Patents

Literature

45results about How to "Small shape error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

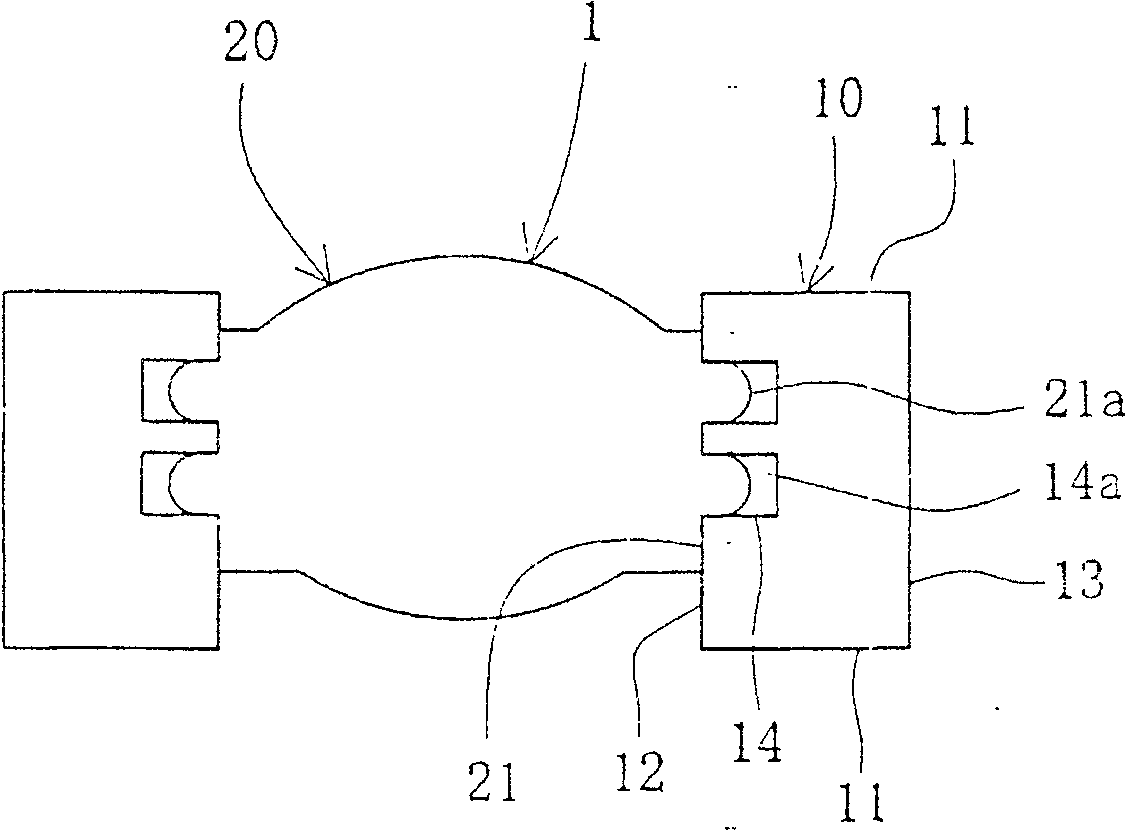

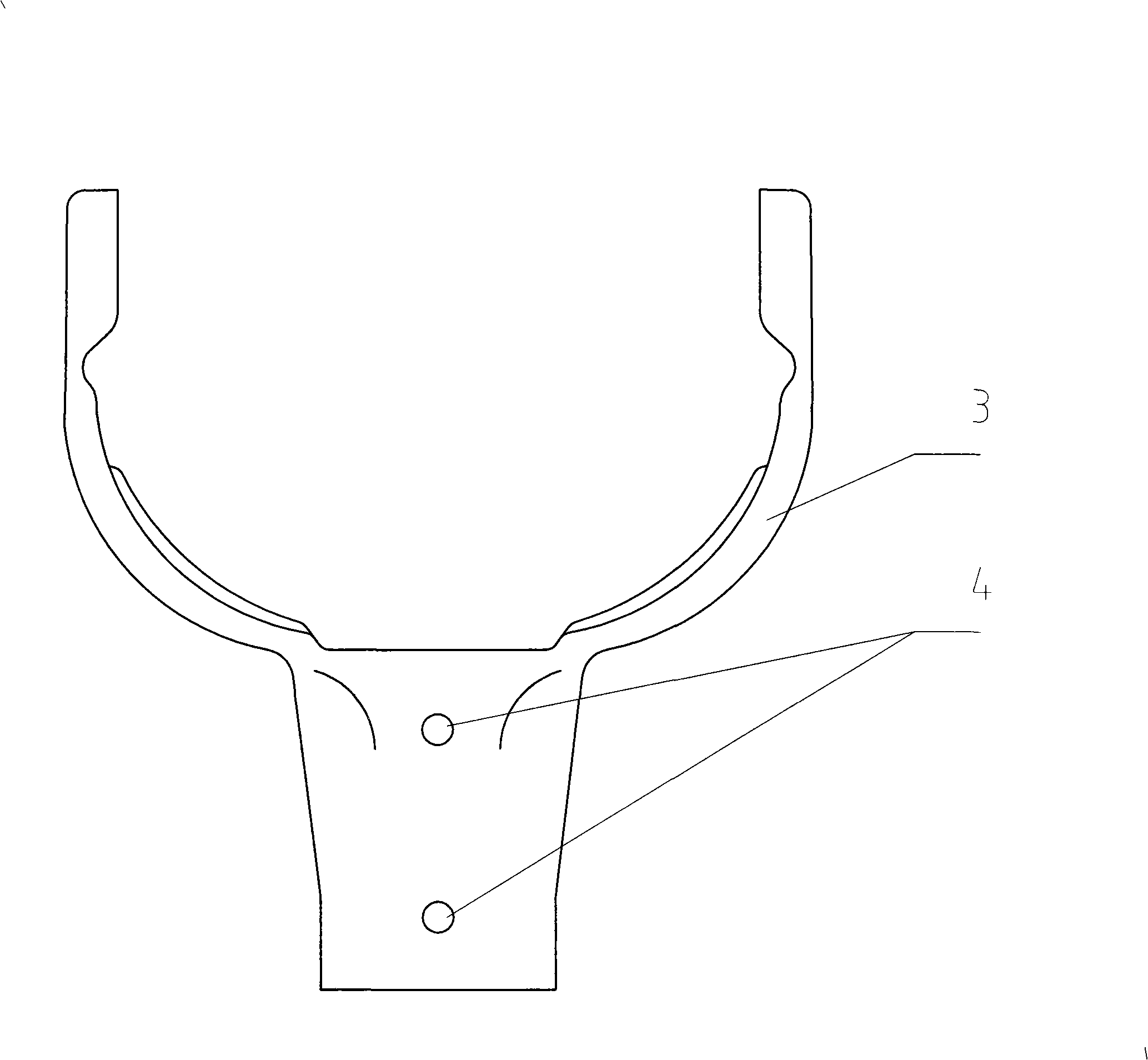

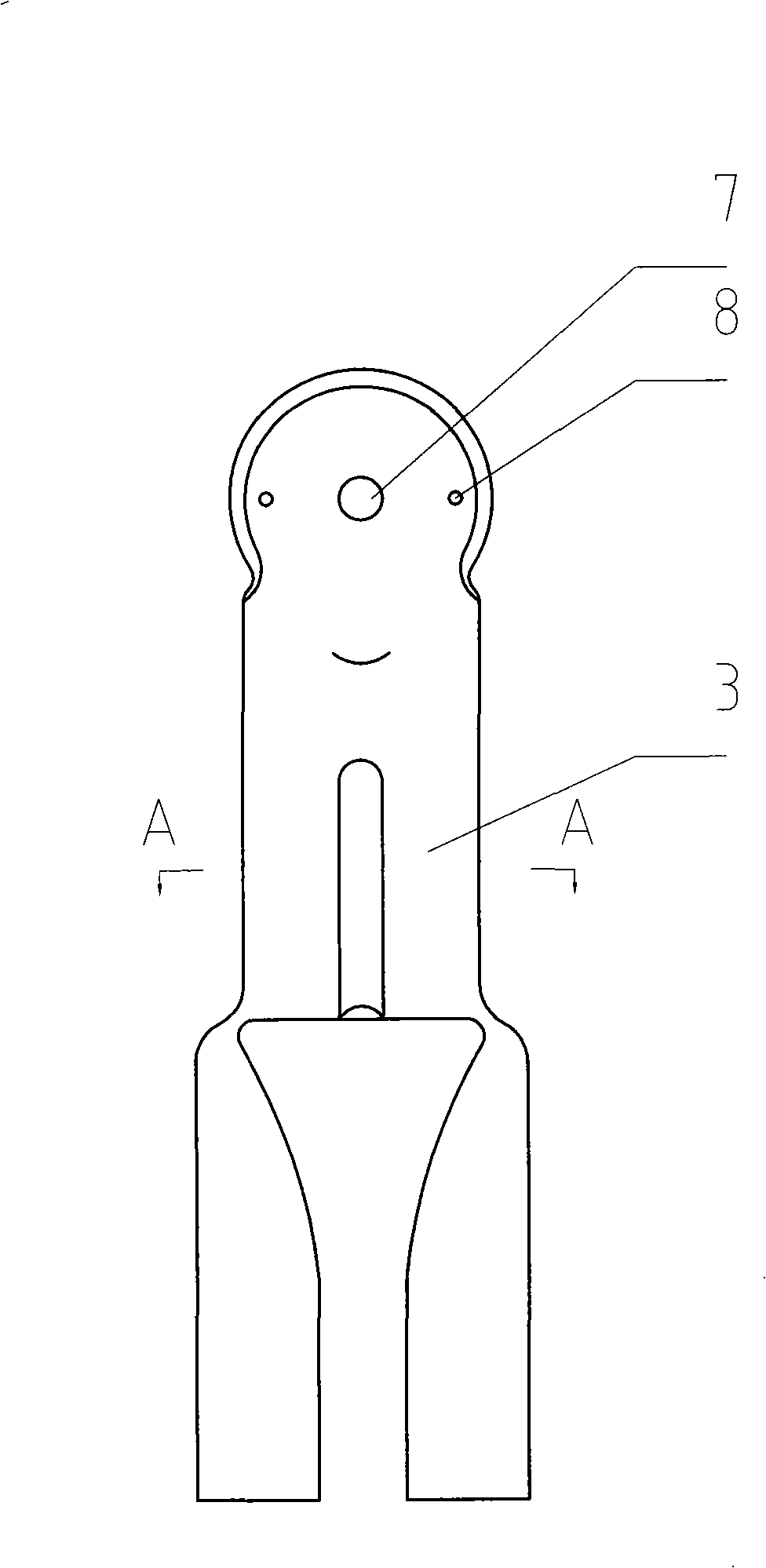

Precise forging molding method for blank of automobile fork-shaped half shaft

InactiveCN102513488AImprove convenienceSafeYielding couplingMetal-working apparatusMachiningMaterials science

The invention discloses a precise forging molding method for a blank of an automobile fork-shaped half shaft, which is characterized by using hot extrusion molding. The method comprises: firstly, heating part of a round material to 1,050 to 1,150 DEG C; secondly, gathering the head part by upsetting and extrusion, heating the gathered head part to 1,050 to 1,150 DEG C and thus, forming the blank by hot extrusion for the first time; and finally, forming the blank by hot extrusion again. The method has the advantages that: heating part of the material saves over 30 percent of energy than heating the whole material; the process method which is closed extrusion eliminates fins on the extruded blank and therefore saves more than 2Kg of materials than free forging; production based on a die forging process is convenient and safe in operation, the drawback of manual control over quality of free forging is overcome, the overall machining allowance is small, and the production efficiency is improved effectively; and the shape error of the product is small, which helps to guarantee the quality of the forgings.

Owner:SHIYAN YUANJUN IND & TRADE

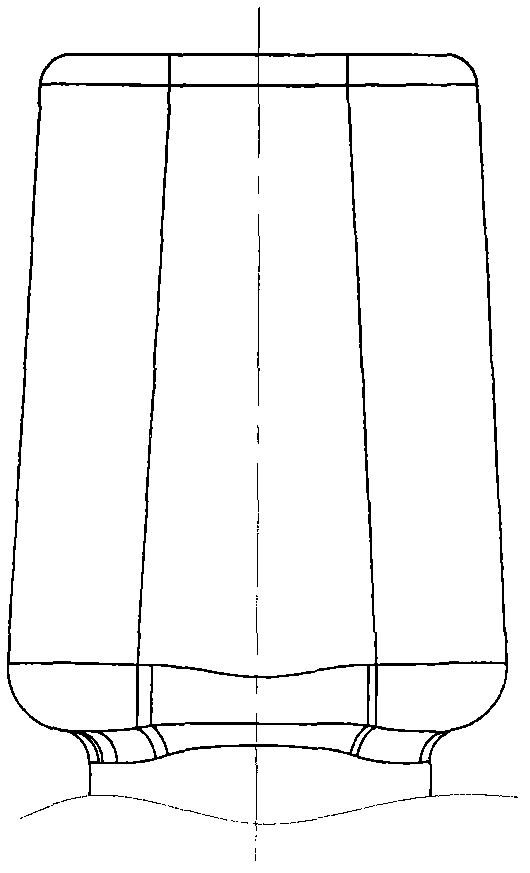

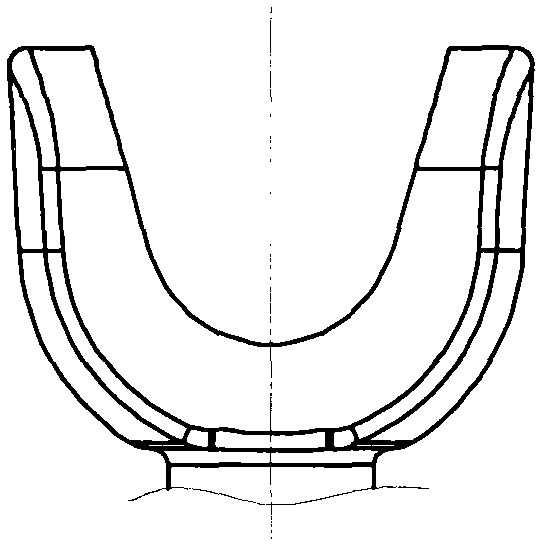

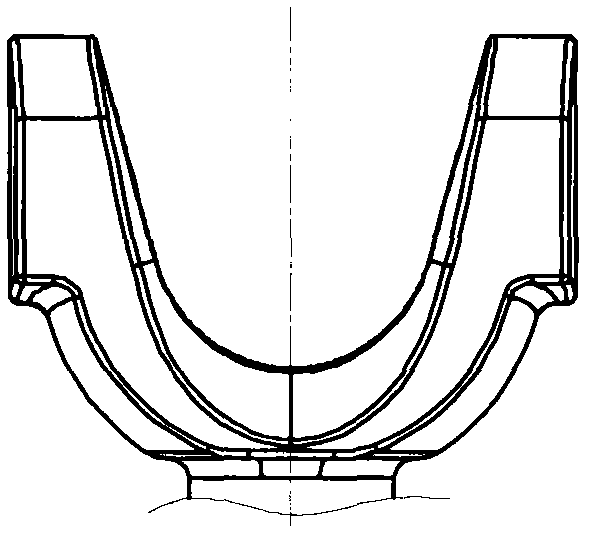

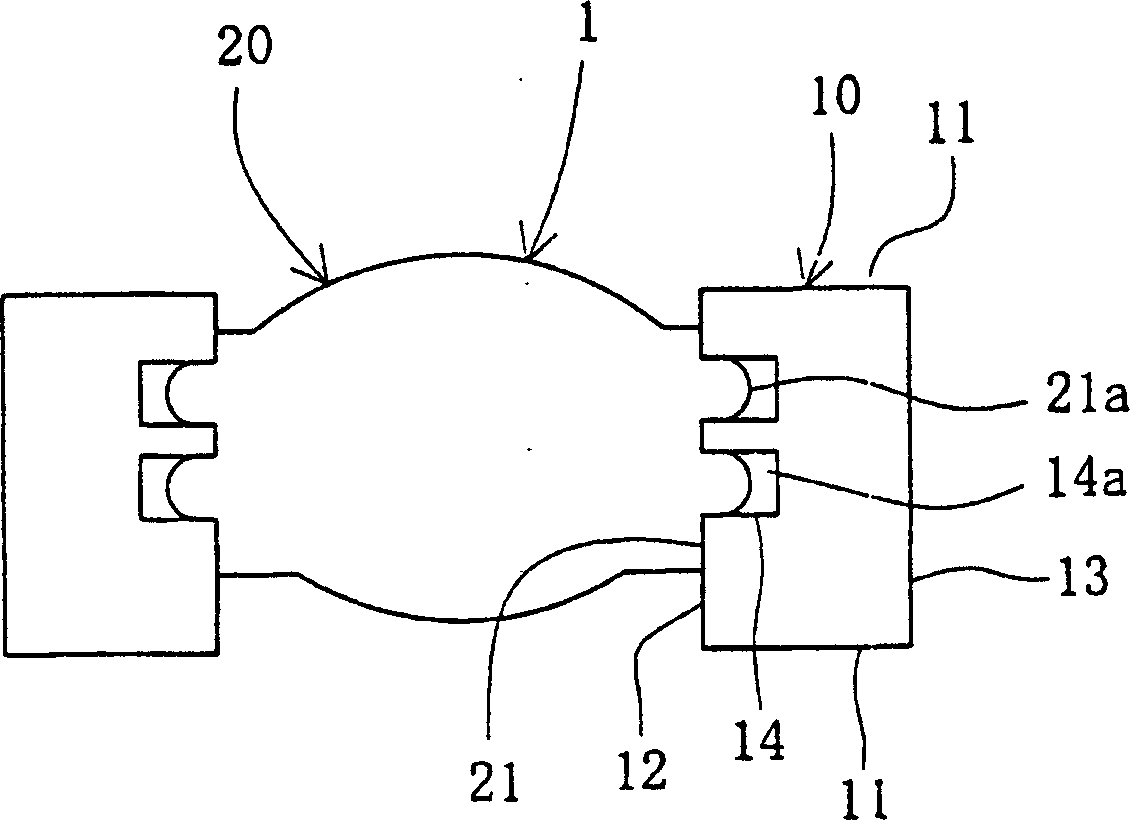

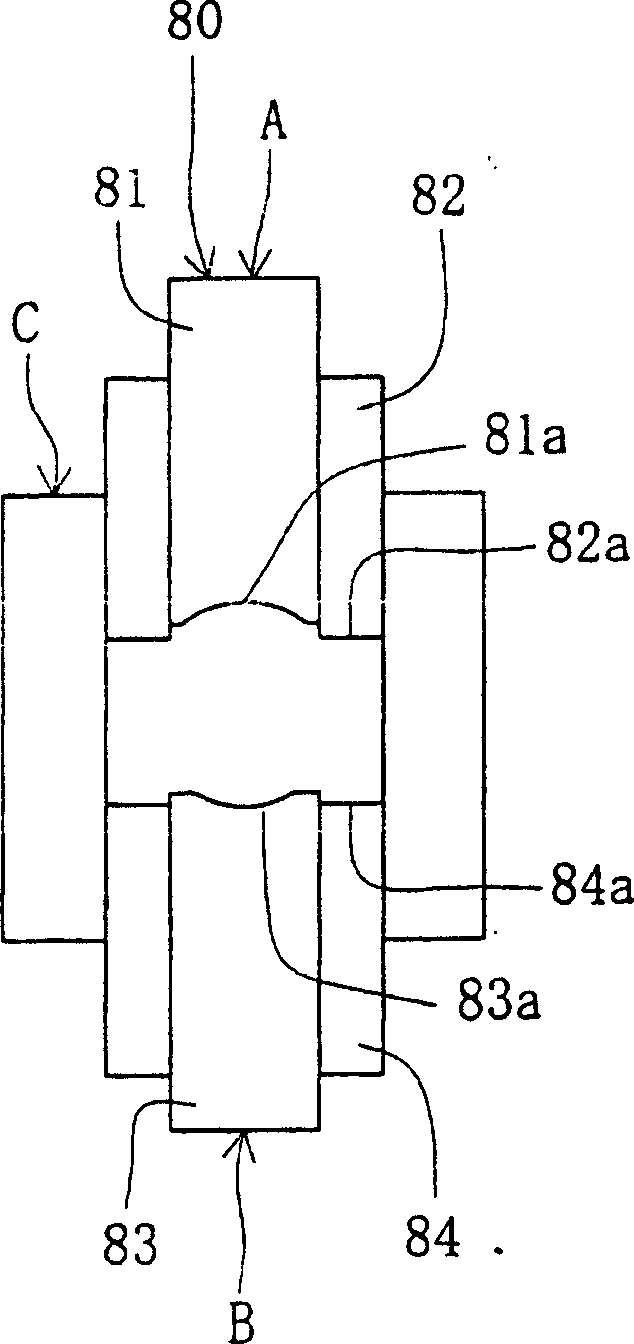

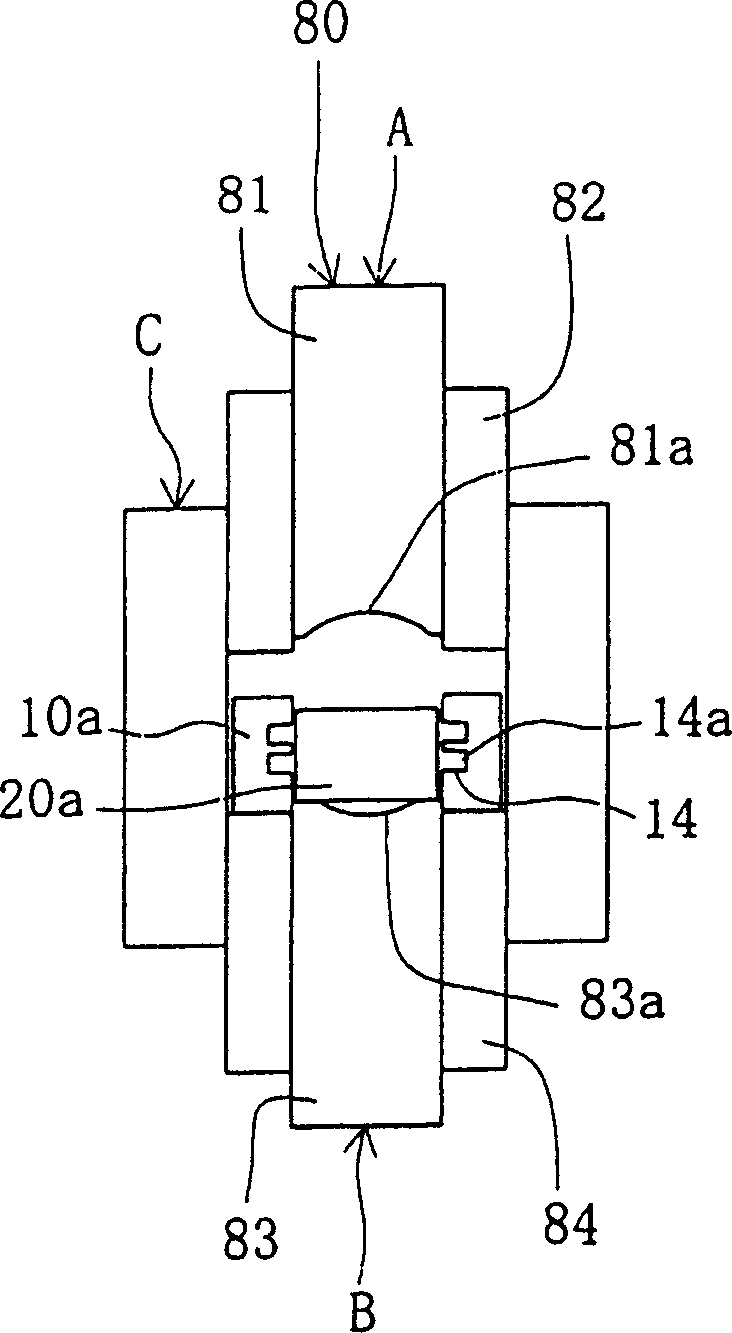

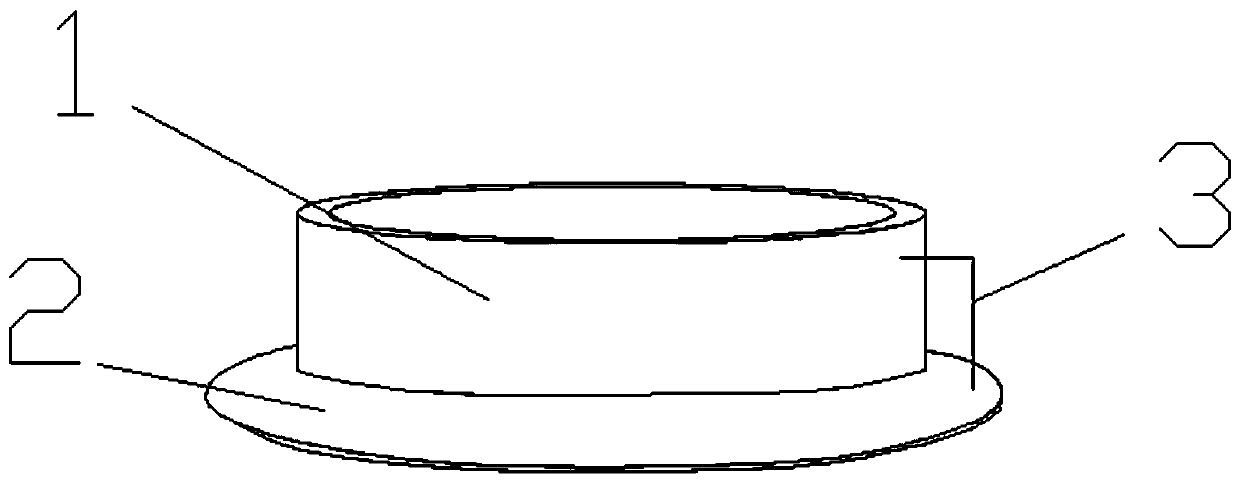

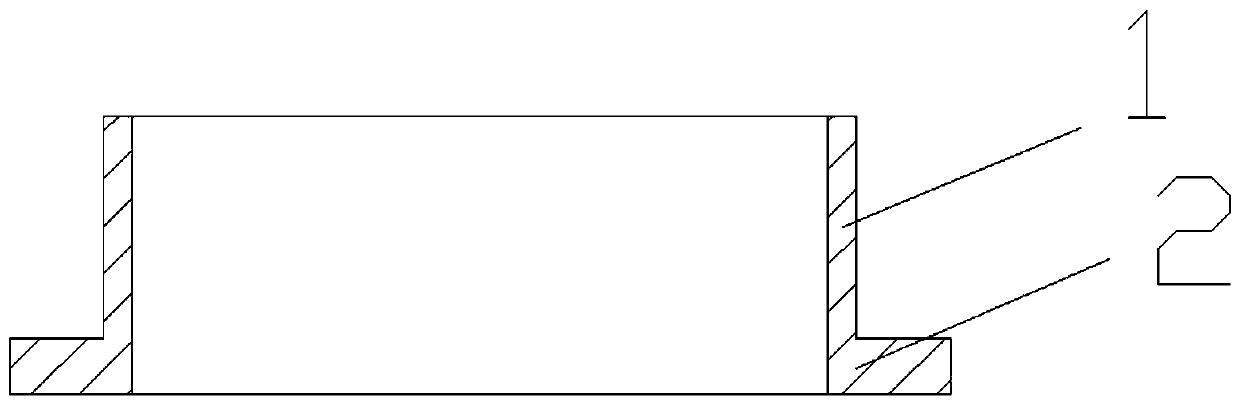

Method for producing optical element with holding frame

A method for making a holder / optical-element assembly includes the steps of positioning a cylindrical holder material in a press-molding die, the holder material having a void part in the inner circumferential surface, positioning an optical-element material inside the holder material, heating the holder material and the optical-element material to their own softening temperatures, press-molding the holder material and the optical-element material to form a cylindrical holder and an optical element, respectively, thereby fixing the optical element to the inside of the holder, allowing a part of the optical element to project outwardly from the outer edge by pressure created during press-molding, and retaining the projected portion in the void part of the holder.

