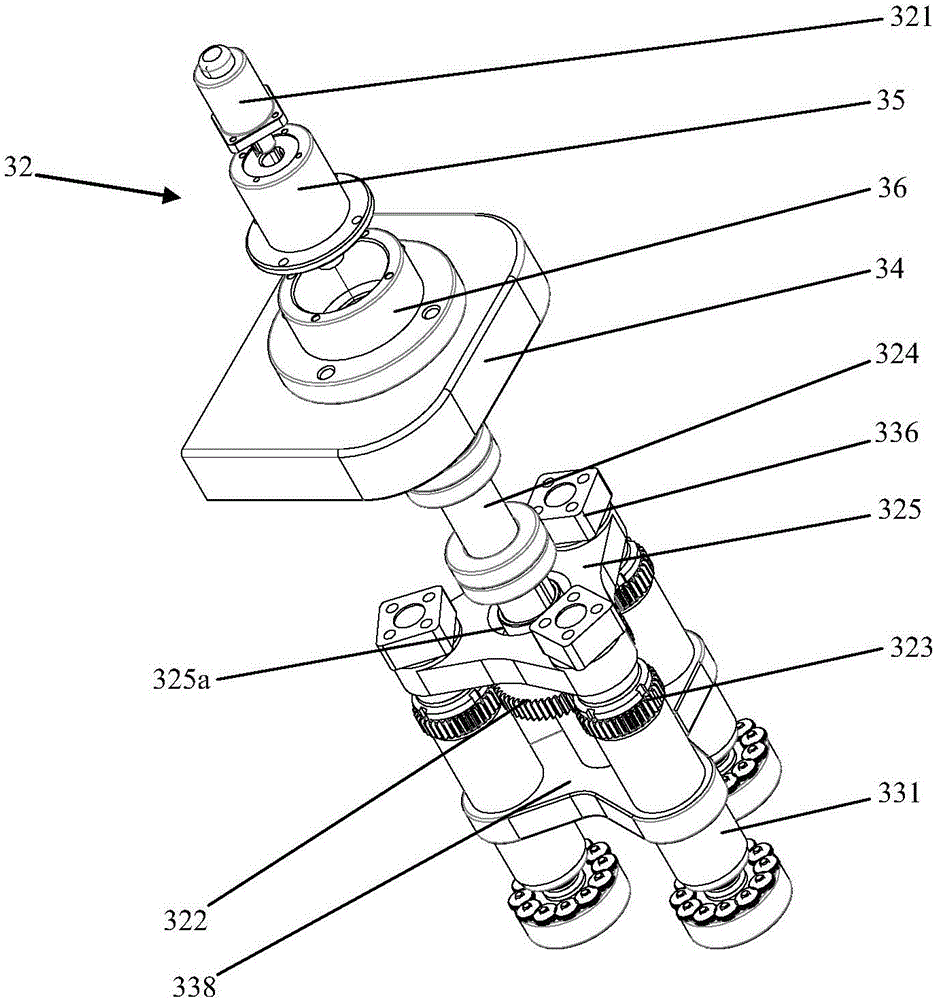

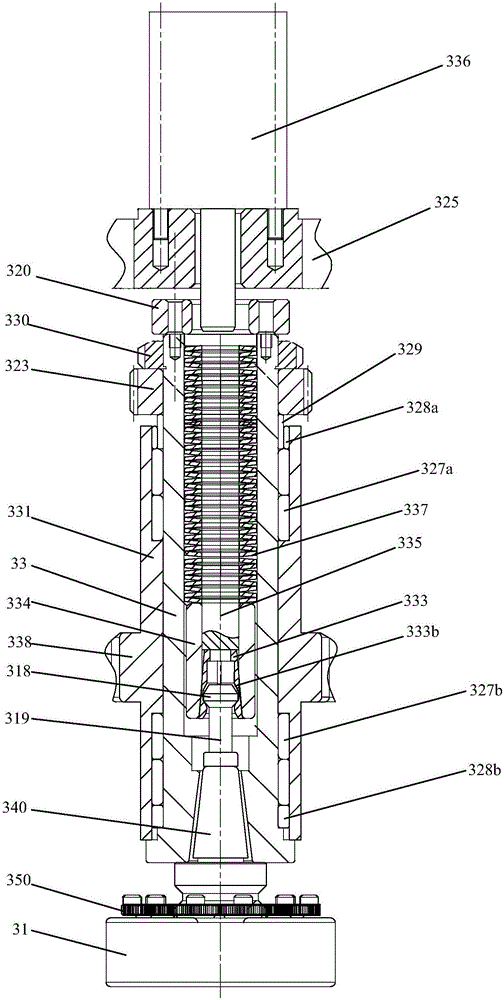

Numerical-control modifying method for machine tool for rope groove processing

InactiveCN108356578AImprove processing speedImprove processing qualityFeeding apparatusLarge fixed membersNumerical controlEconomic benefits

The invention discloses a numerical-control modifying method for a machine tool for rope groove processing. An existing common horizontal type lathe is refitted into a numerical-control lathe capableof processing a rope groove, so that the processing purpose of the rope groove can be completed. A C6031A type common lathe is a conventional horizontal lathe with an allowable maximum processing diameter of 3500 mm and maximum processing length of 6000 mm. When a double-broken-line rope groove is processed in the common C6031A type lathe, feeding of the machine tool cannot meet requirements of aspiral broken line; and after being modified in a numerical-control mode, the machine tool can process the double-broken-line rope groove, so that economic benefits are considerable. Through the numerical-control modifying method for the machine tool for rope groove processing disclosed by the invention, labor intensity of an operator is relieved, tooling times are reduced, a trial-production period and a producing and processing period for a novel product are also shortened, market needs can be timely responded quickly, and the like.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

A kind of diamond grinding and polishing method

ActiveCN104551974BEven consumptionExtended service lifeLapping machinesWork carriersCrystal orientationDiamond grinding

