Combined piston gas ring internal combustion engine

A piston gas ring and internal combustion engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as power reduction, high temperature of piston rings and pistons, increased fuel and oil consumption, etc., to achieve sealing and heat conduction Excellent performance, simple structure and manufacturing process, and the effect of reducing impact and wear

Inactive Publication Date: 2006-07-26

王雪松

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the main function of the gas ring on the piston of the known internal combustion engine is gas sealing and heat conduction, that is, to ensure the sealing of the piston and the cylinder wall, to prevent the combustible gas mixture and high-temperature gas in the cylinder from leaking into the crankcase, and to absorb the heat received by the top of the piston. The heat is transferred to the cylinder wall to avoid overheating of the piston. If the seal is not good, not only the internal combustion engine will be difficult to start, the power will decrease, and the consumption of fuel and oil will increase.

And the outer surface of the piston ring is not closely attached to the cylinder wall, so that the heat at the top of the piston cannot be transferred through the cylinder wall, resulting in excessive temperature of the piston ring and piston or even being burned out. The piston gas sealing rings currently used are all single Body gas sealing ring, which cannot meet the strengthening requirements of internal combustion engines, and the overall requirements of good sealing, running-in, contact pressure, thermal conductivity, economy and manufacturability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

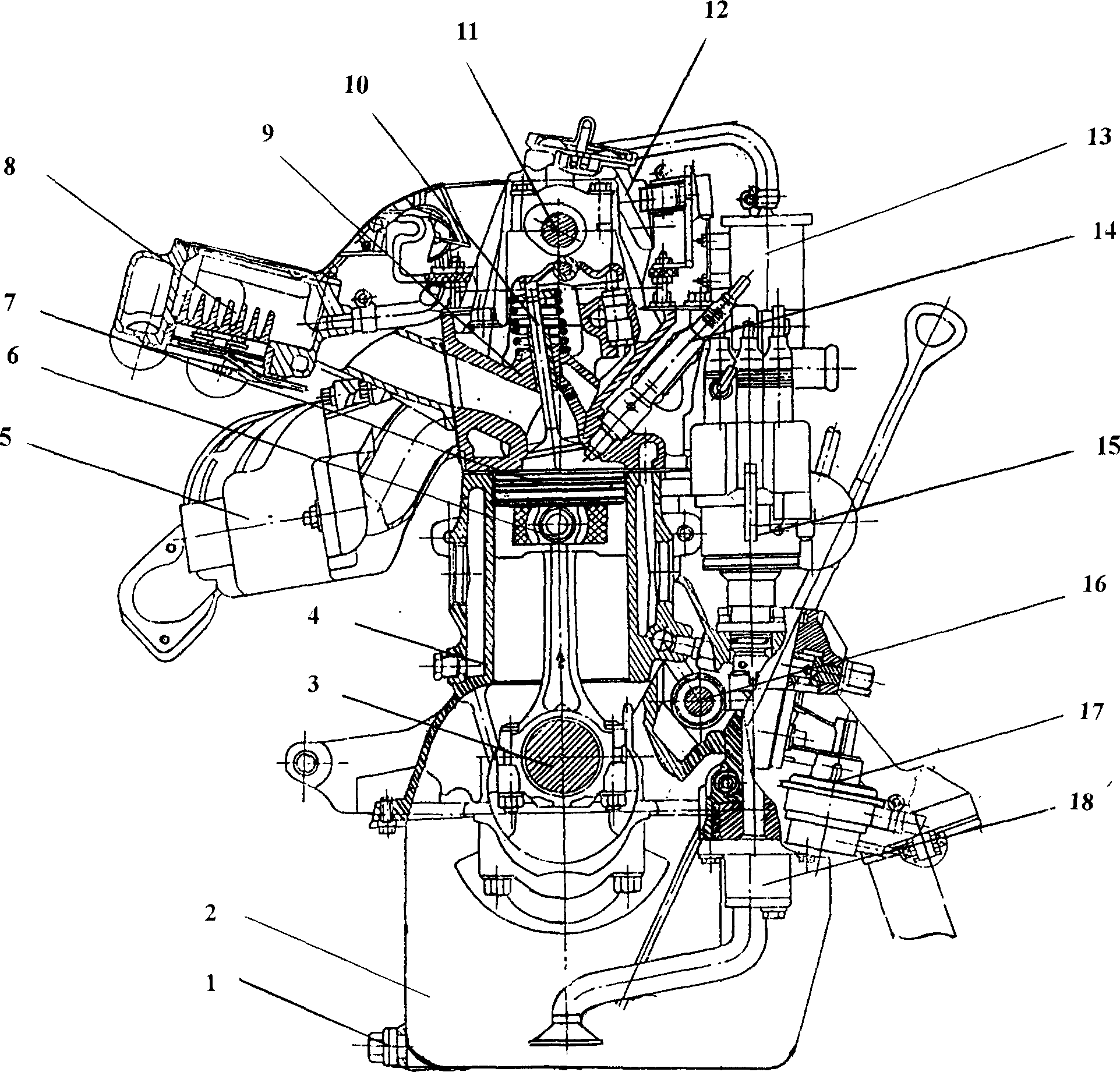

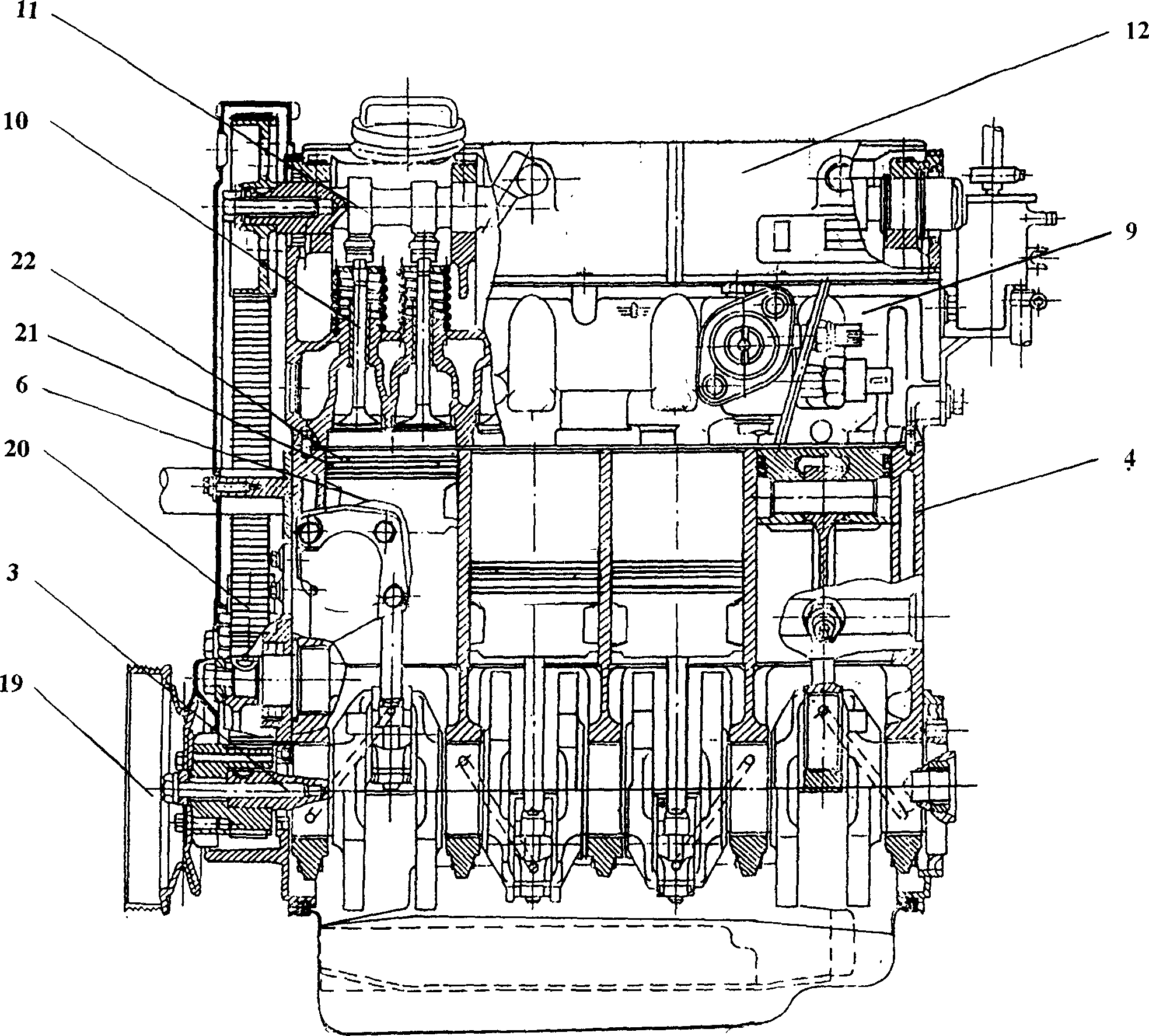

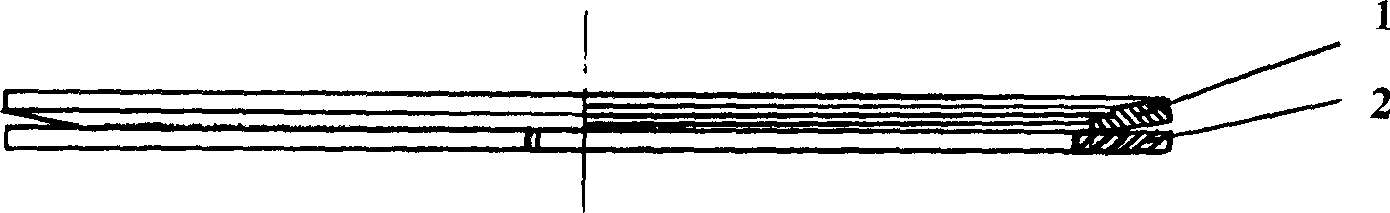

[0020] exist image 3 Among them, the combined gas ring (7) is formed by the secondary twisted gas ring (22) at the top and the main gas ring (21) at the bottom.

[0021] exist Figure 5 Among them, the first air ring on the top of the piston (6) is a combined air ring (7) composed of the upper secondary twisted air ring (22) and the lower main air ring (21), and the second air ring is an oil ring (twenty three).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Disclosed is combination type internal-combustion piston engine, wherein the air ring groove of the piston is provided with an upper auxiliary torsion air ring and a lower main air ring. The invention realizes simplified structure and manufacturing process, low cost, better hermeticity and thermal conductance, and reduced discharge of engine contaminant.

Description

Technical field [0001] The invention relates to a combined piston gas ring internal combustion engine, in particular to an internal combustion engine which adopts a combined piston gas ring gas sealing system composed of an upper auxiliary twisted gas ring and a lower main gas ring in the same gas ring groove on the piston of the internal combustion engine. Background technique [0002] At present, the main function of the gas ring on the piston of the known internal combustion engine is gas sealing and heat conduction, that is, to ensure the sealing of the piston and the cylinder wall, to prevent the combustible gas mixture and high-temperature gas in the cylinder from leaking into the crankcase, and to absorb the heat received by the top of the piston. The heat is transferred to the cylinder wall to avoid overheating of the piston. If the seal is not good, not only the internal combustion engine will be difficult to start, the power will decrease, and the consumption of fue...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02F11/00

Inventor 王雪松

Owner 王雪松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com