Precise forging molding method for blank of automobile fork-shaped half shaft

A precision forging, fork-shaped technology, applied in the field of precision forging, can solve the problems of large product shape error, large machining allowance, poor quality stability, etc., to achieve small product shape error, small machining allowance, product The effect of shape error change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

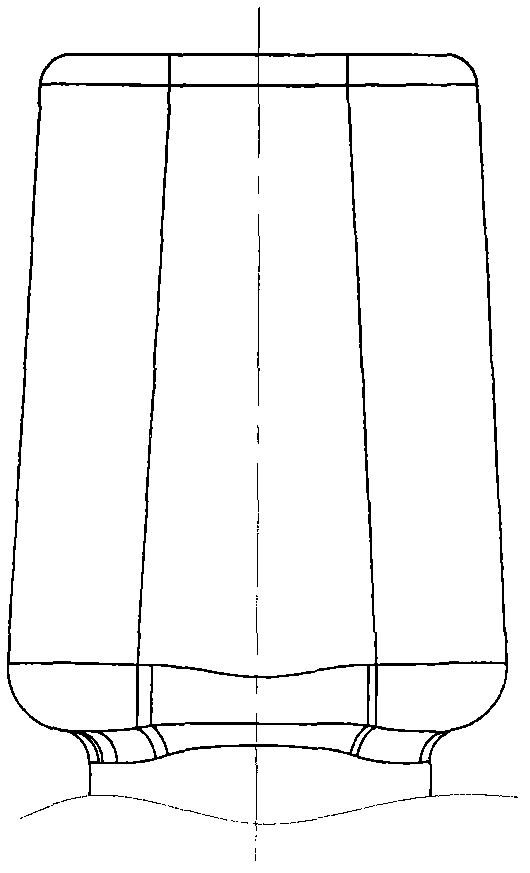

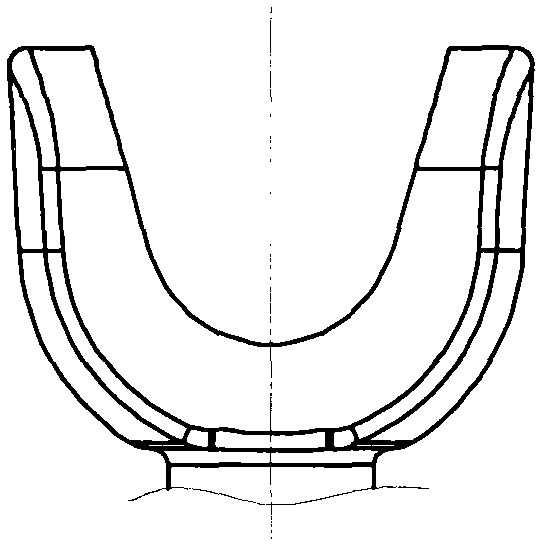

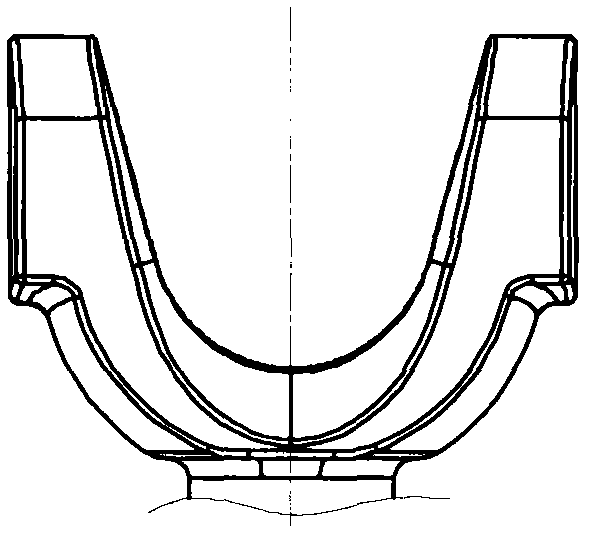

[0014] A precision forging forming method for an automobile fork-shaped semi-shaft blank. The forming method is a hot extrusion forming method: first, the round material is locally heated to 1050-1150 ° C; Gather the head, and then warm it up to 1050-1150°C, and complete the first hot extrusion of the billet; finally, it is formed by the second hot extrusion; in the actual implementation of the patent , pre-heat the mold to 250°C-300°C and spray graphite milk into the cavity during operation; place the sawed bar into an intermediate frequency heating furnace and heat it to 1050-1150°C, and first put the circle on a 200T hydraulic press The heated part of the bar is gathered into a square billet, such as figure 1 As shown; after gathering into a square billet, put the part of the gathered material into an intermediate frequency heating furnace to supplement the temperature to 1050-1150°C, and then hot-extrude it into a fork-shaped piece in a 315T hydraulic press, as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com