Owner:盐城新汇村镇建设发展有限公司

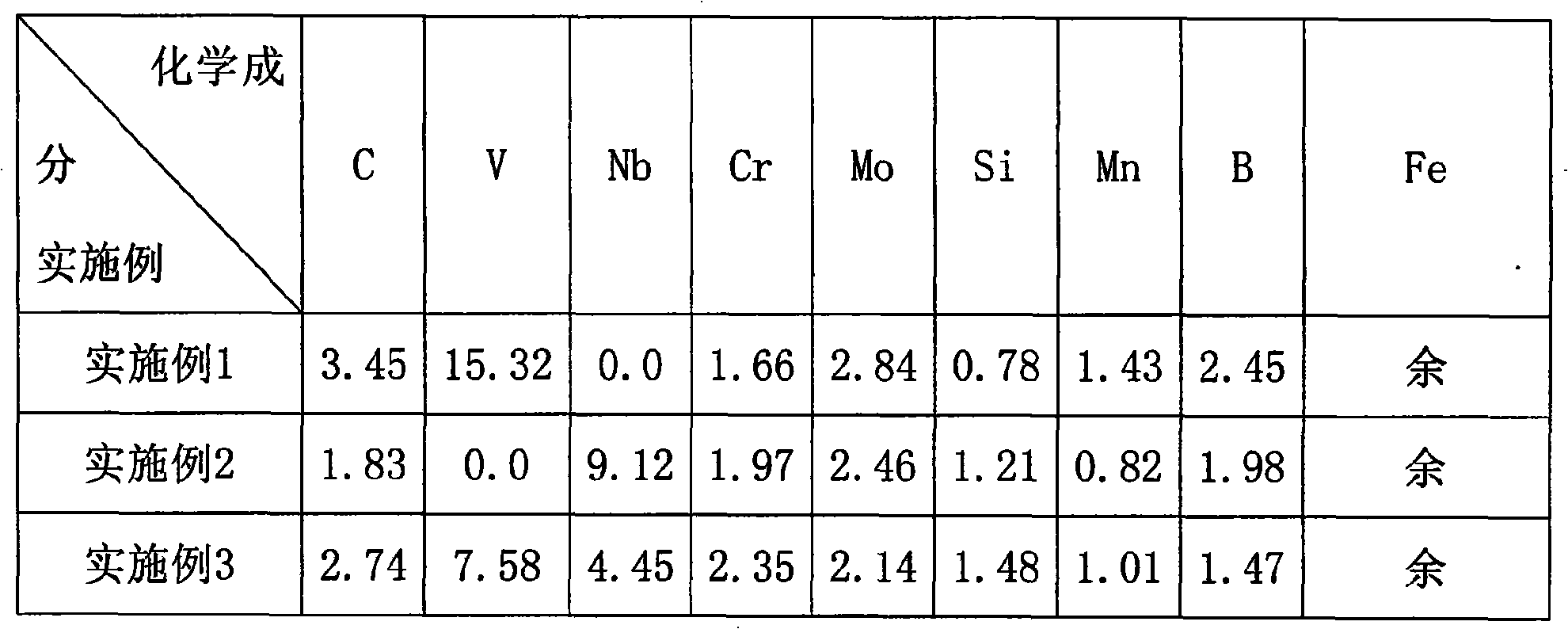

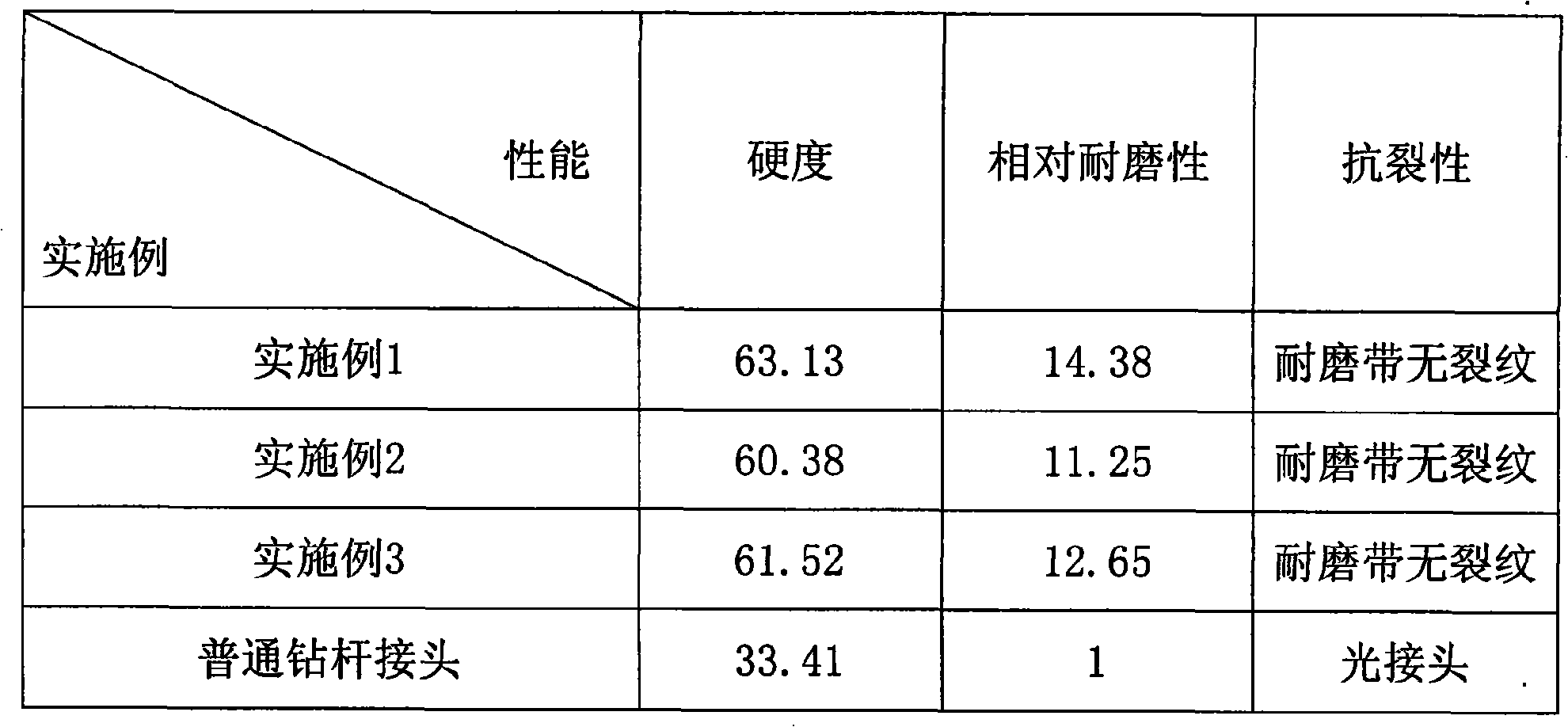

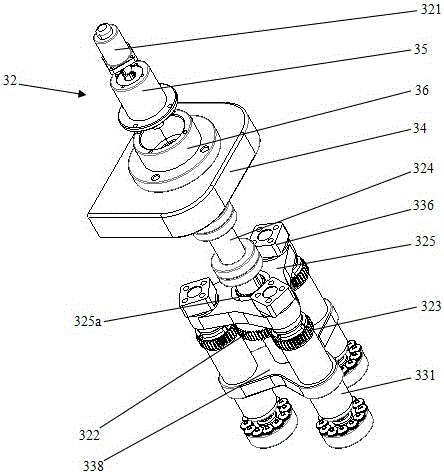

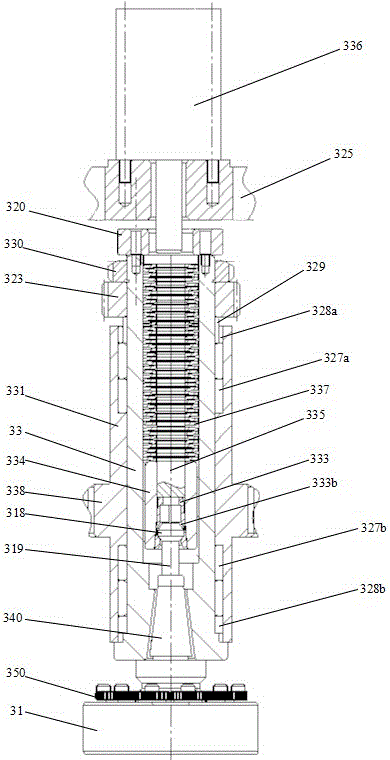

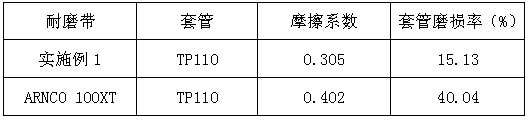

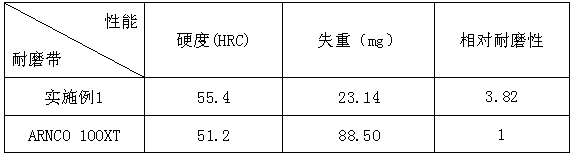

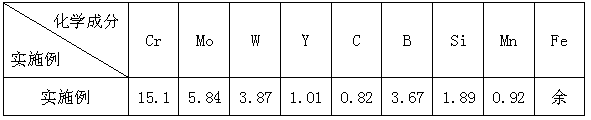

Flux-cored wire with durable drill rod and high cracking resistance

InactiveCN101653881AImprove crack resistanceImprove wear resistanceWelding/cutting media/materialsSoldering mediaTO-18Chemical composition

The invention belongs to the field of welding material, particularly relates to a flux-cored wire with durable drill rod and high cracking resistance. For solving the problem of the prior art that thehigh cracking resistance can not reasonably fit to high wearing feature, the invention provides the flux-cored wire with durable drill rod and high cracking resistance, wherein the chemical composition of the weld metal consists of 1.5% to 3.5% of C, 8.0% to 18% of M, 1.5% to 2.5% of Cr, 2.0% to 3.0% of Mo, 0.5% to 1.5% of Si, 0.5% to 1.5% of Mn, 1.5% to 2.5% of B, and the remains are Fe. M is one or two of V and Nb. Compared to the prior art, the invention has the advantages of: 1 high cracking resistance and high wearing feature, 2 simple resurfacing welding technique, 3 high capability ofrepeating resurfacing welding, 4 good manufacturability of resurfacing welding, and 5 wide scope of application.

