A kind of production method of stainless steel round link chain

A production method and stainless steel technology, applied in the direction of metal chains, etc., can solve the problems of cracking, unstable welding joint quality, unstable dimensional pitch, etc. Small, small shape error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A production method of a stainless steel round link chain, which mainly includes the following steps: raw material selection → blanking → thermal chain knitting → shot blasting → flash butt welding → stretch correction → pickling → inspection, wherein

[0033] ① Selection of raw materials

[0034] Use stainless steel 304L raw materials (hydrochloric acid corrosion resistance), 304L is a variant of 304 stainless steel with lower carbon content, used in occasions that require welding. The lower carbon content minimizes the precipitation of carbides in the heat-affected zone near the weld, and the precipitation of carbides may cause intergranular corrosion (welding corrosion) of stainless steel in certain environments. The resistance of 304L stainless steel Corrosion, appearance, processability, strength and other characteristics far exceed other materials.

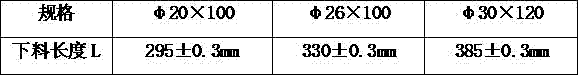

[0035] ②Blanking

[0036] The Q45-125A precision bar shearing machine produced by Shenyang Qiushi Precision Shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com