A method for grinding wheel with arbitrary curved surface for precision grinding of curved surface

A technology for precision grinding and surface contouring, which is used in grinding/polishing equipment, grinding machines, special data processing applications, etc. It can solve the problems of fast tool wear and low processing efficiency, improve shape accuracy and reduce grinding wheel wear rate. , to avoid the effect of single-point contact processing of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited to the scope shown in the examples.

[0043] A kind of method that arbitrary curved surface grinding wheel is used for the precision grinding of curved surface, comprises steps:

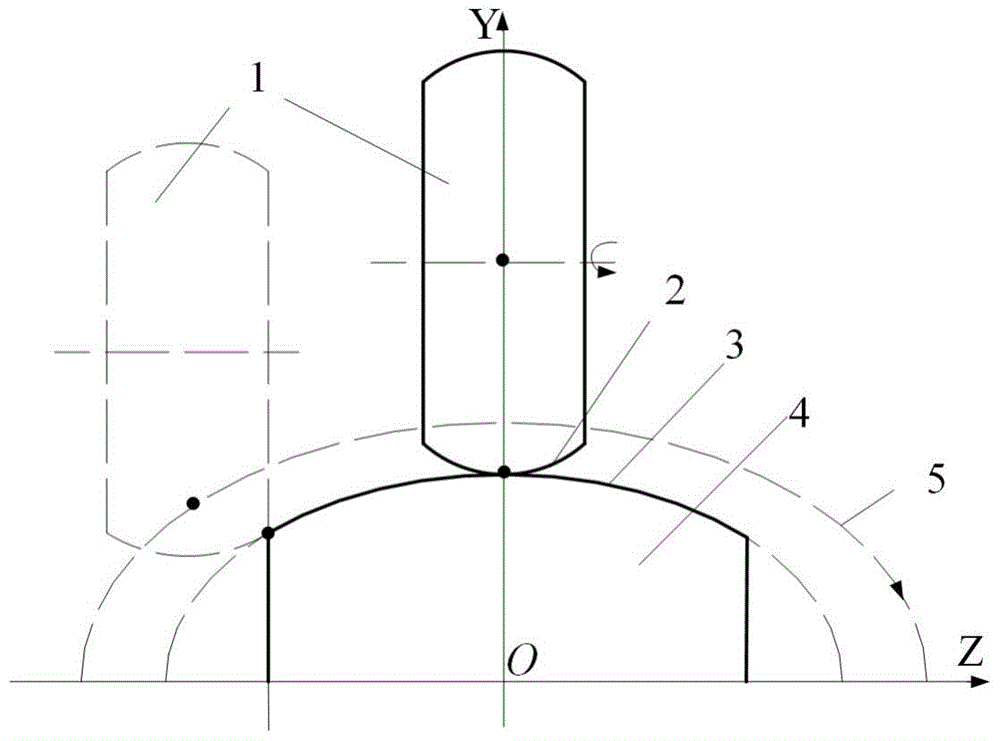

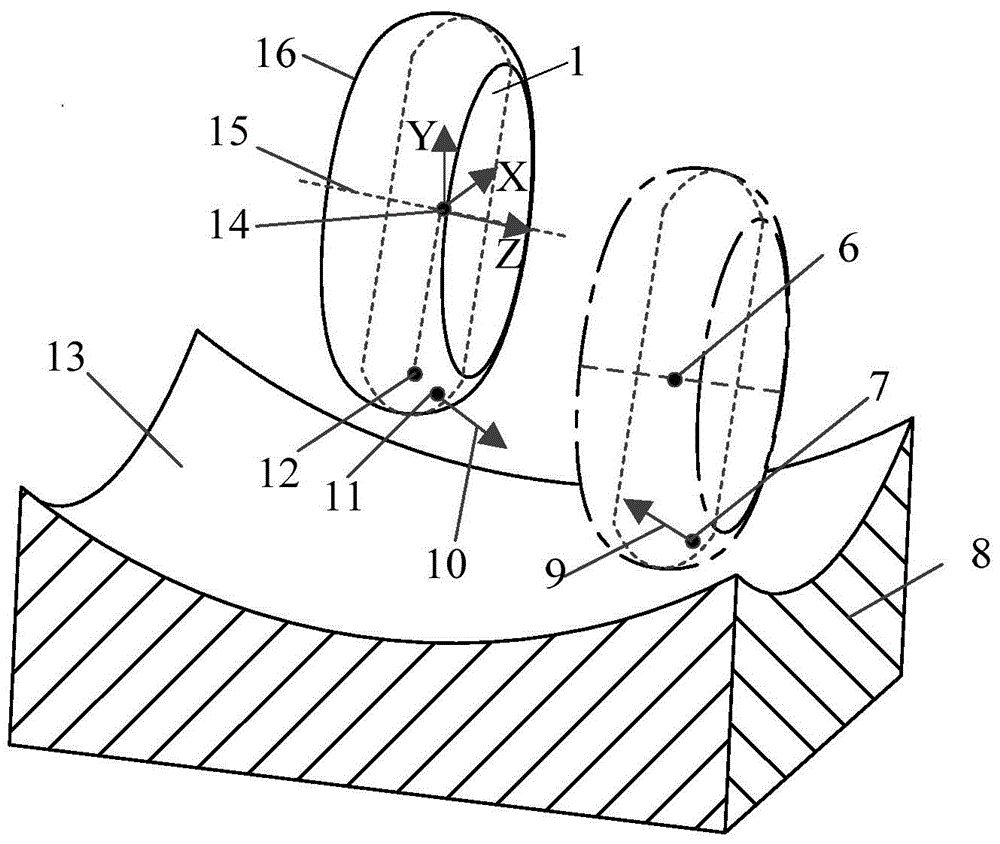

[0044] Step 1, dressing the grinding wheel, trimming the grinding wheel with the corresponding contour surface on the grindstone 4 according to the pre-designed contour surface of the grinding wheel;

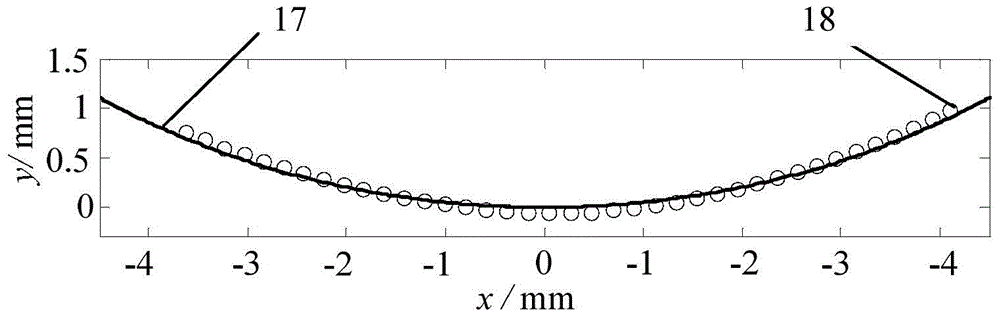

[0045] Step 2, grinding wheel profile compensation, obtain the actual curved surface profile of the grinding wheel by detecting the actual profile detection points of the grinding wheel;

[0046] Step 3. Plan the tool trajectory. According to the principle that the actual contour surface of the grinding wheel and the free-form surface of the workpiece are collinear at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com