Owner:ALPS ALPINE CO LTD

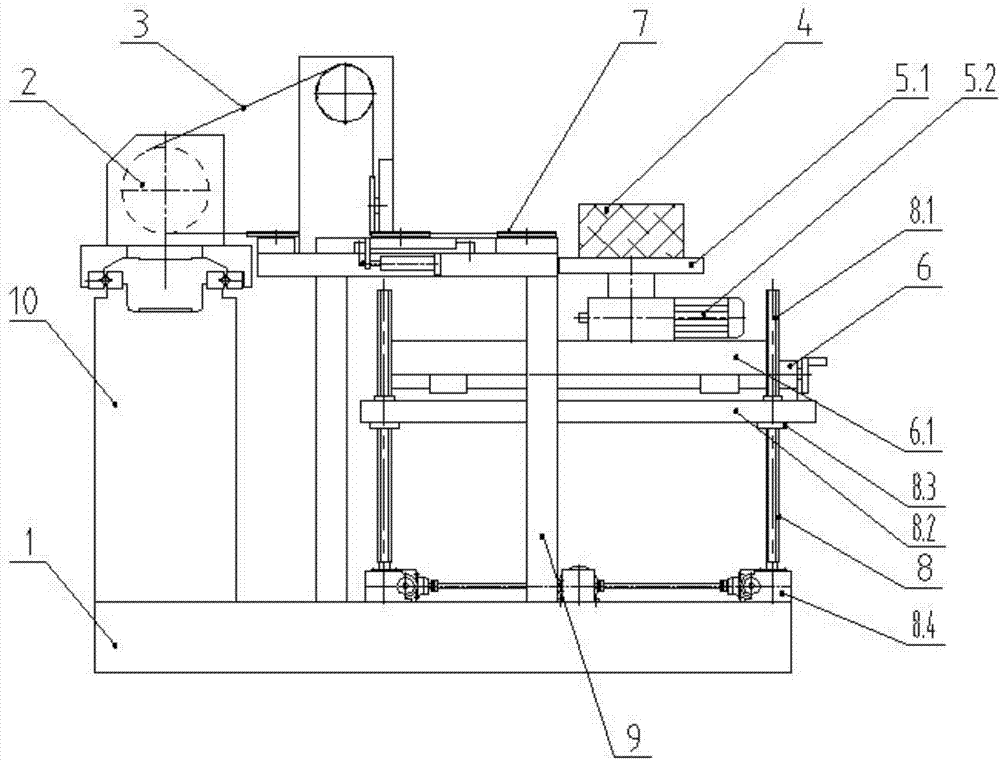

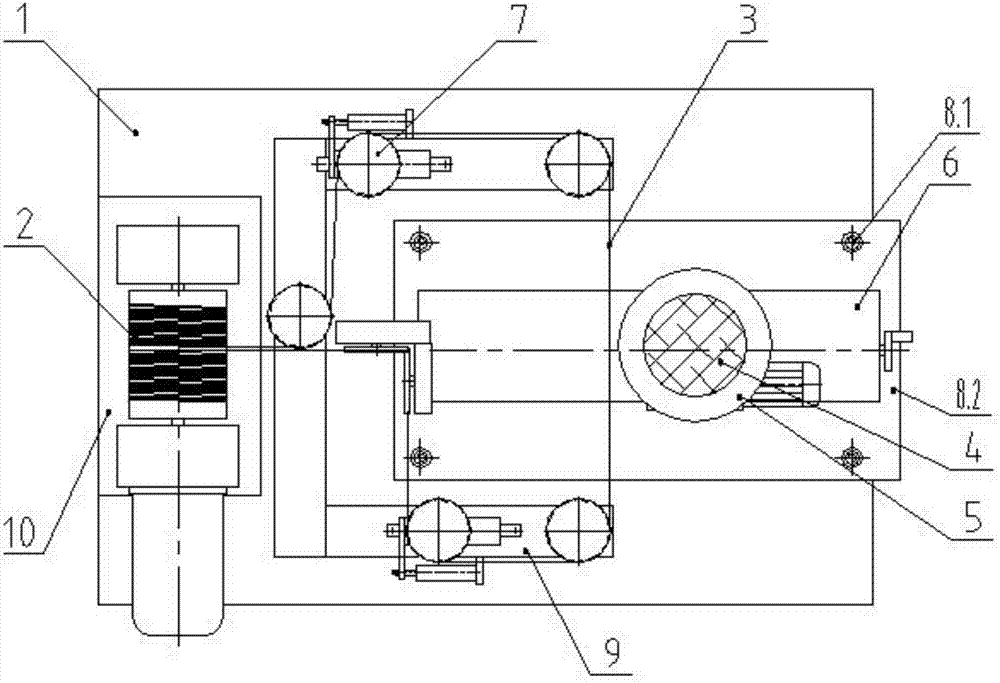

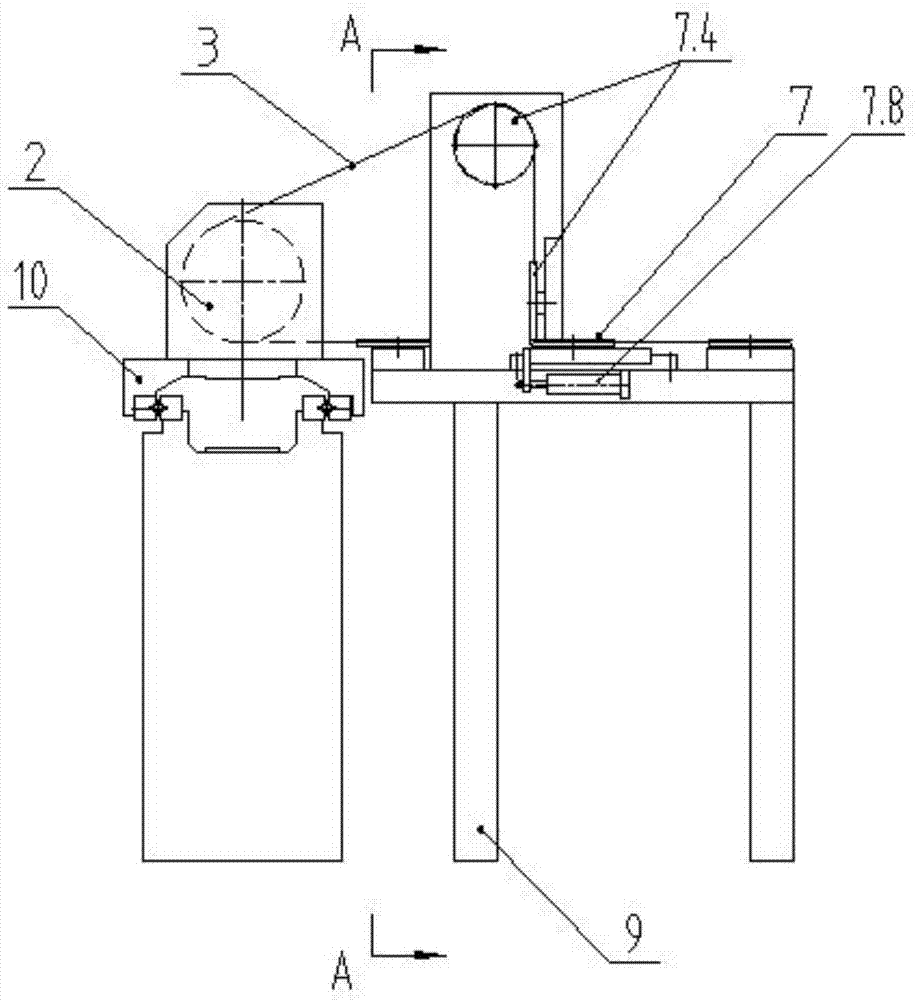

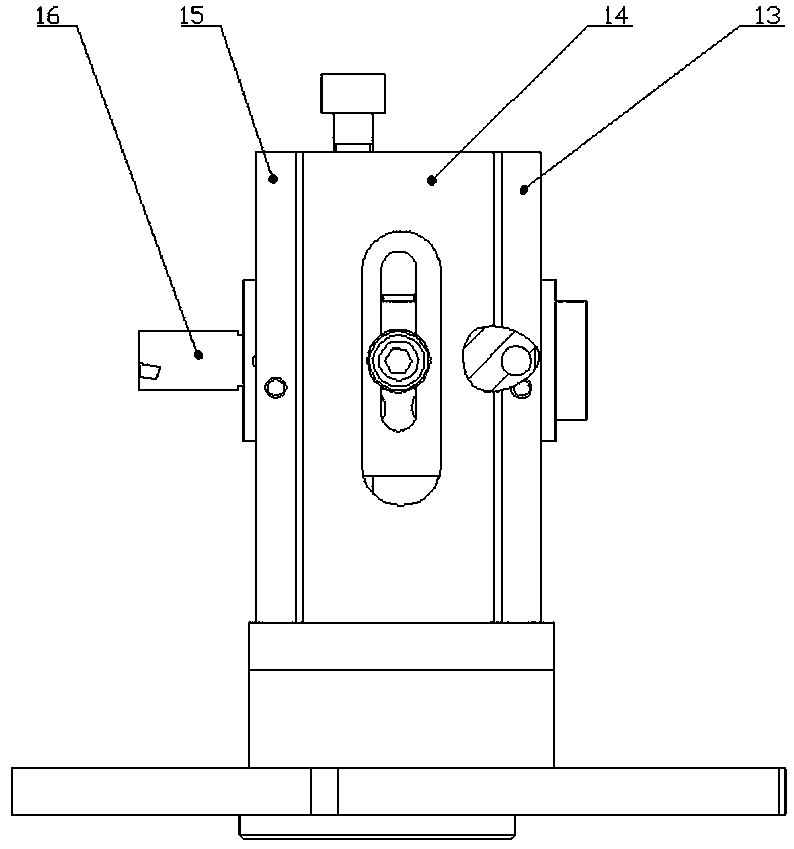

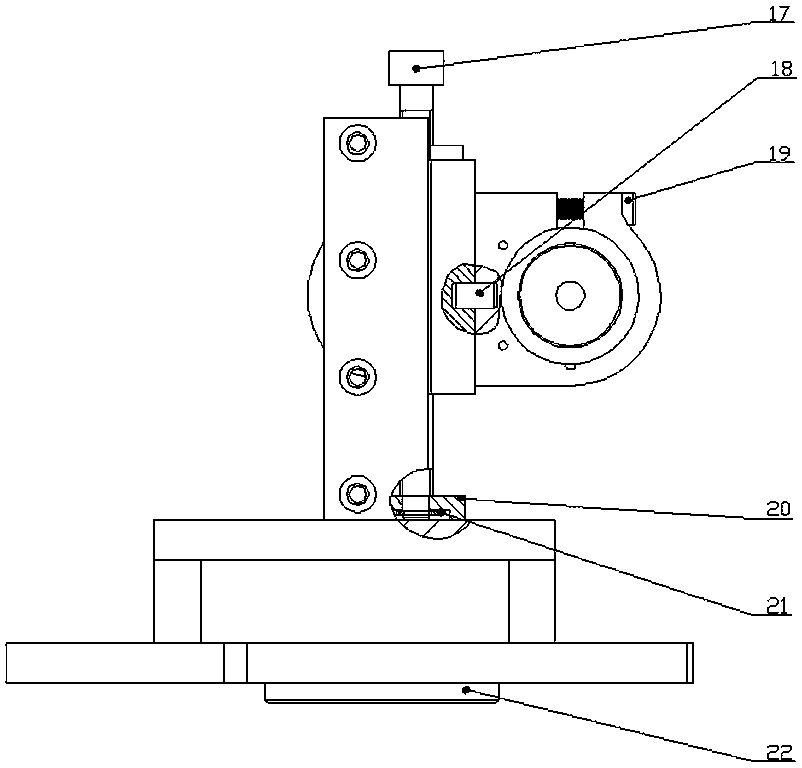

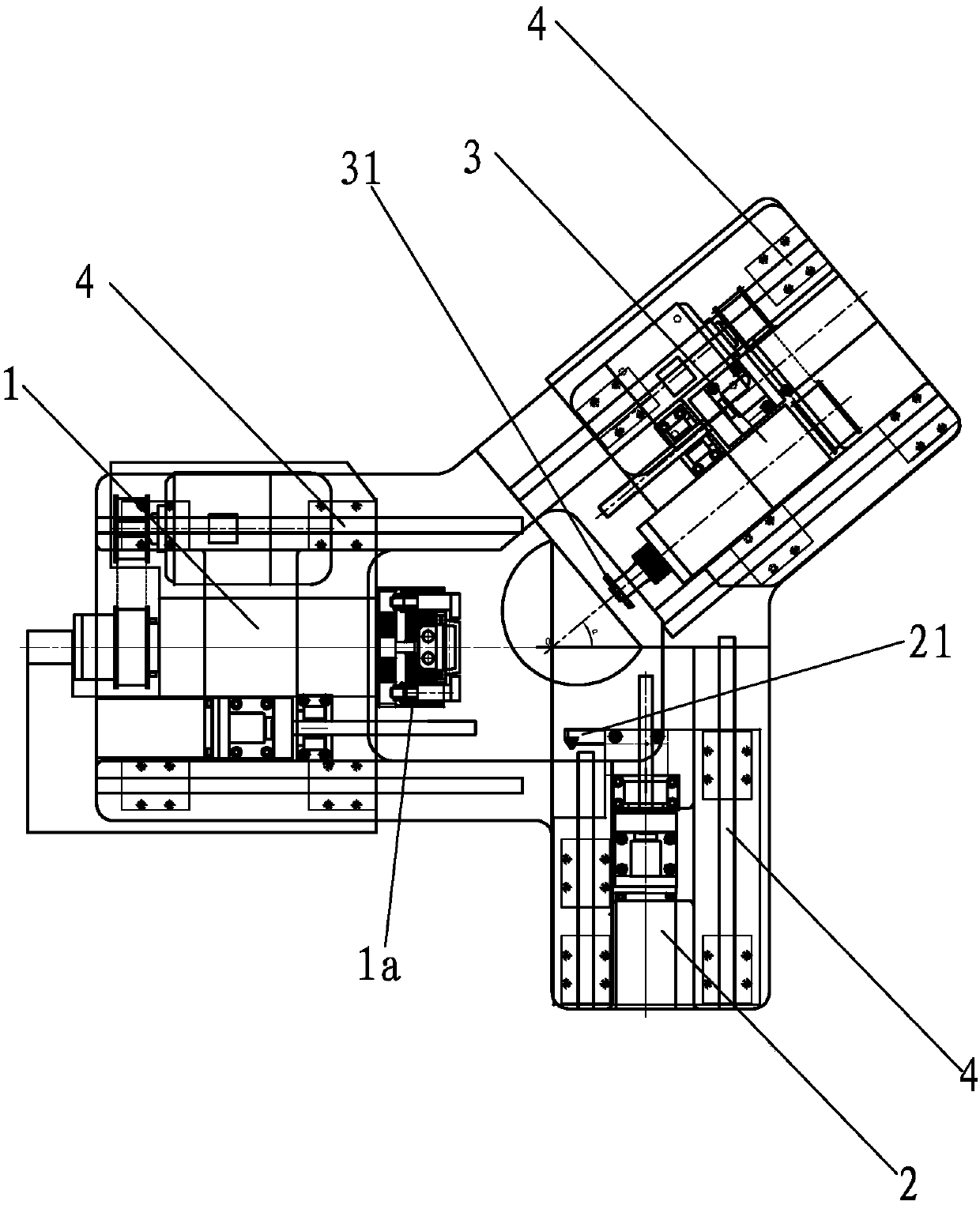

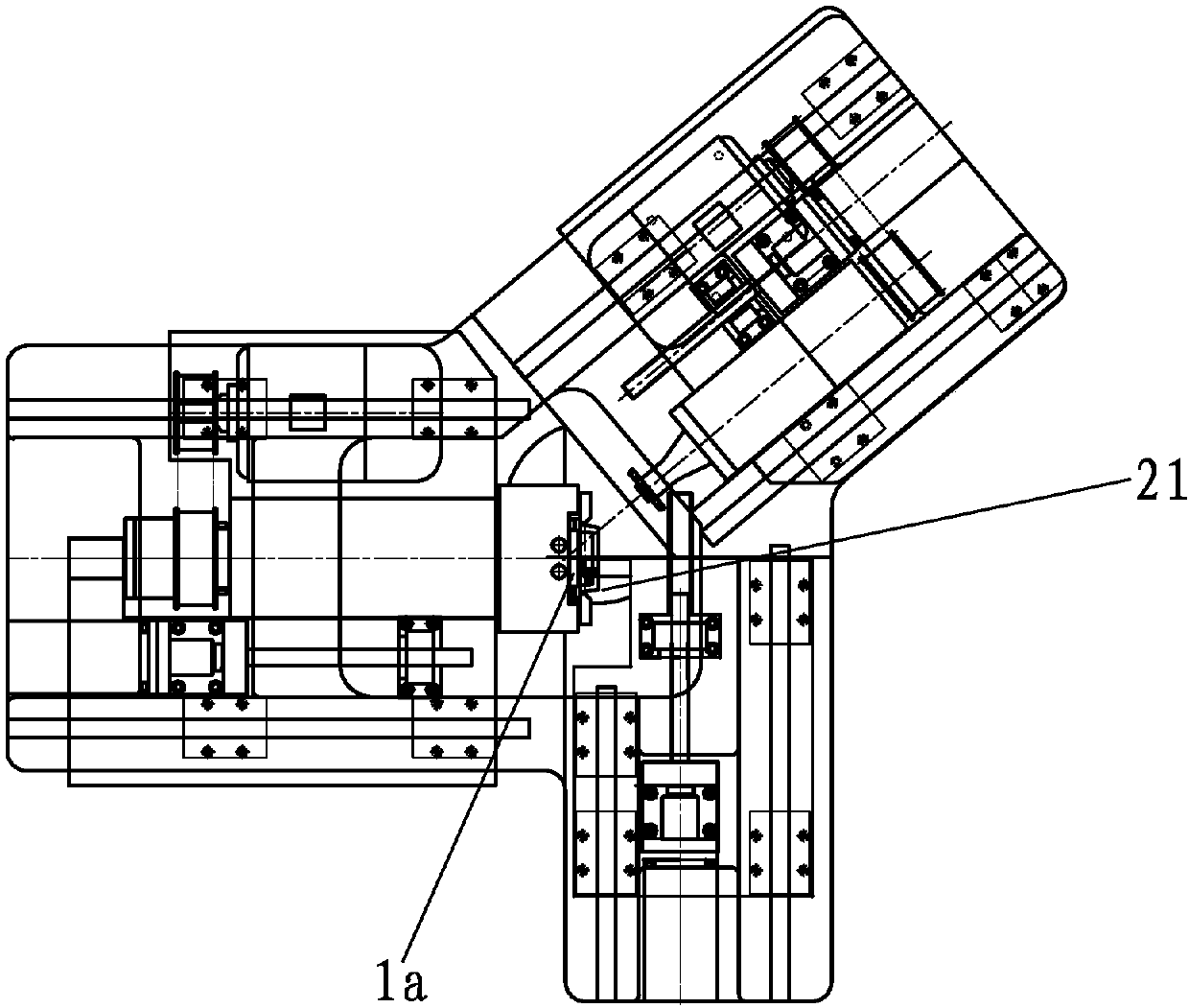

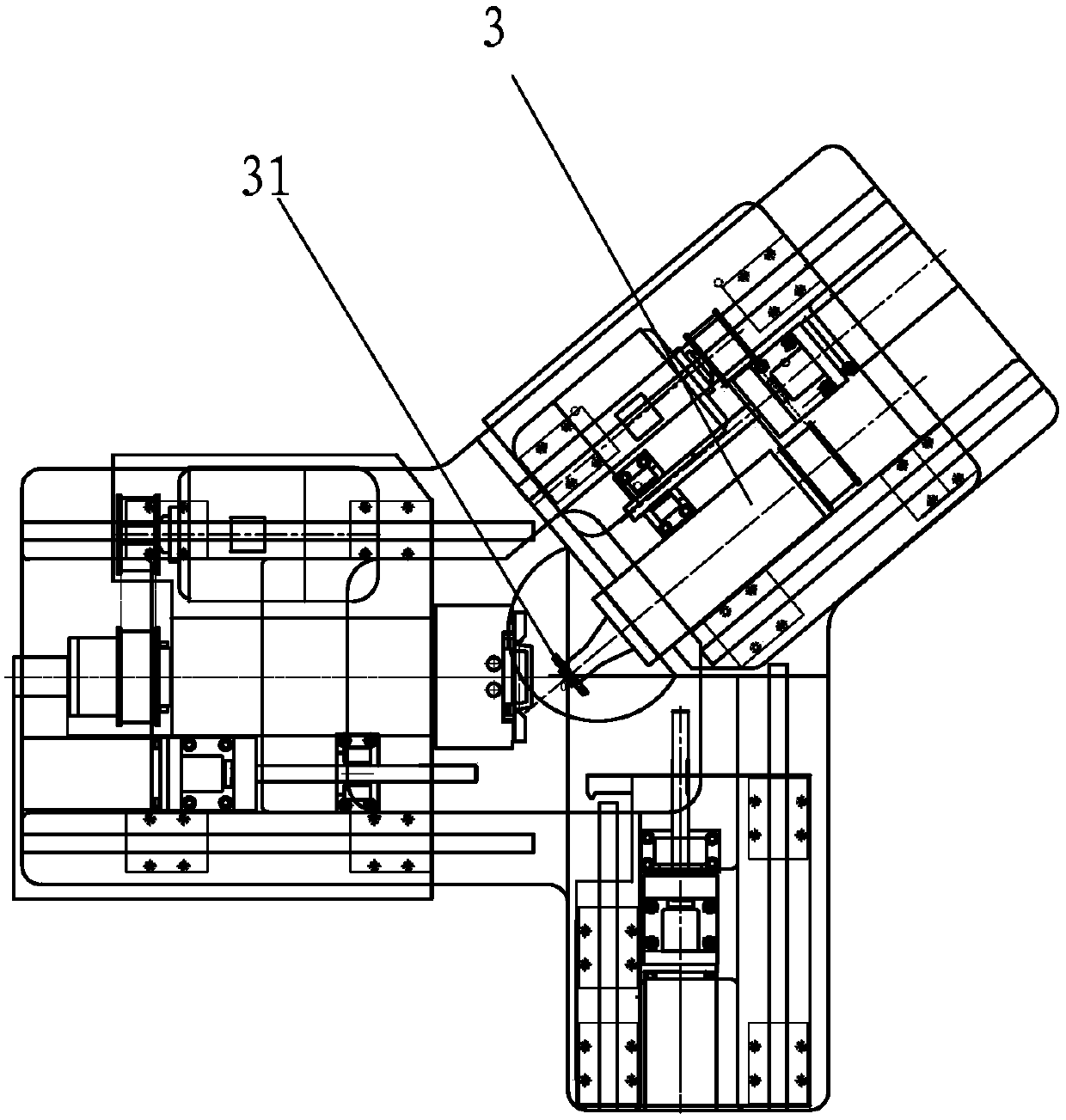

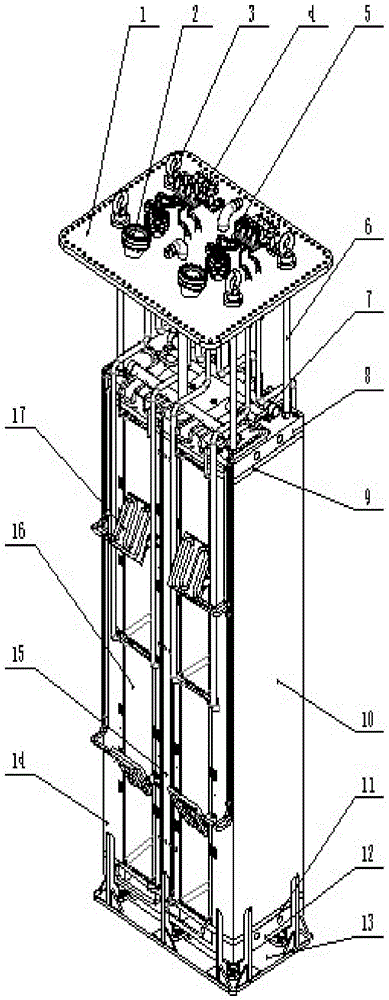

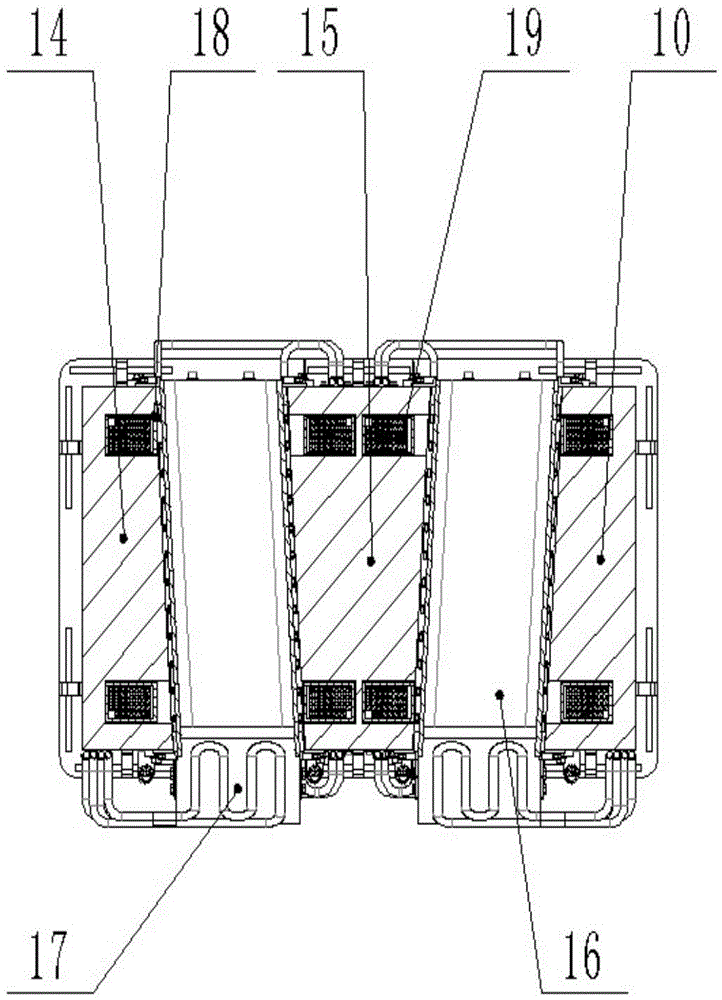

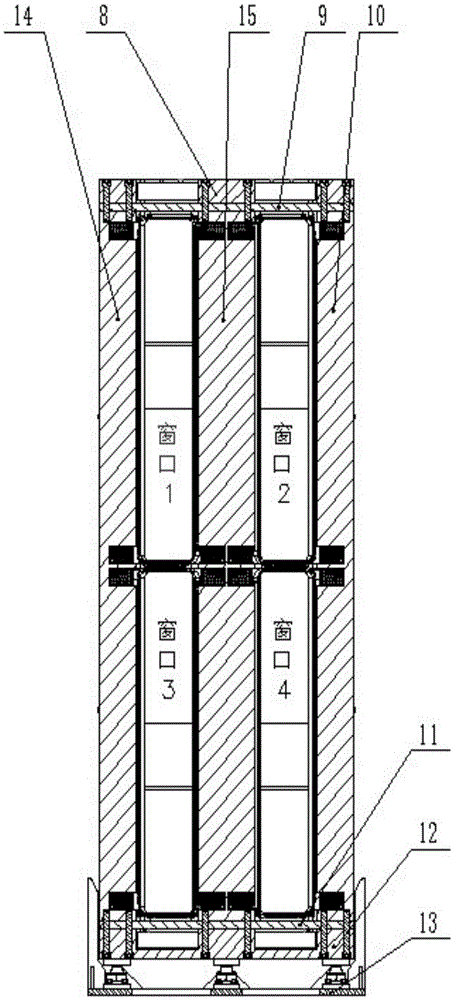

Cutting machine tool horizontally cutting sand line

InactiveCN106881773AEasy to installAchieve horizontal cuttingWorking accessoriesGrinding machinesMetallic materialsLarge size

The invention discloses a cutting machine tool horizontally cutting a sand line. The cutting machine tool comprises a base, a line storage cylinder, a line storage cylinder moving part, a sand line, a worktable assembly, a guide wheel assembly, a lifting mechanism and a guide wheel supporting frame. The central axis of the line storage cylinder is arranged levelly, and the line storage cylinder is driven by the line storage cylinder moving part to achieve transverse moving. The guide wheel assembly is arranged on the guide wheel supporting frame. The lifting mechanism is supported on the base and comprises a top plate arranged levelly above the base. The worktable assembly is supported on the upper end face of the top plate of the lifting mechanism and comprises a worktable which is located on the upper portion of the worktable assembly and can longitudinally move. The guide wheel assembly can achieve sand line horizontal cutting. Further improvement lies in that the lifting mechanism is an electric lifting mechanism. A rotating disc assembly is arranged on the upper end face of the worktable. A nylon or resin layer is arranged on the outer surface of a line storage cylinder body. Non-metallic materials with large sizes and high weights can be cut conveniently and quickly, the production efficiency is high, no stripe cutting can be achieved, and cutting precision is high.

Owner:泰州市江洲数控机床制造有限公司

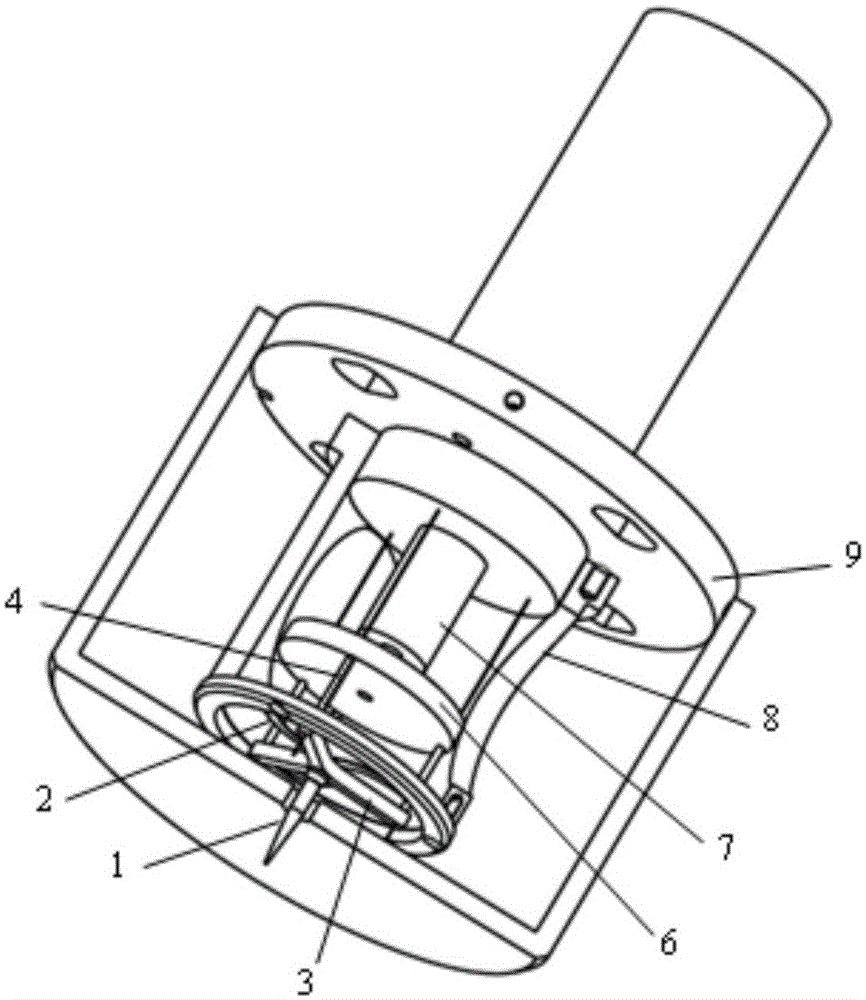

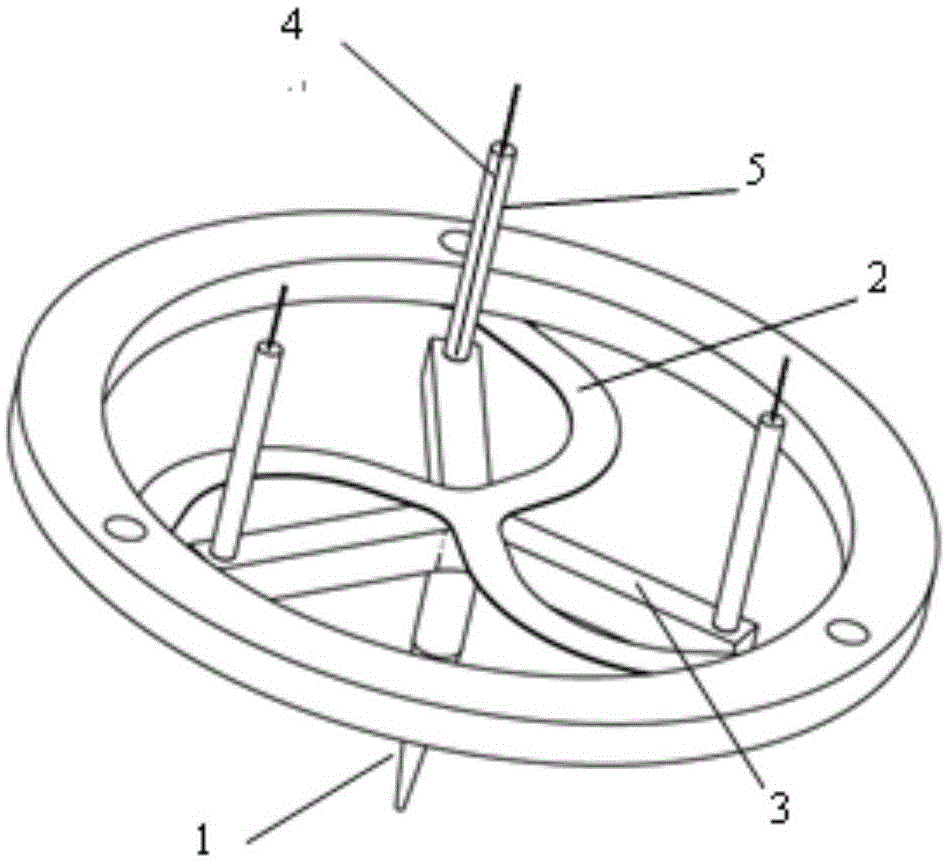

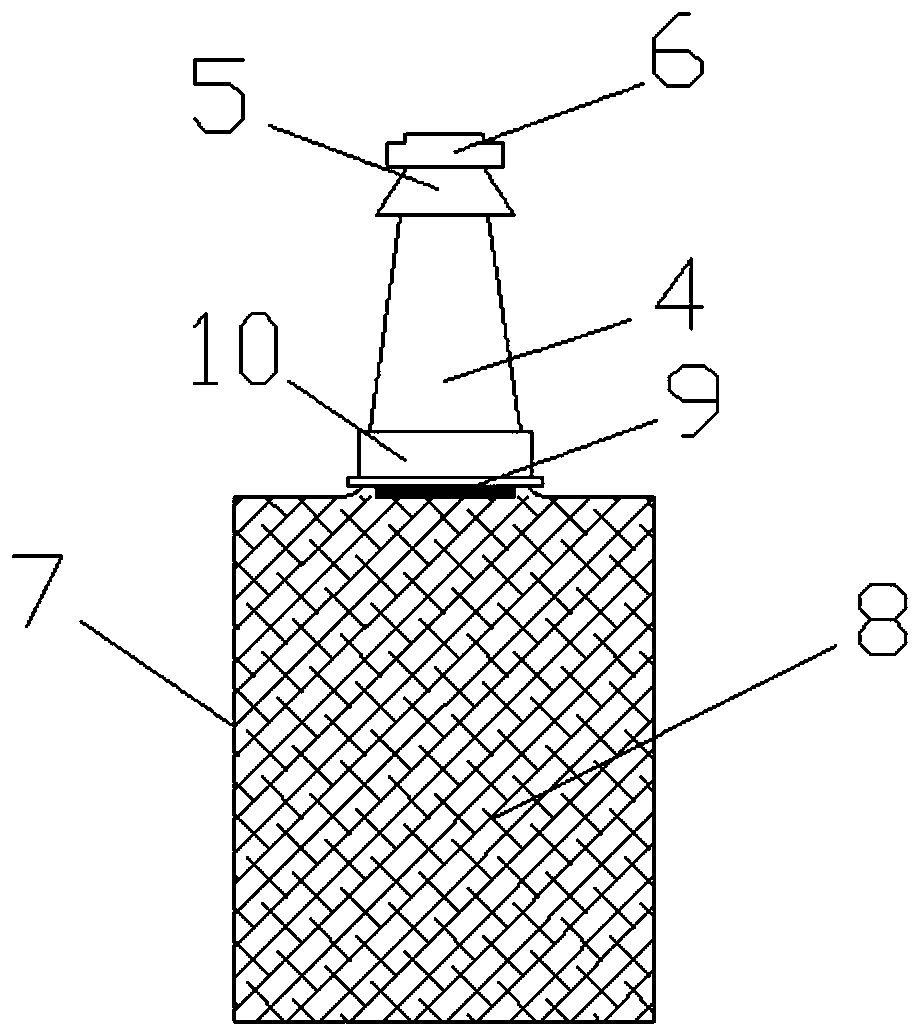

Resonant nano three-dimensional contact measuring head based on optical fiber Bragg grating

InactiveCN105004267ASmall measuring forceReduce the influence of microscopic surface forcesUsing optical meansGratingEngineering

