Punching machine

A punching machine and mold base technology, applied in the field of punching machine structure, can solve problems such as reducing movement resistance, wasting stamping materials, and complicated manufacturing, and achieve excellent guiding accuracy, high guiding accuracy, and reduced machine weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] According to the technical means of the present invention, the methods suitable for the implementation of the present invention are listed below, and are described as follows in conjunction with the accompanying drawings:

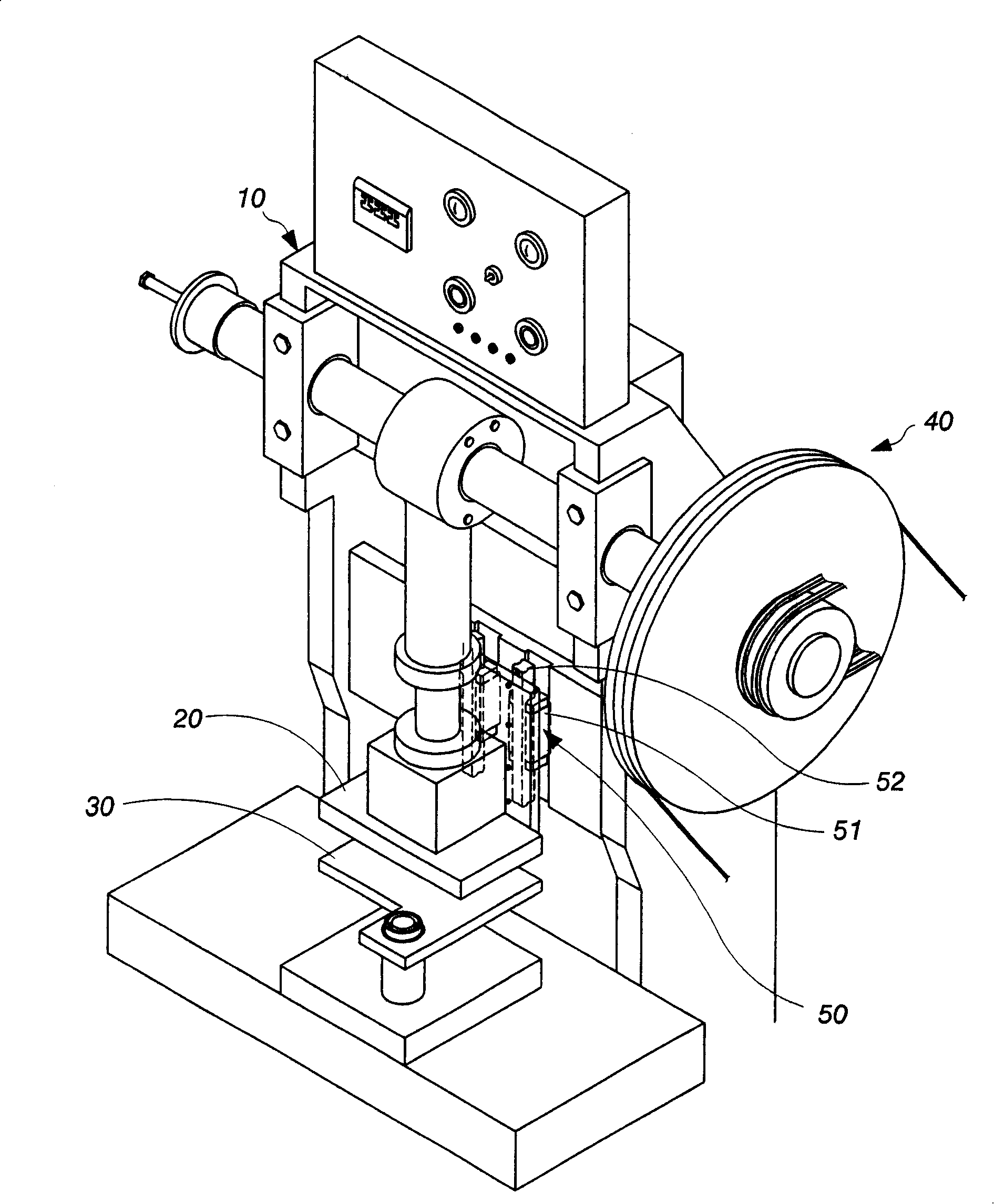

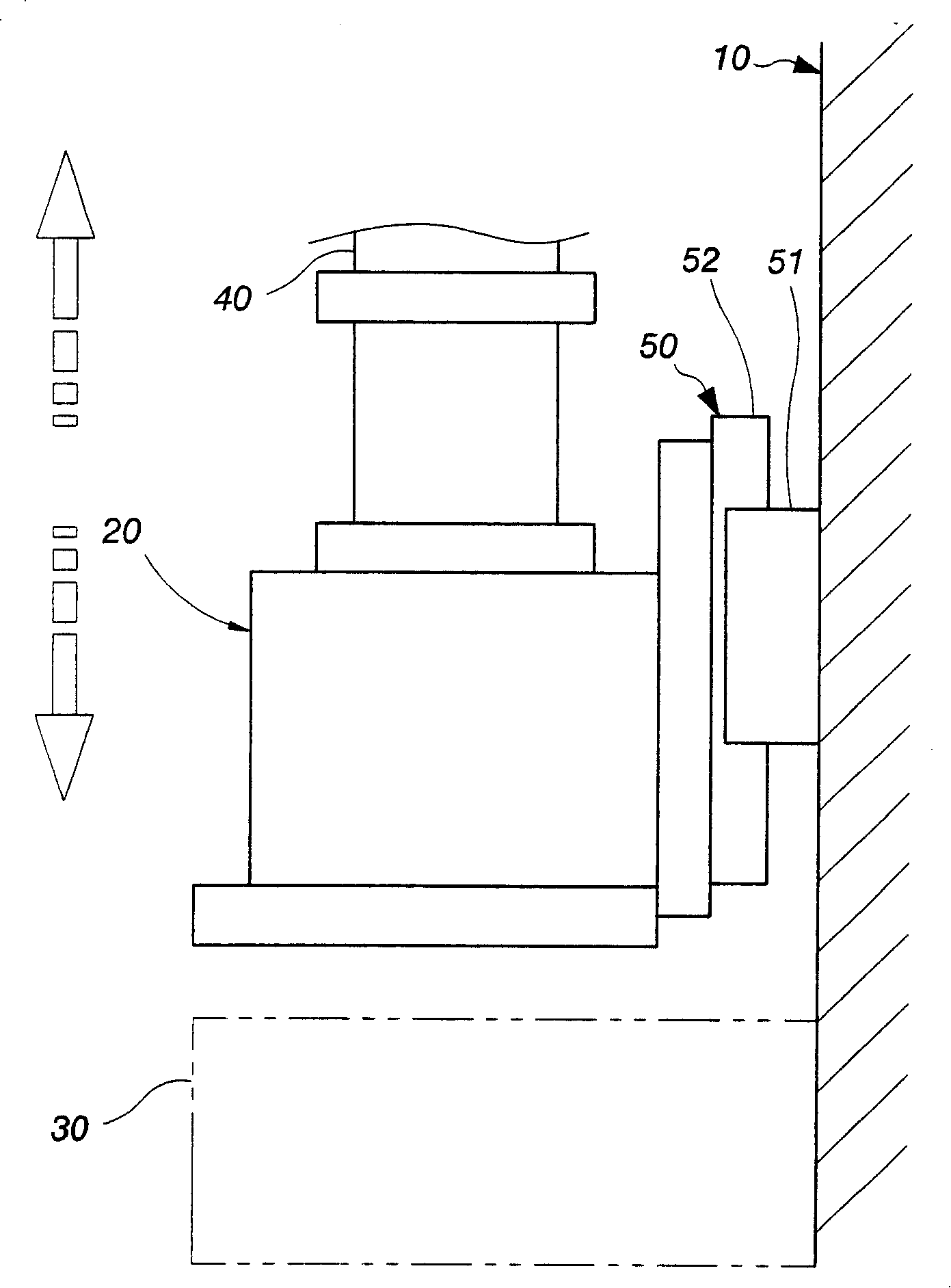

[0027] figure 1 As shown, it is a three-dimensional appearance view of the punch press of the present invention. The composition of the first embodiment of the punch press at least includes a machine platform 10, an upper mold base 20 arranged on the machine platform 10, and a lower mold arranged on the machine platform 10. The base 30, a drive unit 40 for driving the upper mold base 20, and at least one linear slide rail set 50 arranged vertically.

