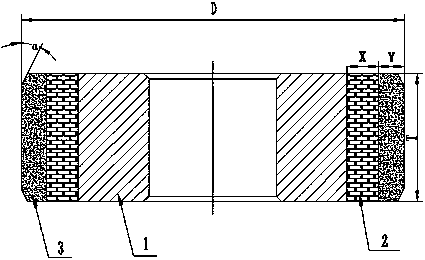

A kind of grinding wheel applied to the concentricity grinding of ceramic ferrule and its preparation method

A ceramic ferrule and concentricity technology, which is applied in the direction of grinding/polishing equipment, grinding devices, abrasives, etc., can solve the problems of high frequency of thimble breakage, broken wires, low production efficiency, etc., to ensure consistent concentricity Sex, avoid broken needle or broken thread, avoid the effect of broken needle and thread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method for a grinding wheel applied to ceramic ferrule coaxiality grinding, comprising the steps of:

[0043] (1) Add the diluted modified phenolic resin solution, zirconia hollow microspheres and calcium fluoride to ethyl acetate at a mass ratio of 1:20:30, and the mass of ethyl acetate is the diluted modified phenolic resin solution , 5 times the total weight of zirconia hollow microspheres and calcium fluoride, stirred in a water bath at 50°C for 3 hours, and added 45wt% sodium chloride solution (the amount of sodium chloride solution was diluted modified phenolic 5 times the total weight of the resin solution, zirconia hollow microspheres and calcium fluoride), heated at 80°C for 60 minutes to obtain a dry block mixture, according to the mass ratio of block mixture and modified polyimide resin 1:2 Add modified polyimide resin, ball mill, and pass through a 100-mesh sieve to obtain a binder, wherein the diluted modified phenolic resin solution refers to a...

Embodiment 2

[0048] A preparation method for a grinding wheel applied to ceramic ferrule coaxiality grinding, comprising the steps of:

[0049] (1) Add the diluted modified phenolic resin solution, zirconia hollow microspheres and calcium fluoride to ethyl acetate at a mass ratio of 1:20:30, and the mass of ethyl acetate is the diluted modified phenolic resin solution , 3 times the total weight of zirconia hollow microspheres and calcium fluoride, stirred in a 90°C water bath for 1 hour, and added 50wt% sodium chloride solution (the amount of sodium chloride solution was diluted modified phenolic 8 times the total weight of the resin solution, zirconia hollow microspheres and calcium fluoride), heated in a water bath at 75°C for 90 minutes to obtain a block mixture, and added according to the mass ratio of block mixture and modified polyimide resin 1:1.5 Modified polyimide resin, ball milled, passed through a 1200-mesh screen to obtain a binder, wherein the diluted modified phenolic resin ...

Embodiment 3

[0054] A preparation method for a grinding wheel applied to ceramic ferrule coaxiality grinding, comprising the steps of:

[0055] (1) Add the diluted modified phenolic resin solution, zirconia hollow microspheres and calcium fluoride to the mass fraction of ethyl acetate at a mass ratio of 1:18:32 (the mass of ethyl acetate is the diluted modified phenolic resin 8 times the total weight of the resin solution, zirconia hollow microspheres and calcium fluoride), stirred in a water bath at 70°C for 2 hours, and added 40wt% sodium chloride solution (the amount of sodium chloride solution was diluted The modified phenolic resin solution, zirconia hollow microspheres and calcium fluoride are twice the total weight)), heated in a water bath at 85°C for 45 minutes to obtain a dry block mixture, according to block mixture and modified polyimide The resin mass ratio is 1:2, adding modified polyimide resin, ball milling, and passing through a 100-mesh screen to obtain a binder, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com