Circular material packing machine

A packaging machine, circular technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of complex equipment structure, low production efficiency, large punching force, etc., to achieve improved packaging quality, low equipment cost, structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

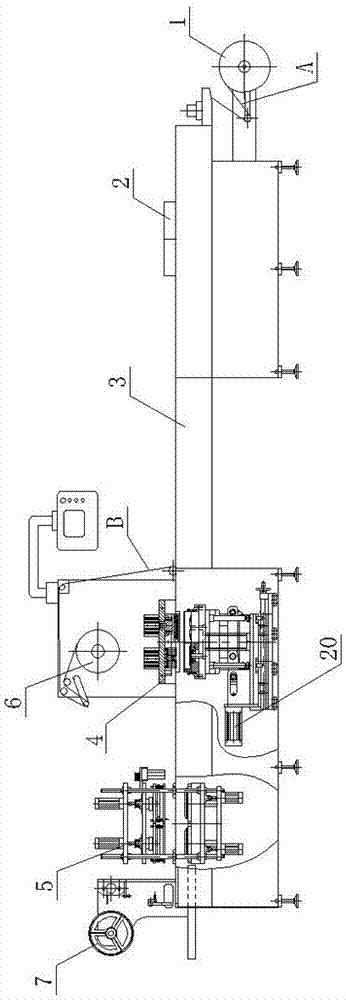

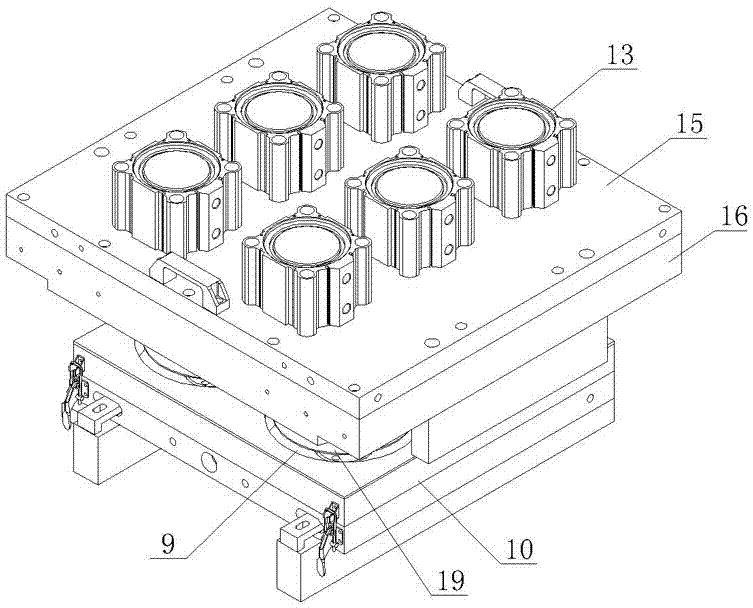

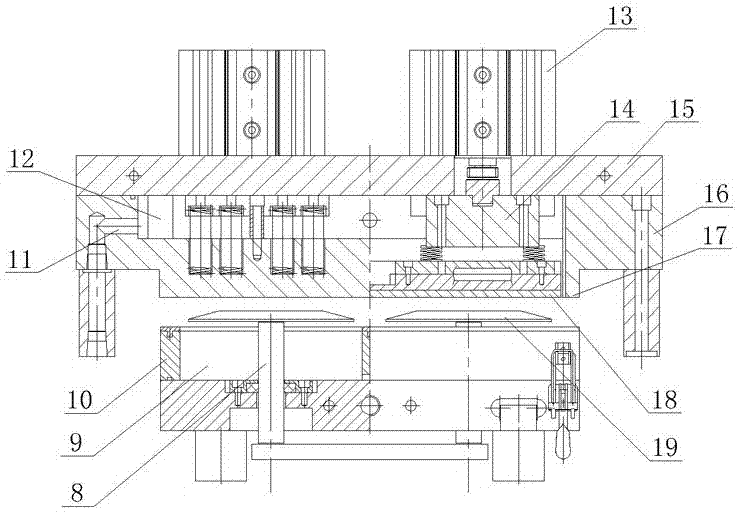

[0014] As shown in the figure, the circular material packaging machine of the present invention includes a lower film unwinding mechanism 1, a forming mechanism 2, a feeding platform 3, a heat sealing mechanism 4 and a cutting mechanism 5 arranged front and rear, and the lower film unwinding mechanism 1 is placed The lower film A of the roll is formed into circular bubbles by the forming mechanism 2, and then materials are manually put into the circular bubbles on the feeding platform 3. An upper film unwinding mechanism 6 is provided above the heat-sealing mechanism 4, and the cutting A waste film winding mechanism 7 is provided on the rear top of the mechanism 5 .

[0015] The cutting mechanism 5 includes a cutting upper die and a cutting lower die. The cutting upper die includes a cutting upper template 27 that is pushed up and down by the first cylinder 24. A top plate 26 is arranged above the cutting upper template 27, and the top plate 26 is fixedly arranged. A cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com