Automatic continuous household paper packing machine

A technology of household paper and packaging machine, which is applied to the packaging, packaging, transportation and packaging of paper products. The effect of sealing quality, improving work efficiency and packaging quality, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

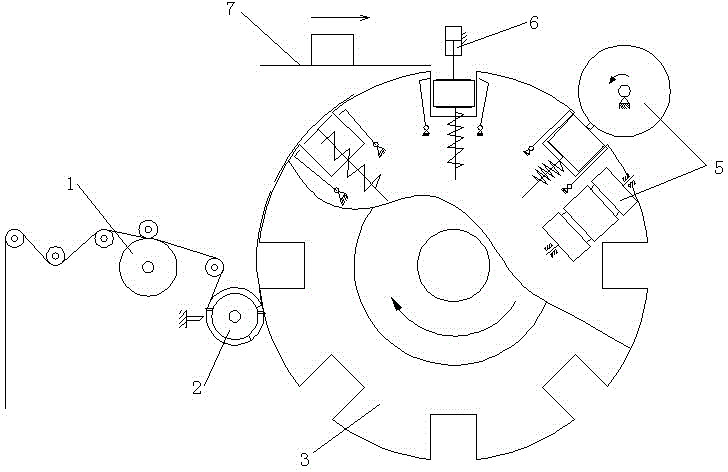

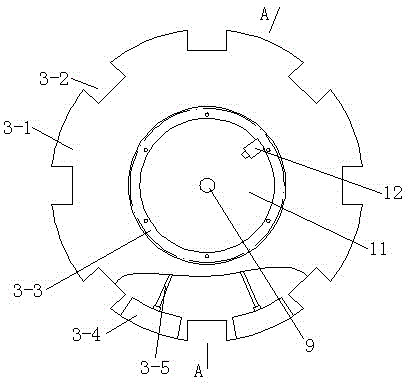

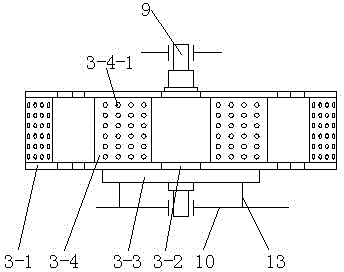

[0035] exist figure 1 —In 16, 1 is the packaging film opening conveying device, 2 is the packaging film cutting device, 2-1 is the outer roller body, 2-2 is the dotted line knife, 2-3 is the long slot hole, 2-4 is the inner roller body , 2-5 is a negative pressure suction hole, 2-6 is a plate with a U-shaped long groove, 2-7 is a cutting knife, 2-8 is a bolt, 2-9 is an annular long groove, 2-10 is a screw, 2-11 is a pressing device, 2-12 is a negative pressure distribution plate, 3 is a disc-shaped mold, 3-1 is a disc, 3-2 is a U-shaped groove, 3-3 is a gear, 3-3-1 is the hole, 3-4 is the negative pressure box, 3-4-1 is the suction hole, 3-5 is the connecting pipe, 3-6 is the sleeve, 3-7 is the pin shaft, 5 is the hot sealing device, 6 is Household paper filling and clamping device, 6-1 is the cylinder, 6-2 is the pressure plate, 6-3 is the support plate, 6-4 is the return spring, 6-5 is the guide rod, 6-6 is the L-shaped swing rod , 6-7 is hinge, 6-8 is push rod, 6-9 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com