The invention discloses a resonant nano three-dimensional contact measuring head based on an optical fiber Bragg grating. The contact measuring head is characterized in that the structure of the measuring head is designed as follows: an integrated probe with a bulb is fixed in the central point of a suspension support in a T shape, support rods, in the same plane, on the suspension support are in radial distribution. A flexible cantilever and the center of the suspension support are fixed together, far ends of flexible arms, in the same plane, on the flexible cantilever are fixed on an outer connection ring, and a measuring probe is formed. Lower ends of FBG sensors arranged in a packaging layer are fixed at the far ends of the support rods of the suspension support. The upper ends of the FBG sensors are fixed at the edge of a piezoelectric ceramic vibration plate. The piezoelectric ceramic vibration plate is fixedly connected with a displacement output shaft of piezoelectric ceramic through screw threads. The piezoelectric ceramic is fixedly connected onto a bottom surface of a measuring head pedestal through screw threads. The contact measuring head is advantaged by high sensitivity, small measuring force, small microscopic surface active force influence, good long-term stability, good repeatability and low anisotropy.

Owner:HEFEI UNIV OF TECH

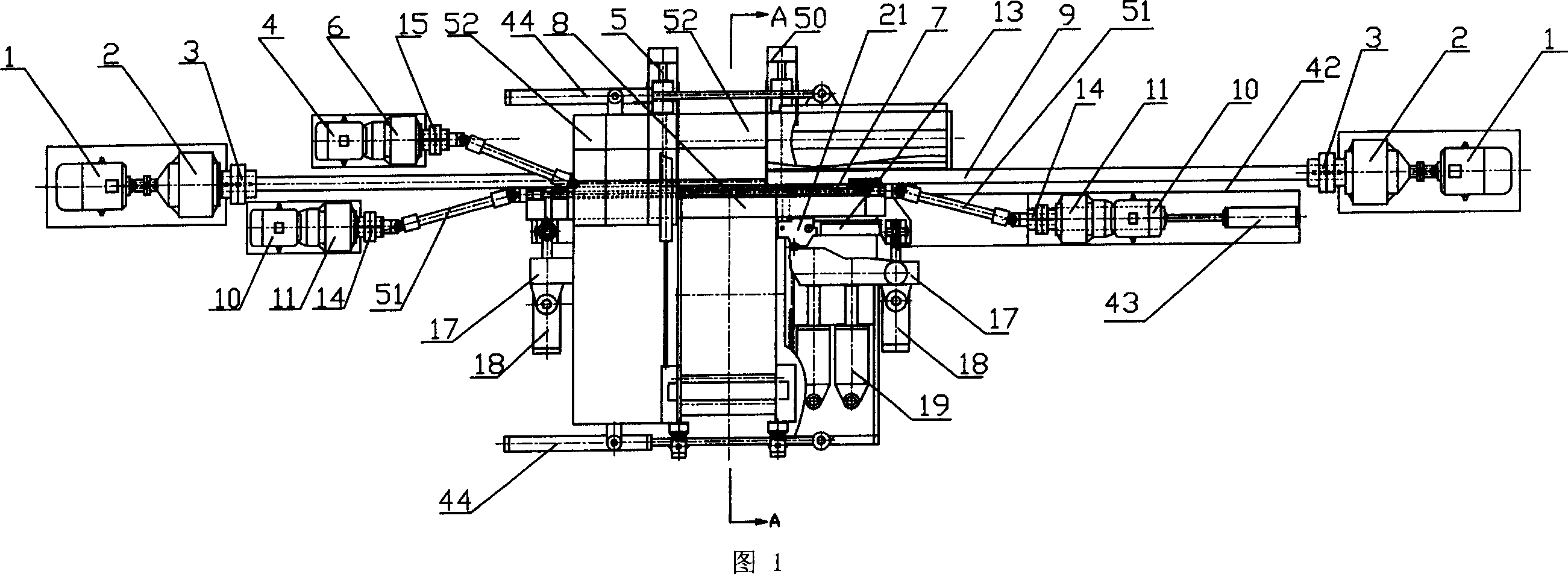

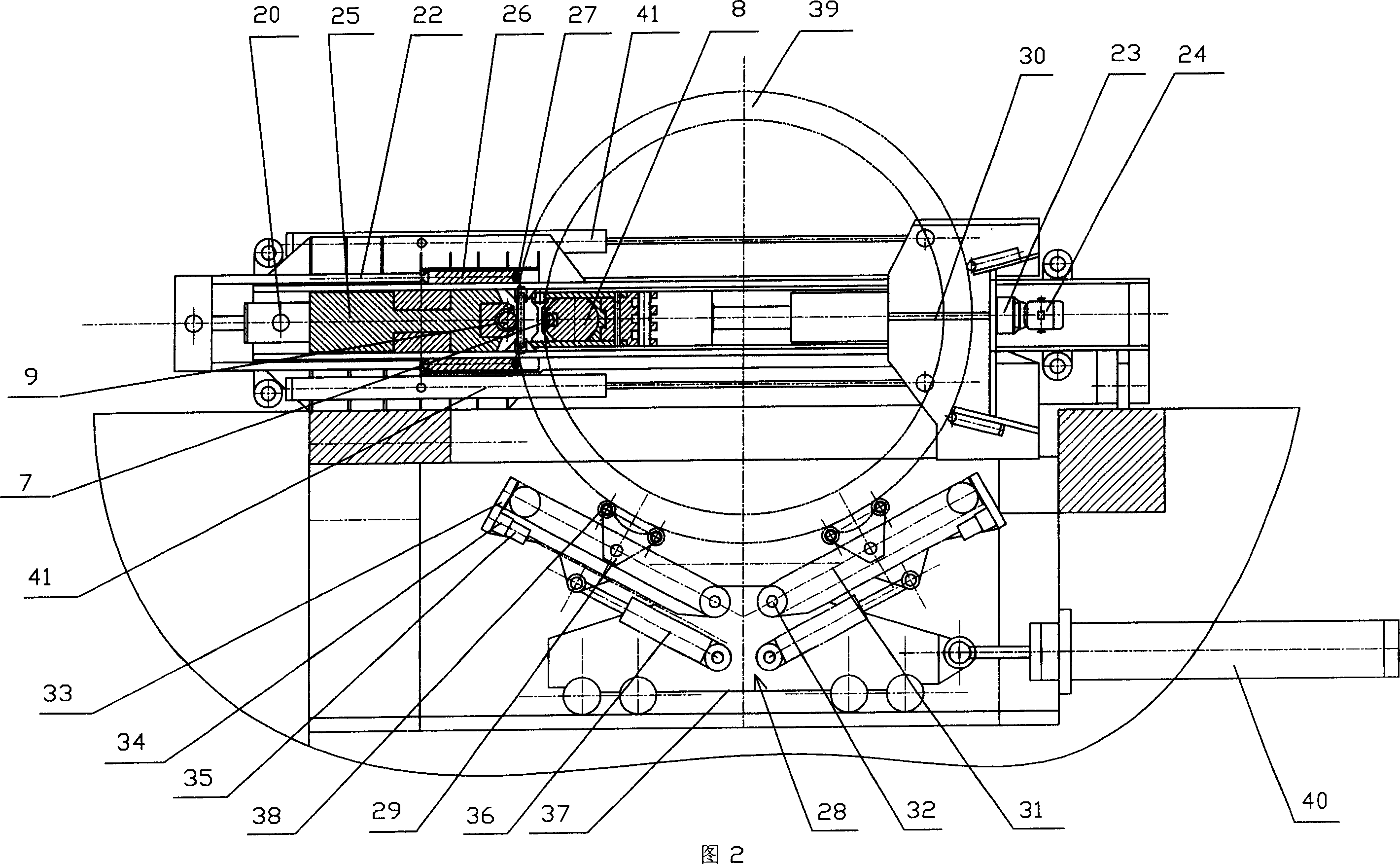

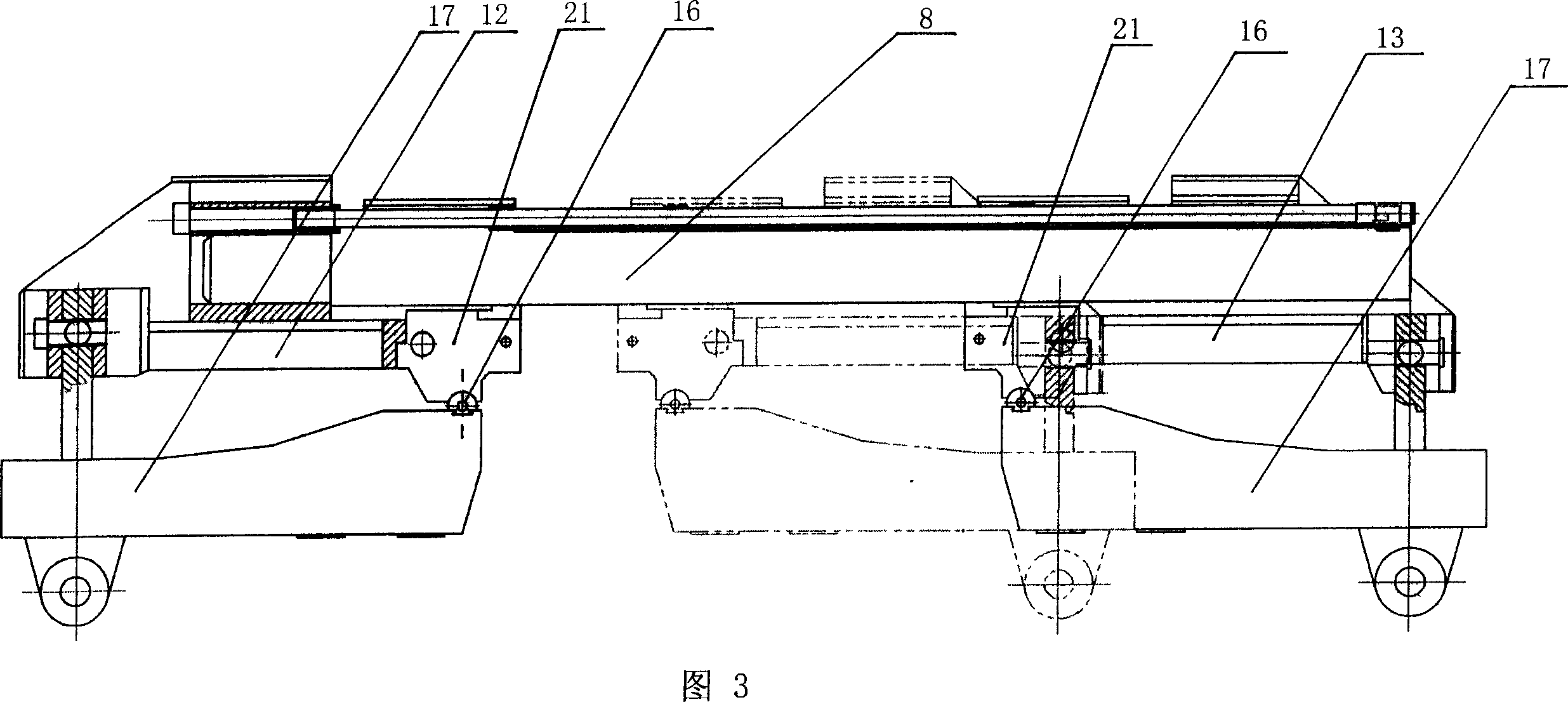

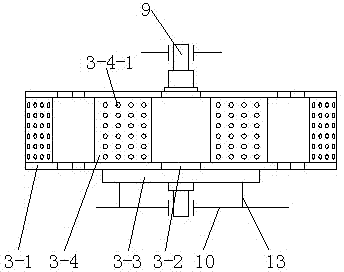

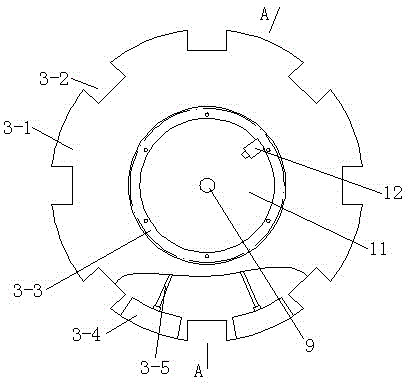

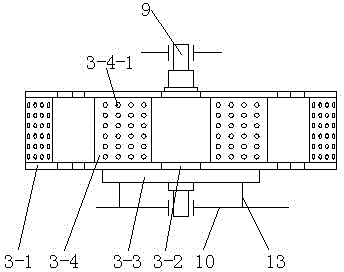

Semi-sank large precise ring rolling machine

ActiveCN101020221AReduce contact areaExpand the range of moldingMetal rollingFixed frameComposite beams

The apparatus for machining large metal ring includes one gate-shaped frame comprising one fixed frame and one movable frame for holding the ring workpiece to be machined, one movable frame driving travel mechanism, one parallel roll pair comprising one fixed roll on the gate-shaped frame and one travel roll on the composite beam, one push mechanism set between the gate-shaped frame and the composite beam to drive the composite beam with movable roll to roll the workpiece, and rotating mechanisms separately on the fixed roll and the movable to rotate them. The present invention has high work efficiency, high product precision and high mechanical performance.