Owner:西安纳特石油技术有限责任公司

a polishing machine

ActiveCN104526543BEven consumptionExtended service lifeLapping machinesWork carriersCrystal orientationEngineering

The invention discloses a milling and polishing machine. The milling and polishing machine comprises a milling disc unit arranged on a rack, and a clamping unit arranged opposite to the milling and polishing face of a milling disc in the milling disc unit. The clamping unit comprises a clamping part used for clamping a work-piece to be machined, and a drive part which drives the clamping part to rotate with the vertical line of the milling and polishing face of the milling disc as the axis. By the adoption of the technical scheme, the milling and polishing machine enables diamond particles to rotate around the vertical line of the milling and polishing face of the milling disc by 360 degrees in the milling and polishing process so that the milling disc can mill the diamond particles in all crystal orientations, on one hand, the step of needing to determine the milling crystal orientations of the diamond particles in the prior art is omitted, and the working efficiency is effectively improved; on the other hand, uniform consumption of the milling disc can be kept, finishing is not needed, and the service life of the milling and polishing machine is prolonged.

Owner:盐城新汇村镇建设发展有限公司

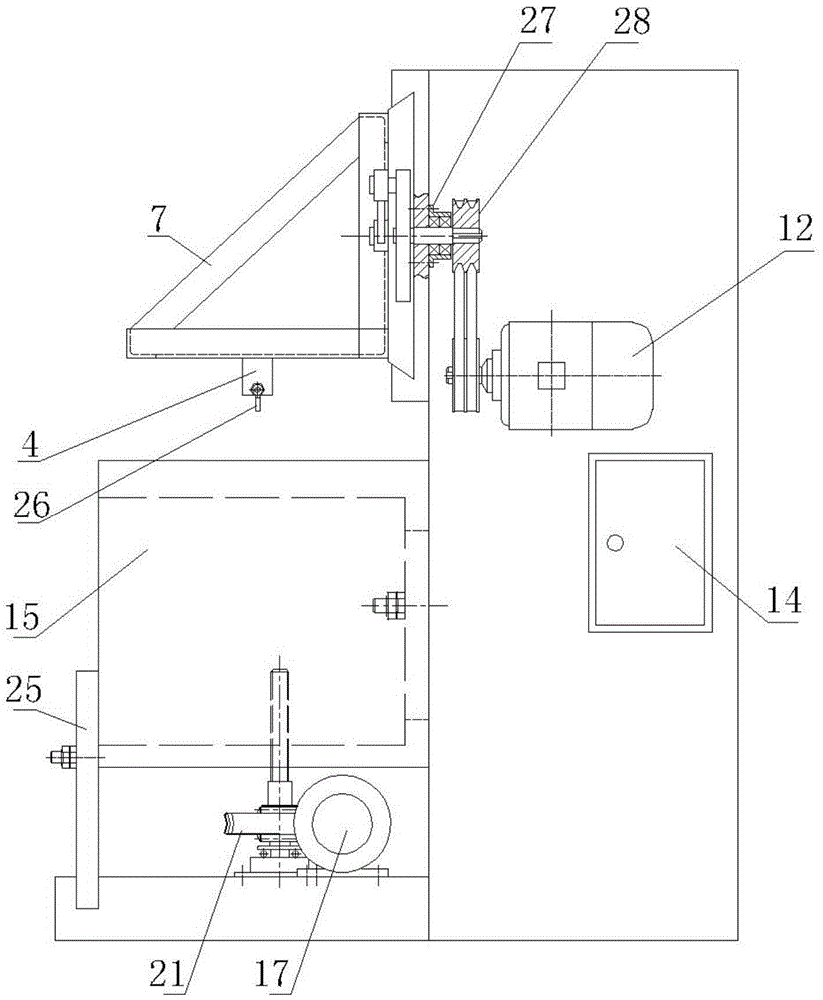

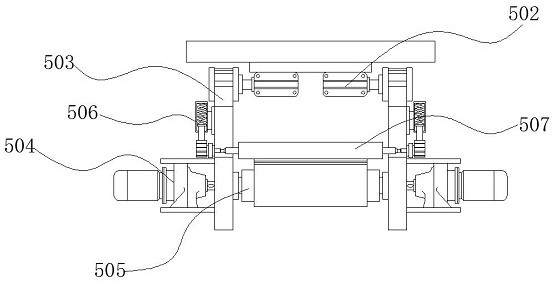

Quartz glass slicer

InactiveCN104310778BImprove straightnessImprove the finishGlass severing apparatusManufacturing cost reductionEngineering

The invention discloses a quartz glass slicer, comprising a body, wherein a slide rail seat in which a slide rail is formed is fixed on the body, a slide carriage is arranged in the slide rail seat, a crank-link mechanism is arranged at one end of the slide rail seat, a drive motor is arranged on one side of the upper part of the body, a crankshaft of the crank-link mechanism penetrates through the slide rail seat and is in driving connection with the drive motor, the free end of a link of the crank-link mechanism is hinged on the middle part of one end of the slide carriage, and a tool rest and a saw blade are fixed in front of the slide carriage; and a lifting platform 15 is arranged in front of the body and below the slide rail seat and is supported on a base in front of the body through a height adjusting device. The quartz glass slicer has the beneficial effects that the quartz glass slicer is reasonable in structure and convenient to use, can be used for slicing large-sized quartz glass plates, is high in automation degree, labor-saving and time-saving and greatly reduces the labor intensity of workers; and the cut quartz glass plates have good section straightness and good finish degree and do not need to be trimmed, so that quartz glass raw materials can be saved, waste can be reduced and the manufacturing cost can be reduced.

Owner:广东盈锋实业有限公司

Welding equipment of plastics acidic bath and welding process thereof

The invention relates to the technical field of cold rolling and pickling line, in particular to a welding equipment and a welding process for a plastic pickling groove . The welding equipment is composed of a worktable, rails, a walking trolley, a machine base on the trolley, a horizontal sliding mechanism, an adjustment screw, a slant sliding mechanism and a welding device. The welding device iscomposed of a motor, a reduction gear, an auger delivery device, a heater and a welding head. The welding process comprises the following steps: the adjustment screw adjusts the degree of inclinationof the slant sliding mechanism, welding material is added into a feed hopper, the power supply of the heater is powered on, the temperature of each heating zone of a machine barrel is respectively controlled in the range as a first zone below 190 DEG C, a second zone below 230 DEG C, and a third zone below 280 DEG C, and the moving speed is controlled to be 0.05-0.08 m / s. The invention has the advantages that the welding quality is improved, and the weld seam factor can reach above 0.9; the equipment is convenient to install and maintenance free, and has long service life. The weld seam is formed in one time, no repeated factory build-up welding is required; the weld seam is free from pore, undercut and over burning, with smooth surface and graceful form, needs no dressing, and is corrosion and ageing resistant.

