Highly-antiwear drill pipe wear-resisting belt flux-cored wire

A technology of flux-cored welding wire and wear-resistant band, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve the problem of reducing casing string collapse resistance, internal pressure resistance, casing string collapse, The whole well is scrapped and other problems, to achieve the effect of improving the anti-wear and anti-friction effect, less spatter, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below through embodiments.

[0014] 1. The processing method of the present invention is a conventional method for flux-cored welding wire: select high-quality thin steel strips of appropriate specifications and pure multiple related metal powders or alloy powders, weigh the various metal powders and alloy powders according to the formula, and mix them evenly. The core powder is made, and then the thin steel strip is uncoiled on the flux-cored wire manufacturing equipment, tied into a U-shape, filled with powder core powder, sealed into an O-shape, rolled and reduced, drawn and reduced and coiled into Flux-cored welding wire with a diameter of 1.6mm~3.2mm is made in the process of disc.

[0015] 2. Embodiments of the present invention:

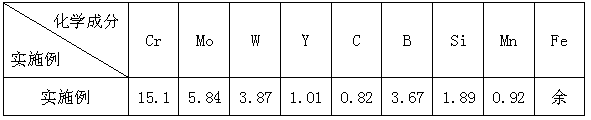

[0016] Table 1: Chemical composition of deposited metal (mass percentage)

[0017]

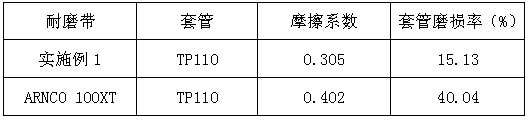

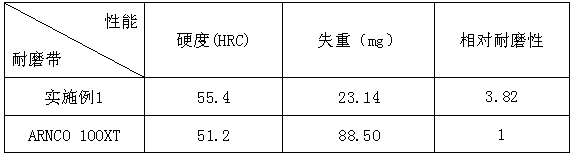

[0018] 3. Comparative test:

[0019] (1) Example 1 The hardness of the metal hardbands surfacing with flux-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com