Owner:WUXI HONGDA HEAVY IND

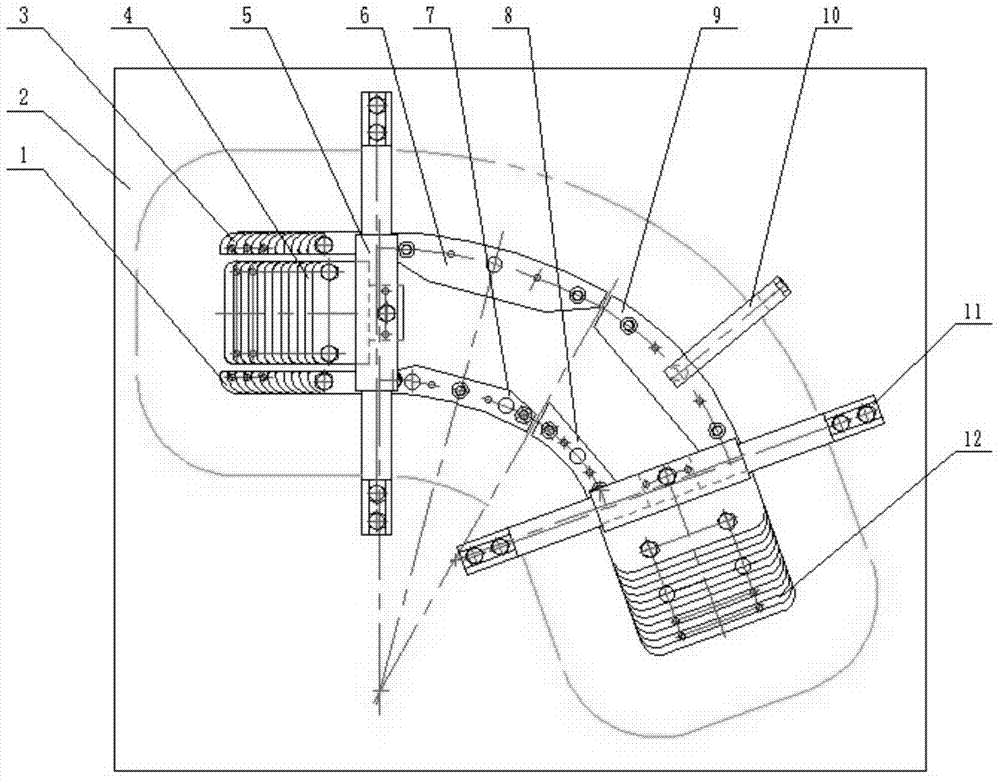

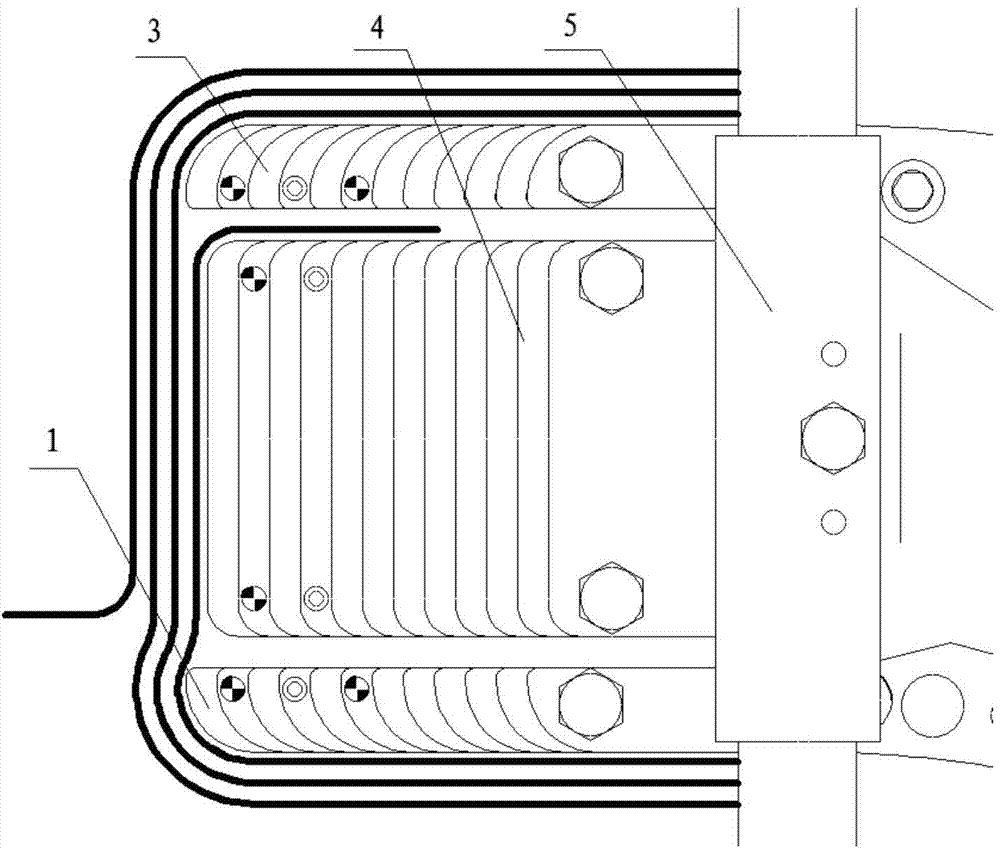

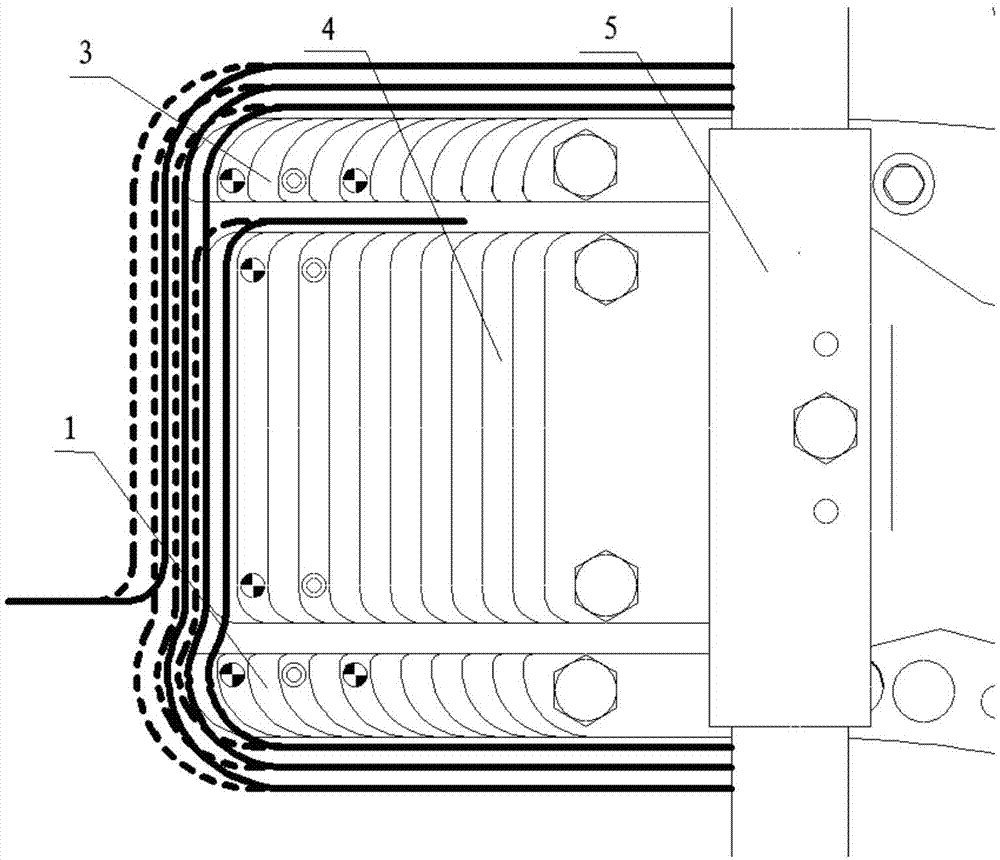

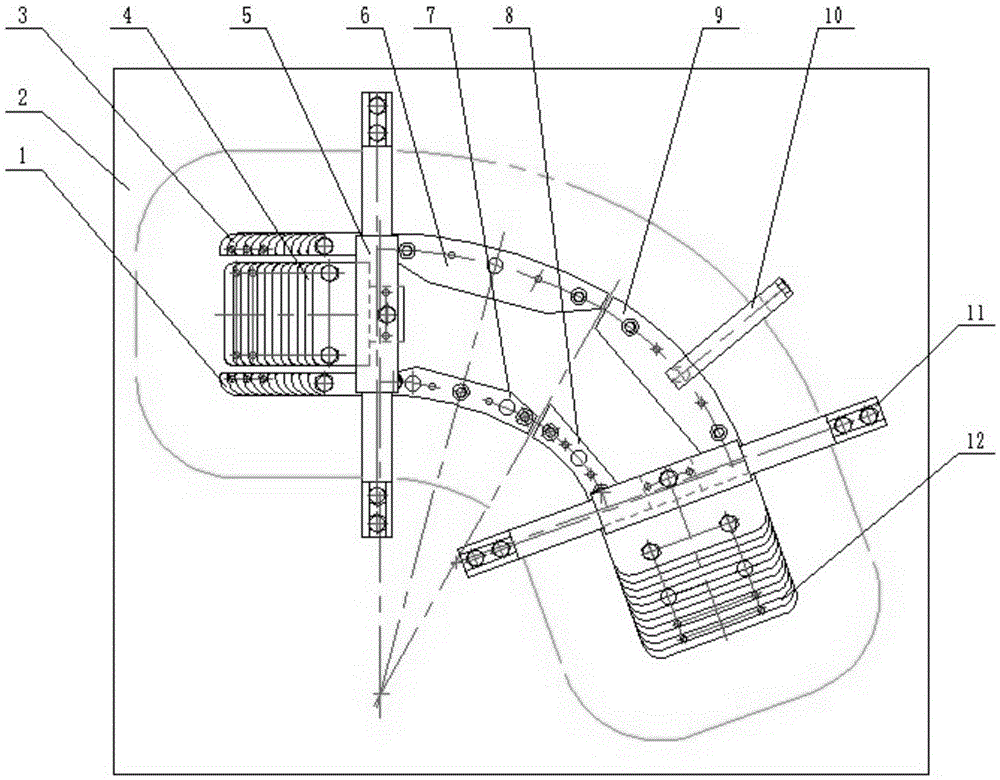

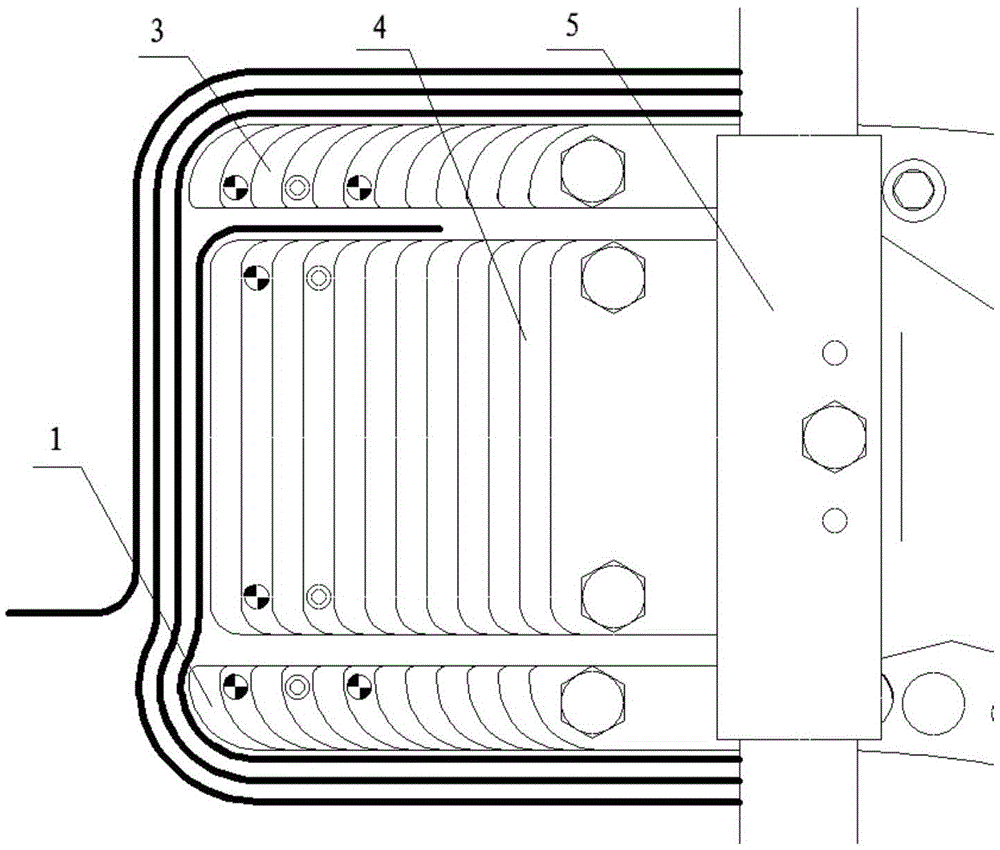

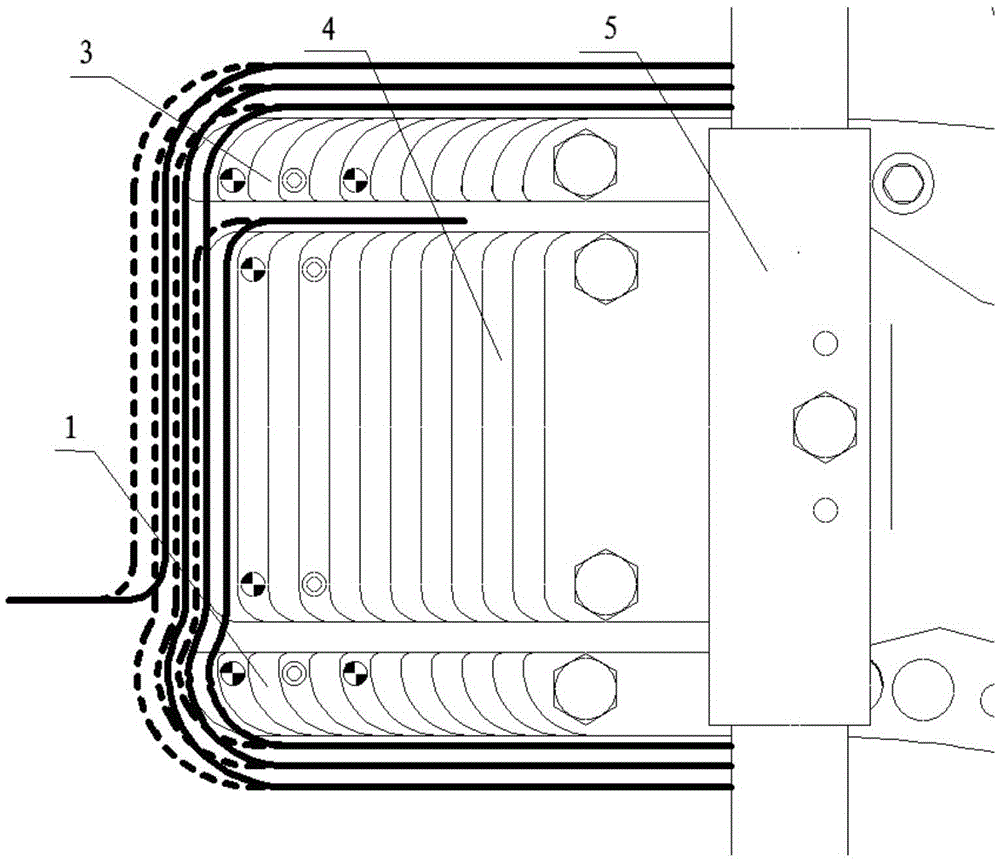

Winding device and method of window type irregular saddle-shaped coil

The invention relates to the technical field of manufacturing processes of window type irregular saddle-shaped coils for compound function electromagnets, in particular to a winding device and method of a window type irregular saddle-shaped coil. The window type irregular saddle-shaped coil comprises step components which are unfolded with two 90-degree flanges on two edges and used for controlling gaps among copper wires of each layer at the 90-degree flanges, the upper edges of wire cakes on each layer are guaranteed to be flush on the same plane after flanging, the step component at one end is horizontally divided into three parts, and gaps are reserved in the middles and used for accommodating copper wire heads, the three parts are fixed on a base plate through locating pins and bolts respectively. A 90-degree back plate is located above the step component with coils unfolded at two ends and used for unfolding two ends of each wire cake to vertical positions layer by layer through a special tool after layer winding, and a saddle shape is formed. The internal quality is good, the performance is reliable, the winding efficiency is high, the cost is low, the boundary dimension and the shape error are small, the stability is excellent, the product consistency is good, the performance of a whole compound electromagnet is modified and improved, the magnetic field index is stable, and the error is small.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

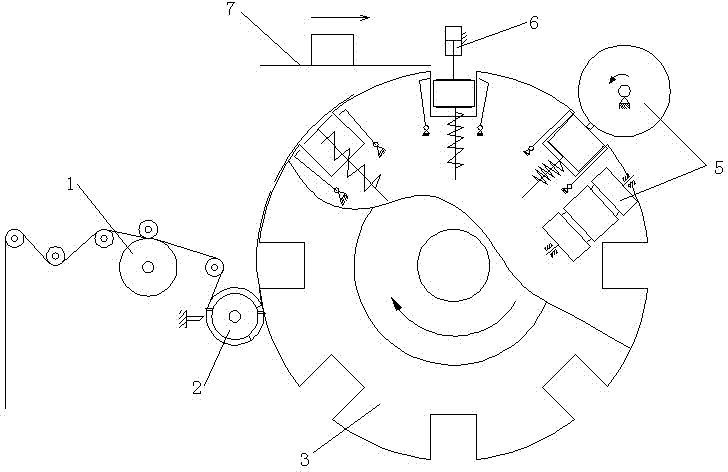

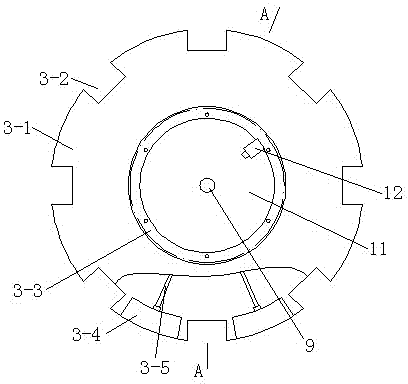

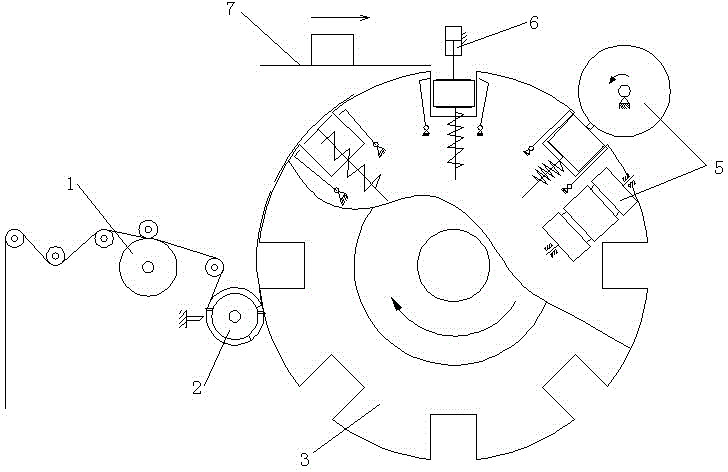

Automatic continuous household paper packing machine

InactiveCN103043244AGuaranteed heat sealing qualityRelatively small errorPaper article packagingPressure systemPulp and paper industry

The invention relates to household paper packaging equipment, and particularly relates to an automatic continuous household paper packing machine. The machine comprises a rack, a negative pressure system, a packaging film opening and conveying device and a burn-seal device. The machine is characterized in that a support shaft is fixedly arranged on the rack; a disc-shaped mould is hollowly sleeved on the support shaft; a household paper feed device, the packing film opening and conveying device and a packing film cutting device are arranged on one feed side of the disc-shaped mould; the burn-seal device is arranged on the upper part of the disc-shaped mould; a household paper packing and clamping device is arranged on the disc-shaped mould; and the disc-shaped mould is driven by a drive system to rotate. According to the technical scheme, the machine is reasonable in structure, external dimension errors and shape errors of the packaged household paper subjected to burn-seal are small, and the quality of a burn-seal surface is good, so that packing machine is very suitable for automatic packaging production line.

