Gear-shifting actuator for new energy automobile

A gear shift actuator and technology for new energy vehicles, applied in gear transmissions, components with teeth, belts/chains/gears, etc., can solve the problems of large space occupation and unsuitable volume requirements for new energy vehicles, and achieve Reduced space, simple structure, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

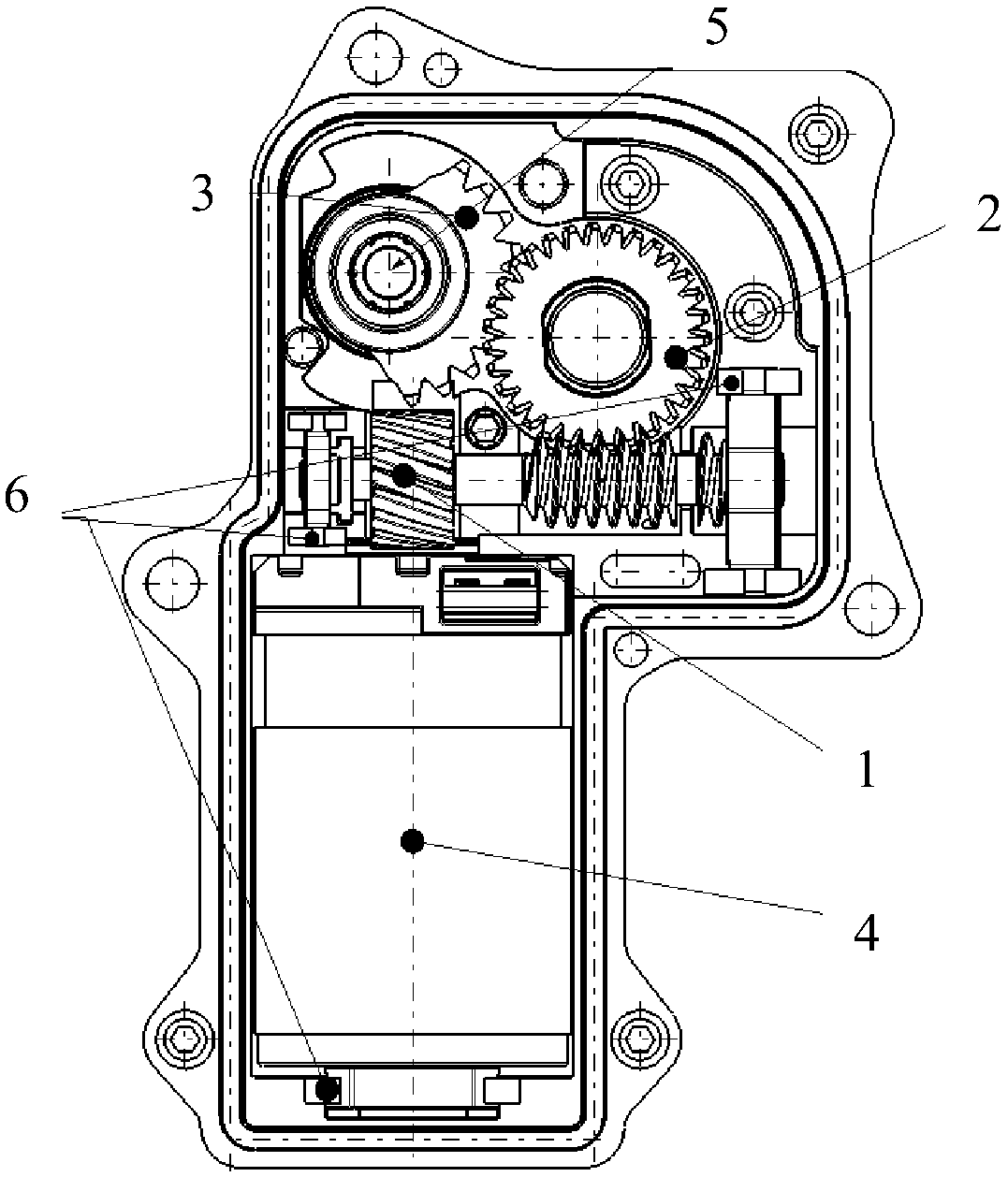

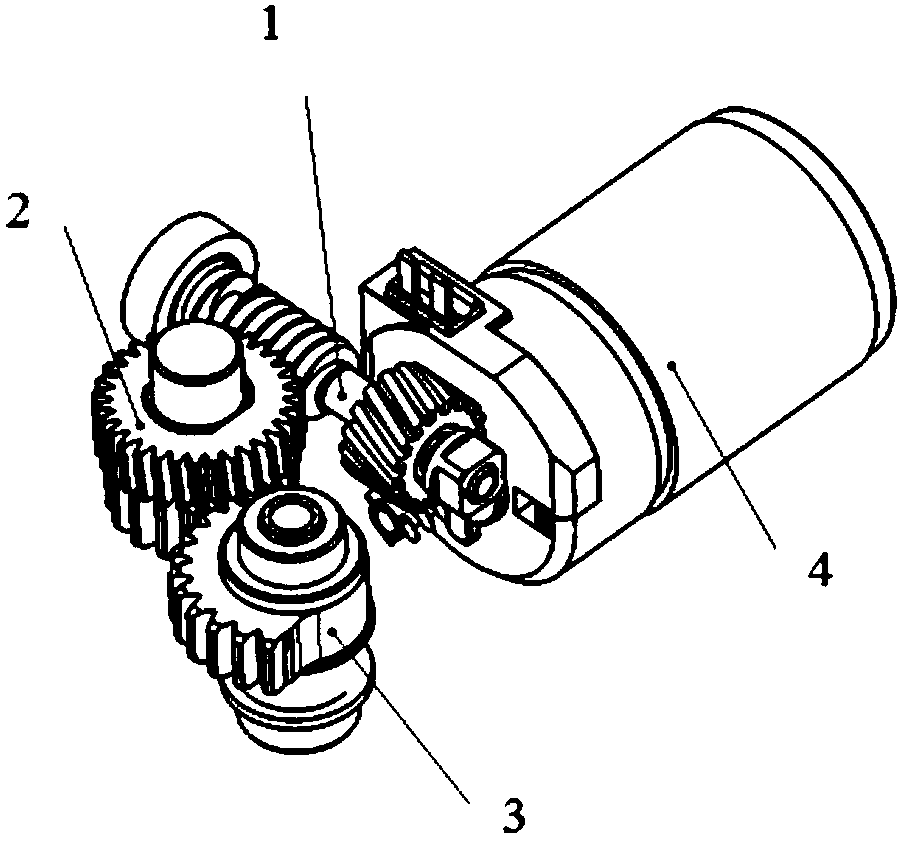

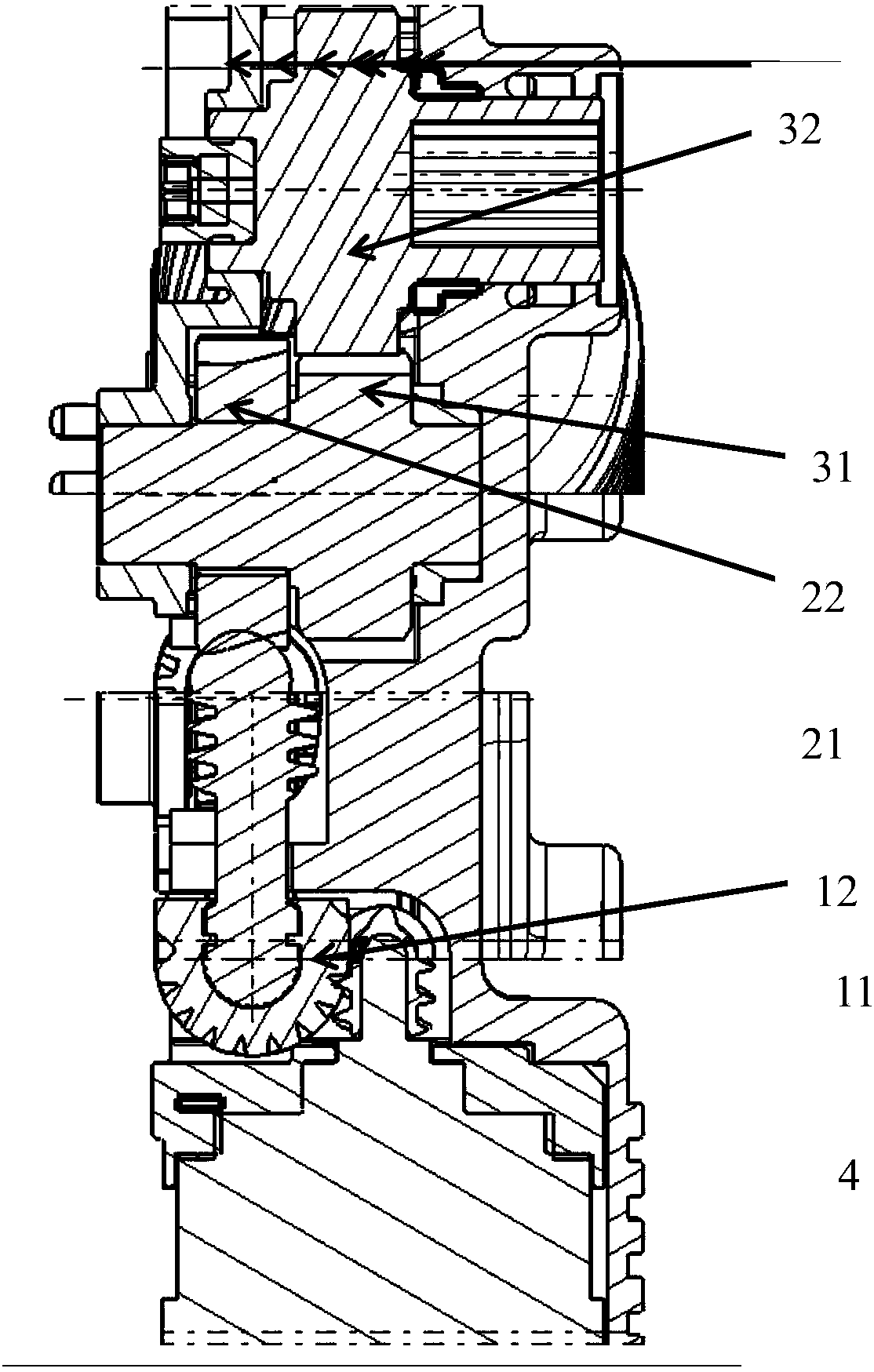

[0031] like figure 1 , figure 2 and image 3 As shown, a shift actuator for new energy vehicles adopts three-stage gear transmission; wherein, the first and second stages adopt worm gears, and the third stage is spur gear transmission, and the first-stage gear 1 is driven by the first The first-stage worm 11 and the first-stage worm 12; the second-stage gear 2 is composed of the second-stage worm 21 and the second-stage worm 22; The first-stage worm gear links the second-stage worm gear through the second-stage worm of the second-stage gear, and then links the third-stage gear of the third-stage gear 3. The third-stage gear is the transition tooth 31, and the third-stage transmission gear is the output, 32. The angle sensor 5 is fixed at the end of the output shaft through the third gear. The fixing of the drive motor and the primary gear is riveting 6 .

[0032] After the power of the motor of the present invention is transformed by the transmission mechanism, the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com