A heating stamping and riveting process for a gear box

A gearbox and riveting technology, applied in the field of sheet metal parts processing, can solve the problems of high scrap rate, gear gearbox can not meet the requirements of use, etc., to achieve the effect of not easy to wave deformation, improve the degree of production automation, and improve the verticality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

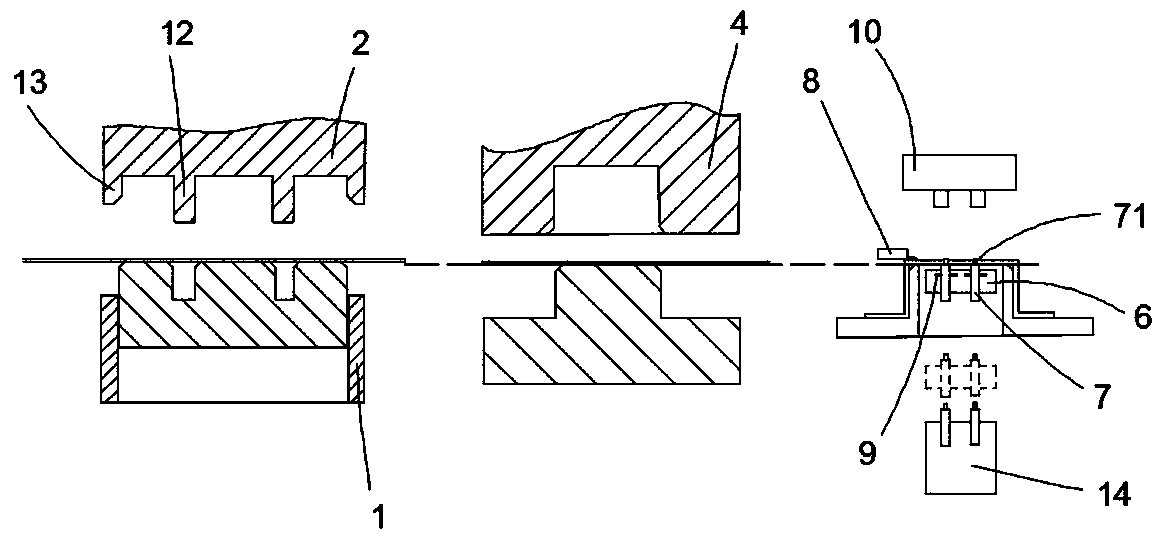

[0030] The invention discloses a heating stamping and riveting process of a gear box, such as Figure 1 to Figure 6 shown, including the following steps:

