Gantry numerical-control milling and grinding integrated lathe of fixed column and movable beam type

A CNC milling and moving beam technology, applied in the field of CNC machine tools, can solve problems such as easy formation of fatigue layers, limited bearing capacity, complex structure, etc., and achieve the effects of avoiding cumulative errors, large bearing capacity, and high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

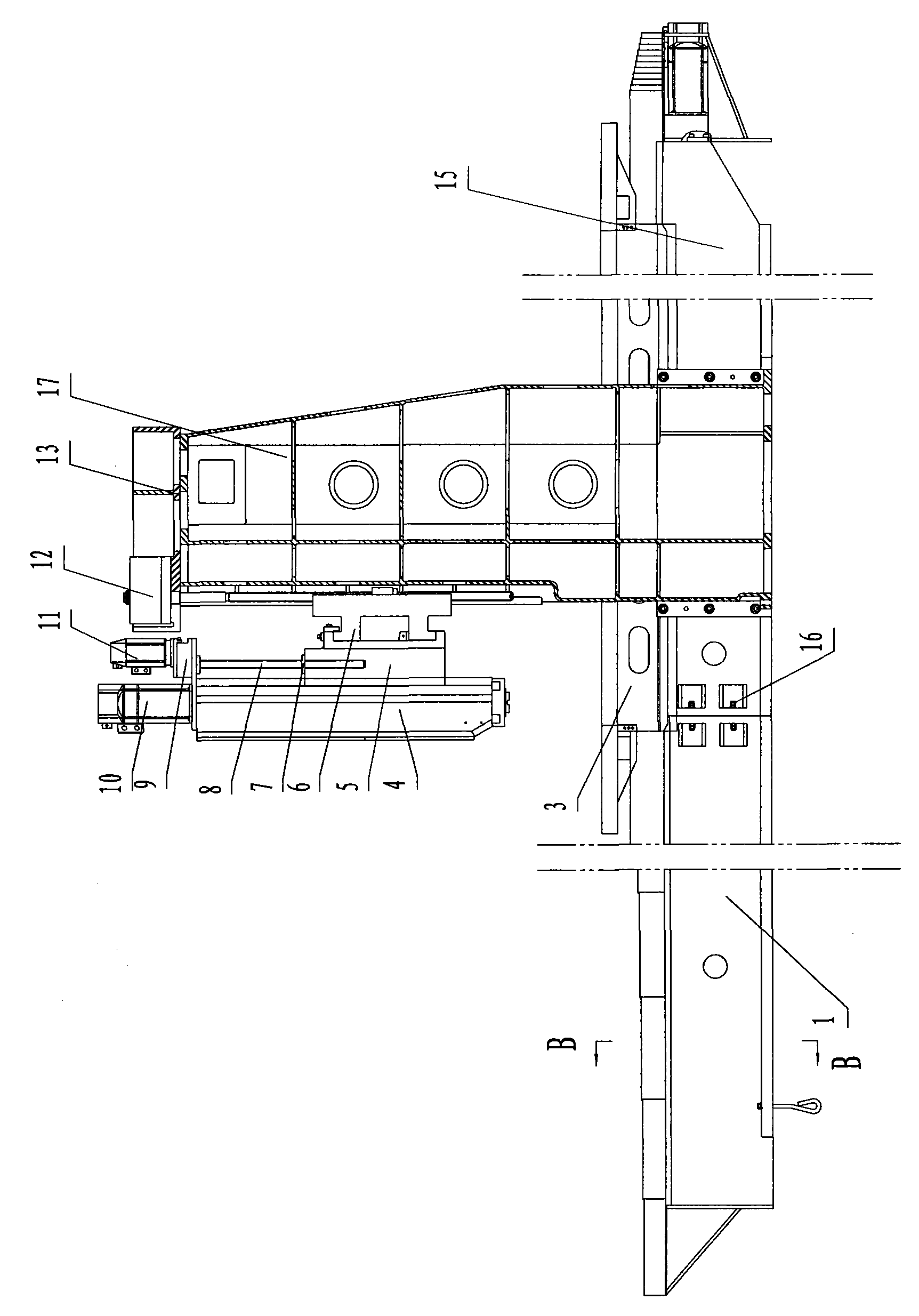

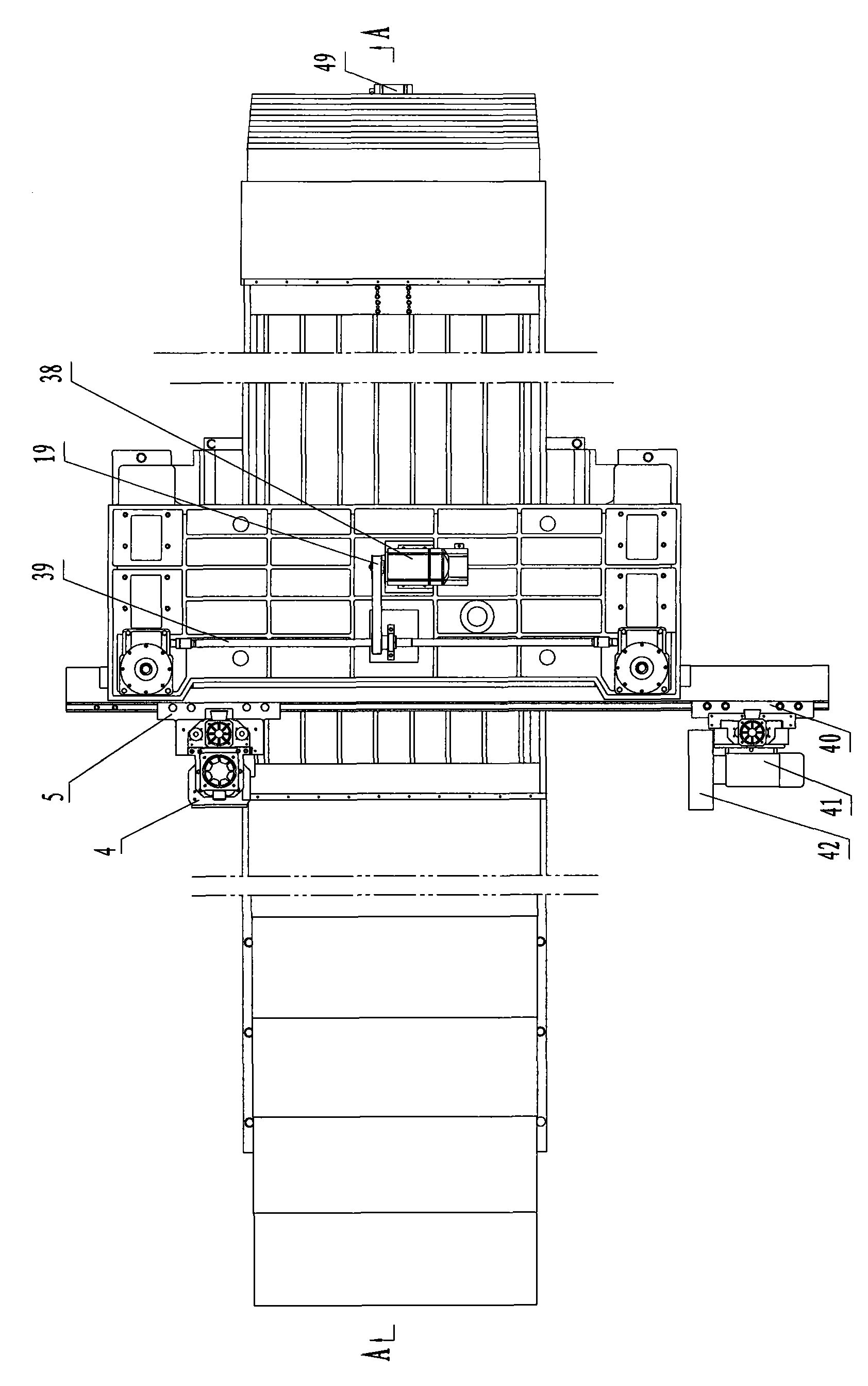

