Process for forming functional film, and process for producing electrode and secondary battery

A manufacturing method and secondary battery technology, which is applied in the direction of electrode manufacturing, secondary battery, electrode collector coating, etc., can solve the problems of pattern damage and failure to form patterns, etc., to reduce shape errors and reduce coating Errors in position and coating shape, effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

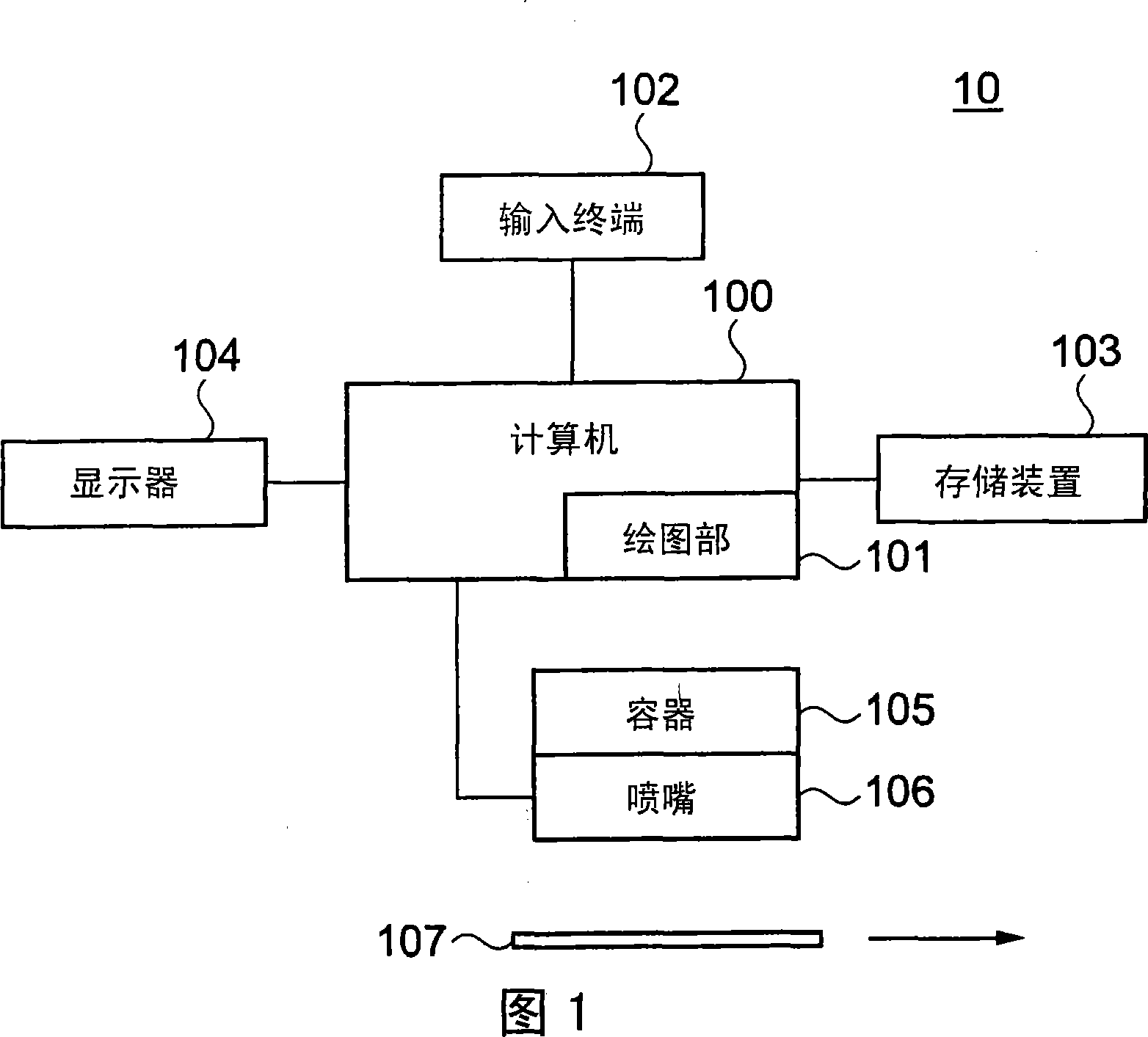

[0047] The present invention will be described in detail below with reference to the accompanying drawings.

