Patents

Literature

111results about How to "Improve running smoothness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

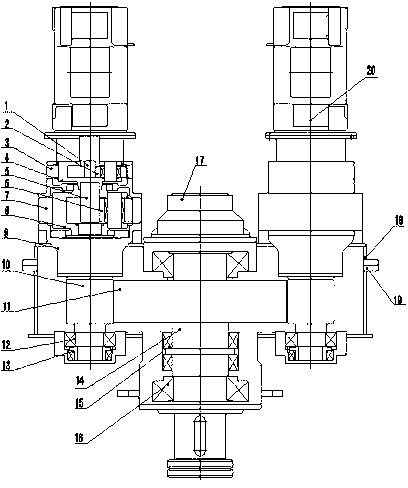

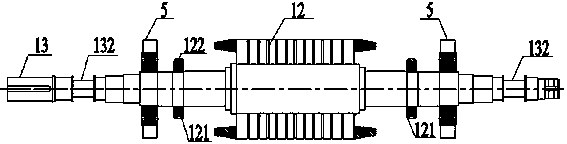

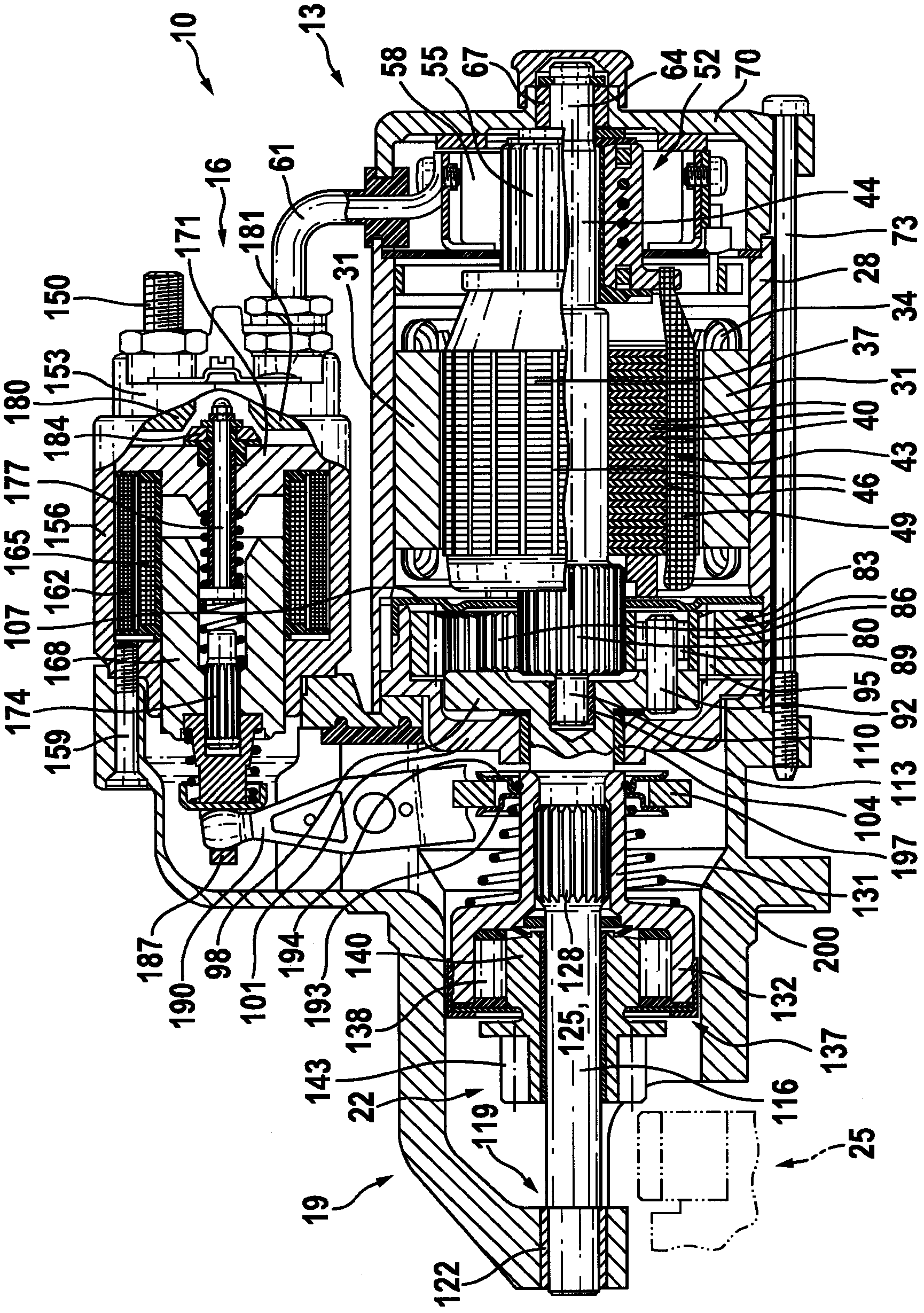