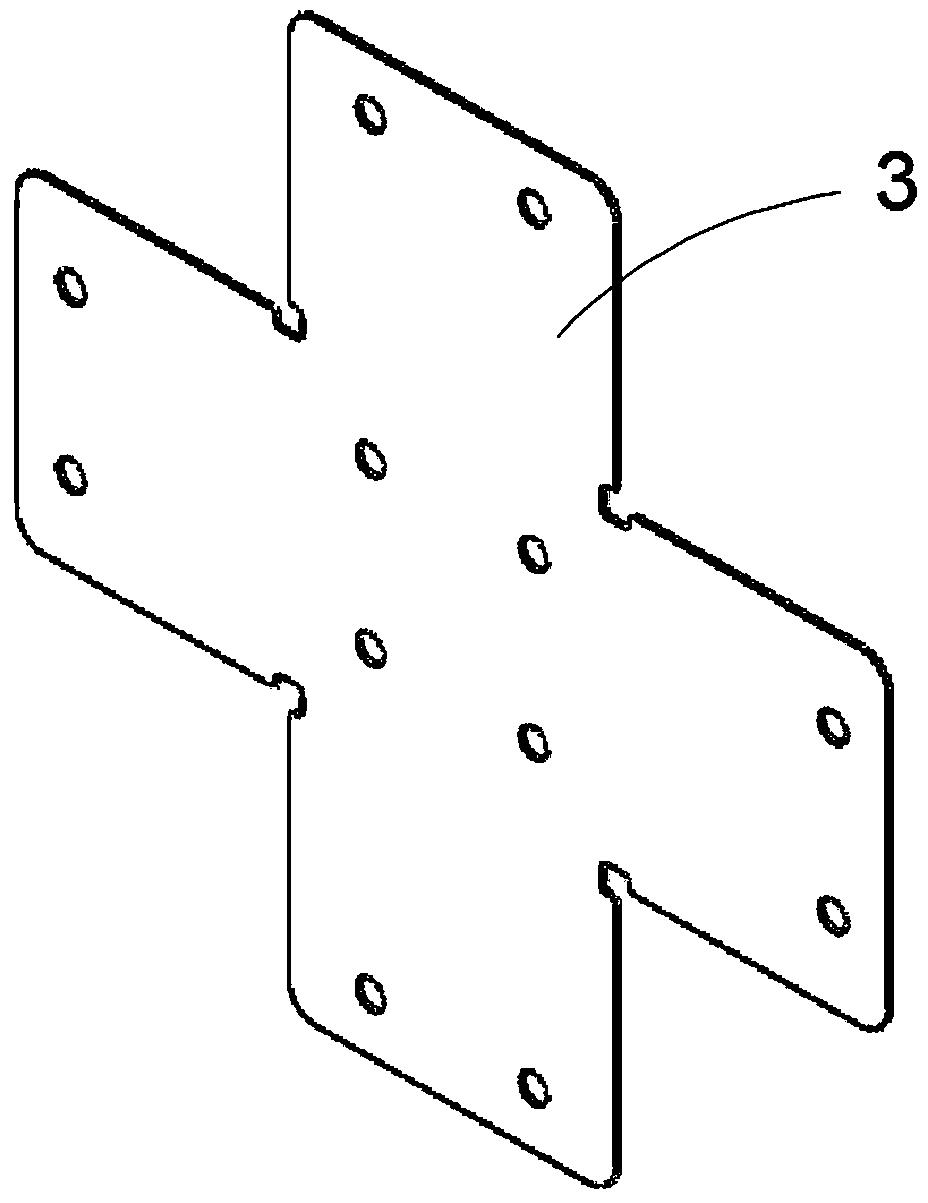

[0031] a. Integrated blanking, punching and edge deburring, blanking die 1 punches and blanks from one side of the sheet metal part, punching and deburring integrated die 2 punches from the other side of the sheet metal part, including punching And flatten the burr, directly integrated stamping to obtain the first semi-finished product 3;

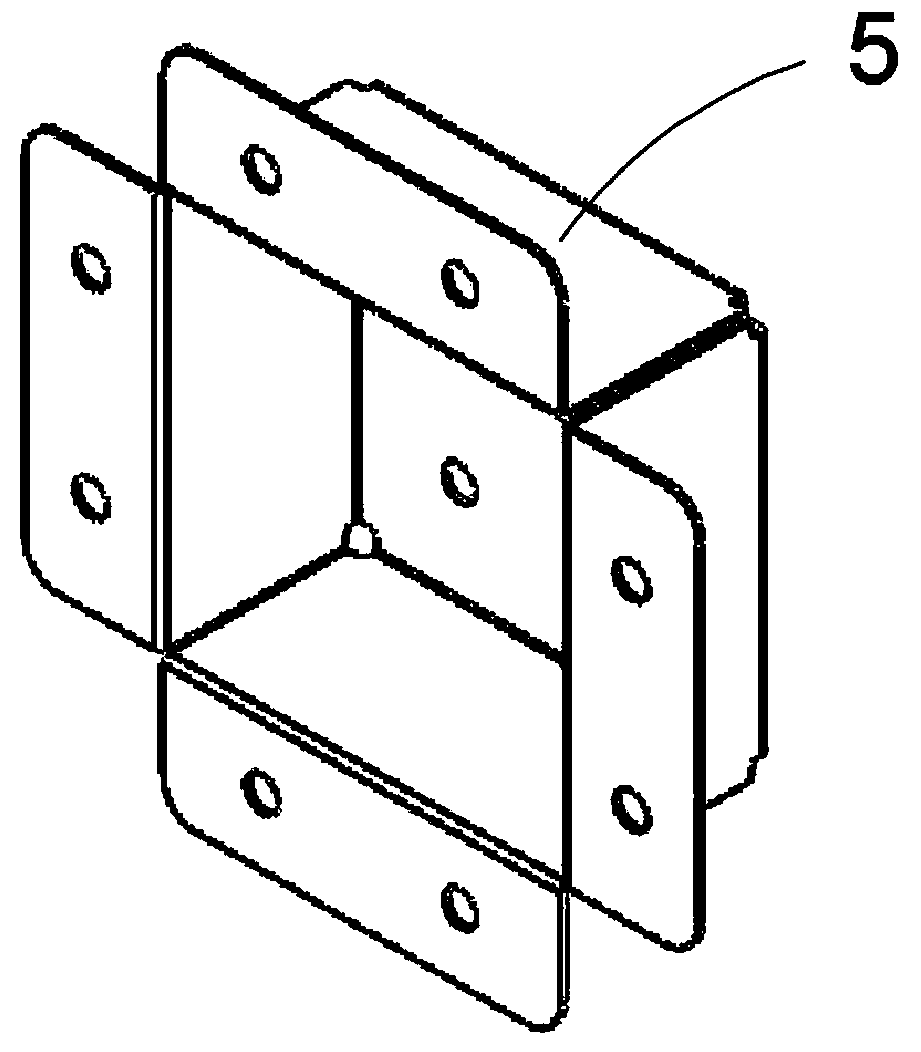

[0032] B, heating stamping flanging, the first semi-finished product 3 that makes in the step a is moved to the flanging station, the first semi-finished product 3 is heated by the support platform of the flanging station, and the flanging mold 4 is self-heating; The side mold 4 punches the heated first semi-finished product 3 out of the flanging to obtain the second semi-finished product 5;

[0033] c. Riveting the gear shaft 7, moving the second semi-finished product 5 prepared in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com