Owner:YINCHUAN LIZHIXIN INTPROP ADVISORY SERVICES

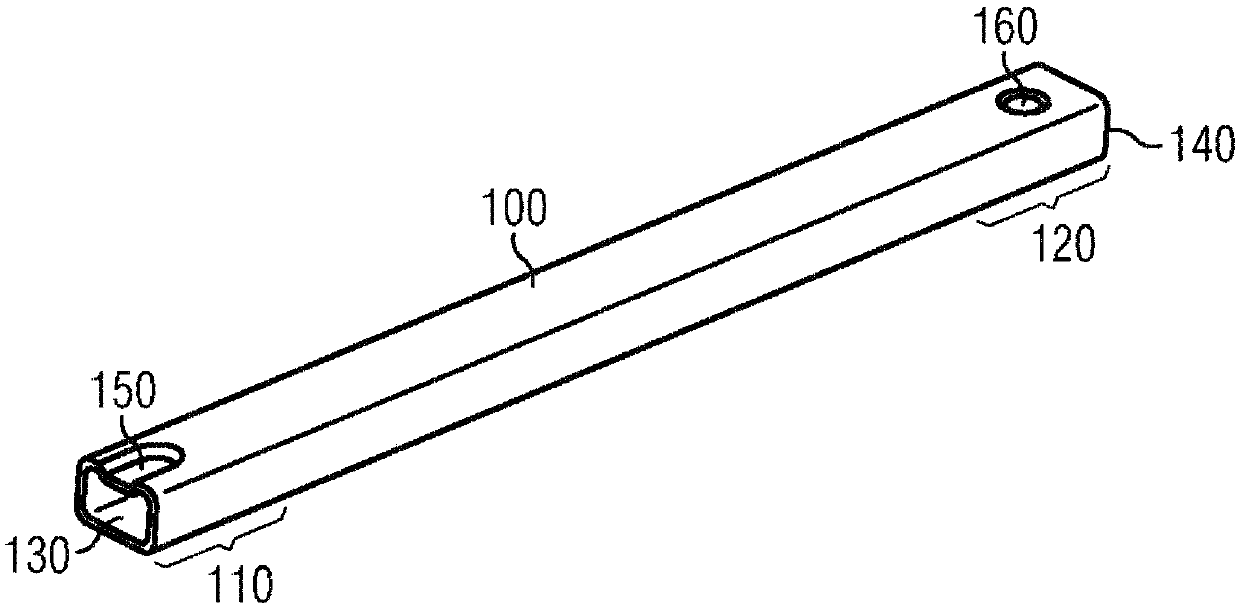

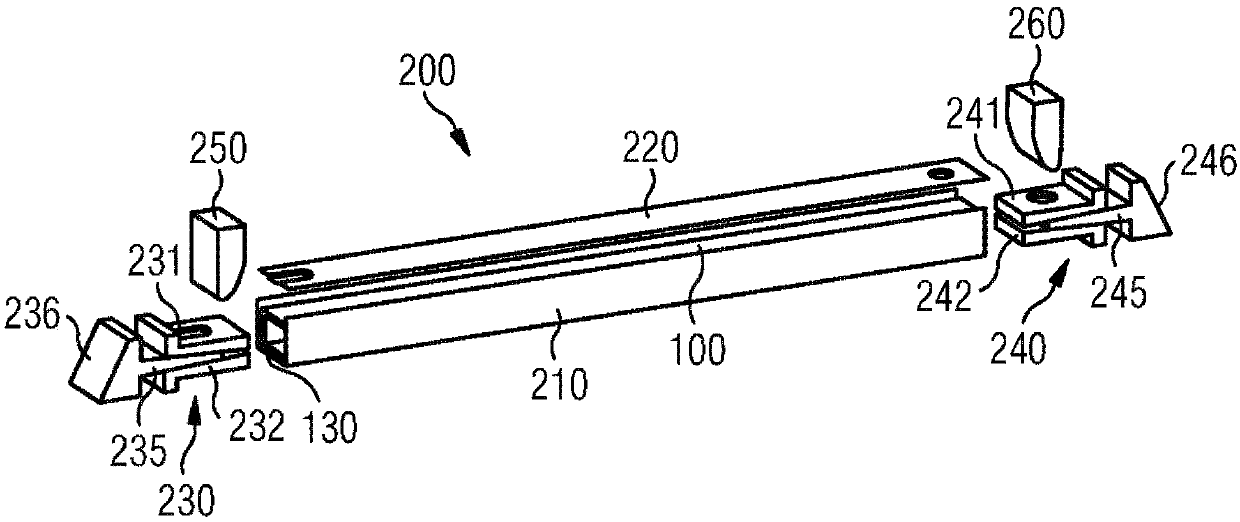

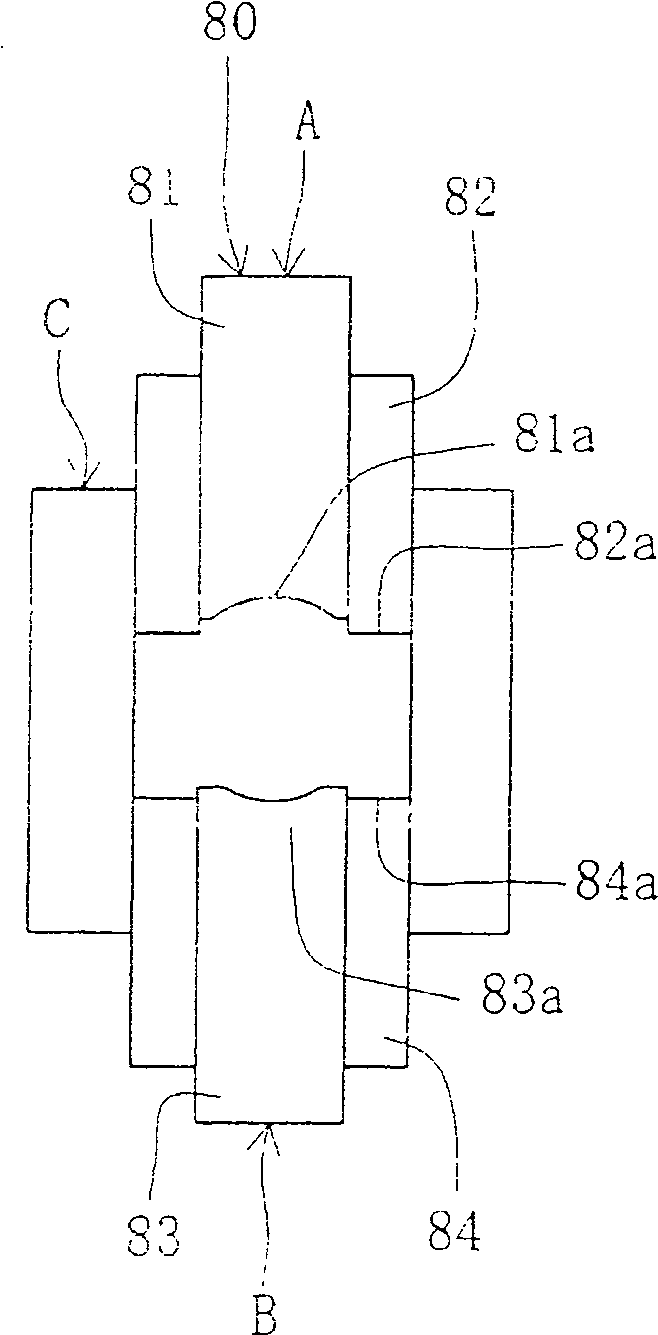

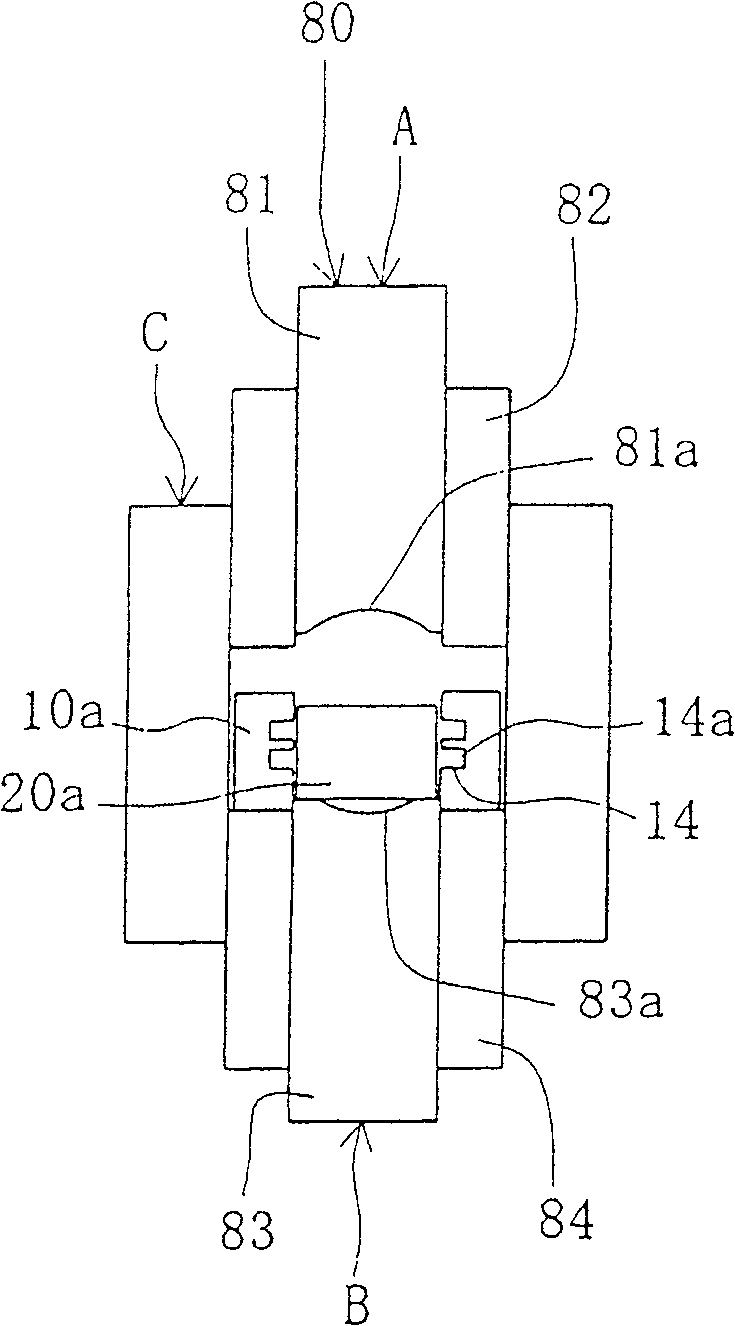

Method and tool for calibration of hollow profile component produced by extrusion for automobile manufacturing

PendingCN109530488ASmall shape errorShort cycle timeShaping toolsVehicle componentsSizingCar manufacturing

The present invention relates to a method for the calibration or end sizing of a hollow profile component (100) produced by extrusion for automobile manufacturing. The method comprises the following steps that: a hollow profile component (100) is inserted into the cavity of an opened press tool (200) and closing the press tool (200); expandable mandrels (230, 240) are introduced into the open profile ends (130) of the hollow profile component (100); the hollow profile component (100) is calibrated or end-sized by applying force simultaneously on the outside and on the inside; and the expandable mandrels (230, 240) are retracted to open the press tool (200) and remove the hollow profile component (100). The present invention further relates to a press tool (200) and a method for manufacturing a hollow profile component (100).

Owner:AUDI AG +1

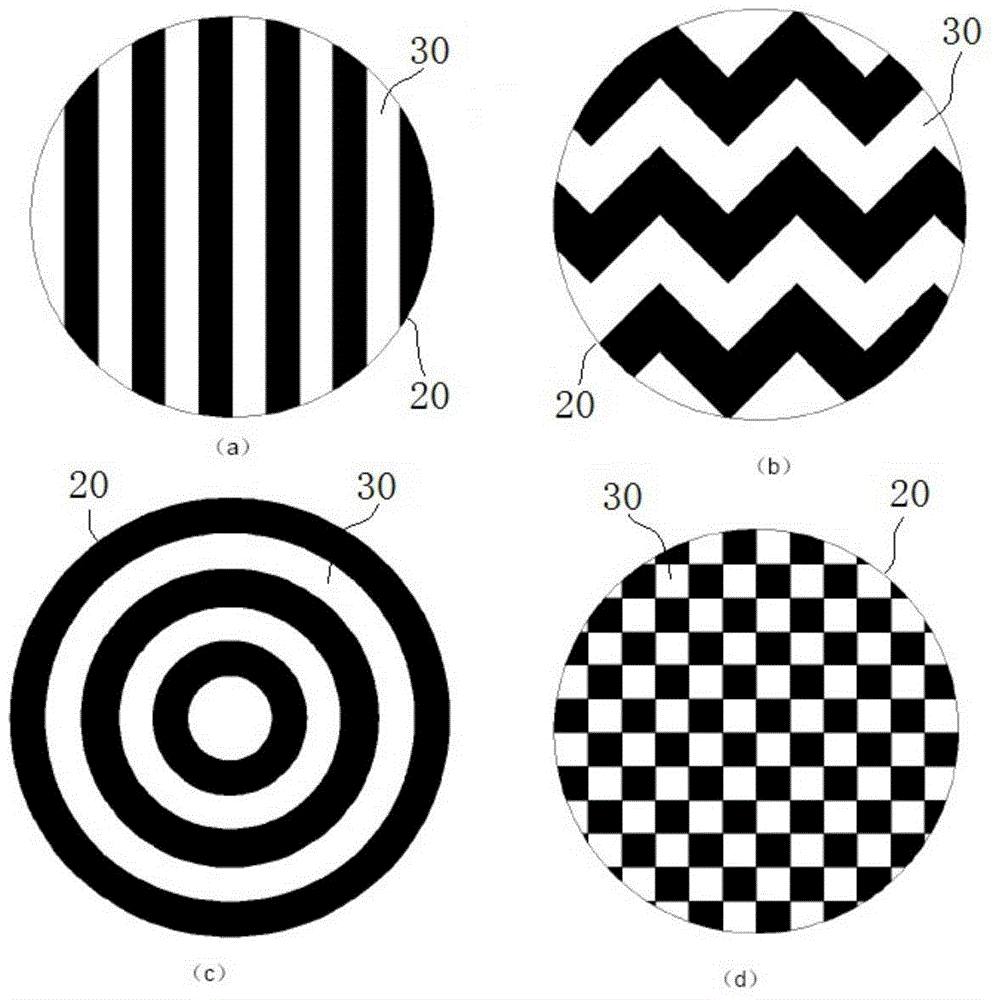

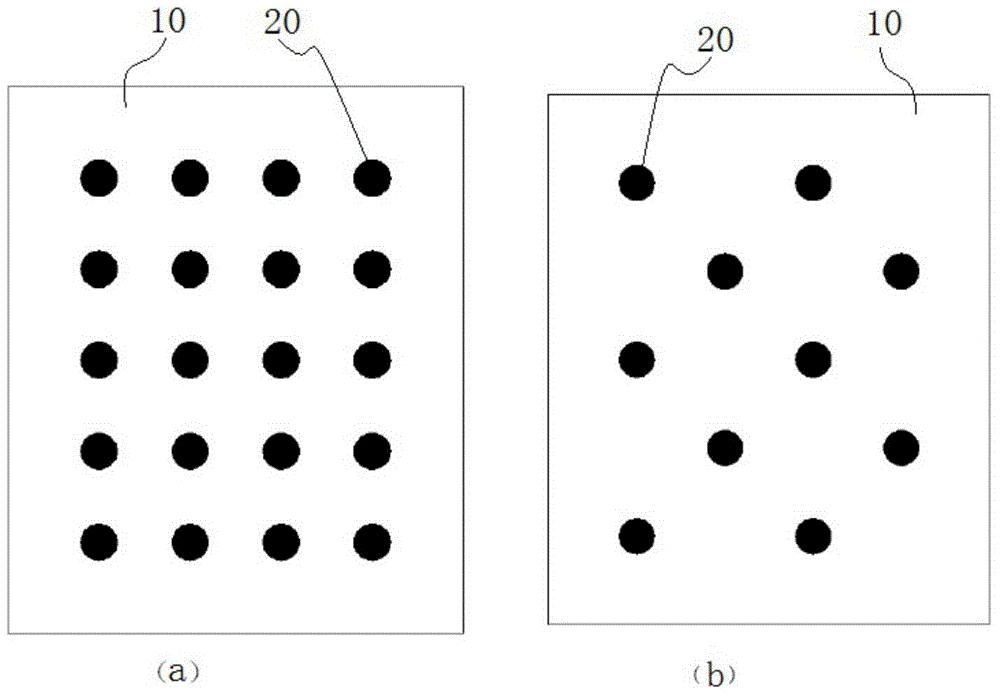

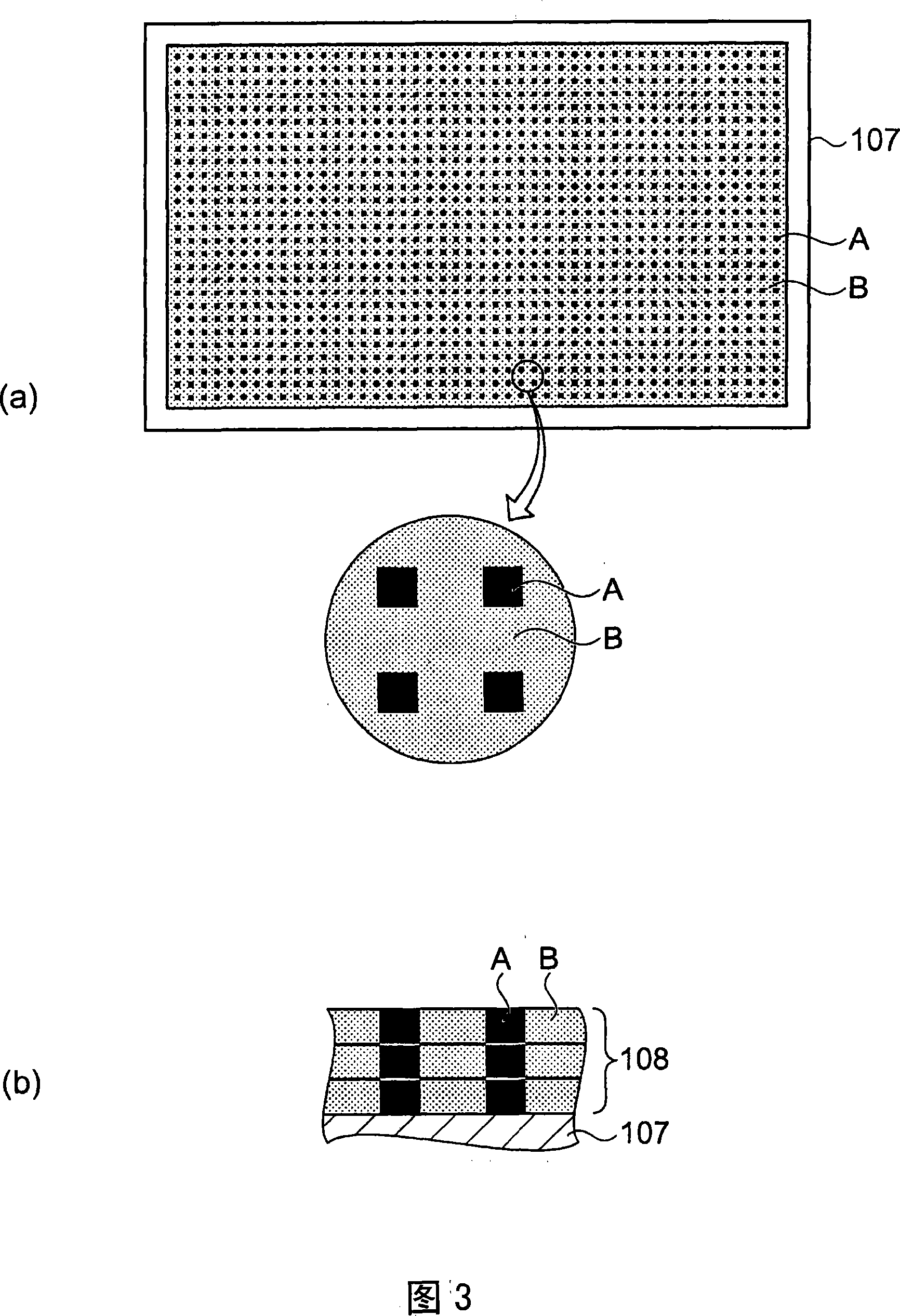

Soft-brittle material processing abrasive tool as well as manufacturing method thereof and method for processing soft-brittle material

ActiveCN104589224AGuaranteed uniformitySmall shape errorBonded abrasive wheelsGrinding devicesBristleSurface roughness

The invention discloses a soft-brittle material processing abrasive tool as well as a manufacturing method of the abrasive tool and a method for processing the soft-brittle material. The processing abrasive tool comprises a base body, wherein a plurality of diamond sheets are fixed on the processing surface of the base body; the processing surfaces of the diamond sheets are arc-shaped surfaces; patterned slots are formed in the arc-shaped surfaces of the diamond sheets; the protrusion height of each of the diamond sheets relative to the base body is 1mm-2mm. The method for processing the soft-brittle material comprise the following steps of grinding the soft-brittle material through the soft-brittle material processing abrasive tool until surface roughness of the surface of the soft-brittle material is detected to be 0.01 micron to 0.1 micron. The processing abrasive tool is utilized to process the soft-brittle material, so that the material processing quality is improved and the ultra-precise processing problem of the soft-bristle material is solved.

Owner:HUNAN UNIV

One-box multi-cast plate and casting method

InactiveCN102652986ASmall shape errorClamping error is smallMoulding flasksUtilization rateMaterials science

The invention discloses a one-box multi-cast plate and a casting method, belongs to the technical field of casting molds and casting methods, and is used for a one-box multi-cast process. According to the technical scheme, the one-box multi-cast plate comprises an upper template and a lower template, wherein a plurality of upper part models and an upper pouring opening model are processed on the upper template; a plurality of lower part models and a lower pouring opening model are processed on the lower template; the upper part models and the lower part models are matched with each other; the upper pouring opening model and the lower pouring opening model are matched with each other; and sand box positioning devices are respectively arranged on two sides of the upper template and the lower template. The casting method comprises the steps of: preparing the designed templates for shaping; after shaping is finished, correcting a cavity; smearing fireproof materials in the cavity; and pouring. The process is simple; the shaping efficiency is greatly improved, and the utilization rate of casting sand is greatly improved; a standard sand box is beneficial to automatic casting; due to the high-precision templates, the blank precision of a casting is improved; and the one-box multi-cast plate can meet various requirements of castings with different shapes.

Owner:河北木源泵业有限责任公司

Automatic continuous household paper packing machine

InactiveCN103043244BGuaranteed heat sealing qualityRelatively small errorPaper article packagingProduction linePressure system

The invention relates to household paper packaging equipment, and particularly relates to an automatic continuous household paper packing machine. The machine comprises a rack, a negative pressure system, a packaging film opening and conveying device and a burn-seal device. The machine is characterized in that a support shaft is fixedly arranged on the rack; a disc-shaped mould is hollowly sleeved on the support shaft; a household paper feed device, the packing film opening and conveying device and a packing film cutting device are arranged on one feed side of the disc-shaped mould; the burn-seal device is arranged on the upper part of the disc-shaped mould; a household paper packing and clamping device is arranged on the disc-shaped mould; and the disc-shaped mould is driven by a drive system to rotate. According to the technical scheme, the machine is reasonable in structure, external dimension errors and shape errors of the packaged household paper subjected to burn-seal are small, and the quality of a burn-seal surface is good, so that packing machine is very suitable for automatic packaging production line.