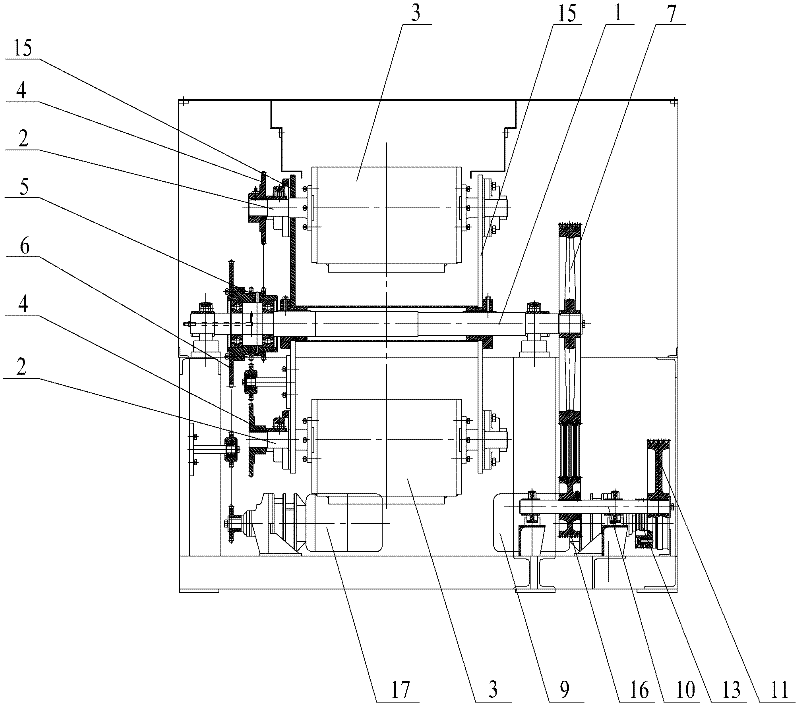

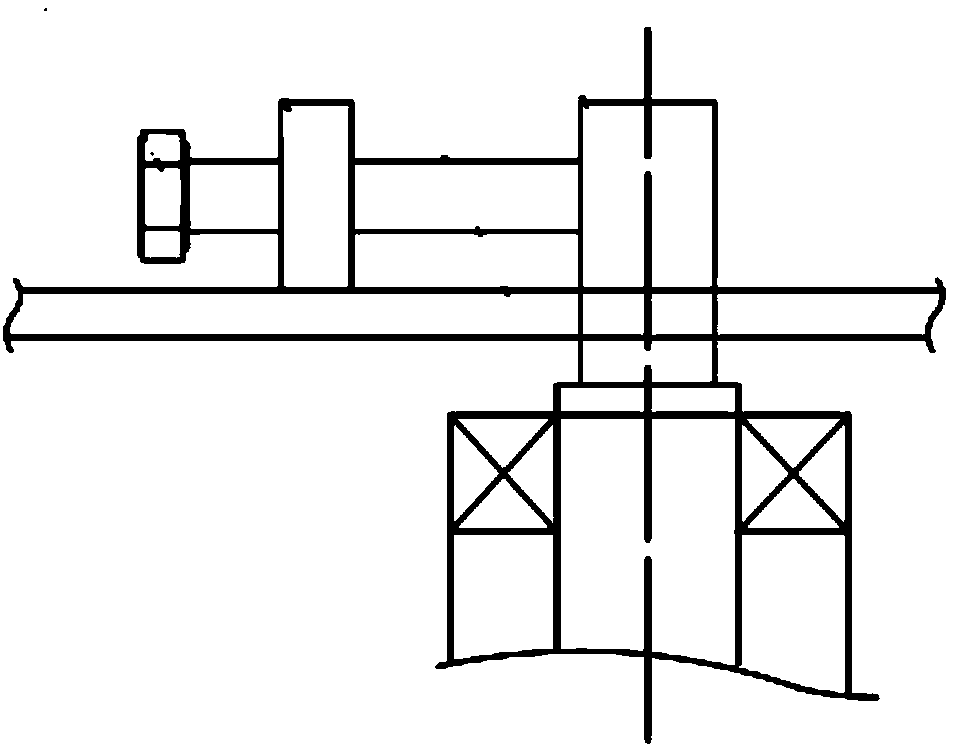

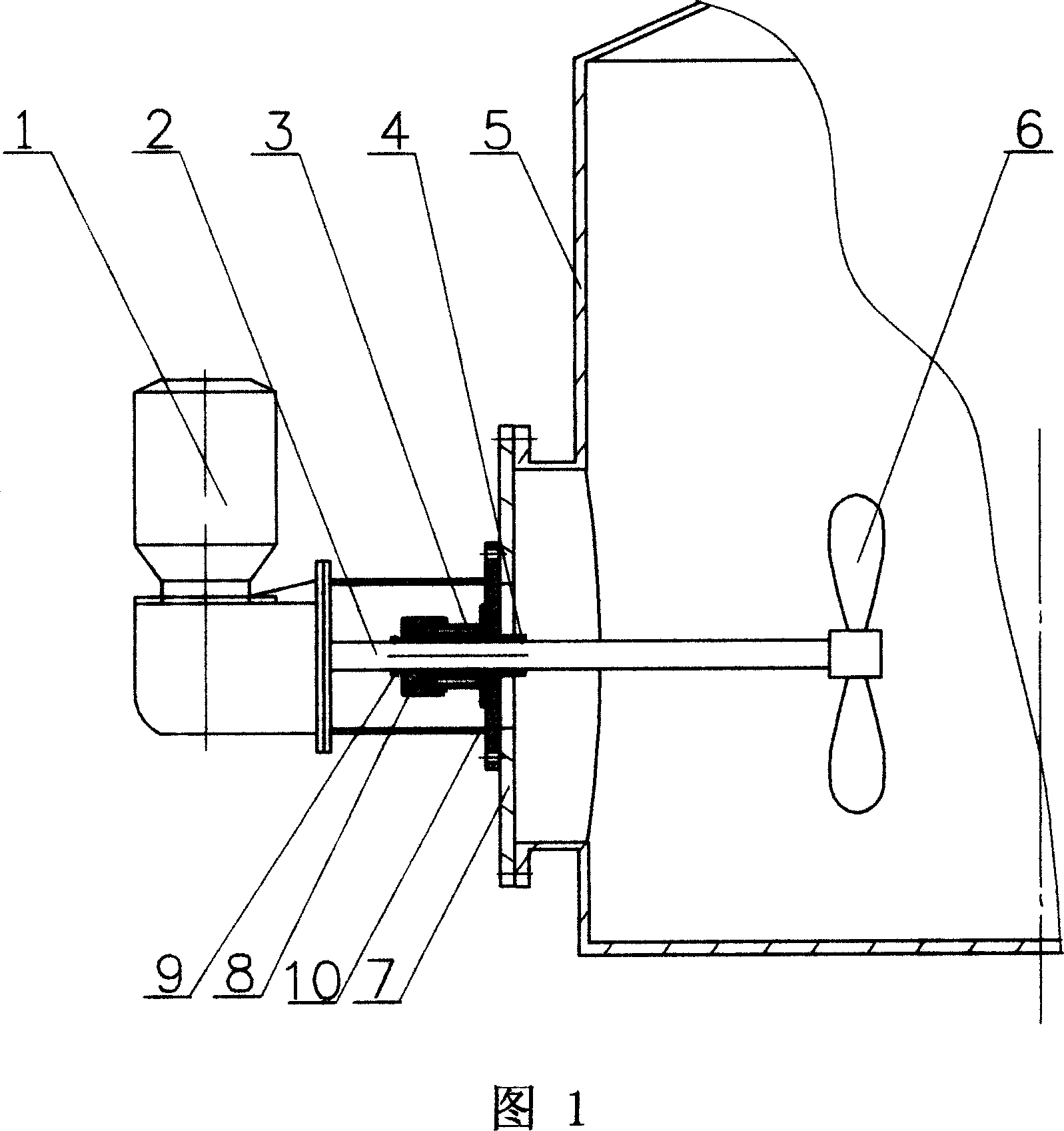

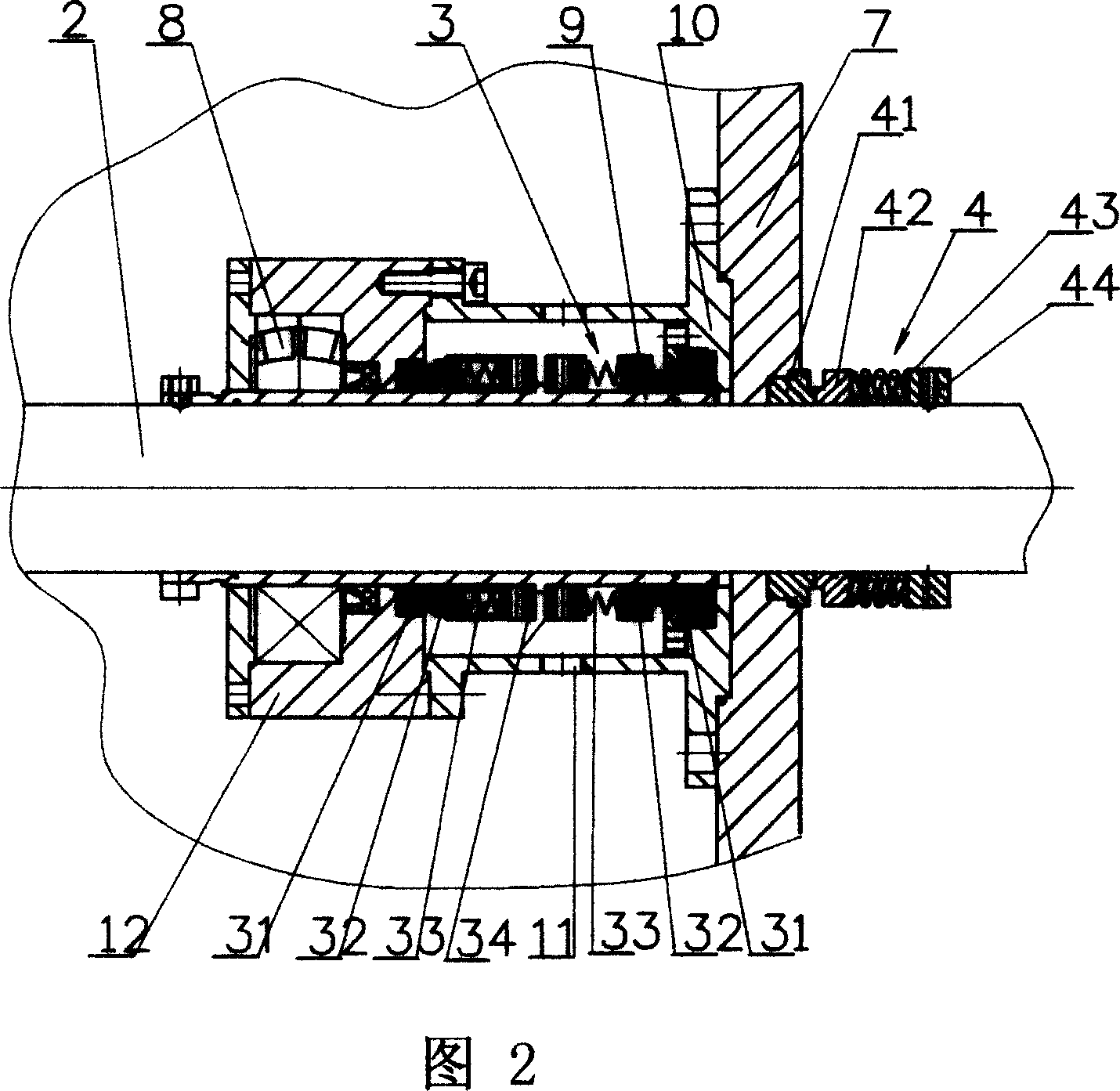