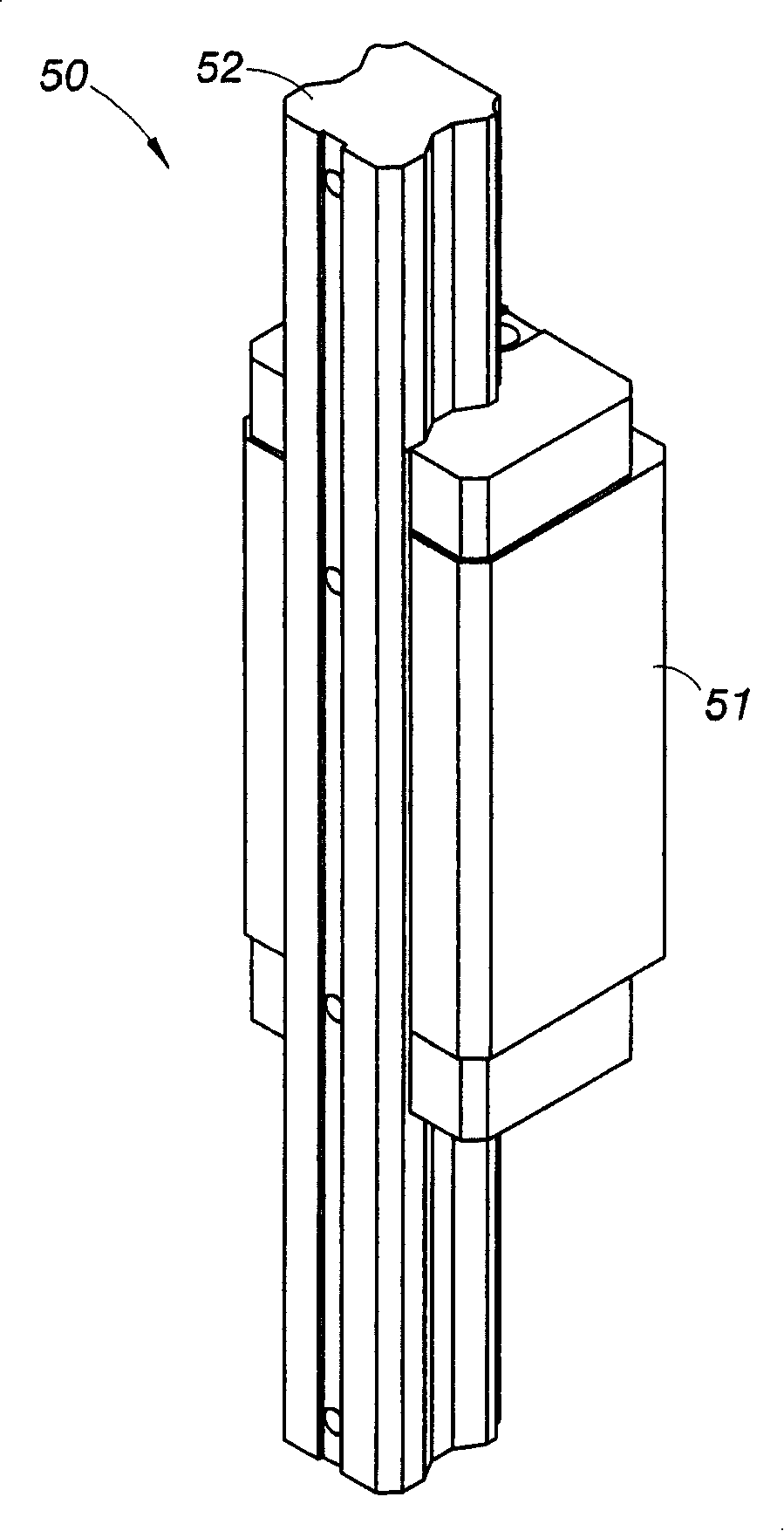

[0028] see figure 1 and figure 2 As shown, among them, figure 2 It is a three-dimensional appearance view of the linear slide rail group of the punch press of the present invention. The linear slide rail group 50 is vertically arranged between the machine table 10 and the upper die base 20. The lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com