Owner:ALIBEI PLASTIC STORAGE TANK ANSHAN

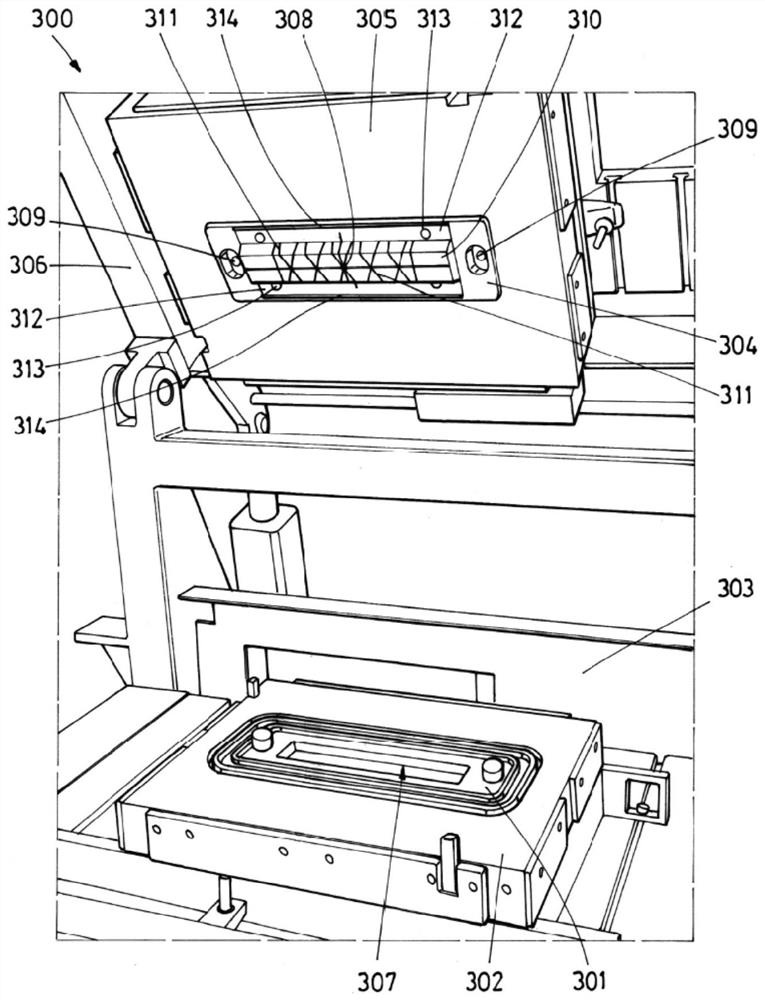

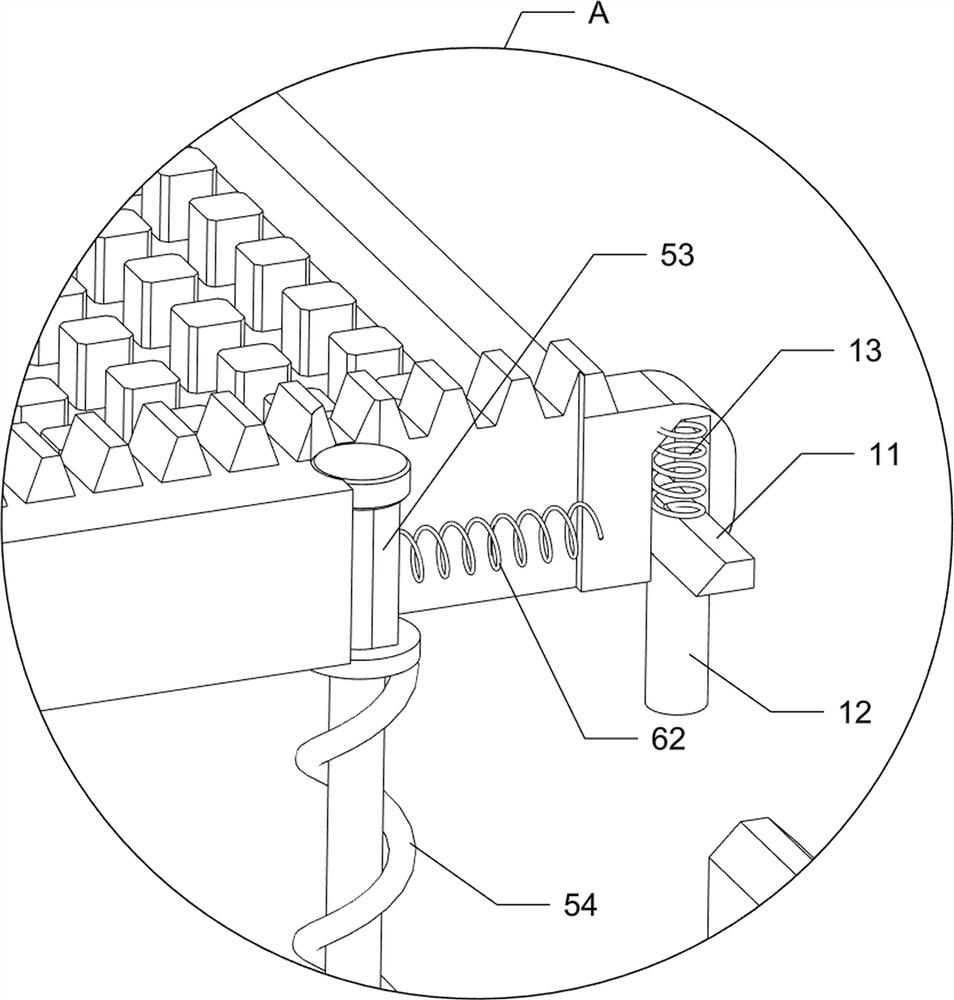

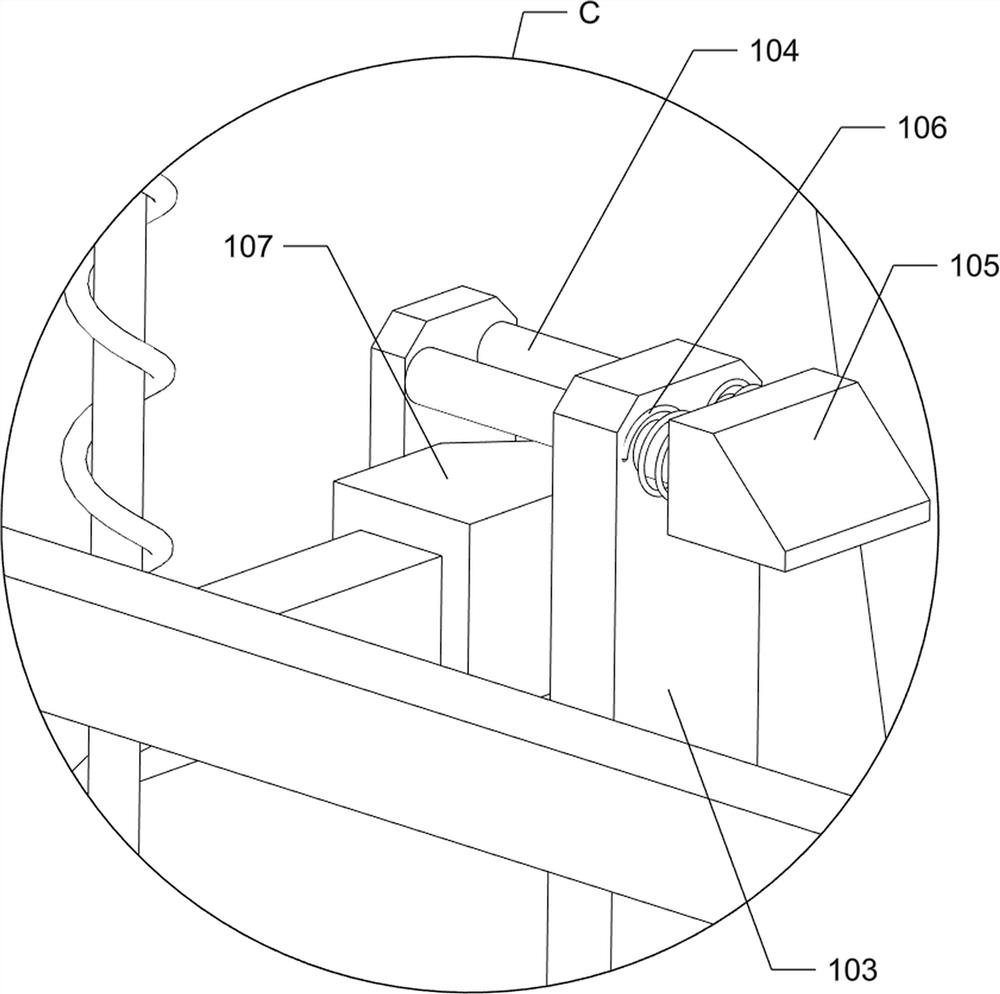

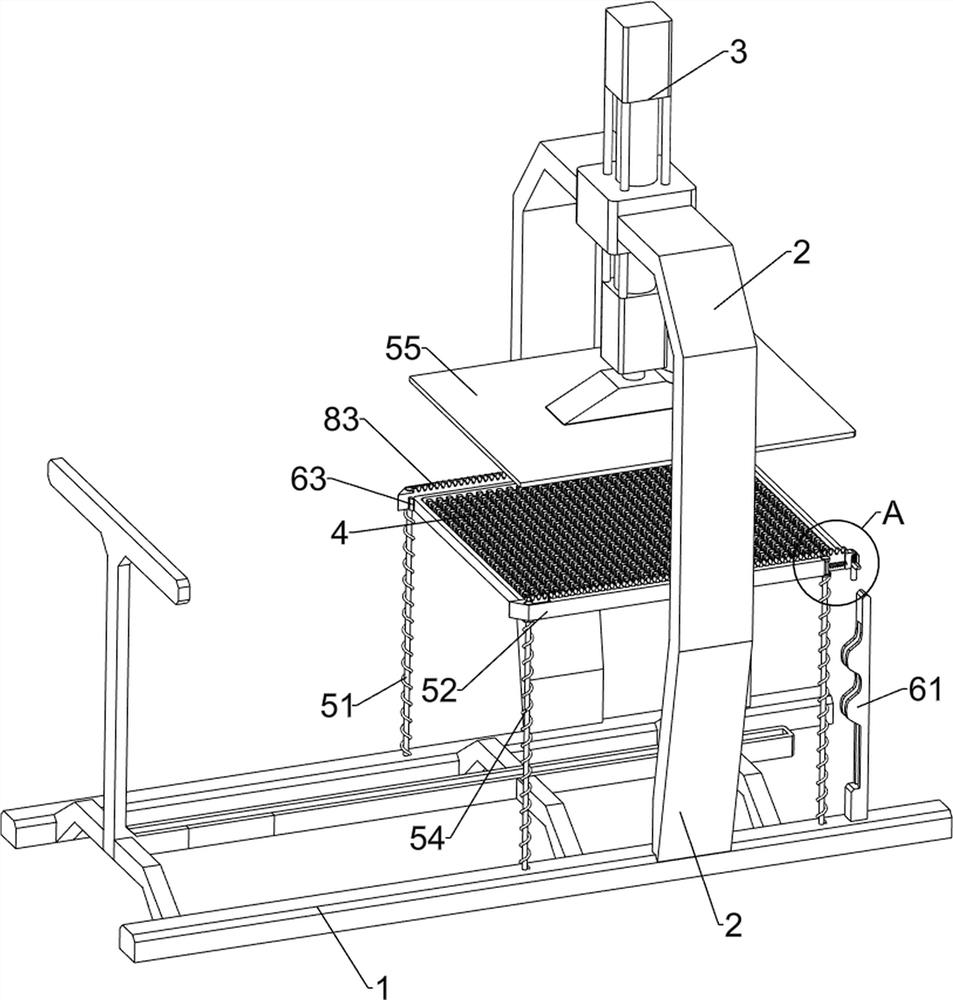

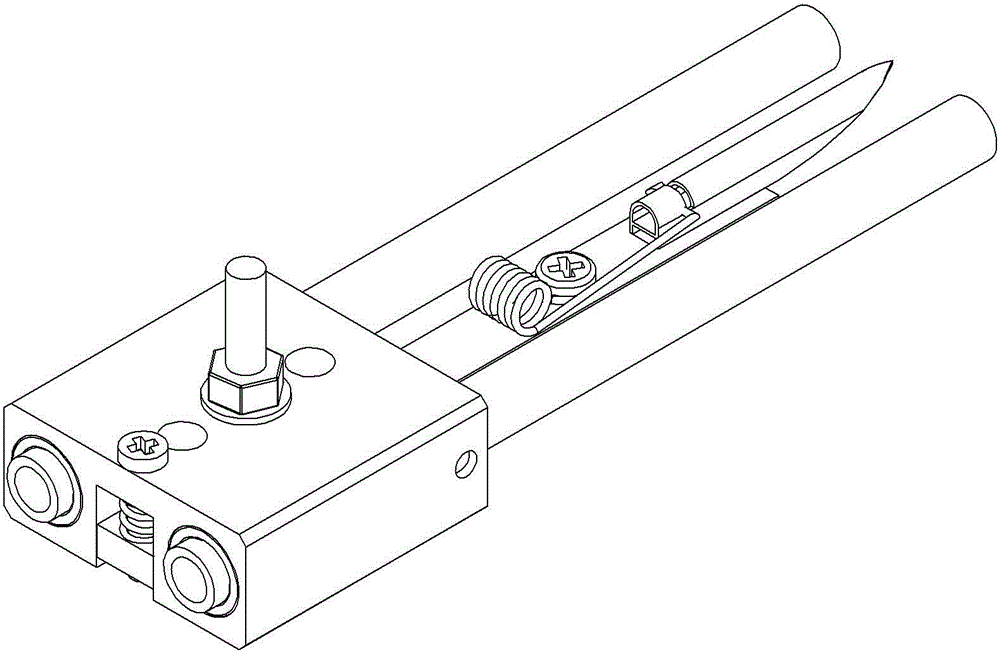

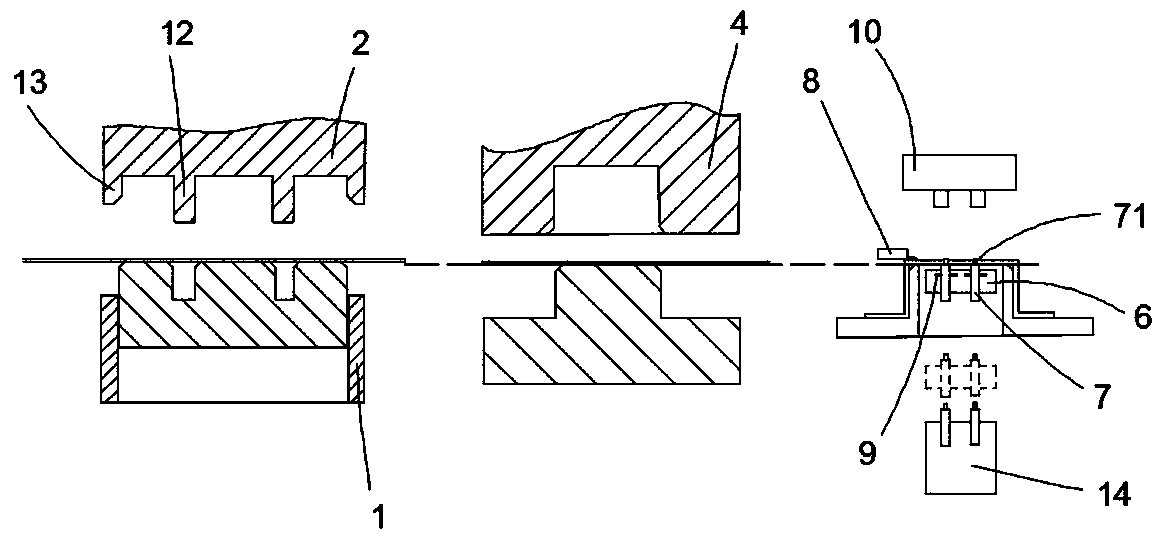

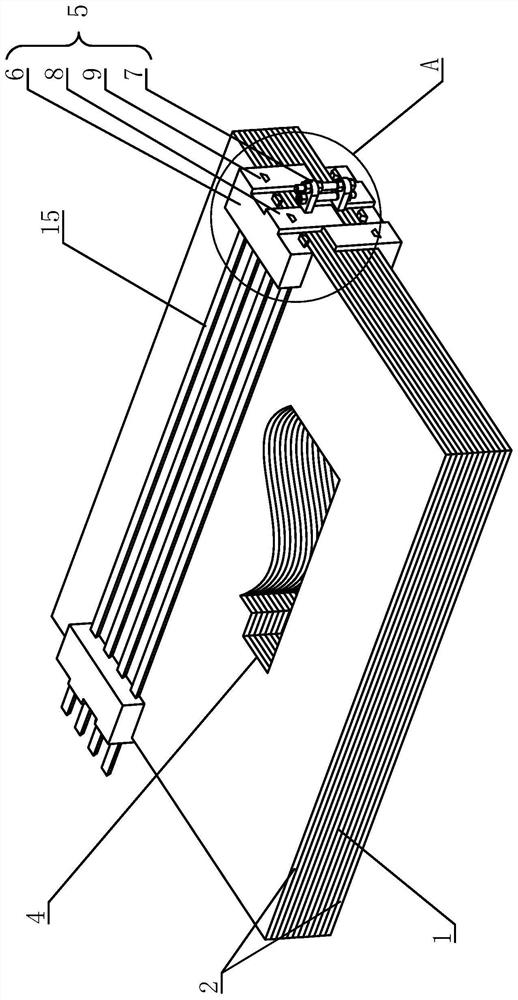

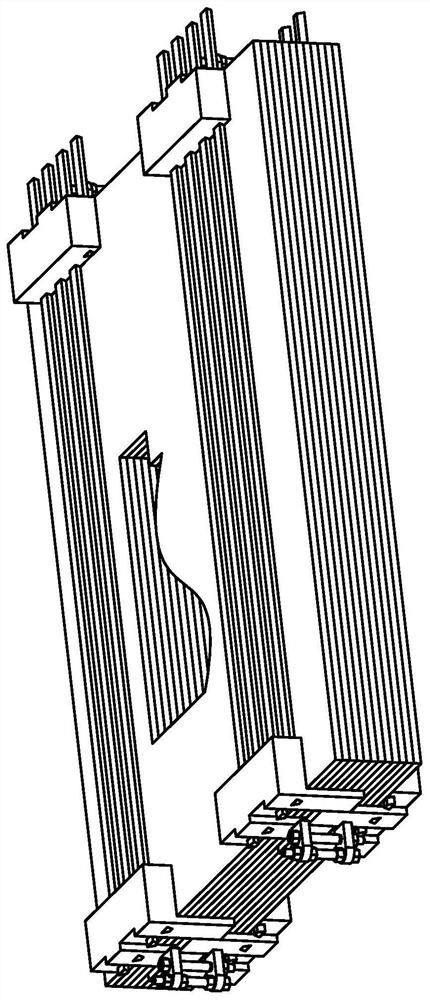

Pole core assembling mechanism for automatic production of lithium battery

InactiveCN113328131AAvoid misalignmentInhibit sheddingPrimary cell manufactureAssembling battery machinesStructural engineeringBattery fluid

The invention discloses a pole core assembling mechanism for automatic production of a lithium battery, and relates to the technical field of lithium battery production. The conveying belt is used for conveying and feeding a container filled with battery fluid; and the gluing mechanism is arranged at the right end of the assembly table. The pole core assembling mechanism also comprises an assembling mechanism which is connected to the top of the assembling table; the lifting cutter is arranged on the right side of the assembling mechanism and fixedly connected with the assembling table. According to the pole core assembling mechanism for the automatic production of the lithium battery, the positive pole film, the diaphragm and the negative pole film are glued and are subjected to side edge limiting in the overlapping process, so the three films can be overlapped, and dislocation at the edges is avoided, so there is no need of cutting for the improvement of the work efficiency; pressure is applied from top to bottom in the process of winding the positive electrode film, the diaphragm and the negative electrode film on the container, so the positive electrode film, the diaphragm and the negative electrode film are firmly adhered to the surface of the container, and meanwhile, bubbles can be prevented from being generated through pressure application.