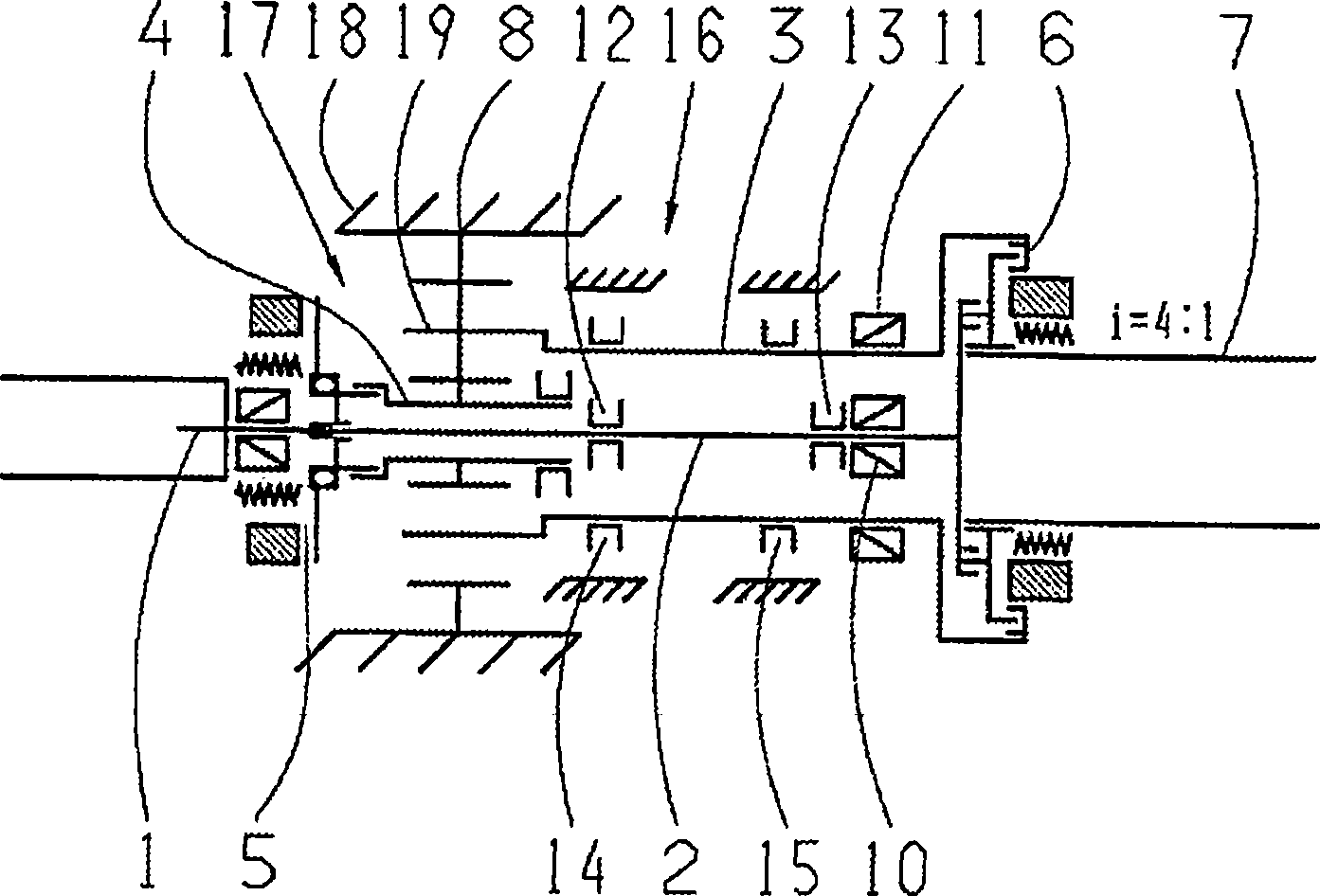

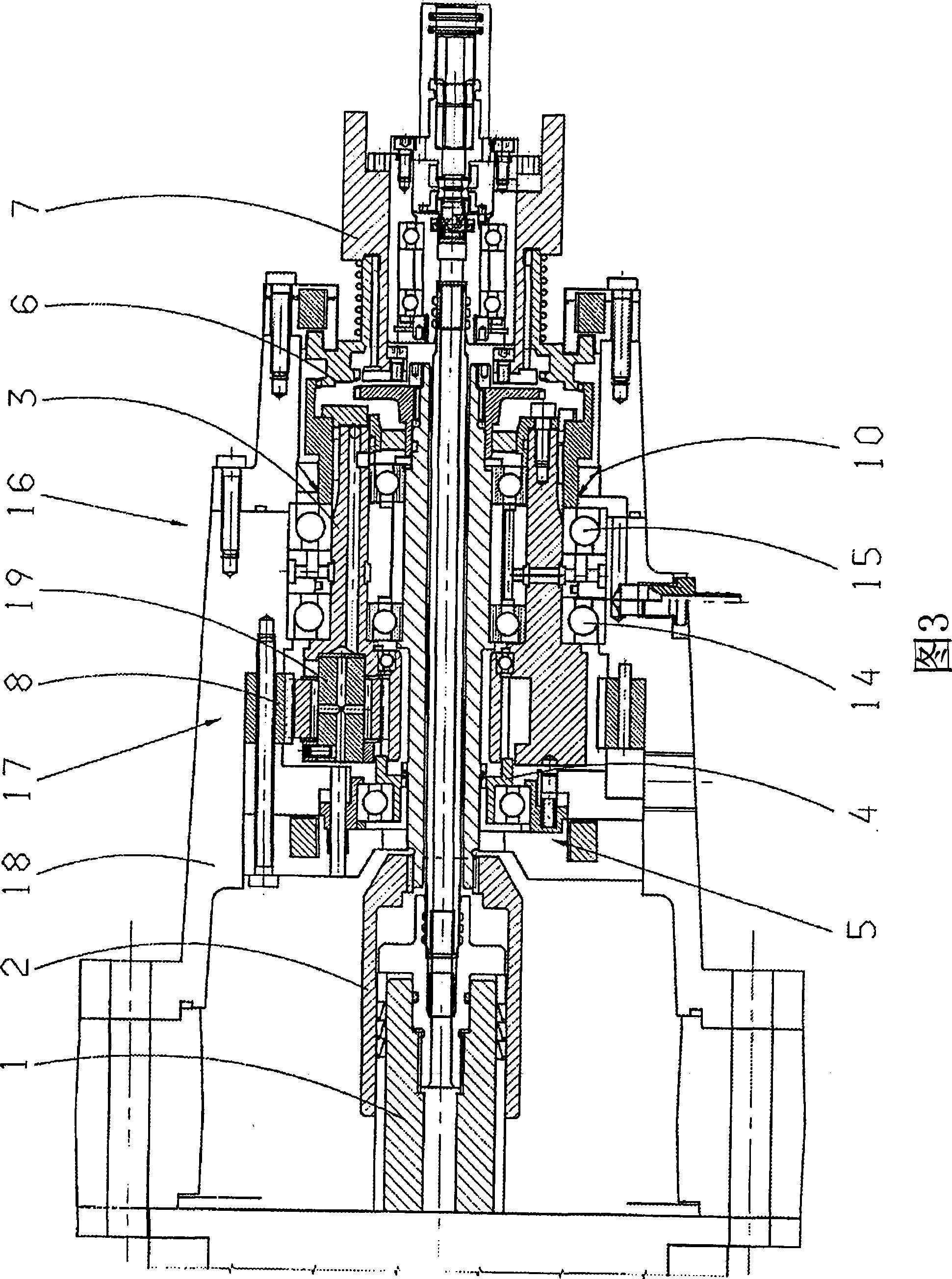

Novel large torque piling machine power head hardened reducer

InactiveCN103016641AReduce loadImprove carrying capacityToothed gearingsFoundation engineeringLow noiseReducer

