Turbine disc tongue-and-groove forming grinding machining device and use method thereof

A technology for forming grinding and processing equipment, applied in metal processing equipment, grinding/polishing equipment, grinding machine parts, etc. Grinding wheel and special equipment, difficult tenon and groove processing and other problems, to achieve the effect of simplifying grinding process and equipment investment, excellent processing surface integrity, and improving comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

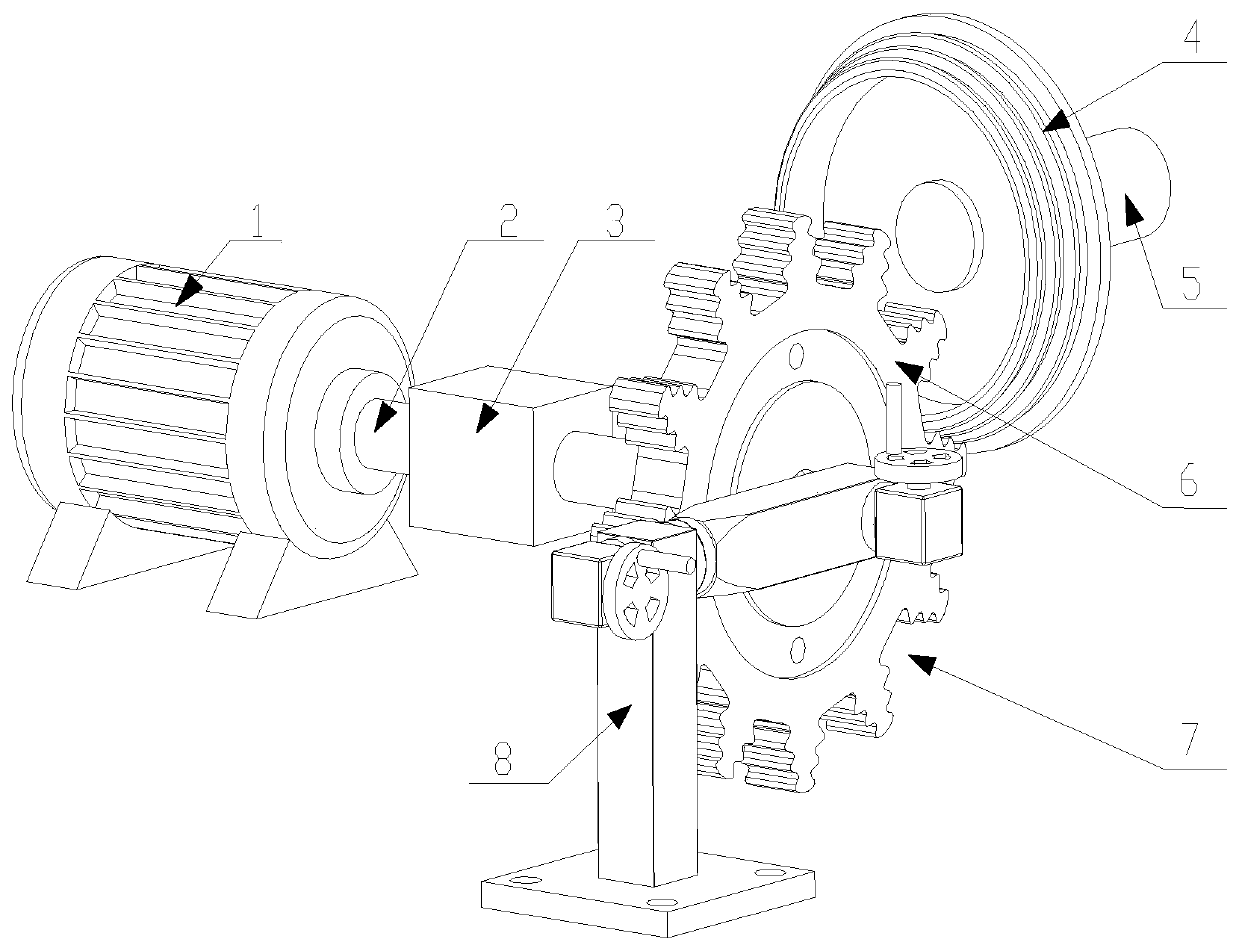

[0043] figure 1 It is a schematic diagram of the annular grinding wheel grinding the tenon and groove of the turbine disc according to the present invention, figure 2 Schematic diagram of the tenon and groove model of the turbine disk for the annular grinding wheel, refer to figure 1 , 2 As shown, the powder metallurgy superalloy turbine disk tenon and groove forming grinding processing equipment, the transmission device 3 connects the turbine disk with the stepping motor 1 and the turbine disk 6 through the transmission shaft 2, and the turbine disk 6 is clamped on the turbine disk fixture 8 The annular emery wheel 4 is installed on the machine tool main shaft 5, and the annular emery wheel 4 rotates at a high speed to grind the tenon groove of the turbine disc during grinding. Rotate down to the desired angle for another side grinding of the tongue and groove.

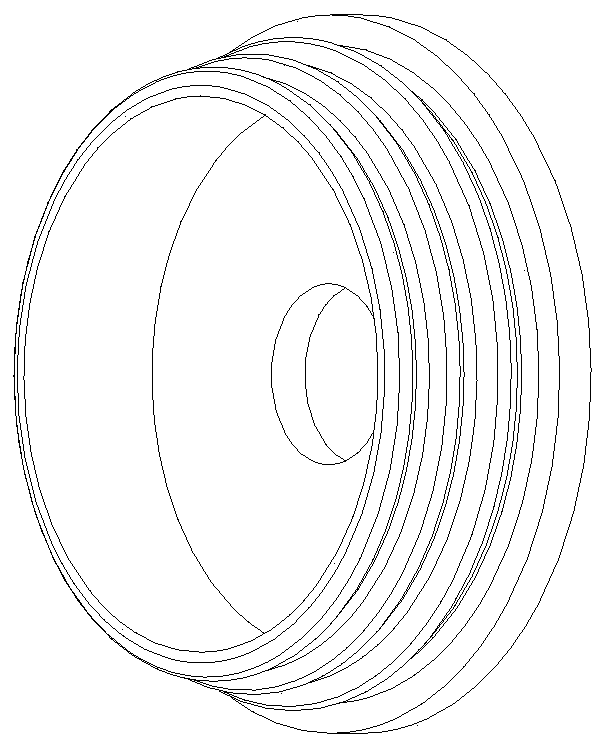

[0044] image 3 It is the axonometric drawing of the annular grinding wheel of the first embodiment, Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com