Back-pack electric air-flow cotton, fruit picking machine

A knapsack type, picking machine technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of high labor intensity, difficult to adjust suction, lower cotton quality grade, etc., to improve harvesting speed, light machinery weight , the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

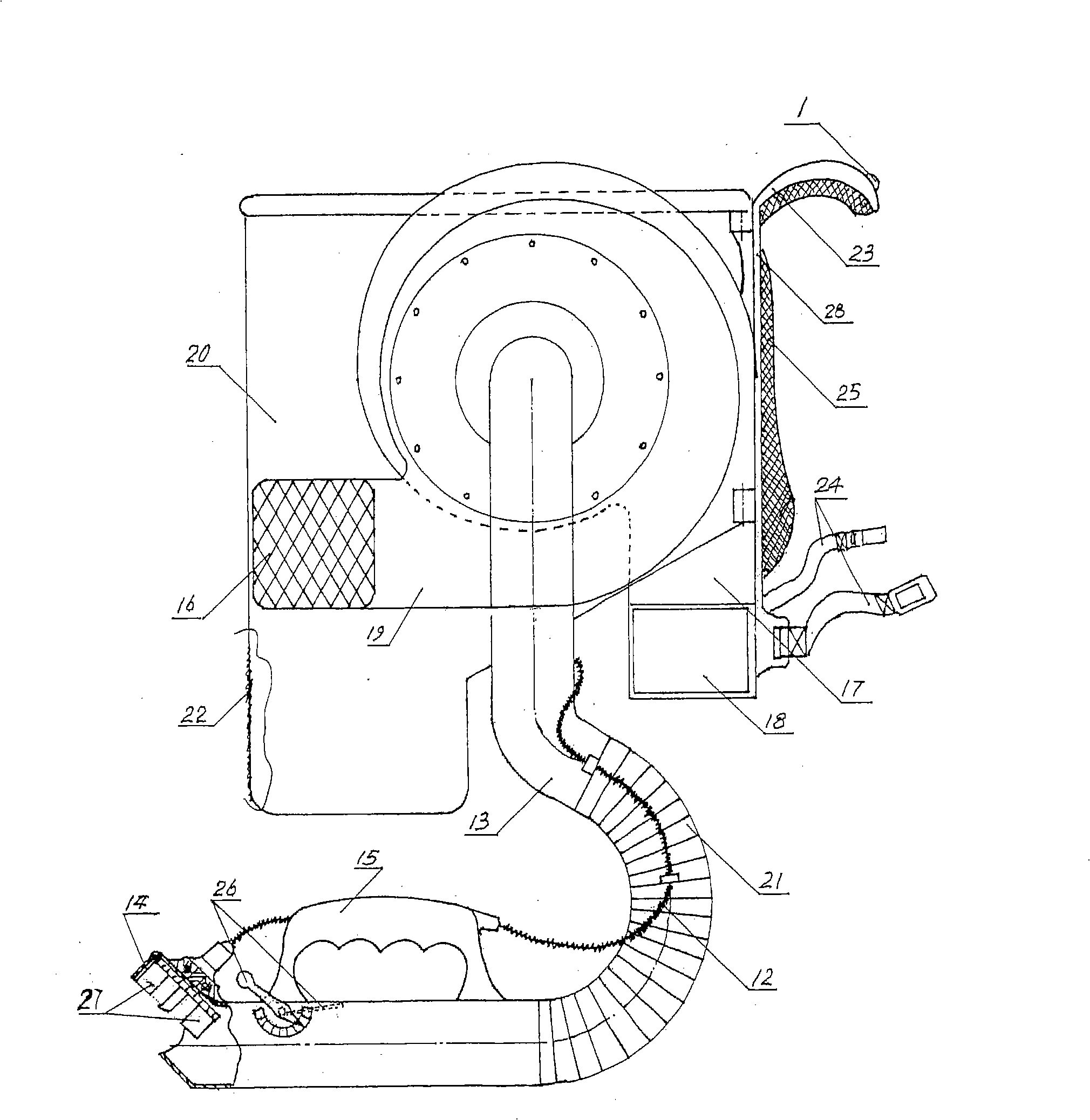

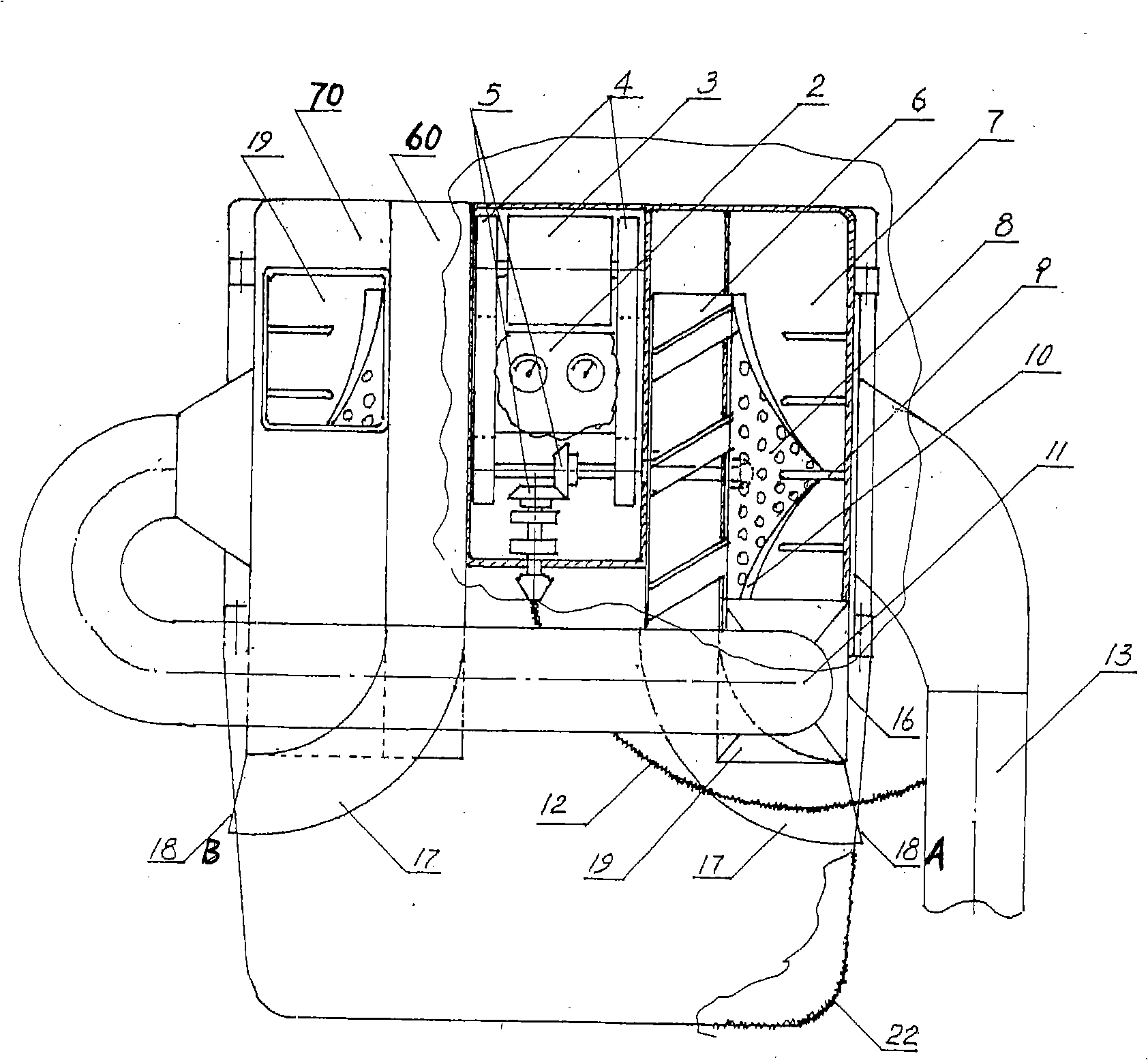

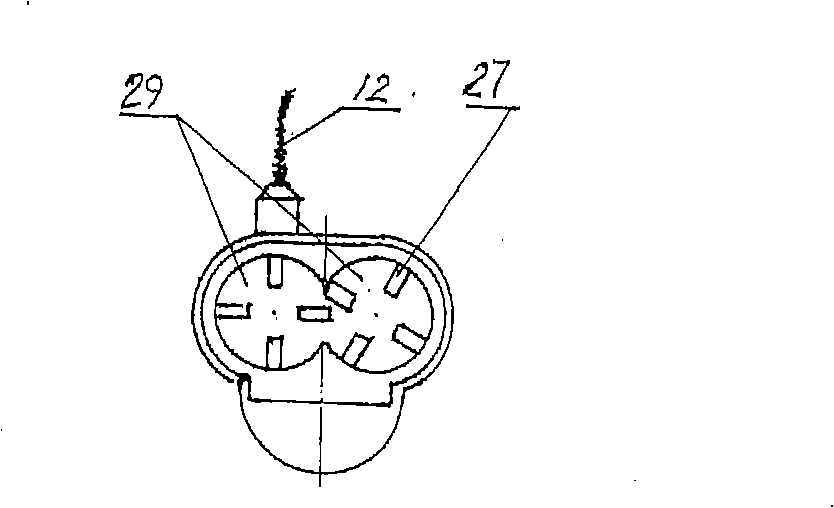

[0017] see Figure 1 to Figure 3 , the motor 3 is installed on the mechanical connection plate 28, the power output shaft of the motor is connected to the input end of the toothed belt combination 4, the output end of the toothed belt combination is connected to the left and right suction fans 60,6, and the rotating shaft ends of the left and right suction fans are connected to the rotating perforated cover 8 , the rotating perforated cover is provided with a guide plate 10, and the left cleaning chamber 70 is provided with an exhaust gas sundry B outlet 18B and flowers and fruit outlets 19, and the flowers and fruit outlets are connected to the software ventilation storage box 20, and the software ventilation storage box A zipper 22 is installed on the edge of the box, and the right cleaning chamber 7 is provided with main and auxiliary air inlets and waste gas sundries A outlet 18A, the main air inlet is connected to a fixed air inlet pipe 13, and the other end of the fixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com