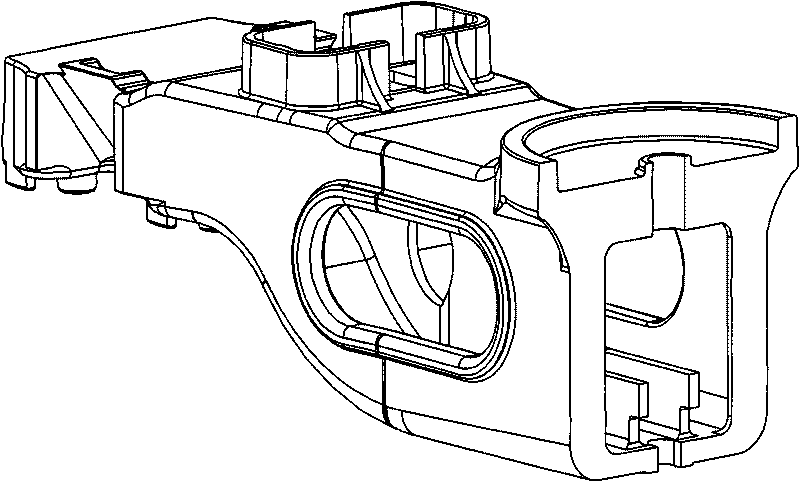

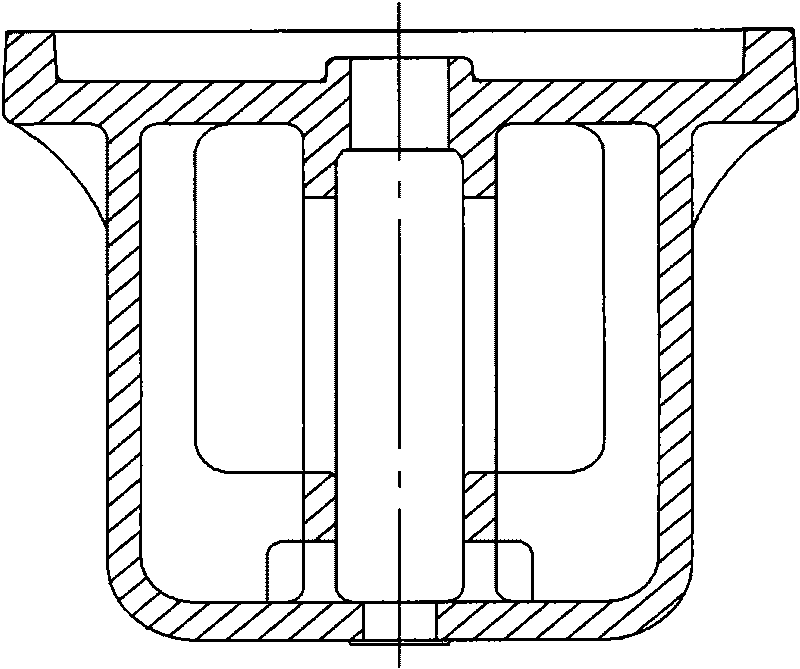

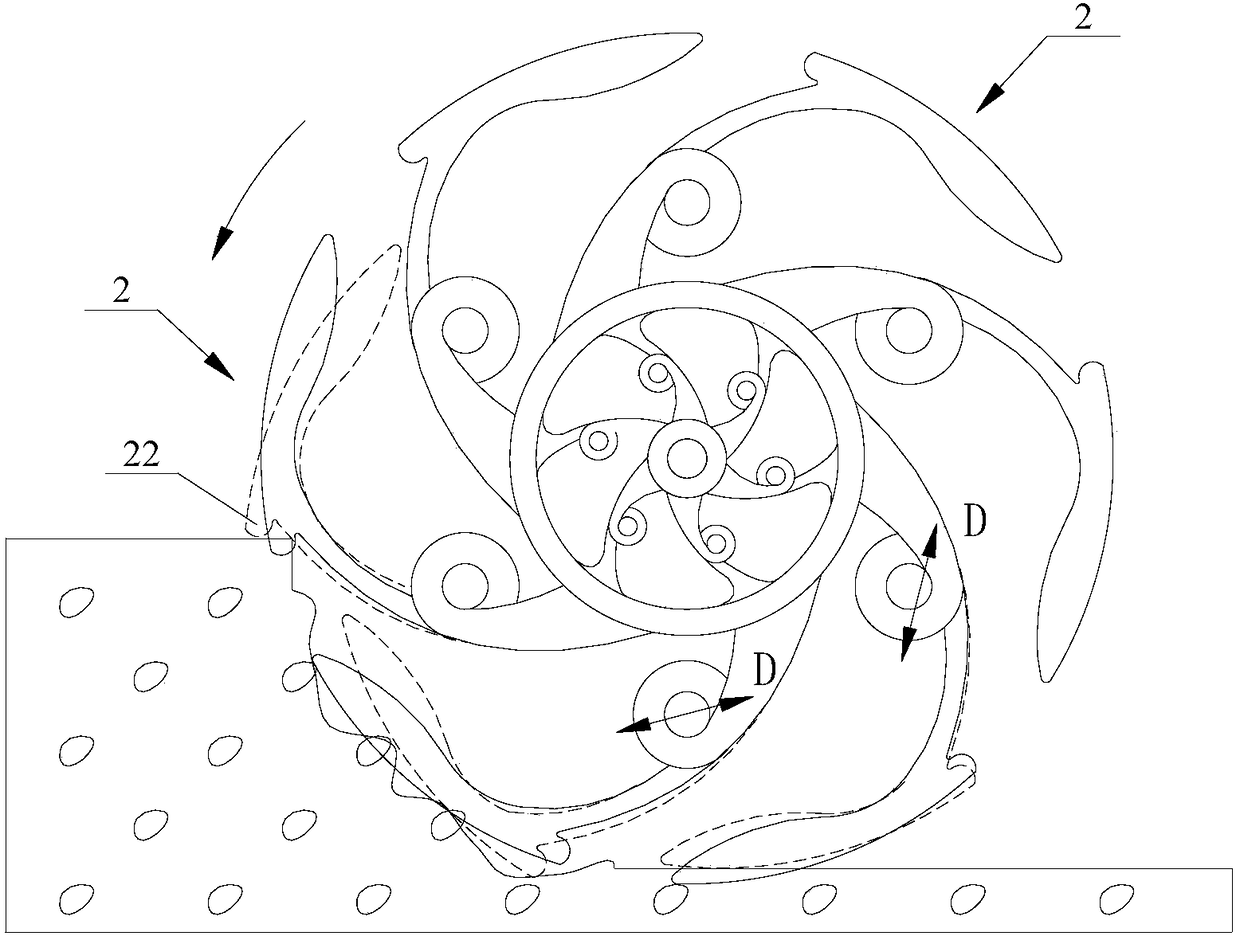

The invention relates to a novel large torque piling machine power head hardened reducer. The reducer comprises an engine body, a cover body, a central gear, an output shaft and more than two groups of planetary transmission mechanisms, wherein two ends of the output shaft are respectively supported on the engine body and the cover body in a penetrating manner; the output shaft at one side of the engine body is in end connection with a grouting device system; the central gear is connected onto the output shaft in a penetrating manner and is arranged between the engine body and the cover body; the more than two groups of planetary transmission mechanisms are supported on the engine body by taking the output shaft as a symmetric center; the planetary transmission mechanism comprises an input motor, and first-stage and second-stage planetary transmission mechanisms; the input motor is connected to an inclined gear shaft which is arranged in the engine body and the cover body through the first-stage and second-stage planetary transmission mechanisms; and the inclined gear shaft is meshed with the central gear. By adopting the more than two groups of planetary transmission mechanisms, the running power of the reducer is shunted; the reducer can stably and safely run for a long time under the large torque in matched with the meshed inclined gear shaft and the output shaft through the combination supporting of a roller bearing and a plane bearing; and the reducer has the advantages of compact structure, stable running, shunted work load, little equipment abrasion, low noise and long service life.