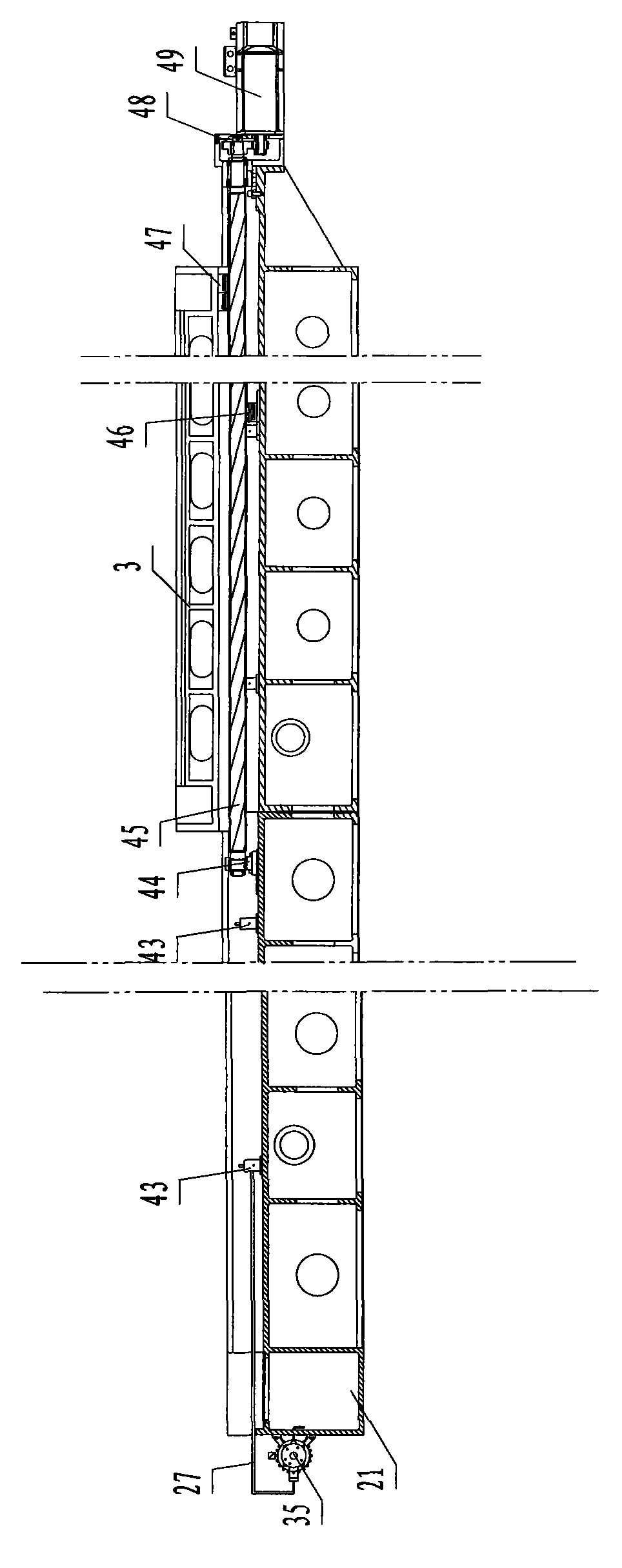

[0028] Refer to attached figure 1 , 2, 3, 4, 5 make the present invention. The fixed column movable beam type gantry CNC milling and grinding integrated machine tool includes a bed 2, an electrical cabinet 33, a system operation panel 32, a workbench 3, a left column 17, a right column 14, a beam 6, a distance beam 22, a workpiece fixture and The top beam 13 is provided with a V—flat guide rail on the bed 2, and the workbench 3 is set on the V——flat guide rail. The workbench 3 moves along the V——flat guide rail. Left column 17 and right column 14 are respectively fixed on both sides, top beam 13 is fixed on the upper end of left column 17 and right column 14, in order to locate, upper distance beam 22 is set between left column 17 and right column 14, workpiece Fixtures are fixed on the workbench 3, and it is characterized in that: on the left column 17 and the right column 14, a beam 6 is provided through a beam driving device, so that the beam 6 can be moved up and down al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com