Owner:DONGGUAN UNIV OF TECH

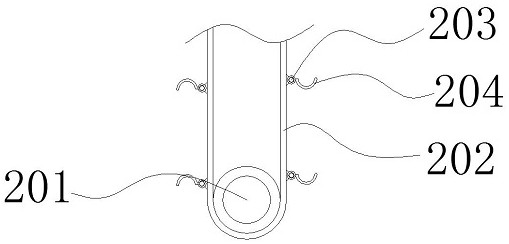

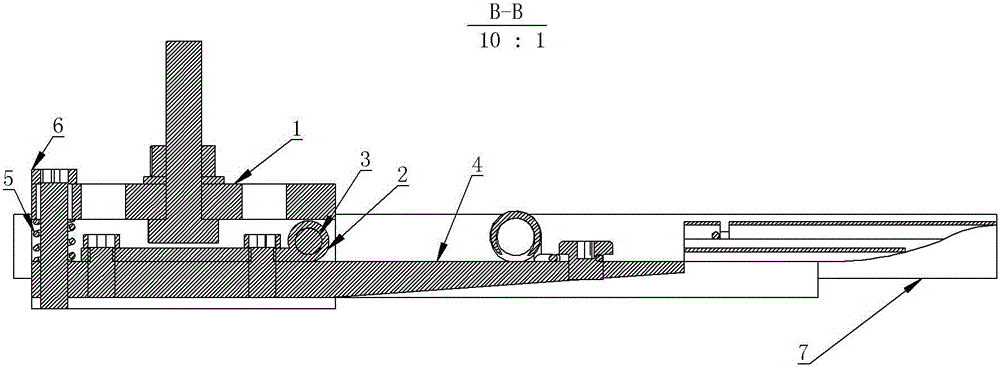

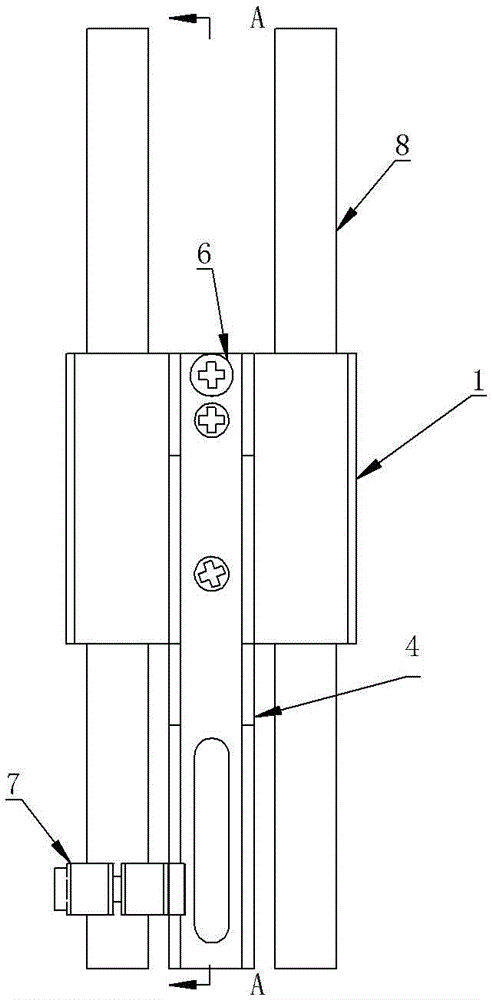

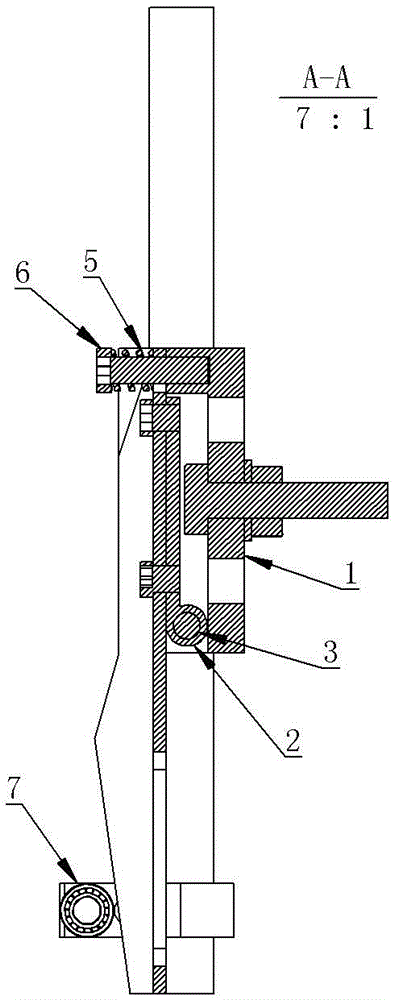

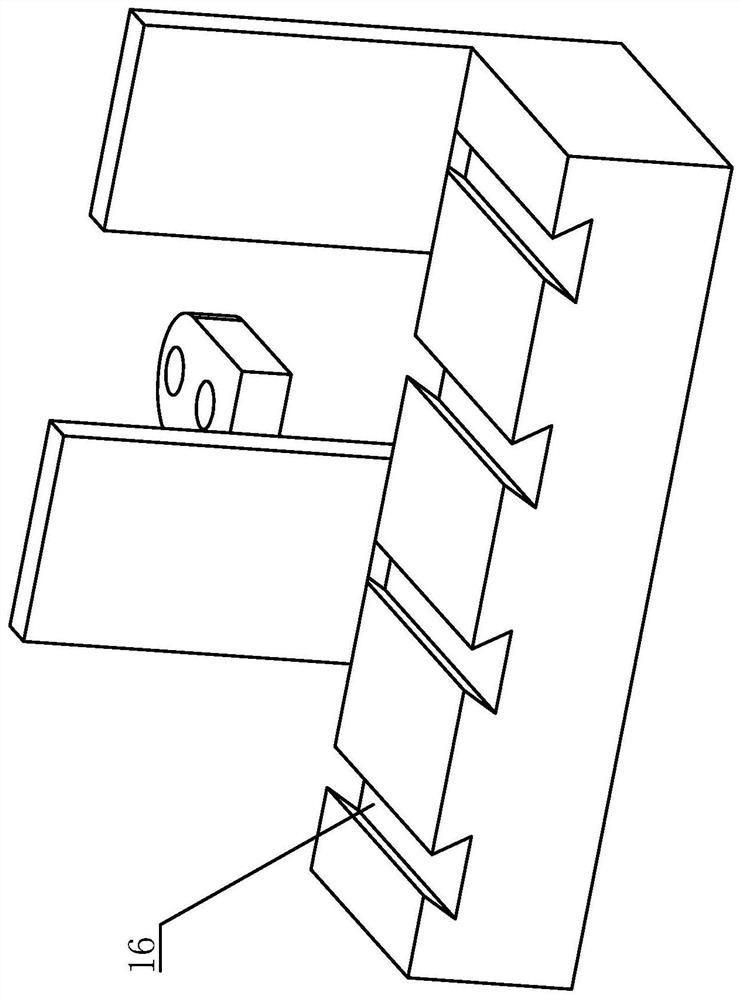

Device for stitch adjustment of upper slider

InactiveCN106480617ANovel structureAutomatic steppingTufting apparatusEngineeringMechanical engineering

The invention belongs to the field of carpet machinery and relates to a device for stitch adjustment of an upper slider. The device comprises the slider, an angle adjusting sheet, a small shaft, a needle, a spring, an adjusting screw and a slide way and is characterized in that the angle adjusting sheet is connected with the small shaft which is arranged on the slider, the needle is arranged on the angle adjusting sheet, the spring is arranged between the slider and the angle adjusting sheet, the adjusting screw penetrates the slider and the spring to be connected with the angle adjusting sheet, and the slider is arranged on the slide way. Automatic stitching is realized by needle angle adjustment, and stitch uniformity, carpet surface smoothness and freeness of manual trimming are realized.

Owner:天津市宝坻区东亚光大地毯厂

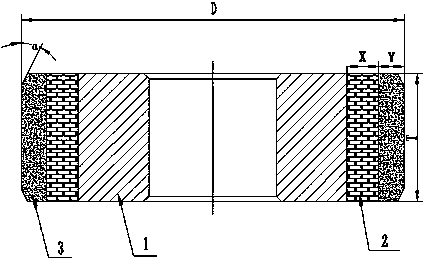

High-speed diamond grinding wheel and preparation method thereof

InactiveCN106826589AImprove processing efficiencyAvoid damageAbrasion apparatusGrinding devicesTechnological systemAdamite

The invention discloses a high-speed diamond grinding wheel. The high-speed diamond grinding wheel comprises a substrate and a grinding block. The grinding block covers the substrate and is composed of, by mass, 37-55% of a diamond grinding material, 30-45% of corundum and 18-30% of a ceramic bond. Raw materials of the ceramic bond comprise, by weight, 40-45% of SiO2, 10-15% of Al2O3, 18-20% of B2O3, 9-10% of Li2O, 7-8% of Na2O and 7-9% of K2O. The firing temperature of the bond is 750-820 DEG C, the pullout strength to the grinding material is high, damage of adopted diamond is greatly reduced under the designed technological system, and the grinding wheel does not need to be trimmed in the grinding process.

Owner:台山市兰宝磨具有限公司

Highly-antiwear drill pipe wear-resisting belt flux-cored wire

InactiveCN102029483BReduce wearReduce splashWelding/cutting media/materialsSoldering mediaInternal pressureCasing string

Owner:西安纳特石油技术有限公司 +1

Diamond grinding wheel and preparation method thereof

ActiveCN102922436BImprove processing efficiencyLow costAbrasion apparatusGrinding devicesProcess systemsAdamite

The invention belongs to the field of grinding tools, and discloses a diamond grinding wheel and a preparation method thereof. The diamond grinding wheel comprises a base body and an abrasion block, and a raw material of the abrasion block contains a ceramic binding agent made of the follow raw materials: SiO2 of 40-46wt%, Al2O3 of 8-13%, B2O3 of 18-22%, Na2O of 8-10%, CaF2 of 11-15 wt%, Li2O of 4-6wt% and TiO2 of 1-2wt%. The diamond grinding wheel can effectively improve processing efficiency of gorilla glass, reduce processing cost, reduce pollution to environment, and meets the requirements for grinding and processing the gorilla glass. In addition, according to the diamond grinding wheel, firing temperature of a binding agent is low, holding force on an abrasion material is strong, damage on diamond is greatly reduced under a process system, and the grinding wheel does not need to be repaired in the grinding process.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Air guide plate and its preparation method and solidification molding method of stiffened wall panel containing it

