Resonant nano three-dimensional contact measuring head based on optical fiber Bragg grating

A fiber-optic Bragg and resonant technology, applied in the field of nanometer three-coordinate measuring head, can solve complex processing and assembly problems, achieve good flexibility, reduce anisotropy and measurement errors, and achieve high edge quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

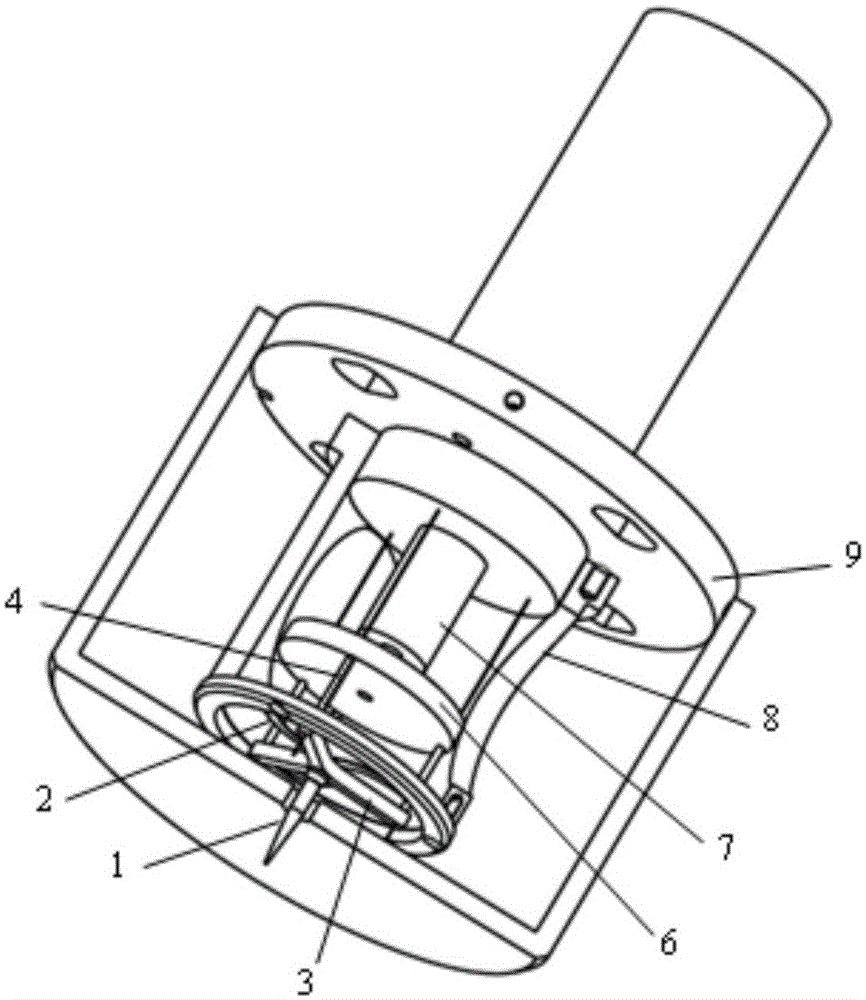

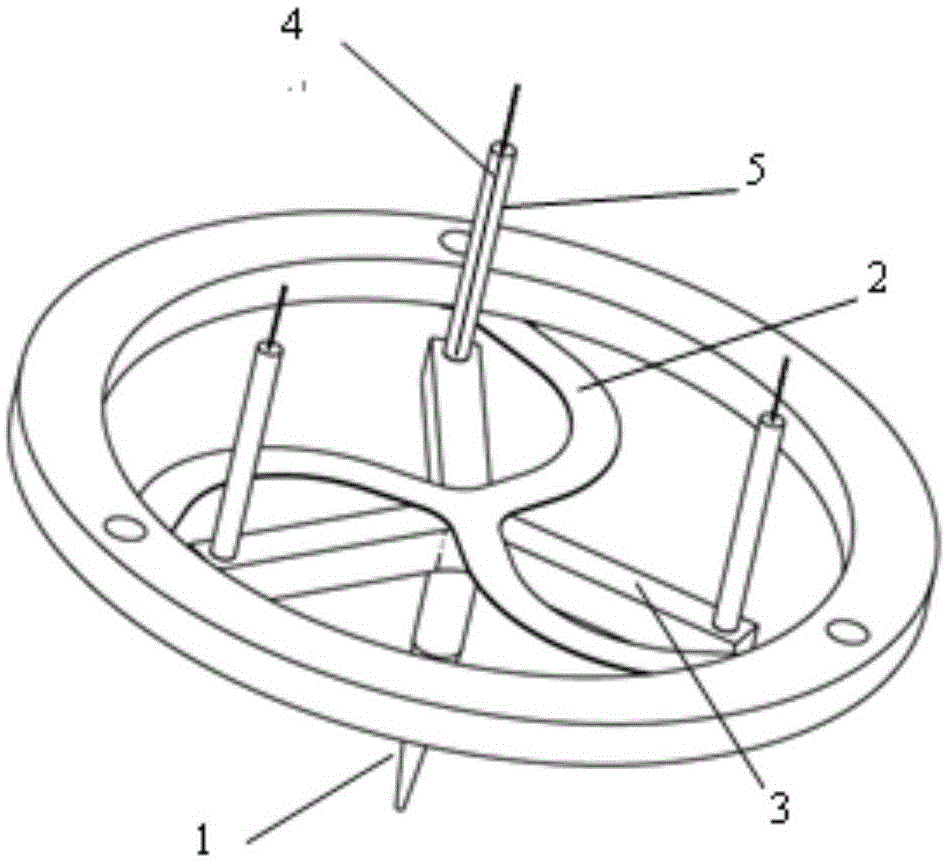

[0027] see figure 1 and figure 2 , the structure of the fiber Bragg grating-based resonant nano three-coordinate touch probe in this embodiment is set as:

[0028] The integrated probe 1 with a ball head is fixed on the central point of the suspension support 3 in a "T" shape, and the support rods on the suspension support 3 in the same plane are radially distributed, and the flexible cantilever 2 and the suspension support The sharp centers of 3 are fixed together, and the distal ends of the flexible arms on the same plane on the flexible cantilever 2 are fixed on the outer connecting ring 8 to form a measuring probe. This flexible cantilever support is connected to the center of the suspension support at one point, and the arms are staggered. Change, the flexible cantilever supports the force arm to increase, and the distal end of the suspension support is not constrained by the flexible cantilever, so that the force measurement of this structure is smaller and the flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com