Owner:YINCHUAN LIZHIXIN INTPROP ADVISORY SERVICES

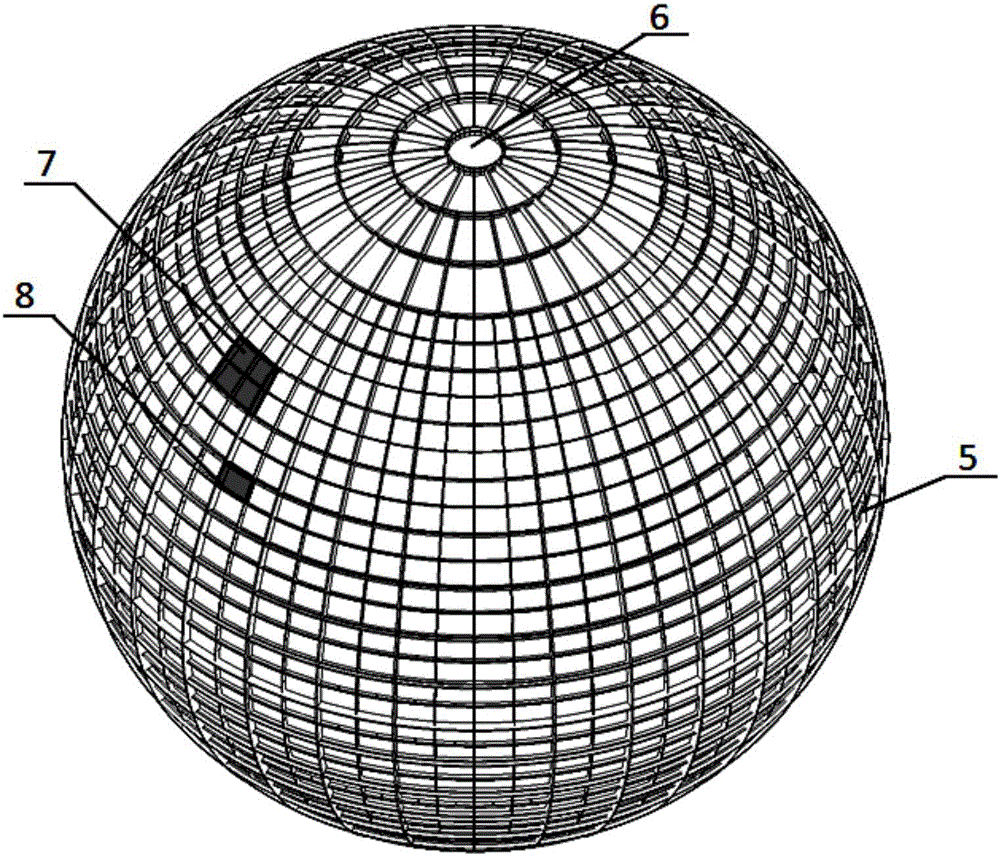

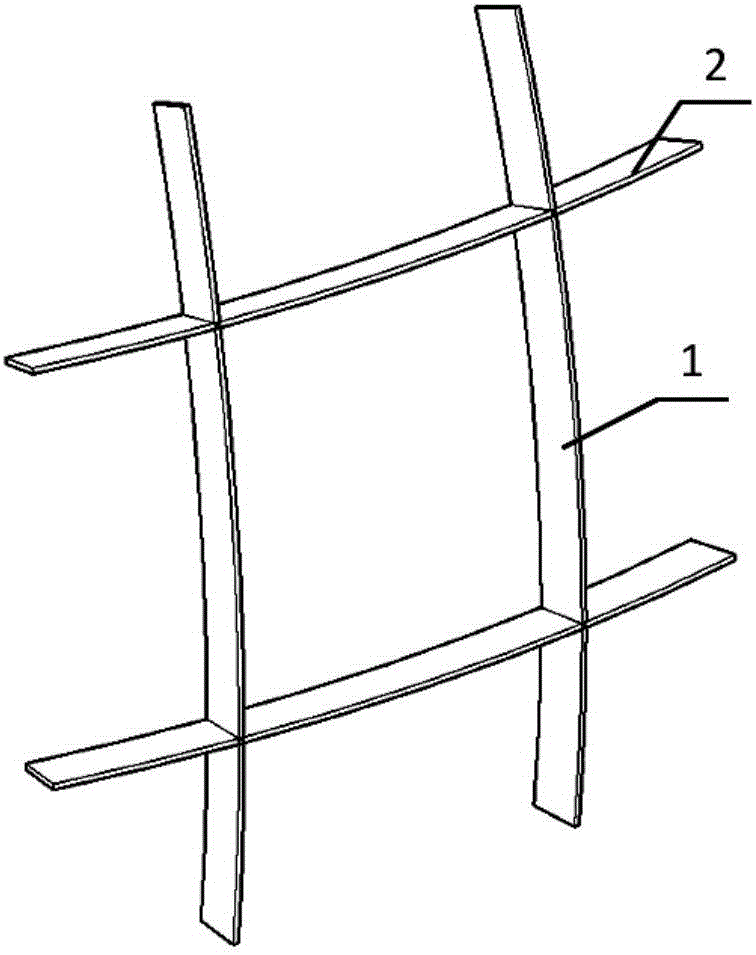

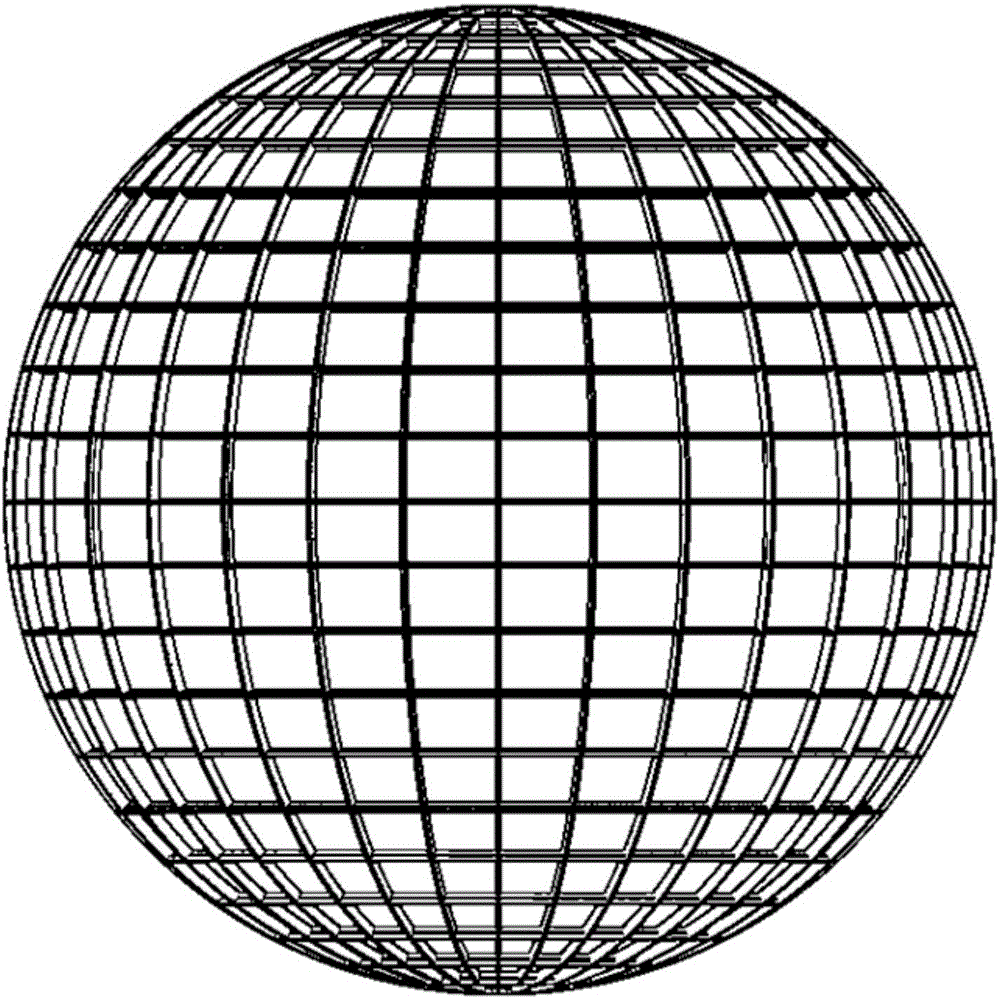

Subdivided sheet combined spherical latticed housing

InactiveCN106567459AIngenious ideaAchieve conversionArched structuresVaulted structuresEngineeringLatitude

The invention discloses a subdivided sheet combined spherical latticed housing. The lattice housing includes longitude flat sheets and latitude flat sheets; a spherical surface is divided into main grids in the longitude direction and the latitude direction; common arc sheet members are arranged in the longitude direction, and discontinuous arc sheet members are arranged in the latitude direction; the main grids are divided into subdivided grids according to a cross-shaped manner or a groined shaped manner; arc flat sheet members are arranged in one direction continuously and arranged in the other direction discontinuously; edges of the subdivided grids are connected to the main grids; and similarly, the subdivided grids are divided into multi-level subdivided grids according to the cross-shaped manner or the groined shaped manner. The components of subdivided sheet combined spherical latticed housing are arc flat sheet members which are easy to process and manufacture, the arc flat sheet members are combined to form a curved spherical housing; the spherical latticed housing is beautiful in appearance and is large in space utilization rate; subdivided main-sub grid structure is adopted, the structural layer is clear, the stability of the flat sheet members can be improved, and the structure integrity is excellent.

Owner:ZHEJIANG UNIV

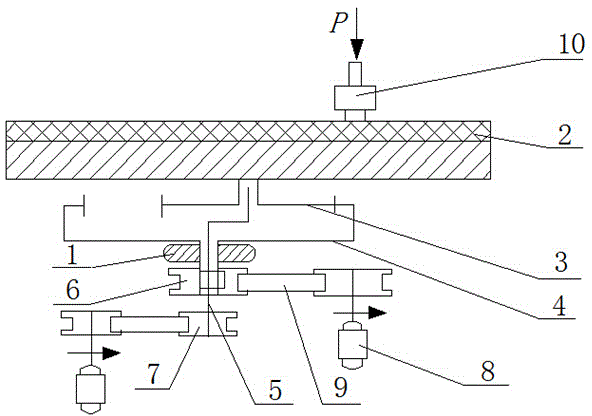

End surface grinding device for fiber connector

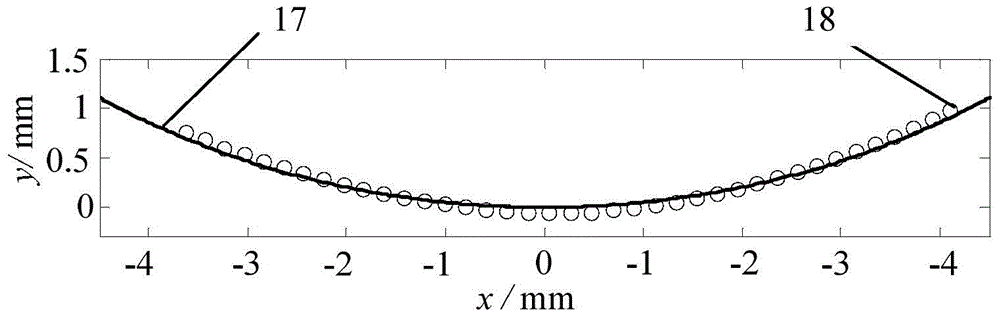

InactiveCN104802070AImprove coupling efficiencySmall change in curvatureGrinding drivesLapping machinesCoupling efficiencySurface grinding

The invention discloses an end surface grinding device for a fiber connector. The device comprises a grinding plate and a rack, wherein the grinding plate is arranged at the upper part of the rack; a planetary gear and a gear ring are arranged between the grinding plate and the rack; a tying rod for connecting the planetary gear with the gear ring passes through the middle part of the rack; a first belt wheel and a second belt wheel are arranged below the rack; the first belt wheel is connected to the gear ring; the second belt wheel sleeves the tying rod; the first belt wheel and the second belt wheel are respectively connected with motors through synchronizing belt. When in grinding and polishing, the average relative speed of the end surface of the fiber connector can be kept constant within the given processing period by the surface; the end surface can form a microsphere surface according to the non-uniform contact pressure of the fiber connector and the grinding plate, so that the purpose of increasing the coupling efficiency of the fiber connector can be achieved, and the grinding plate is avoided irregular wear.

Owner:安庆市吉飞软件开发有限公司

Winding device and winding method for window-type irregular saddle-shaped coil

ActiveCN104124055BImprove inner qualityImprove performanceInductances/transformers/magnets manufactureSaddle coilCopper wire

The invention relates to the technical field of manufacturing processes of window type irregular saddle-shaped coils for compound function electromagnets, in particular to a winding device and method of a window type irregular saddle-shaped coil. The window type irregular saddle-shaped coil comprises step components which are unfolded with two 90-degree flanges on two edges and used for controlling gaps among copper wires of each layer at the 90-degree flanges, the upper edges of wire cakes on each layer are guaranteed to be flush on the same plane after flanging, the step component at one end is horizontally divided into three parts, and gaps are reserved in the middles and used for accommodating copper wire heads, the three parts are fixed on a base plate through locating pins and bolts respectively. A 90-degree back plate is located above the step component with coils unfolded at two ends and used for unfolding two ends of each wire cake to vertical positions layer by layer through a special tool after layer winding, and a saddle shape is formed. The internal quality is good, the performance is reliable, the winding efficiency is high, the cost is low, the boundary dimension and the shape error are small, the stability is excellent, the product consistency is good, the performance of a whole compound electromagnet is modified and improved, the magnetic field index is stable, and the error is small.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

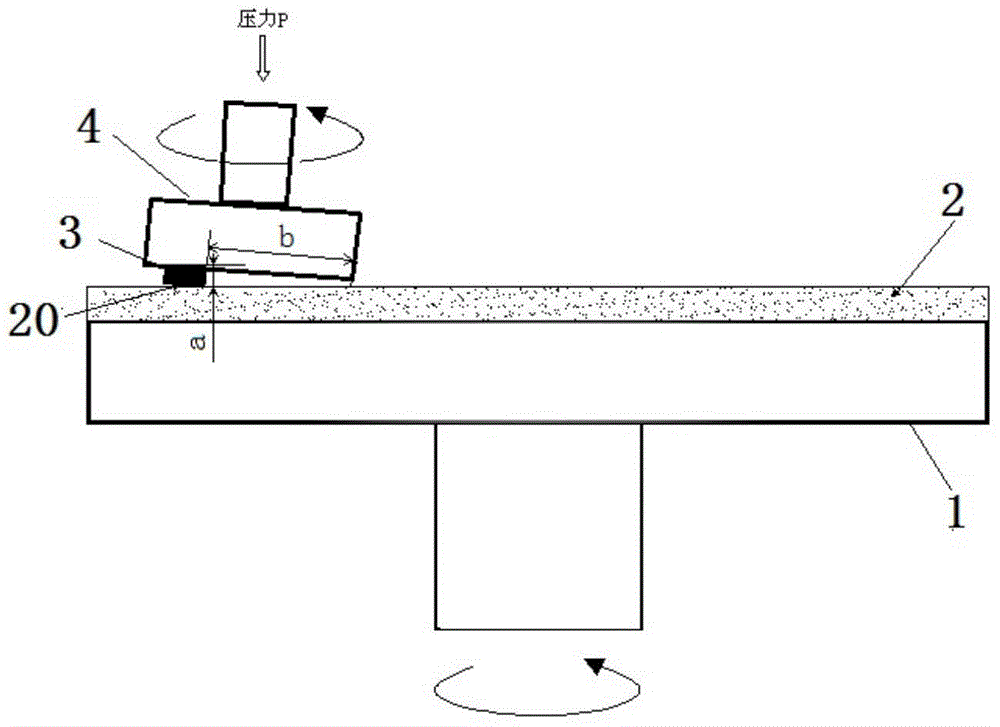

A kind of indentation manufacturing method of surface with microlens or microlens array structure

InactiveCN105607163BFlexible shapeMachining accuracy is easy to controlLensWork performanceMicro lens array

The invention discloses a method for preparing indentations of a surface of a micro-lens or micro-lens array structure. The method comprises the steps of: manufacturing an indenter with an end having the micro-lens shape; performing smooth machining of the to-be-shaped surface of the micro-lens or micro-lens array structure; on a forming press, machining by the indenter with the speed as s and the pressure as m according to the indentation method to form lens-shaped indentations on the surface to be shaped; measuring and calculating the error between the indentation shape and the lens shape of the end of the indenter and compensating or modifying the shape of the indenter; carrying out indentation formation again by using the indenter which is already subjected to shape compensation or modification; if it is required to form the micro-lens array structure, setting the vertical and horizontal distances based on the working performance of the lens array, machining with the vertical and horizontal distances as the distance close to the lens center to generate other indentations on the mould plane and forming the micro-lens array structure; and cutting off the material bump parts generated during the indentation extrusion process and performing coating. The method simplifies the procedures of the batch treatment process for the surface of the micro-lens or micro-lens array structure.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

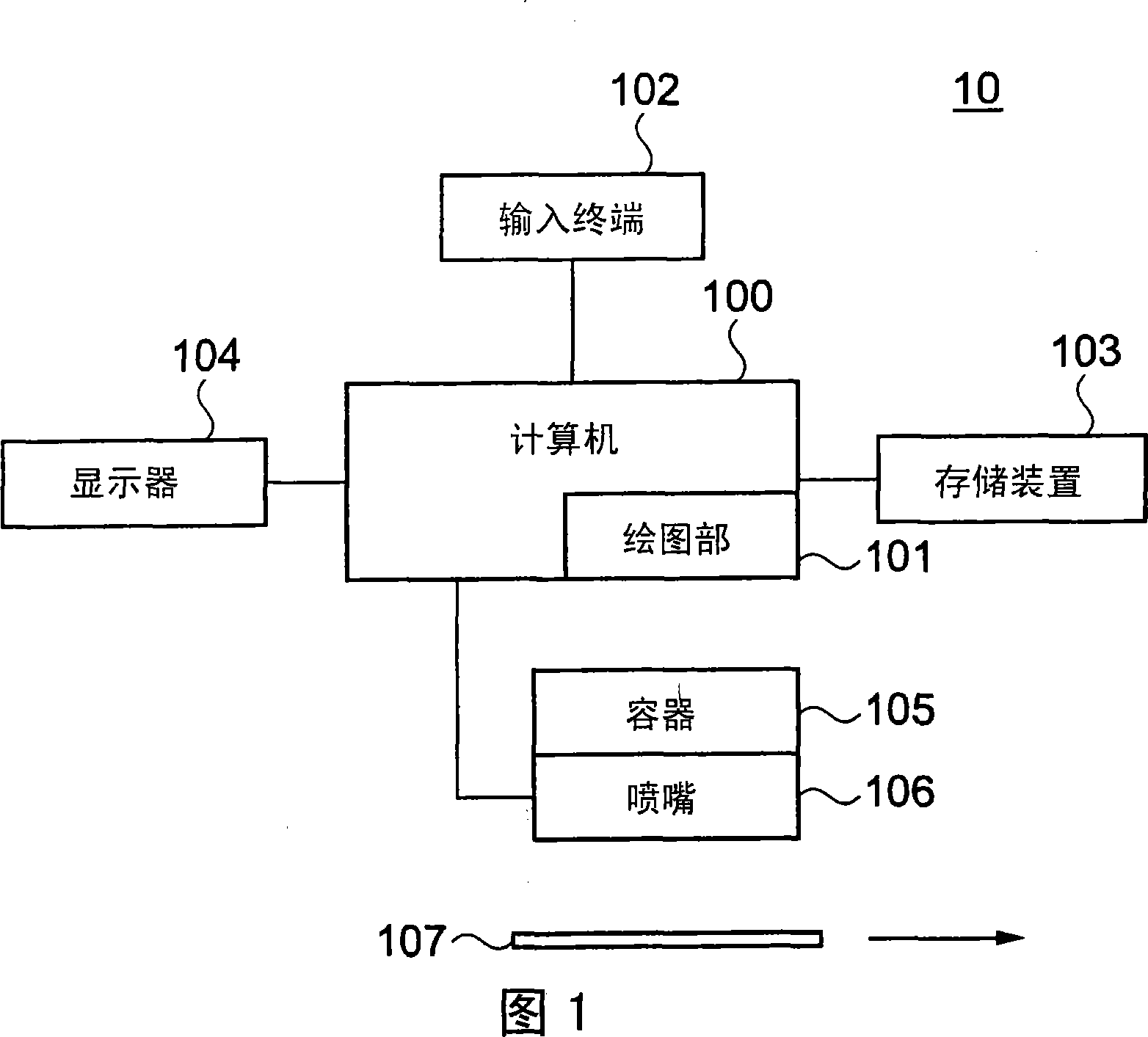

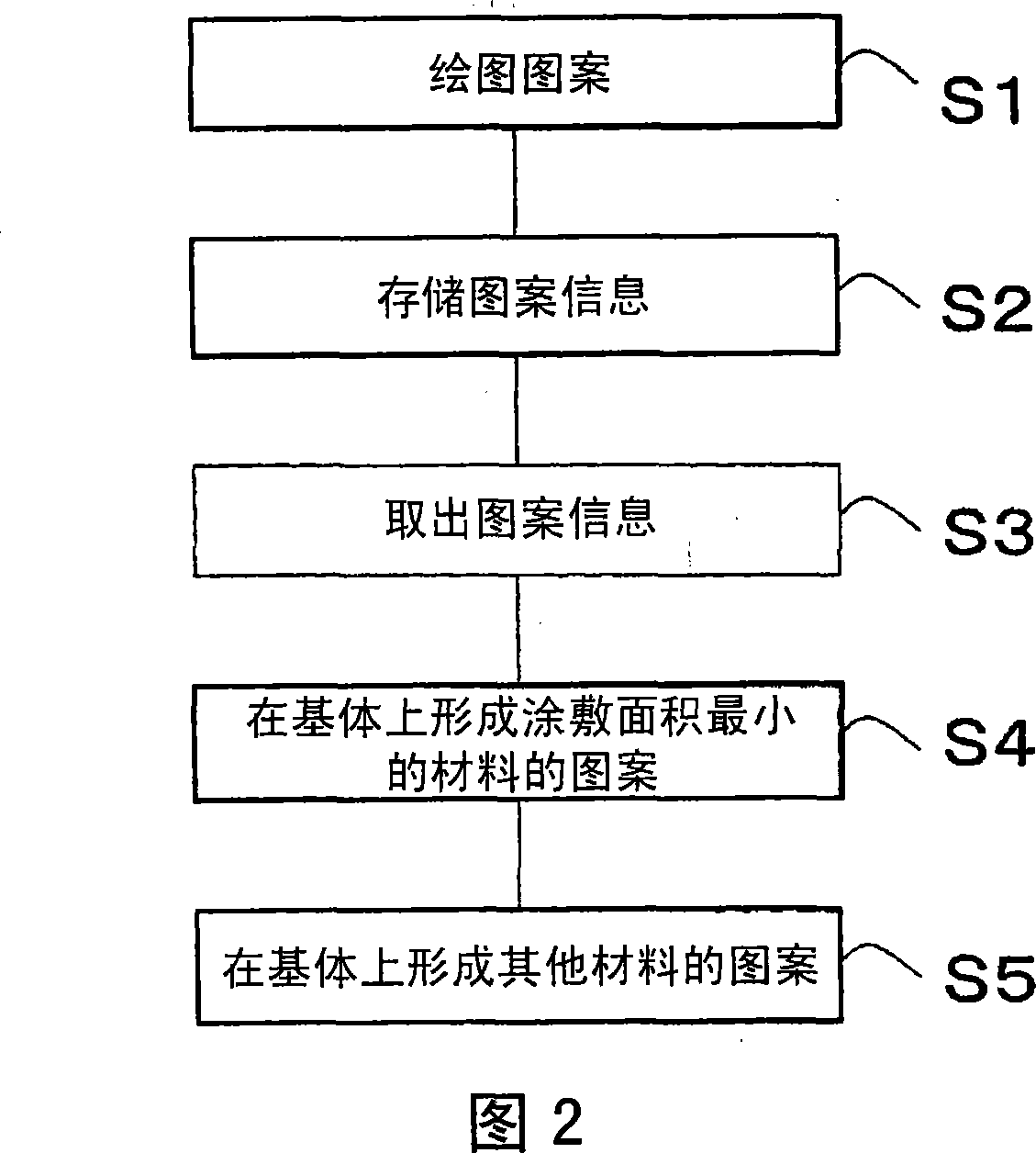

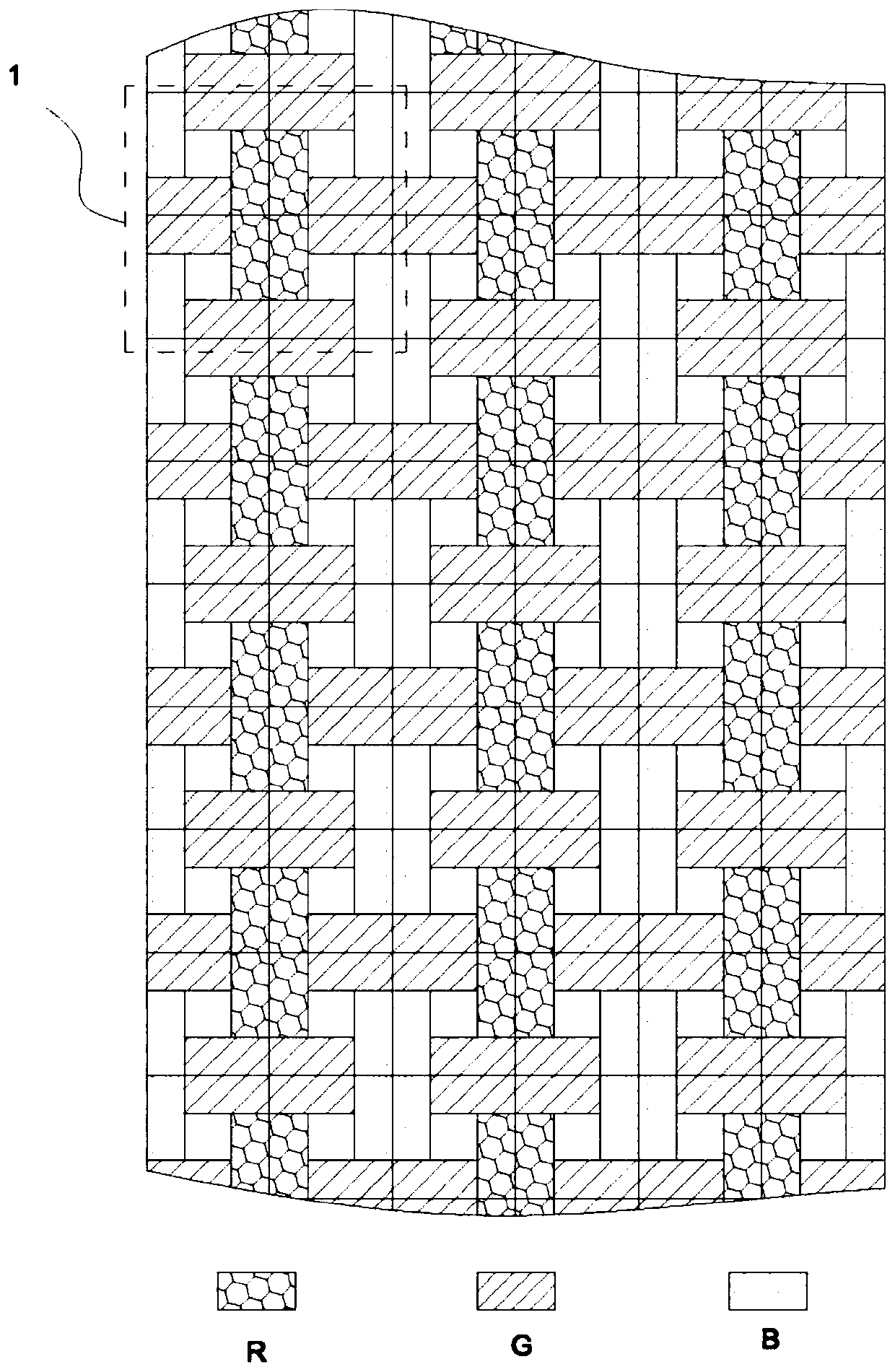

Process for forming functional film, and process for producing electrode and secondary battery

ActiveCN101060171AClose in performanceReduce mistakesLiquid surface applicatorsFinal product manufactureMaterials scienceCoating

A method is provided for forming a functional film having at least first and second functional materials arranged in accordance with a prescribed coating pattern on a substrate. The method includes discharging the first functional material having a smaller coating surface area than the second functional material according to the prescribed coating pattern onto the substrate using a droplet discharge apparatus, and discharging the second functional material according to the prescribed coating pattern onto the substrate using the droplet discharge apparatus after the first functional material is discharged onto the substrate.