The invention discloses a gas guiding plate, a preparation method and a curing molding method of a stiffened wall plate comprising the gas guiding plate and belongs to the technical field of composite molding. The preparation method of the gas guiding plate includes the steps that a blank gas guiding plate is manufactured through a hard porous material, and holes matched with the bottom faces of ribs in shape are formed in the blank gas guiding plate; and blind holes are formed in the blank gas guiding plate, and the gas guiding plate is obtained. The hard porous material can disengage after the stiffened wall plate is overall molded, and no scrap edge needs to be machined on the edges of the ribs.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Lower slide block stitch adjusting device

InactiveCN106480619AUniform stitchingNovel structureTufting apparatusEngineeringMechanical engineering

Owner:天津市宝坻区东亚光大地毯厂

A kind of grinding wheel applied to the concentricity grinding of ceramic ferrule and its preparation method

ActiveCN107717765BWell mixedImprove sharpnessAbrasion apparatusGrinding devicesMicrosphereEthyl acetate

The invention relates to a preparation method of a grinding wheel applied to coaxiality grinding of a ceramic ferrule, and belongs to the technical field of ultra-precision machining of optical fiberconnecting material. The u preparation method comprises the following steps of 1, a diluted modified phenolic resin solution, a zirconium oxide hollow microsphere and calcium fluoride are added into ethyl acetate, and are stirred for 1 -3 hours at the temperature of 50-90 DEG C a sodium chloride solution is added, a mixture is heated for 45-90 minutes for at the temperature of 75-85 DEG C, a blockmixture is obtained, then modified polyimide resin is added, ball milling is carried out, and sieving is carried out to obtain a binding agent; 2, diamond and the binding agent prepared in the step 1are weighted according to the mass ratio of 1 to 3-8, sieving is carried out, pressing is carried out at the temperature of 280 DEG C with the pressure of 5 MPa to 15 MPa, the pressure maintaining time is 30-80 minutes, so that a grinding layer is obtained; 3, the grinding layer is bonded to fluorosilicone rubber, the fluorosilicone rubber is adhered to a grinding wheel base body to obtain a grinding wheel semi-finished product; and 4, feeding hole and the discharging hole chamfering of the semi-finished grinding wheel is carried out to obtain a finished product.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Film pasting process of door plate

PendingCN109693395ANo trimming requiredControllable appearanceCoatingsInjection molding machineInjection solution

The invention discloses a film pasting process of a door plate. The film pasting process of the door plate comprises the following steps that S1, the temperature of the surface on which a die is to bepasted with a film is controlled at 15-75 DEG C, the middle part is lower in temperature, and the peripheral part is higher in temperature; S2, the film is electrostatically adsorbed on the surface on which the die is to be pasted with the film; S3, an injection molding machine is divided into a front section and a back section, an injection solution is injected into the die from the middle partof the die, the speed of injection of the front section is 10%-25% of the rated speed, the injection quantity is 20%-40% of the total material quantity, and the temperature of the injection solution is 170-200 DEG C; and the speed of injection of the back section is 45%-75% of the rated speed, the injection quantity is 60%-80% of the total material quantity, and the injection solution temperatureis 200-230 DEG C; and S4, after the injection solution is cooled and molded, the die is removed, and a finished product is taken out. According to the film pasting process of the door plate, the appearance and the color of the film are more easily to control, the surface of the product is diversified, and the prepared door plate with the pasted film is not required to be trimmed and is abrasion-resisting.

