A kind of indentation manufacturing method of surface with microlens or microlens array structure

A technology of microlens array and manufacturing method, which is applied in the fields of lenses, optics, instruments, etc., can solve the problems of environmental condition requirements, many influencing factors, and difficult control, etc., and achieve simple processing path, simple process, and less wear of the pressure head Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0041] A method for indenting a surface with a microlens or microlens array structure, the method comprising the steps of:

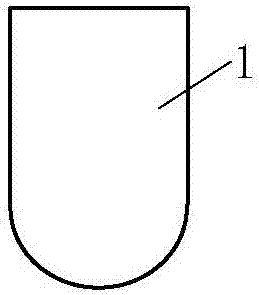

[0042] Step 1, preparing an indenter with a microlens shape at the end;

[0043] Step 2, smoothing the surface of the microlens or microlens array structure to be formed;

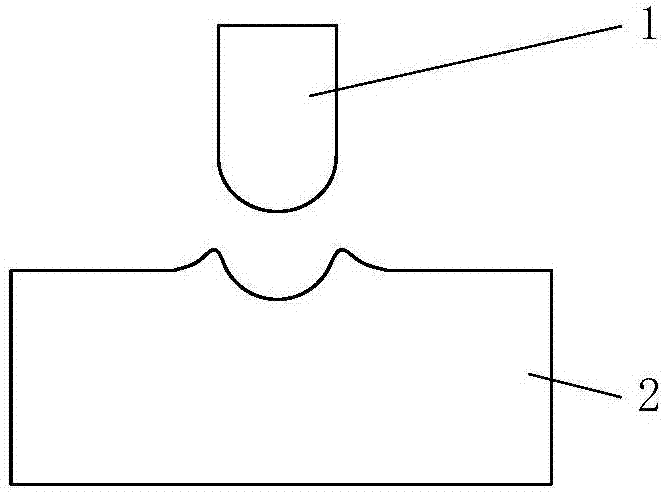

[0044]Step 3, on the forming press, the indenter in the step 1 uses the indentation method to process a lenticular dent on the surface to be formed at a speed of s and a pressure of m; s is 0.01mm / s~ 10m / s, m is 10N~10kN;

[0045] Step 4: unload the pressure of the indenter, and measure and calculate the error between the shape of the dent described in step 3 and the shape of the microlens at the end of the indenter in step 1 after the embossed dent has fully elastically recovered, Compensating the error on the shape of the indenter or trimming the indenter s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com