Owner:SEIKO EPSON CORP

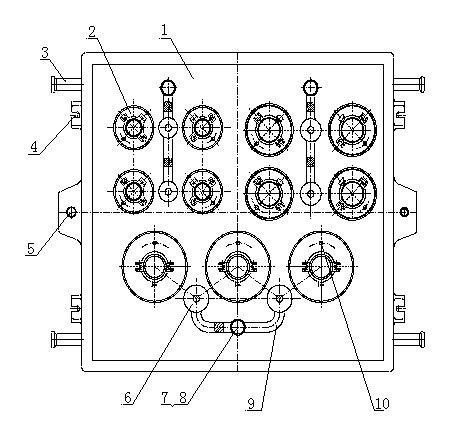

Manufacturing method of vacuum inner ultra-large quadrupole lens

The invention discloses a method for manufacturing a vacuum inner ultra-large quadrupole lens, which comprises the steps of decomposing and designing the quadrupole lens into four magnet yokes and four magnetic poles, forging a blank, and performing heat treatment; processing a magnet yoke and a magnetic pole, and pre-assembling a lens iron core; carrying out disassembling and nickel plating; winding a semi-finished coil, and carrying out epoxy vacuum pouring to obtain a coil; disassembling the four nickel-plated parts, installing the coil, and assembling to obtain a quadrupole lens iron core;welding an end cover at one end of the vacuum pipeline with radiating strips; installing iron core water cooling pipes on two end surfaces of the quadrupole lens iron core; enabling the vacuum pipeline with the radiating strips to penetrate into a central hole of the quadrupole lens iron core, connecting an iron core water cooling pipe with a cooling water pipe on the end cover, and welding the other end cover; and enabling a coil wire outgoing line and the cooling water pipe on the end cover to sequentially penetrate into a transition section vacuum pipeline and a vacuum isolation pipeline to obtain the vacuum inner ultra-large quadrupole lens. According to the manufacturing method, the coil is isolated from the vacuum environment, the vacuum degree is not affected, and the performance of the ultra-large quadrupole lens in vacuum is improved.

Owner:兰州科近泰基新技术有限责任公司

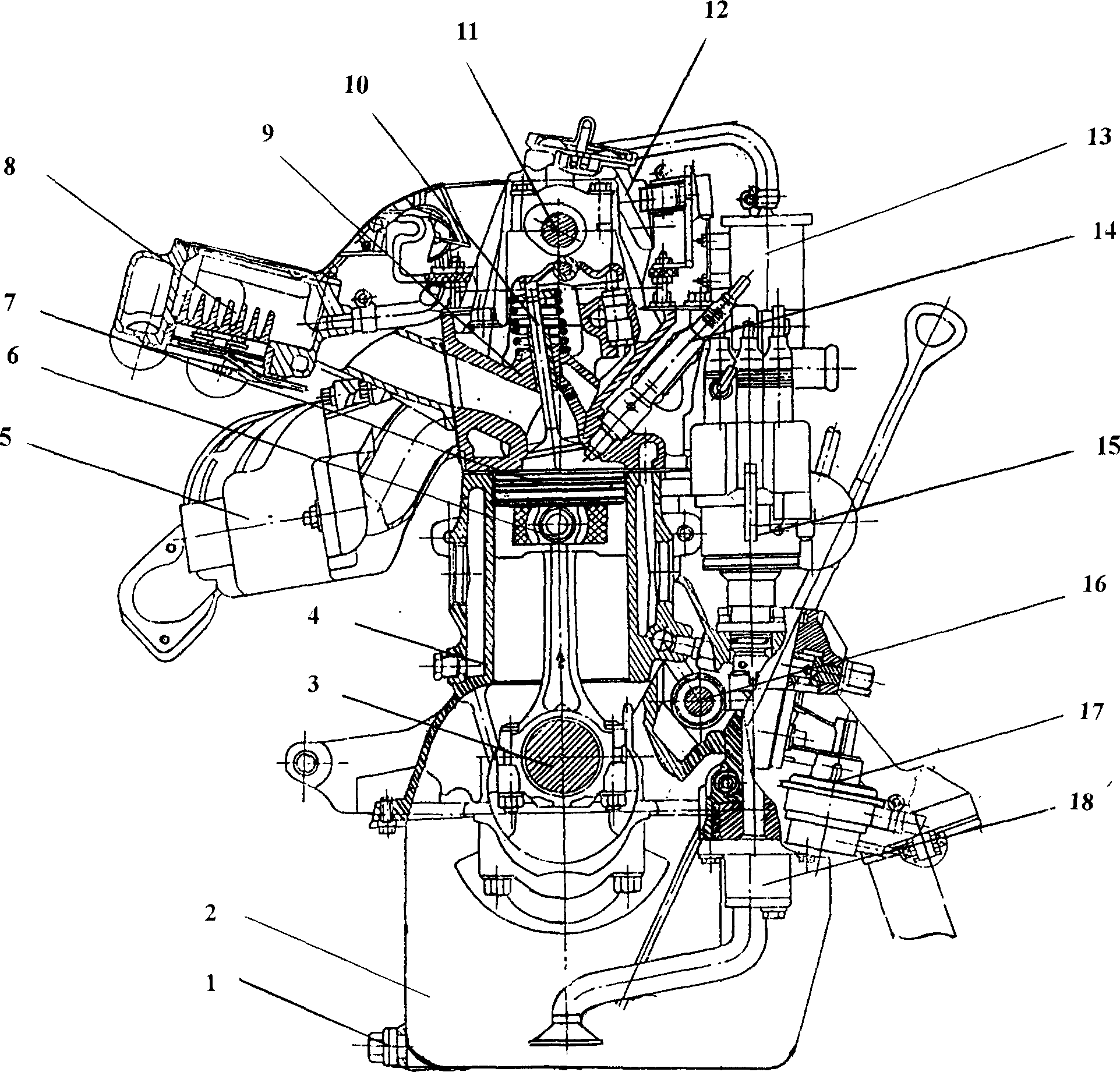

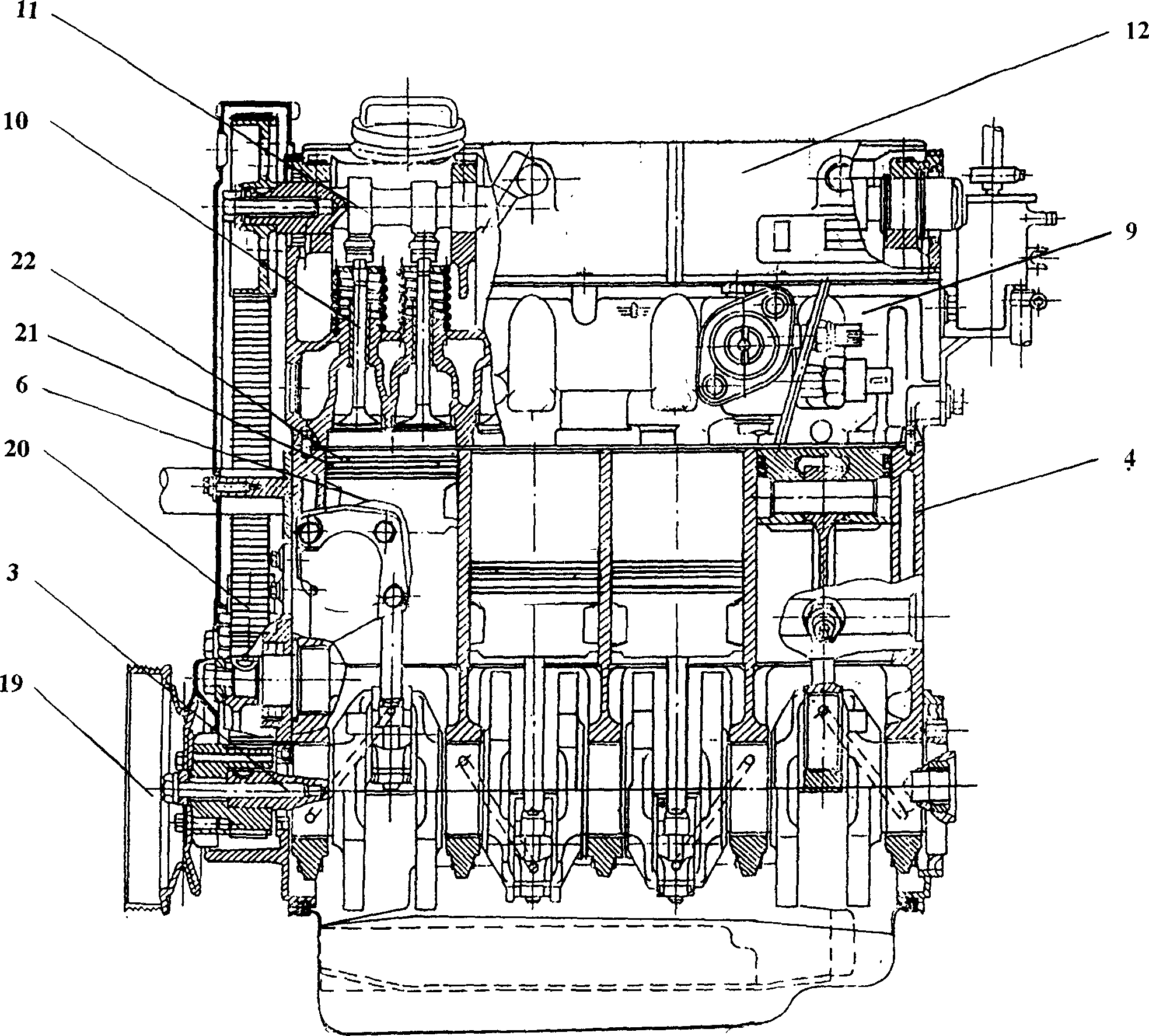

Combined piston gas ring internal combustion engine

InactiveCN1807867APrevent up and down movementEliminate oil pumpingSealing arrangements for enginesMachines/enginesCombustionExternal combustion engine

Disclosed is combination type internal-combustion piston engine, wherein the air ring groove of the piston is provided with an upper auxiliary torsion air ring and a lower main air ring. The invention realizes simplified structure and manufacturing process, low cost, better hermeticity and thermal conductance, and reduced discharge of engine contaminant.

Owner:王雪松

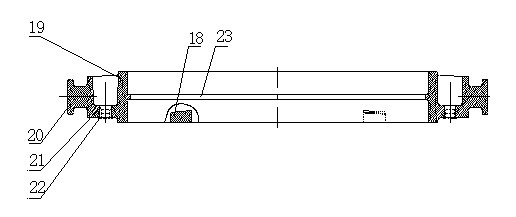

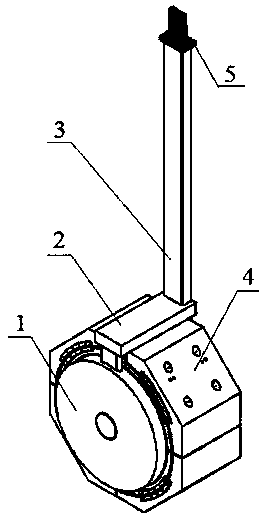

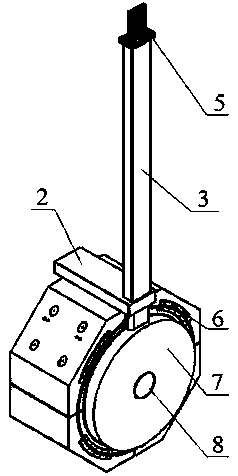

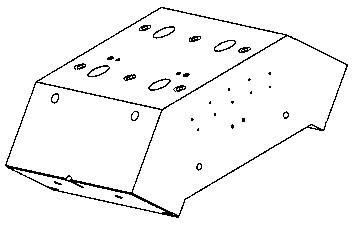

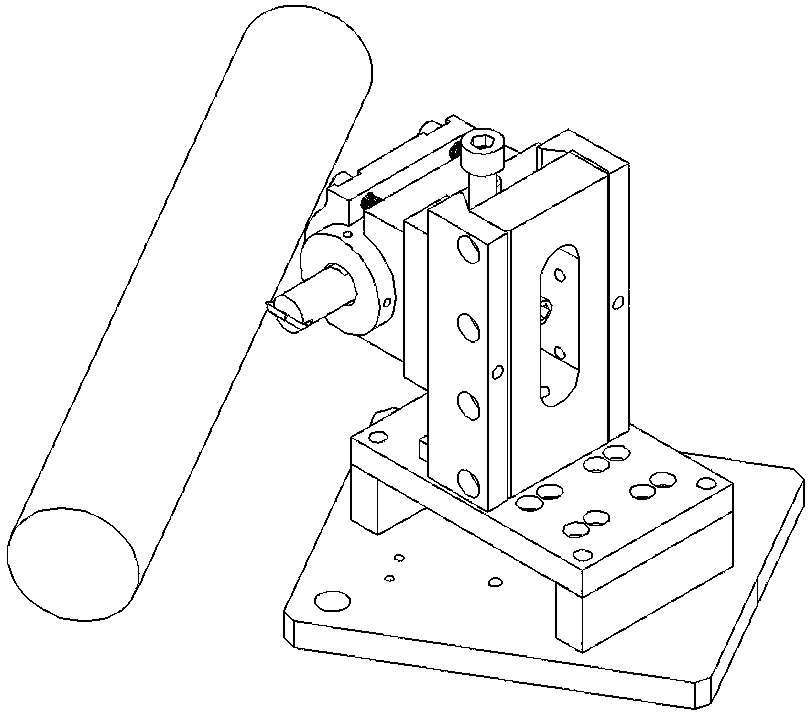

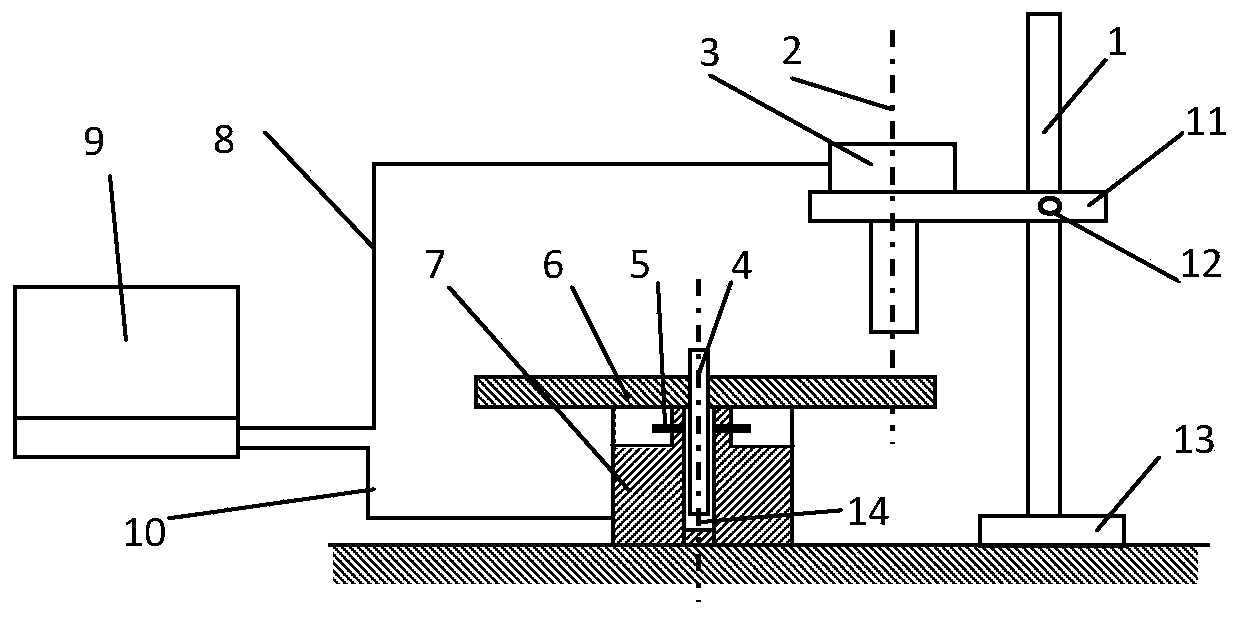

One-dimensional ultrasonic linear vibration turning device

InactiveCN111390200AChange cutting propertiesImprove surface qualityAuxillary equipmentLarge fixed membersEngineeringLinear vibration

The invention discloses a one-dimensional ultrasonic linear vibration turning device, and belongs to the technical field of turning devices. The technical problem of surface quality after cutting is solved. According to the solution scheme, a central rotating block is arranged below the center of a bottom plate, a pad block is detachably arranged above the bottom plate, a guide rail mounting plateis arranged across the pad block, a swallowtail slot left guide rail and a swallowtail slot right guide rail are arranged vertically above the guide rail mounting plate, and the left side and the right side of a swallowtail slot base are separately matched with the swallowtail slot left guide rail and the swallowtail slot right guide rail; and a sliding block seat is arranged on the outer side ofthe swallowtail slot base, a clamping seat is mounted on the outer side of the sliding block seat, a pin shaft is arranged between the assembly surface of the sliding block seat and the clamping seat, the clamping seat rotates around the pin shaft, and a through hole for clamping a variable amplitude rod assembly is formed in the clamping seat. The one-dimensional ultrasonic linear vibration turning device can improve the surface quality after cutting, and can select suitable cutting process parameters such as edge inclination angles, main deflection angles and front angles according to different materials and working conditions.

Owner:TAIYUAN UNIV OF TECH

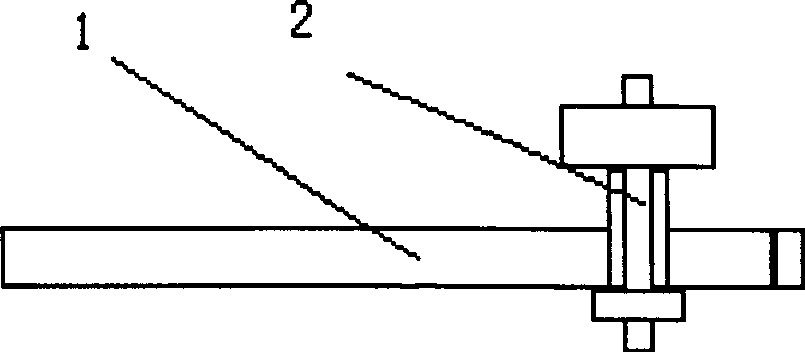

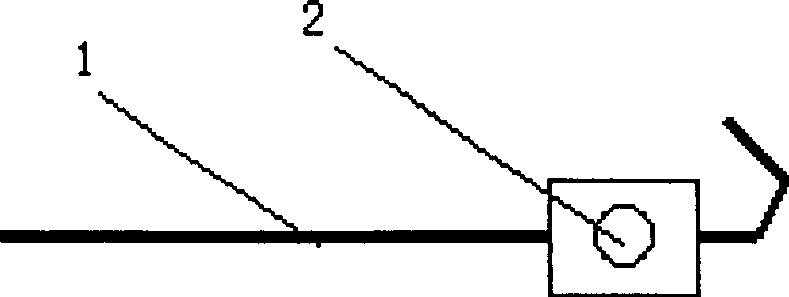

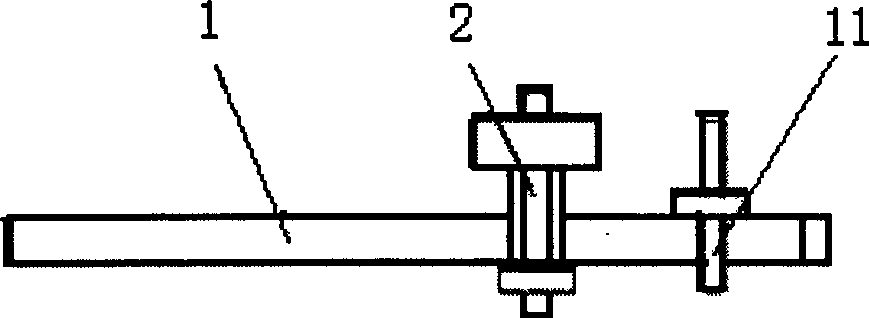

Working device and method for band-type blade

The invention relates to a processing device with band shape blade and a bender and two sets of punch device. The first set of punch die is set in front of the bender, the second set behind. The first set can have different punch die structure, and the second has a structure with band blade bottom end. When the distance between the bender and the second punch die is long, it can be rectified by the rectifier between the bender and the punch die. The manufacturing for the band shape blade comprises the bending and cutting the blade into two parts. When the material band blade is fed in throughthe first punch die, the top of the punch cut out the required precision and shape notch, then the strip shape blade is fed into the bender for bumping to form the band blade connected with the stripblade. Then, send to the second punch die to cut off the bottom end of the strip blade to the final product. Return the strip blade to the bender after the band blade is separated from the strip blade and recycle it again and again.

Owner:RICHLY TOP CNC EQUIP SHENZHEN CO LTD

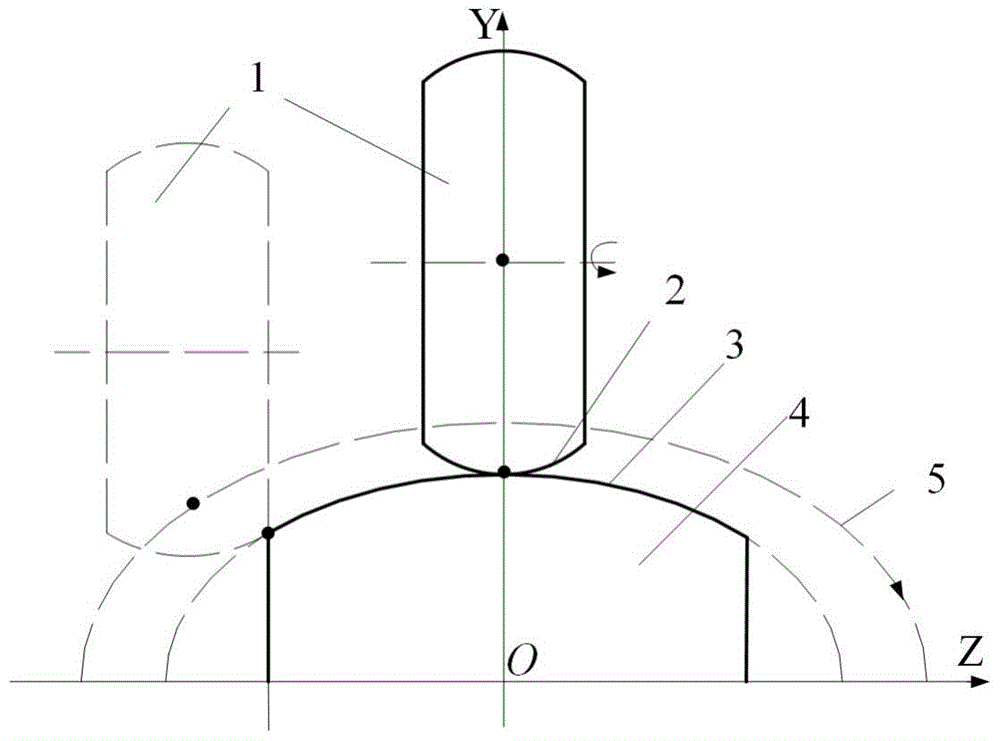

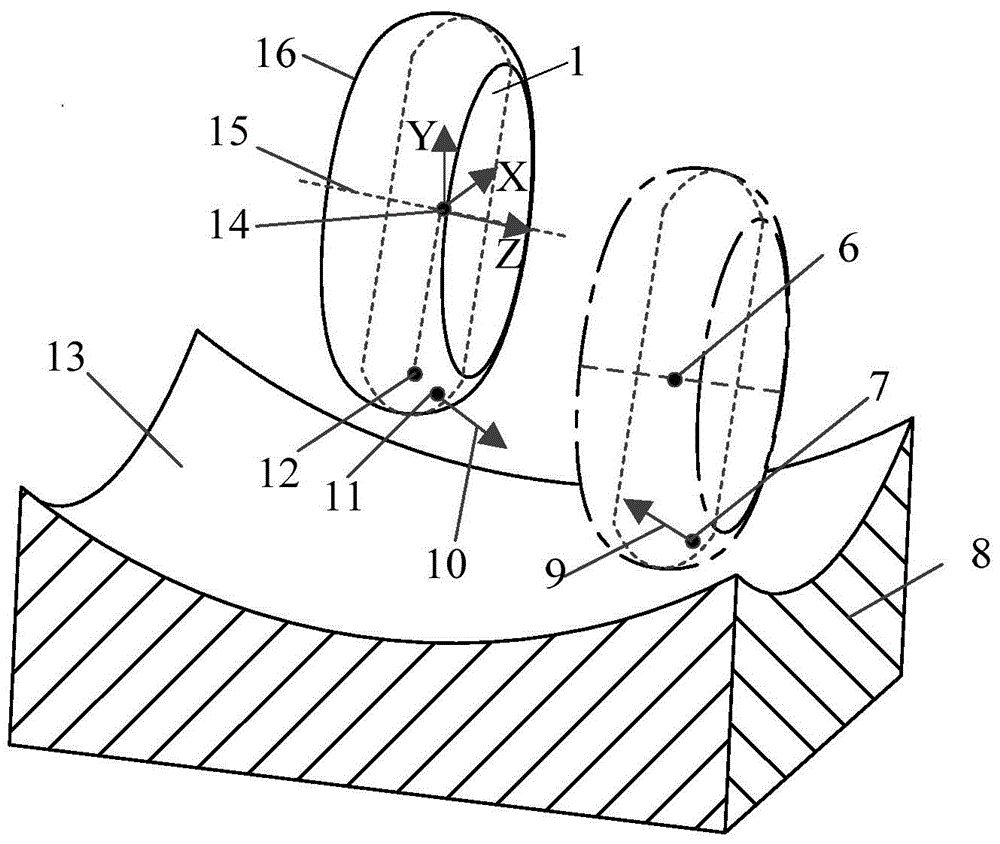

Method for machining inner spherical surface of bearing seat through movement forming

InactiveCN107717669AShape error reductionSmall shape errorSpherical surface grinding machinesGrinding feedersSpherical bearingGrinding wheel

The invention discloses a method for processing the inner spherical surface of a bearing seat through motion forming. The inner spherical surface of the bearing seat is ground with a diamond grinding wheel, which can be used for a long time without shaping and grinding, because the processing method of the present invention is formed by a motion The method of grinding the inner spherical surface adopts three numerical control feeding steps of diamond grinding wheel spherical center feeding, bearing seat spherical center feeding and diamond grinding wheel spherical diameter feeding, and uses the compound rotation circle of the bearing seat and the rotation circle of the diamond grinding wheel to form The ball is used to complete the grinding of the inner spherical surface of the bearing seat. The invention discloses a method for processing the inner spherical surface of the bearing seat through motion forming, without the need of correcting the grinding wheel, the grinding wheel has a long service life, and the processing accuracy and efficiency are high.

