Semi-sank large precise ring rolling machine

A ring rolling machine, semi-submerged technology, applied in the direction of metal rolling, can solve the problems of reduced mechanical properties, large grain size, high energy consumption, etc., to achieve the effect of reducing working hours, improving utilization rate, and small contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

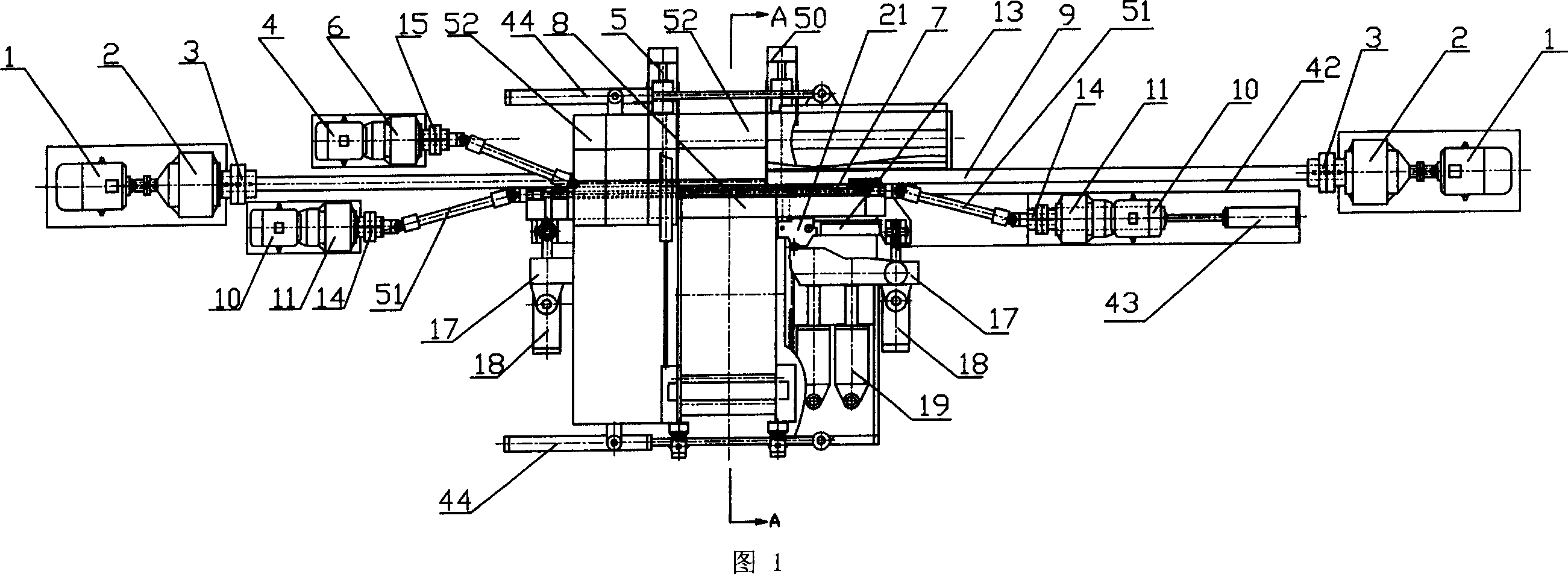

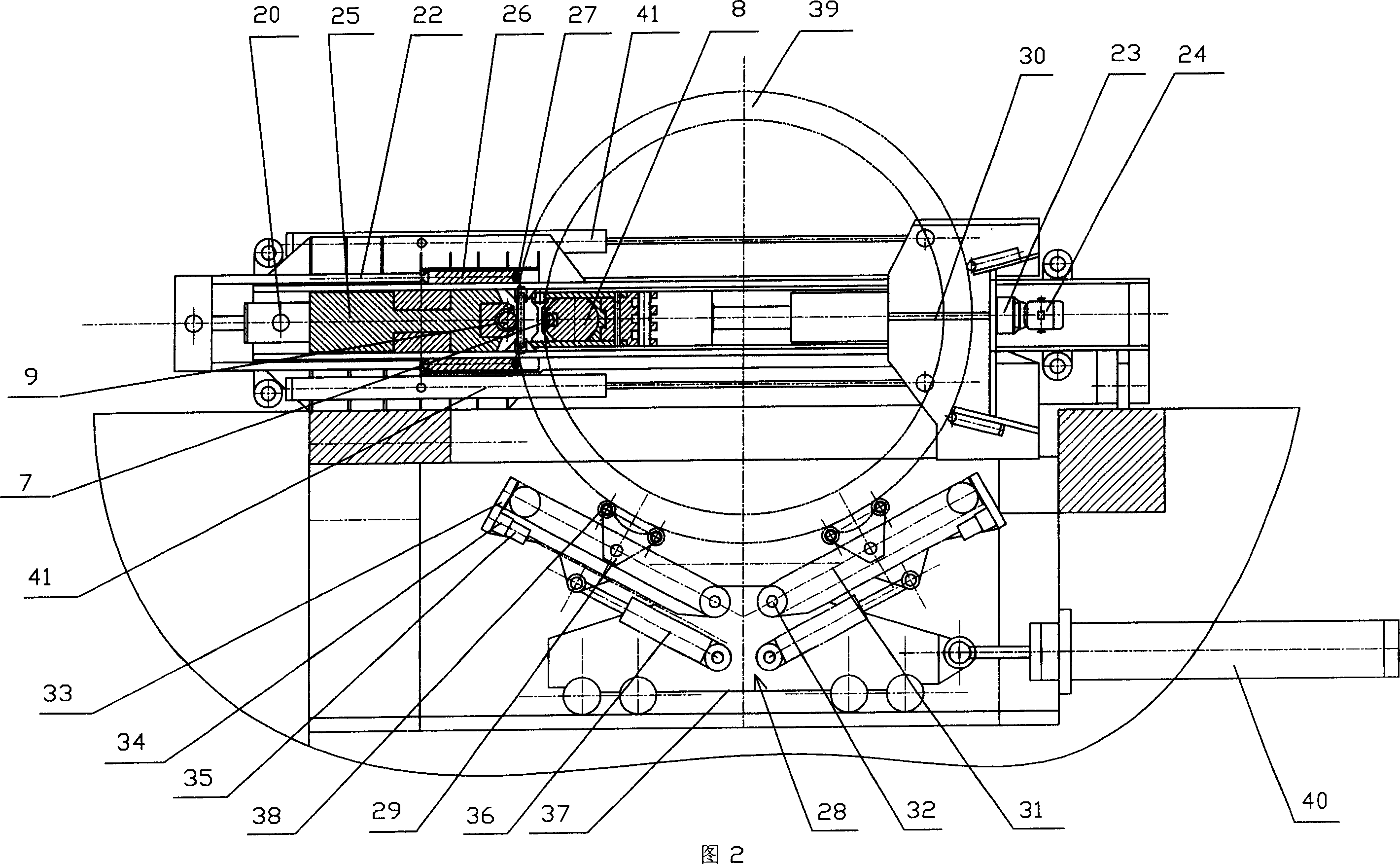

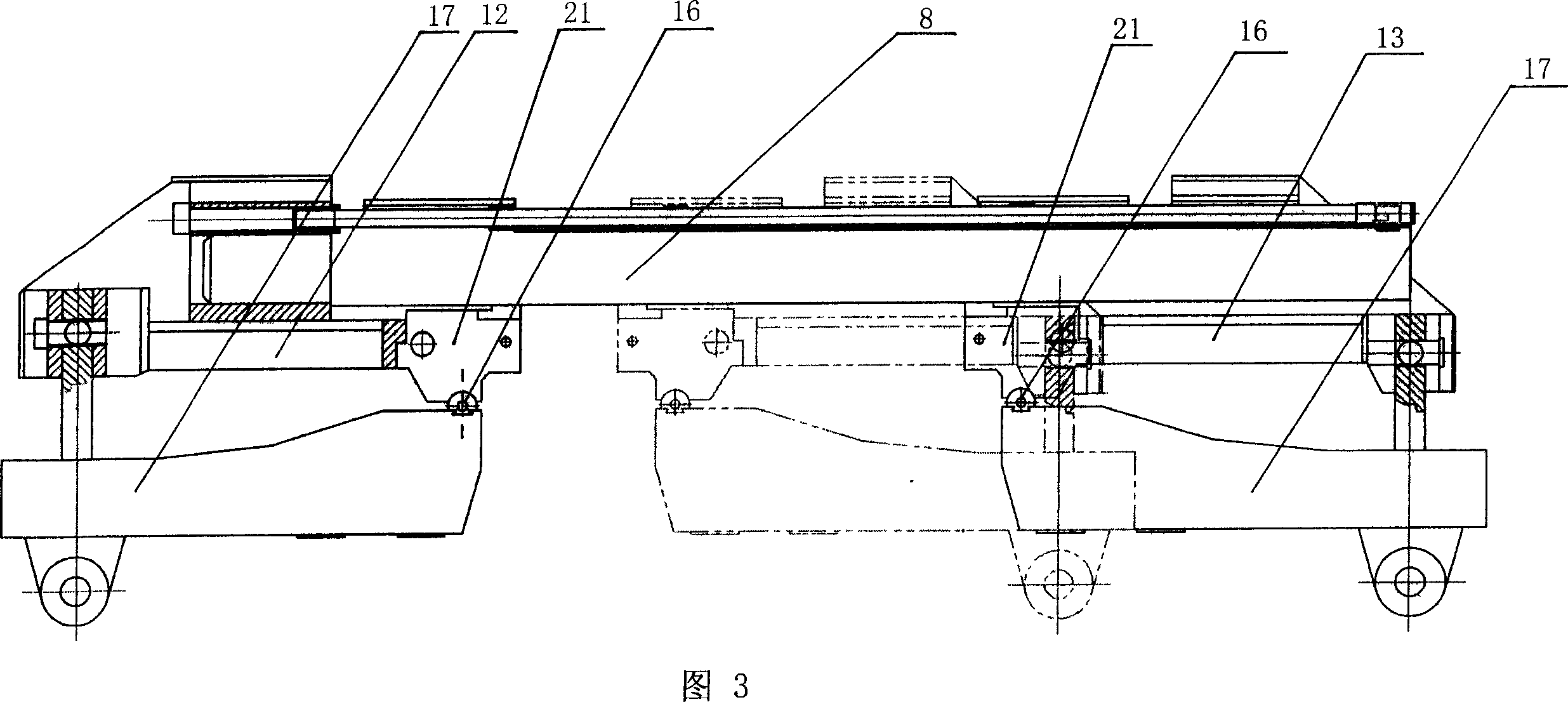

[0031] As shown in the figure: the large-scale precision ring rolling machine includes a door frame for clamping the ring workpiece 39 to be processed. The door frame includes a fixed frame 5 and a movable frame 50, and the fixed frame 5 and the movable frame 50 are both provided. on the base 52, and placed on the ground in a horizontal position, a moving mechanism for driving the mobile frame 50 to move relative to the fixed frame 5 is set between the mobile frame 50 and the fixed frame 5, and the mobile frame 50 can be moved by the oil cylinder 44 or the electric pusher. Driven by a mechanism such as a rod or rack and pinion, the translation is realized and approached to the fixed frame 5. In order to ensure smooth sliding, a slide rail should be provided between the mobile frame 50 and the base, and the clamping surface of the fixed frame 5 is opposite to the mobile frame 50. And parallel to the end face of the annular workpiece 39 to be processed, the base 52 and the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com