Manufacturing method of vacuum inner ultra-large quadrupole lens

A technology of quadrupole lens and manufacturing method, which is applied in the direction of accelerators and electrical components, can solve the problems of weight and volume limitations, high coil gas output rate, and affecting the vacuum degree of large vacuum chambers, and achieve high processing accuracy and good magnetic field indicators , the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

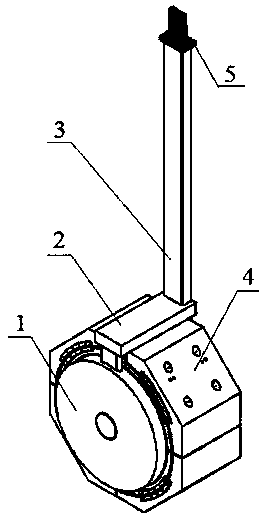

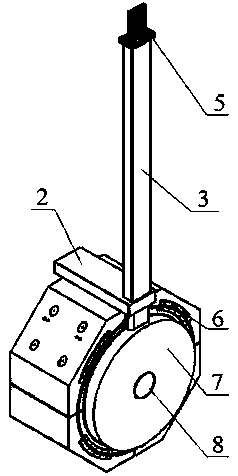

[0036] The invention provides a method for manufacturing a super-large quadrupole lens in a vacuum, and the manufacture is completed figure 1 and figure 2 The super-large quadrupole lens in the vacuum shown in the prior art meets the requirement of isolation between the coil and the vacuum environment. The manufacturing method is specifically carried out in the following steps:

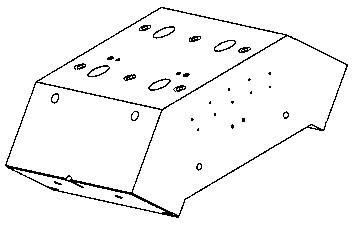

[0037] 1) Decompose and design the lens core in the super-large quadrupole lens in vacuum into upper left yoke, lower left yoke, upper right yoke, lower right yoke and upper left magnetic pole, lower left magnetic pole, The upper right magnetic pole and the lower right magnetic pole, the structure and size of the four yokes are exactly the same, and the structure and size of the four magnetic poles are exactly the same; according to the size and material required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com