Owner:福建省德源智能科技有限公司

Method for producing optical element with holding frame

A method for making a holder / optical-element assembly includes the steps of positioning a cylindrical holder material in a press-molding die, the holder material having a void part in the inner circumferential surface, positioning an optical-element material inside the holder material, heating the holder material and the optical-element material to their own softening temperatures, press-molding the holder material and the optical-element material to form a cylindrical holder and an optical element, respectively, thereby fixing the optical element to the inside of the holder, allowing a part of the optical element to project outwardly from the outer edge by pressure created during press-molding, and retaining the projected portion in the void part of the holder.

Owner:ALPS ALPINE CO LTD

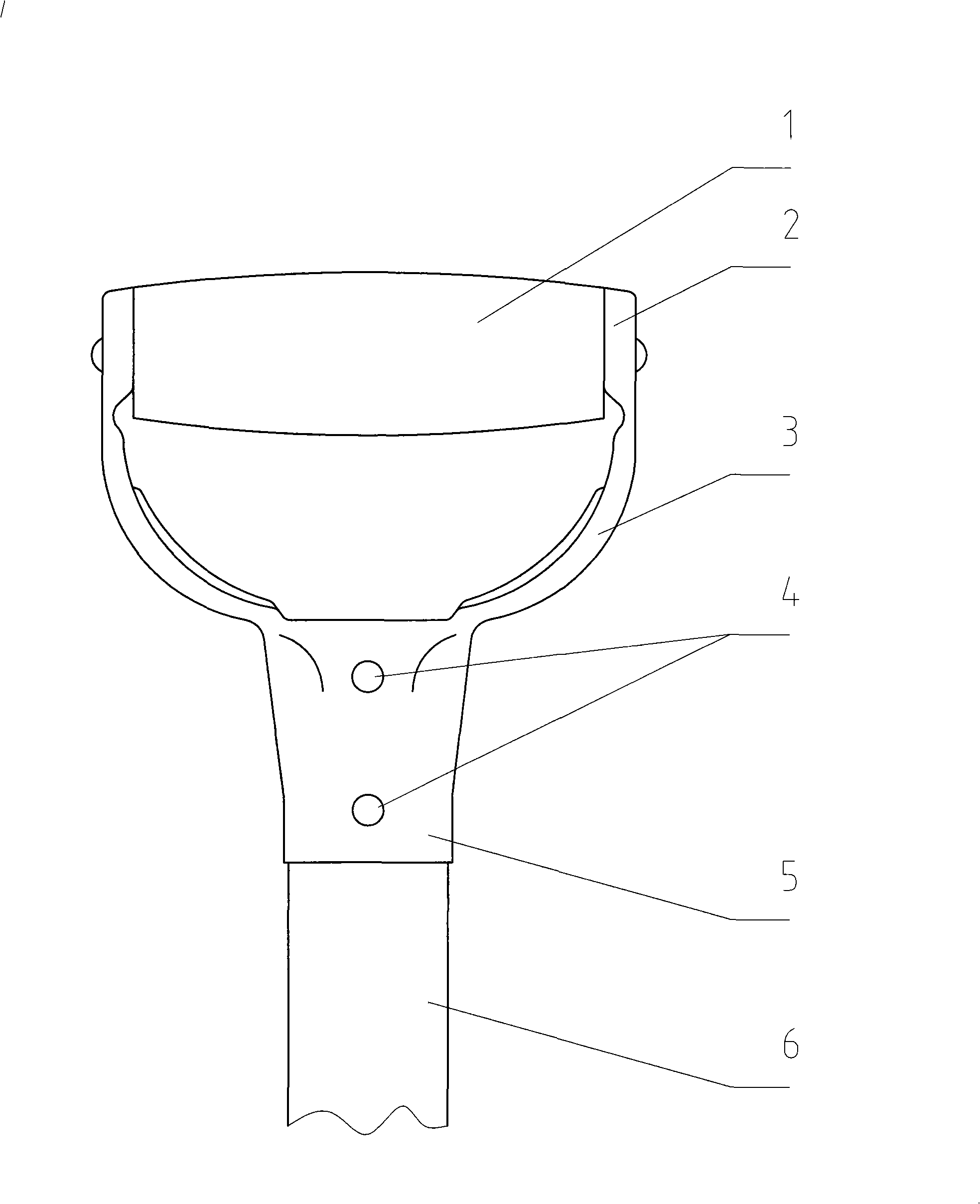

Integral type garden tool handle

InactiveCN101301750ASimple structureEasy to useMetal-working hand toolsSEMI-CIRCLEMechanical engineering

The invention relates to a tool handle, in particular to an integrated garden tool handle. The handle comprises a handle body and a holding handle; the handle body is composed of an upper supporting body which is fixed with the holding handle and a lower connecting body which is fixed with the tool handle; the supporting body is provided with a convex stiffener; the connecting body is composed of two arc surfaces which are less than the semi-circle; two arc surfaces and the supporting body are an integral connecting structure by punch forming; the integral connecting structure is arranged with a connecting hole. The handle has simple structure and convenient usage, reduces the material usage, has small shape error generated during the assembly process, has no needs of alignment, and effectively reduces the operation difficulty and improves the operation efficiency.

Owner:TANGSHAN YANNAN SHOVEL MAKING

A method for grinding wheel with arbitrary curved surface for precision grinding of curved surface

ActiveCN104741994BAvoid single point contact machiningReduce wear rateGeometric CADGrinding machinesPoint cloudEngineering

Owner:SOUTH CHINA UNIV OF TECH

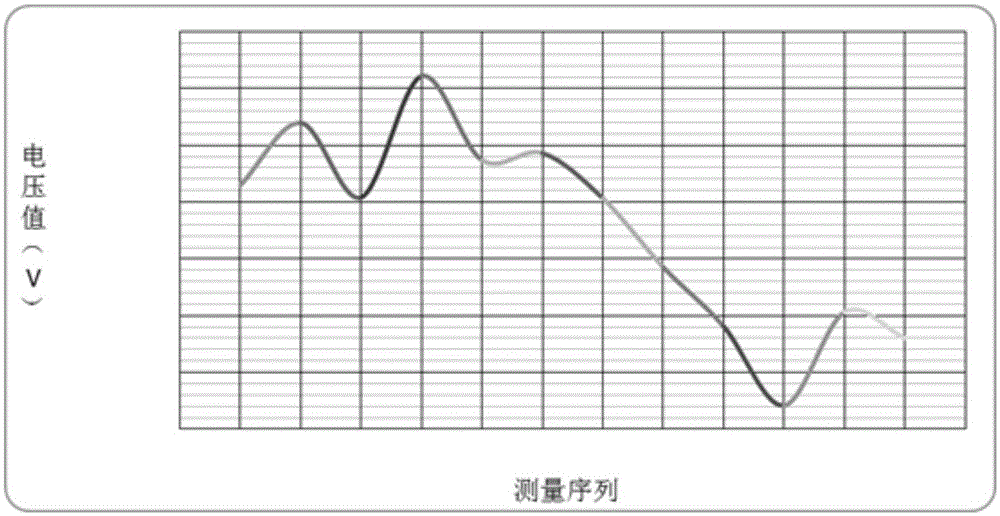

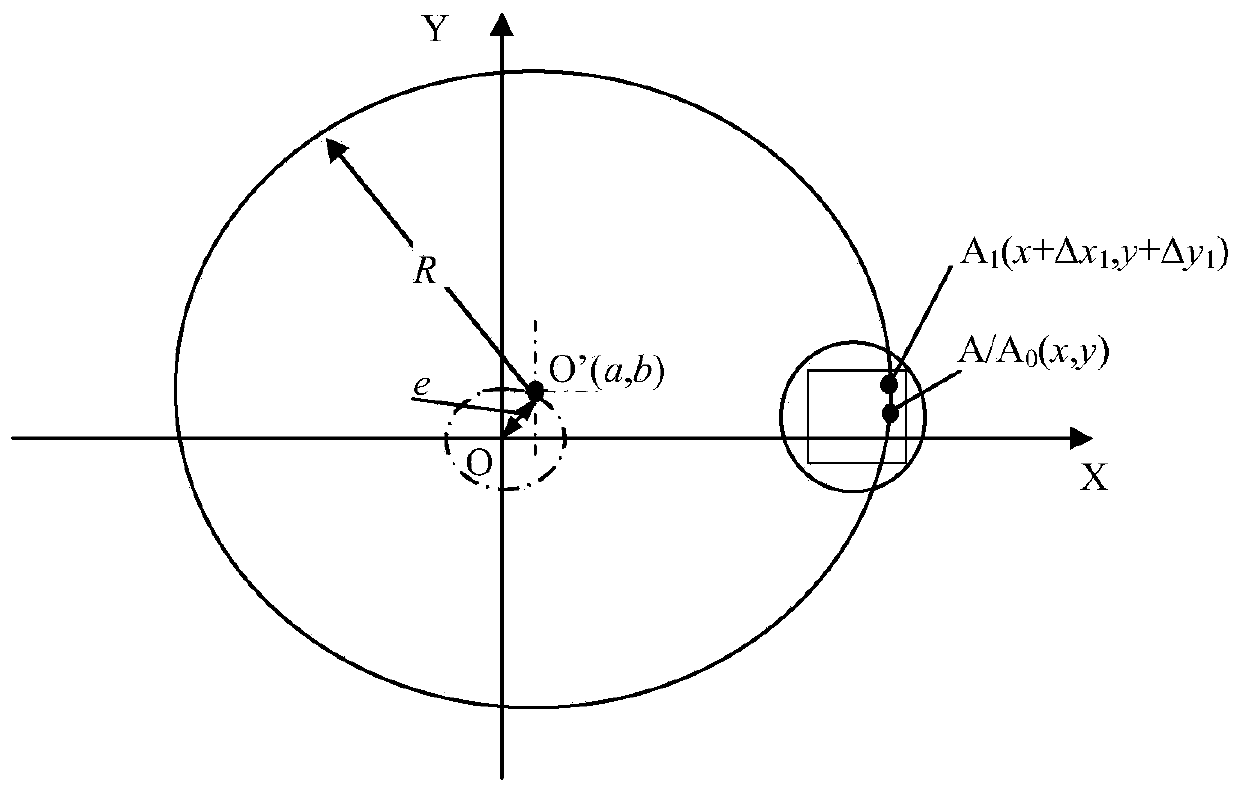

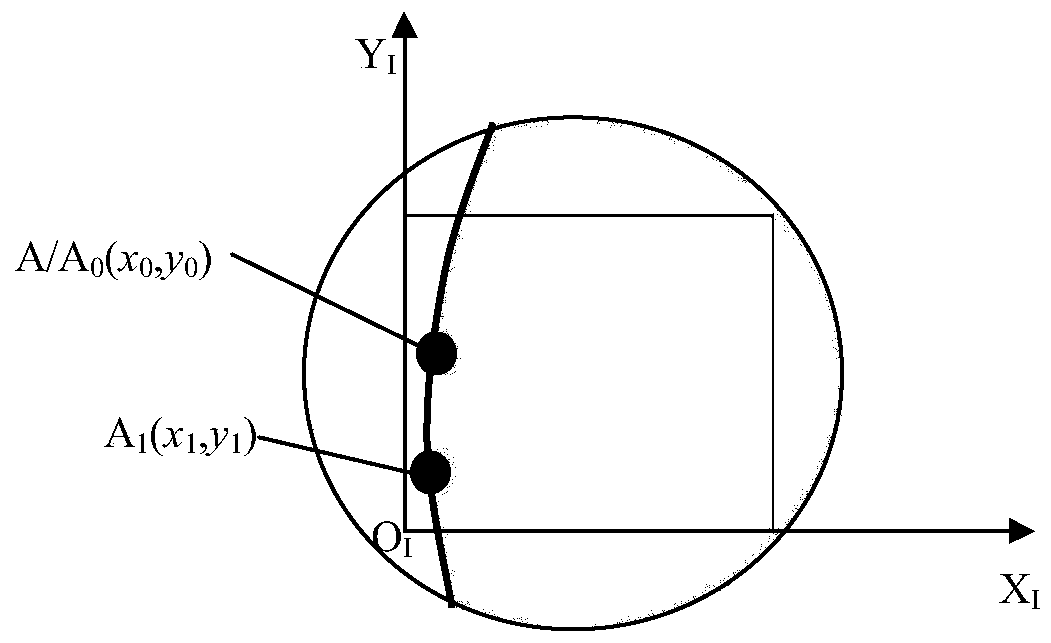

Radius of turntable and mounting eccentric four-index coordinate incremental detection method and detection device

The invention relates to a method and a device for detecting a turntable radius and installation eccentricity four-rotation-position coordinate increments. A rotating shaft of a tested turntable component is fixed on a standard turntable, a circumferential eccentric rotation position fixed point coordinate increment equation set of each point of four rotation positions is established, the equationset is solved to obtain a central deviation coordinate of the turntable at an initial rotation position, and the turntable radius, the installation eccentricity and the central deviation of the turntable at any rotation position are calculated. The device is simple and practical and is easy to operate; the proposed method is simple, convenient, high in precision and is easy to implement, efficient and high-precision measuring device and method are provided for the size and error detection of turntable components, and reference is provided for the fine tuning of the concentricity of the turntable components. The method and device provided by the invention are suitable for the size and eccentricity error detection of the turntable components such as a circular grating, a mechanical modulation disk, a coded disk of a photoelectric encoder, and the like, and are especially suitable for the detection in which the eccentricity error of the turntable is relatively small, and the size and shape errors are much smaller than the eccentricity error.

Owner:耿佳钰

Sparassis crispa bag-planting device adopting necking ring and using method of sparassis crispa bag-planting device

ActiveCN109937804AStable structureNot easy to fall offCultivating equipmentsMushroom cultivationSparassis crispaEngineering

The invention relates to the technical field of a sparassis crispa bag-planting process, and discloses a sparassis crispa bag-planting device adopting a necking ring and a using method of the sparassis crispa bag-planting device. The bag-planting device comprises a plastic bag, a compost, a original matrix, a sealing ring, a sealing plug and the necking ring, wherein the compost is arranged in theplastic bag, the original matrix is arranged on the surface of the compost, the sealing ring and the sealing plug are arranged at the mouth of the plastic bag, and the necking ring is arranged on theouter wall of the plastic bag; and the necking ring comprises a ferrule and a bottom support, and the ferrule is arranged above the bottom support. The using method comprises the following steps: penetrating the necking ring in the sealing ring and the sealing plug vertically and downwards and pressing the necking ring on the surface of the compost fixedly by a user with one hand, lifting up thesealing ring by the user with the other hand, tensioning the plastic bag, enabling the plastic bag to unfold completely, and keeping the mouth of the plastic bag upright. The sparassis crispa bag-planting device adopting the necking ring has the characteristics of convenience in use, uniform specification and cost saving.

Owner:容益(海南)农业开发有限公司 +1

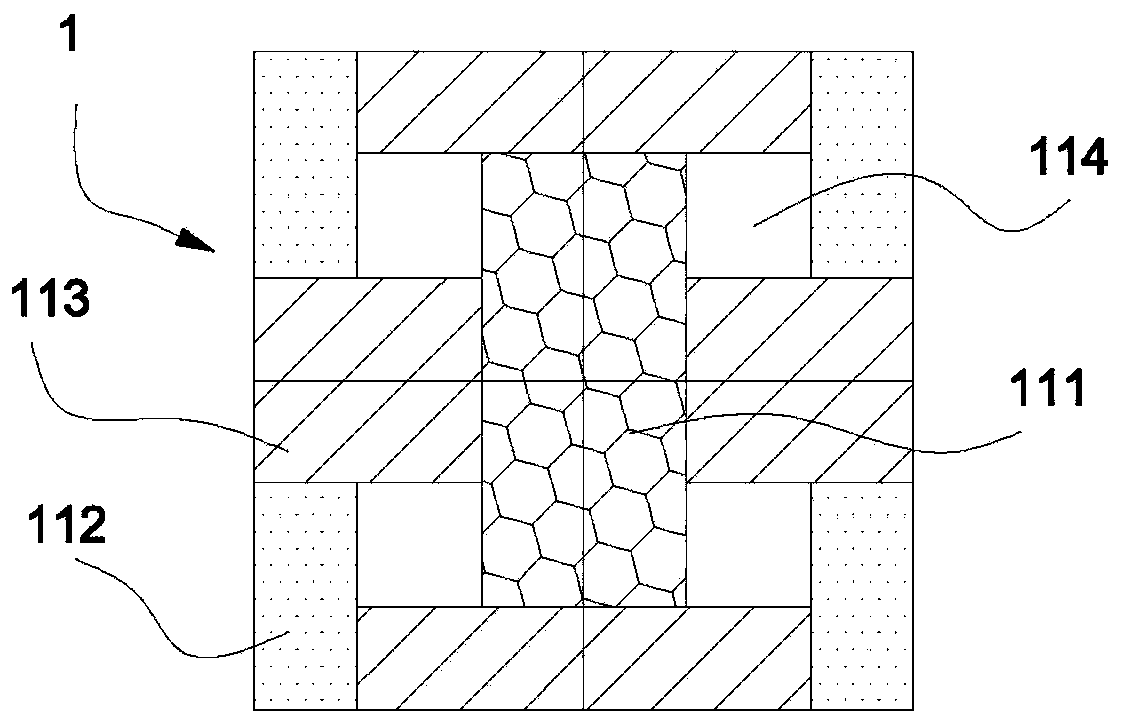

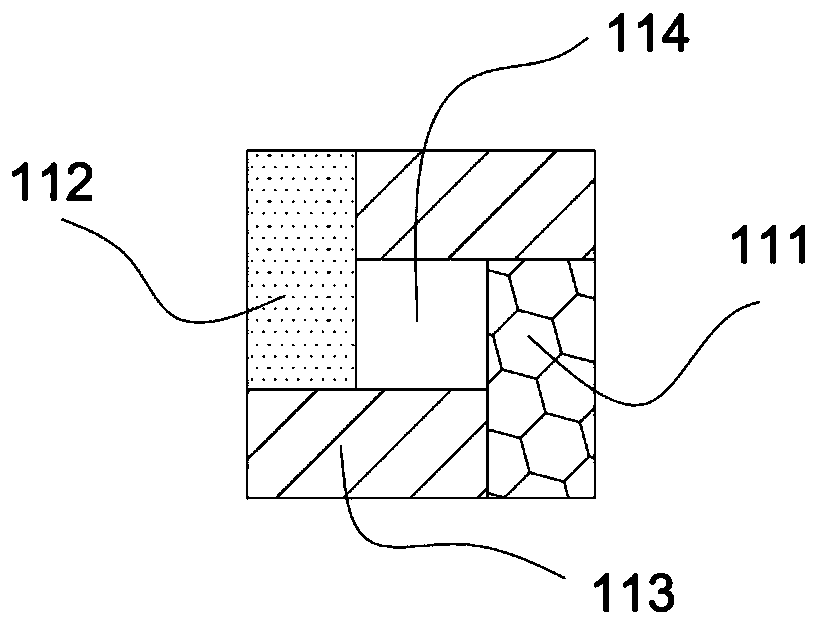

Pixel arrangement structure, display panel and display device

InactiveCN109904194AImprove PPIReduce manufacturing difficultySolid-state devicesSemiconductor devicesPixel densityDisplay device

The invention discloses a pixel arrangement structure, a display panel and a display device. The pixel arrangement structure comprises multiple repeating units, and each repeating unit comprises multiple subunits arranged in an array; each subunit comprises multiple sub-pixels, the multiple sub-pixels comprise at least three sub-pixels with different colors, the multiple sub-pixels are arranged ina circular pattern, and two adjacent sub-pixels on a circular arrangement track have different colors; and on the track, one or more one sets of relative arrangement sub-pixels have the same color. According to the pixel arrangement structure, the display panel and the display device, mask making difficulty is reduced, and pixel density of the display device is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

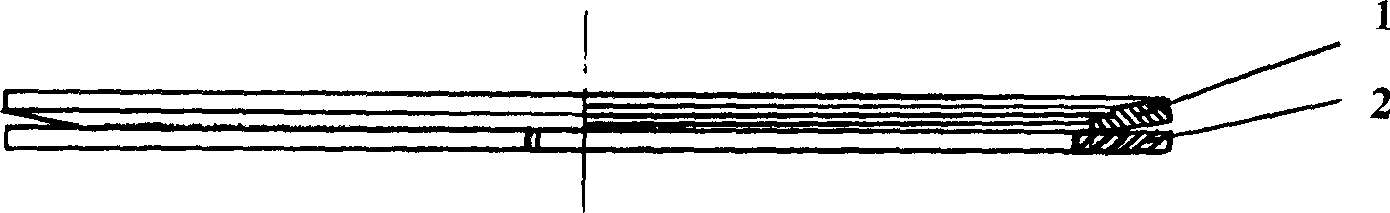

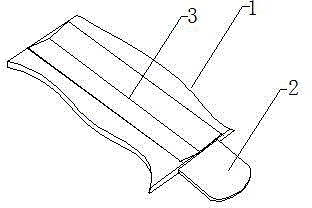

Diamond band saw blade

InactiveCN105799066ACutting efficiency is lowImprove grinding efficiencyStone-like material working toolsBand shapeMetallic materials

The present invention discloses a diamond band saw blade. The diamond band saw blade comprises a stainless steel base body, a row of strip-shaped teeth fixed on the stainless steel base body, and a row of sawteeth extruded from the side surface of the stainless steel base body; the strip-shaped teeth and the sawteeth are formed by diamond; the stainless steel base body is band-shaped; the sawteeth project from the stainless steel base body by 3mm; and the front sides of the sawteeth are annular. According to the diamond band saw blade, the stainless steel base body is driven by a rotating shaft to move circumferentially, and the sawteeth formed by the diamond are used for cutting; the diamond band saw blade is high in grinding efficiency, low in shape error and easy to retain; the diamond band saw blade is capable of cutting silicon columns, graphite, jade products, ceramics and other metal materials efficiently; in addition, for partial small changes, the strip-shaped teeth on the outer surface of the stainless steel base body are directly used for shaping; and as a result, the purposes of grinding and cutting are achieved.

Owner:天津鑫凯建业科技有限公司

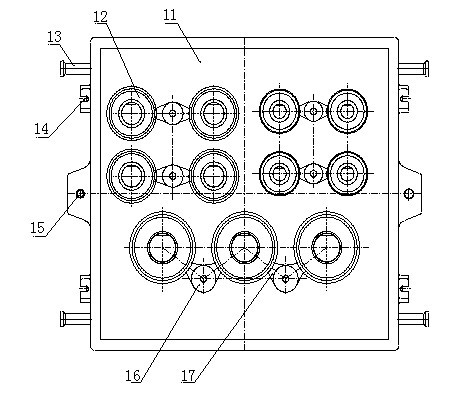

Manufacturing method of four-channel special-shaped deflection magnet in vacuum

The invention relates to the technical field of the technologies for manufacturing ion beam deflection electromagnets-four-channel special-shaped deflection magnets, in particular to a method for manufacturing a vacuum special-shaped deflection magnet with four internal channels. The method for manufacturing the vacuum special-shaped deflection magnet with the four internal channels comprises the steps that the periphery, the upper surface and the lower surface of a left magnet body, the periphery, the upper surface and the lower surface of a right magnet body and the periphery, the upper surface and the lower surface of a middle magnet body are respectively machined, and oblique planes of the three magnet bodies are machined on a large CNC machining center; with the bottom surfaces of the magnet bodies as the criterion, coil grooves are machined in the three magnet bodies respectively on the large CNC machining center; the machined magnet bodies are preassembled; a coil is wound around a machined coil winding die; epoxy vacuum pouring is conducted on the coil; the coil is packaged in a vacuum box after epoxy vacuum pouring is completed; helium mass spectrometer leak detection is conducted on the vacuum box containing the coil, wherein the vacuum degree reaches 1*10<-8> Pa, and the vacuum leak rate is not higher than 1*10<-9>Pa.L / S; the vacuum box, containing the coil, judged to be qualified through leak detection and an iron core are assembled together, and magnetic field testing is conducted. According to the method for manufacturing the vacuum special-shaped deflection magnet with the four internal channels, the magnet manufactured according to the method is simple in structure, assembly is easy and fast, adjustment is convenient, the machining precision is high, and the boundary dimension error and the shape error are small.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

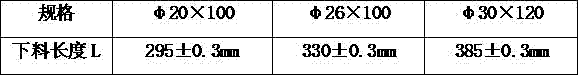

A kind of production method of stainless steel round link chain

The invention discloses a production method for a stainless steel round-link chain. The production method mainly comprises the following steps: selecting raw materials; blanking; performing hot chain weaving; performing shot blasting; performing flash butt welding; stretching and correcting; pickling; inspecting. The production method adopts a high-efficiency, automatic and assembling-line mode; the welding performance and the size precision of a product are ensured by a flash butt welding sequence, so that the appearance error of the product is small, and the product quality is ensured; after pickling treatment is adopted, so that stainless steel large-diameter round-link chain products of Phi 20X100, Phi 26X100 and Phi 30X120 are excellent in corrosion performance; the production method is more suitable for conveying work of high-corrosion chemical solution, such as hydrochloric acid.

Owner:SHANDONG LIANGDA FASING ROUND LINK CHAINS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com