[0048]

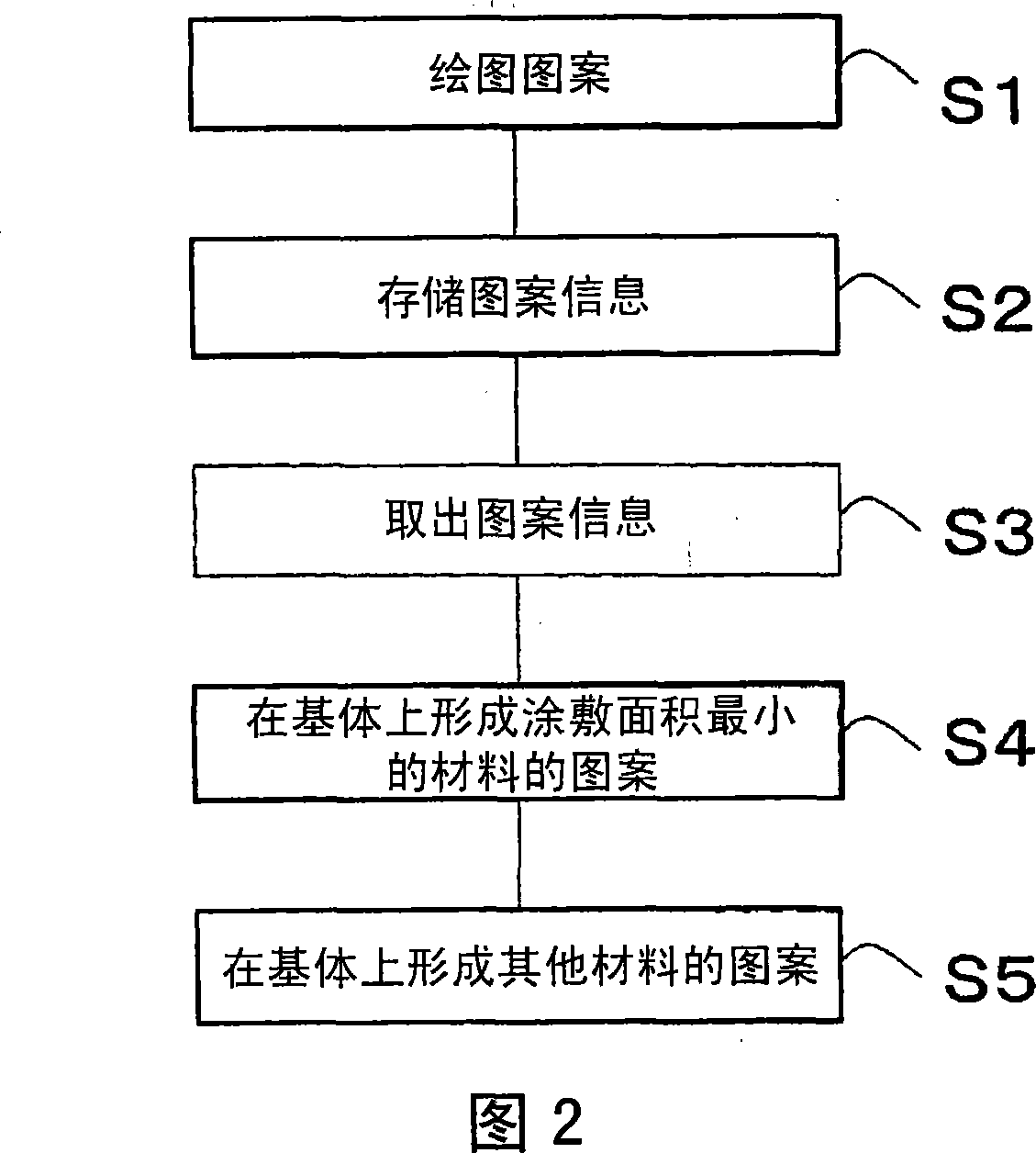

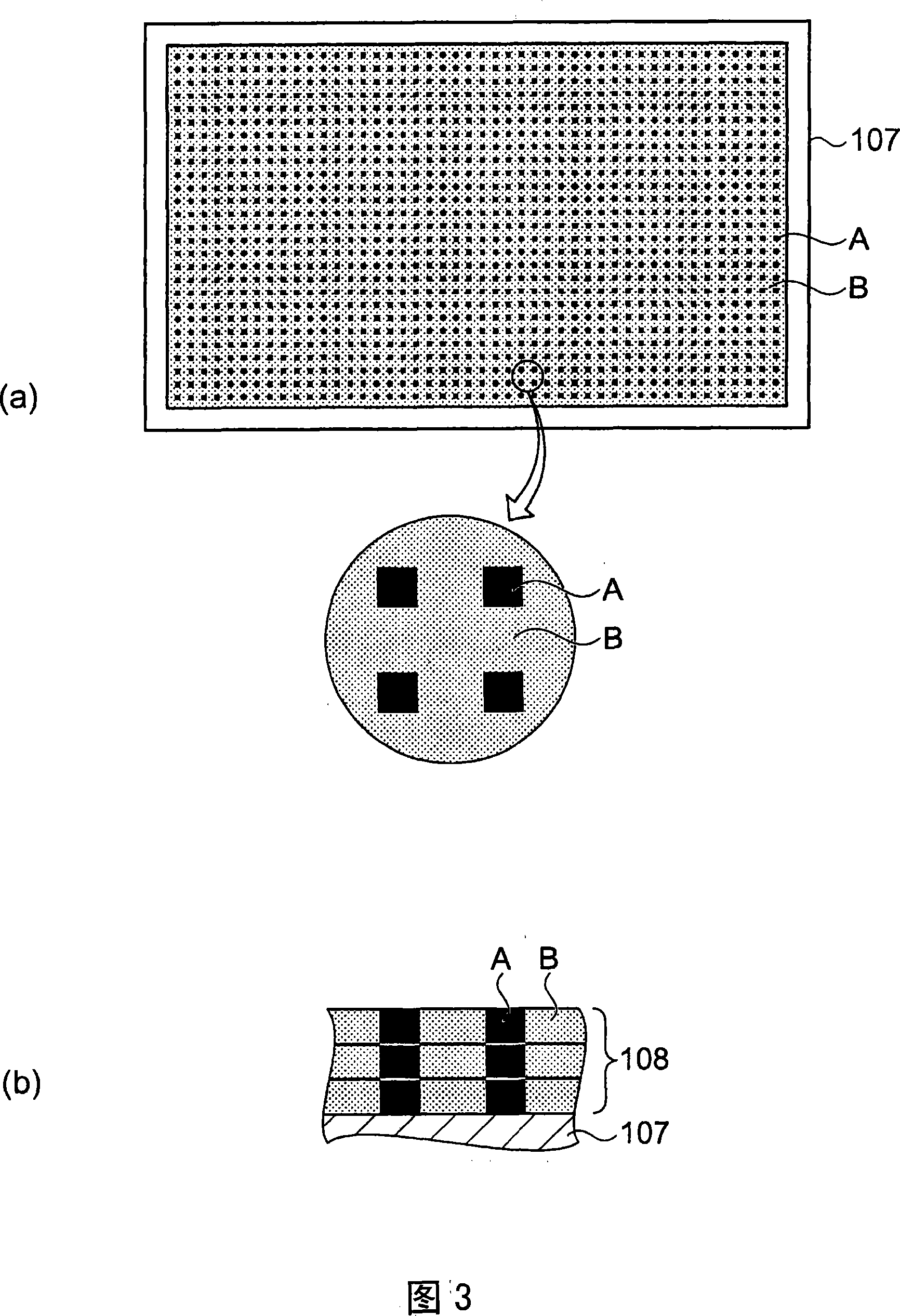

[0049] In the method for forming a functional film of the present invention, two or more functional materials are ejected onto the substrate by a droplet ejection device, thereby forming a functional film composed of two or more functional materials. The forming method is characterized in that according to a pre-designed coating pattern, the functional material with the relatively smallest coating area among the two or more functional materials is first coated on the substrate, and then the functional material with a relatively large coating area is coated. permanent material, thereby forming a functional film with a predetermined pattern.

[0050] Here, the term "pattern" refers to the design of which regions on the substrate to attach two or more functional materials having different functions. Patterns are designed semi-empirically to obtain functional f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com