Owner:厦门富桂通科技有限公司

A heating stamping and riveting process for a gear box

ActiveCN107378414BEasy to bendLess prone to distortionShaping toolsMetal working apparatusPunchingWork in process

Owner:太仓市华天冲压五金制品厂

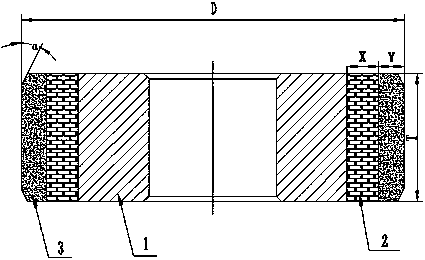

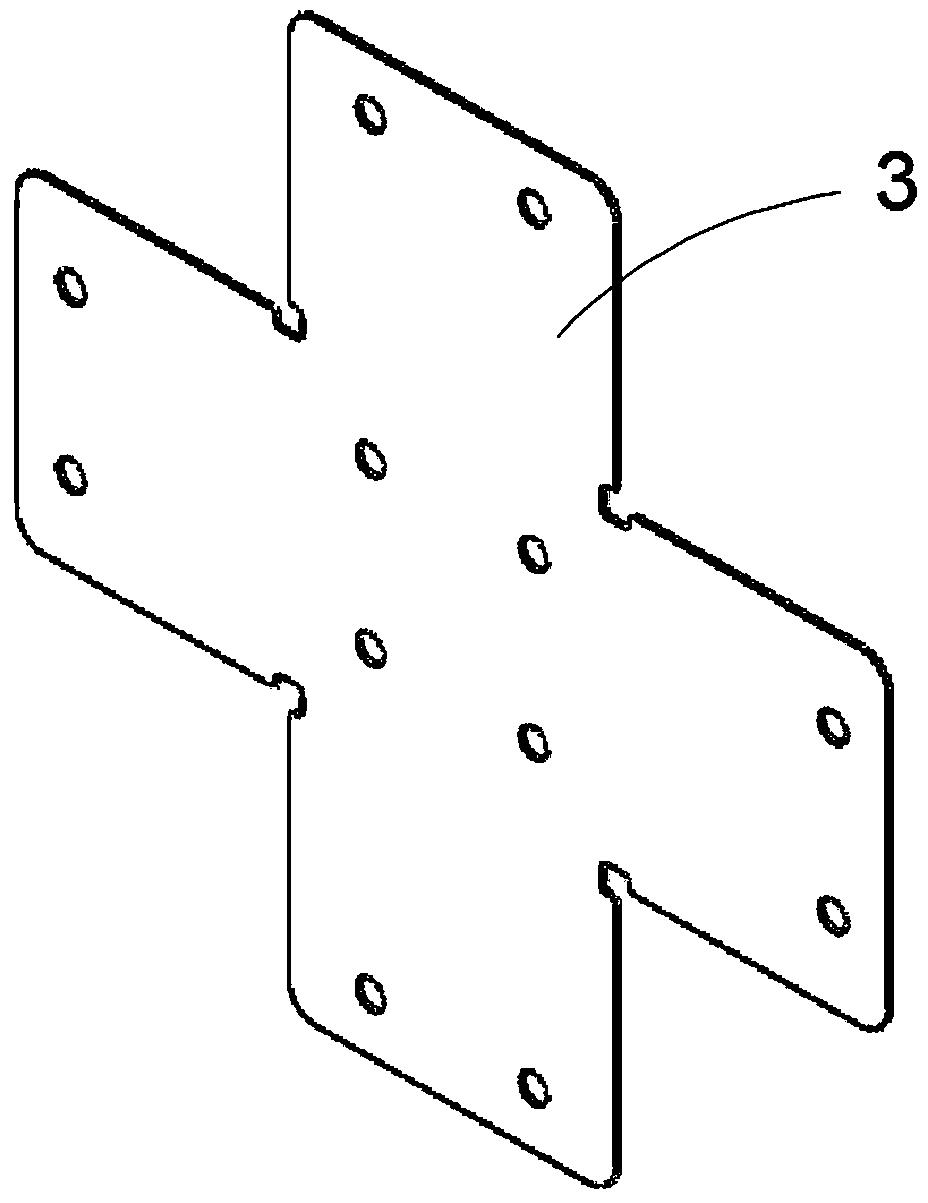

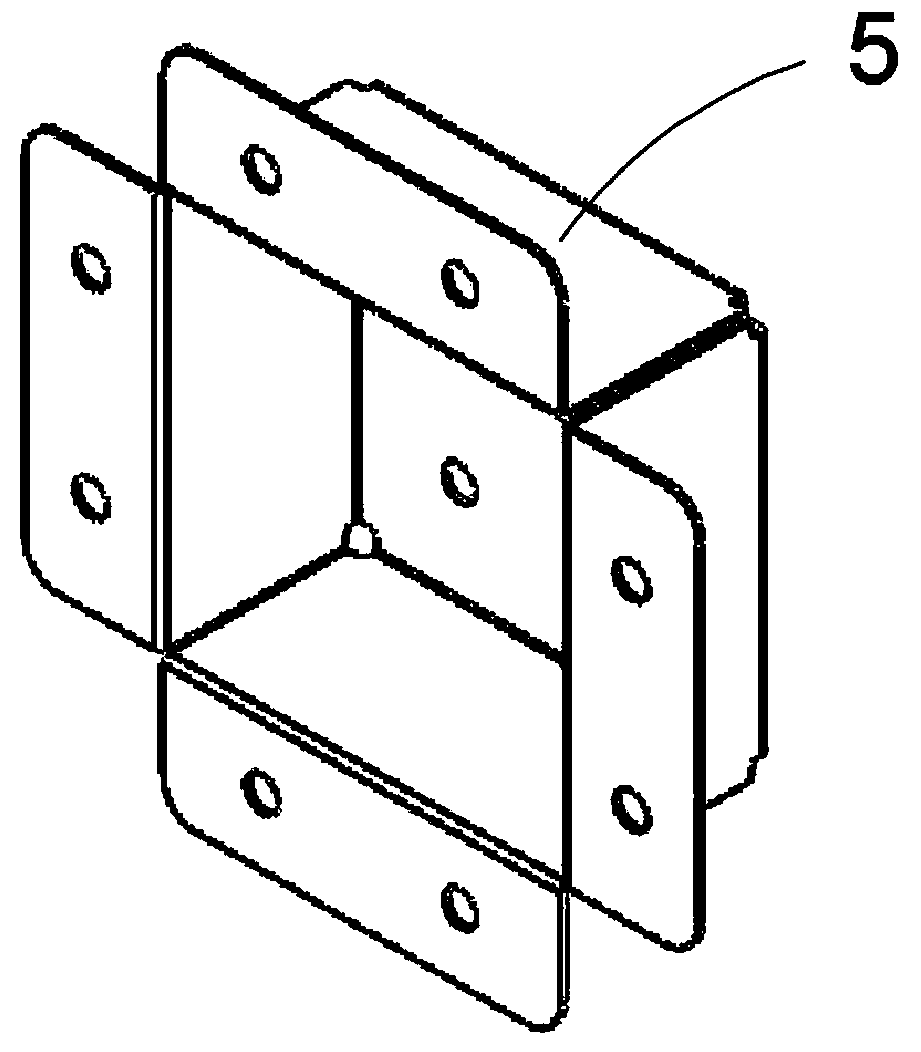

High-precision electron beam radiation field stop block

ActiveCN112846495AImprove machining accuracyNo trimming requiredWelding/cutting auxillary devicesAuxillary welding devicesRadiation fieldEngineering

The invention discloses a high-precision electron beam radiation field stop block, and mainly relates to the field of radiotherapy equipment. The high-precision electron beam radiation field stop block comprises a plurality of barrier plates, two retaining plates and a clamping device, ray passing holes are formed in the barrier plates and the retaining plates, the multiple barrier plates are arranged in an up-and-down mutual stacking mode, and the barrier plates are machined by lead plates of 0.5-3 mm; and the retaining plates are stacked on the upper side and the lower side of the stacked barrier plates, the retaining plates are machined by cold-roll steel plates of 1-3 mm, the two retaining plates are pressed towards the barrier plates through the clamping device, and the barrier plates and the retaining plates are fixed. The high-precision electron beam radiation field stop block has the beneficial effects that the manufacturing of the radiation field stop blocks in different shapes can be rapidly completed, and meanwhile, the higher machining precision is guaranteed.

Owner:SHANDONG UNIV QILU HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com