Owner:JIANGSU TAILAI REDUCER

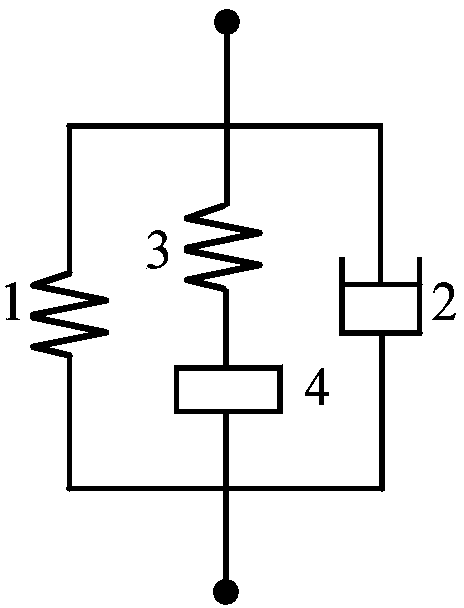

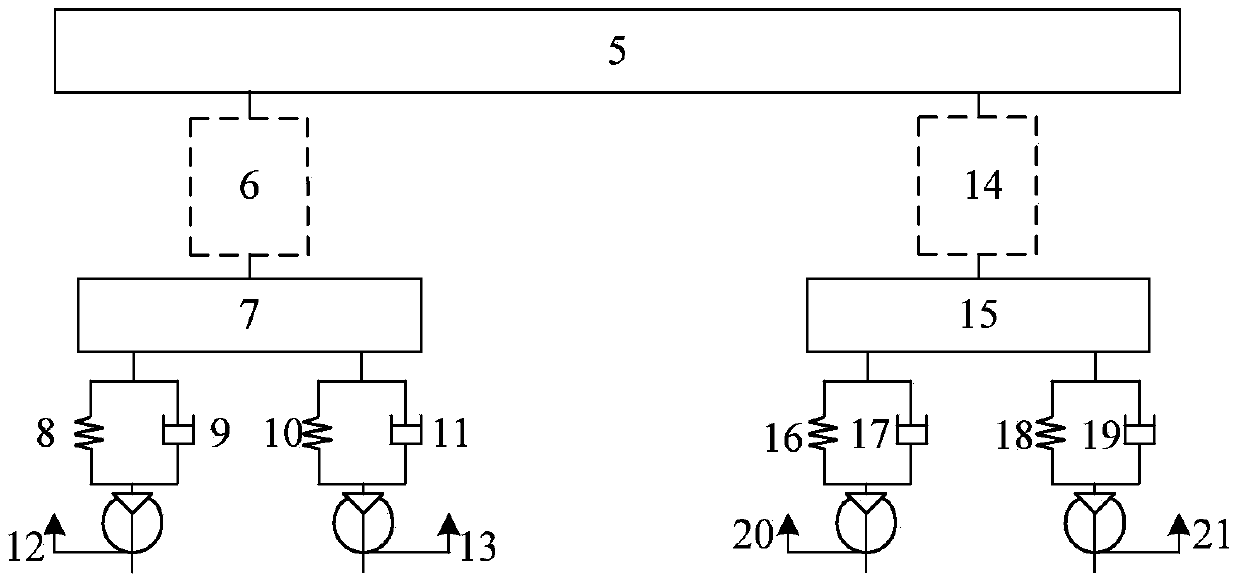

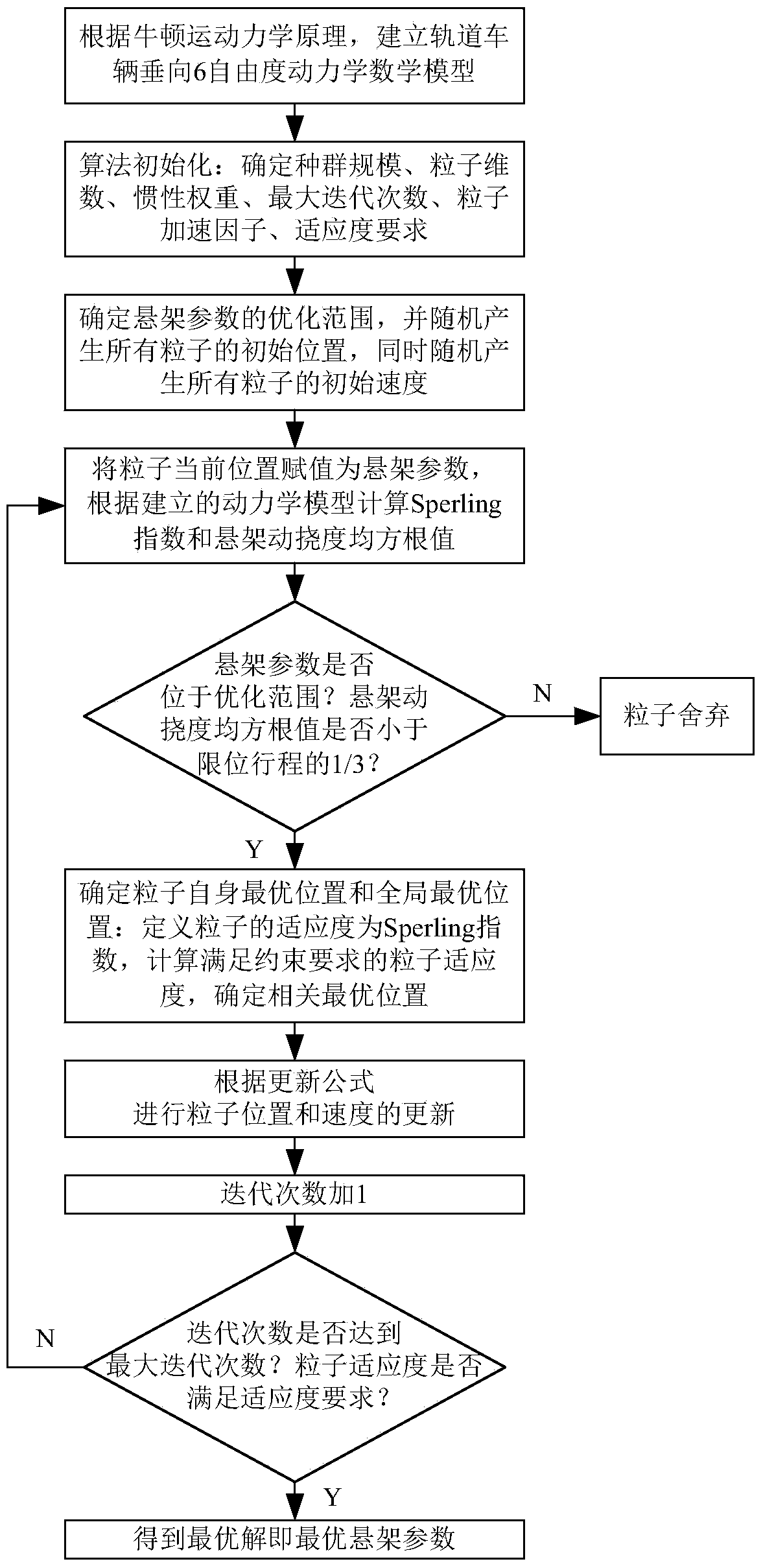

Railway vehicle second level vertical suspension applying inerter and parameter determining method thereof

InactiveCN103991458AGood structural complexityImprove running smoothnessBogiesSpecial data processing applicationsAutomotive engineeringParticle swarm optimization

The invention provides a railway vehicle second level vertical suspension applying an inerter and a parameter determining method thereof. The railway vehicle second level vertical suspension comprises the inerter, a damper, a main spring and an auxiliary spring, and the main spring is in parallel connection with the damper and then is in parallel connection with a series connection structure of the inerter. According to the suspension parameter determining method, the minimum of a Sperling index is used as an optimization object, under the premise that the root-mean-square value of the dynamic deflection of the second level vertical suspension is not beyond one third of a limiting stroke, the parameter is obtained by optimization through a particle swarm optimization algorithm. A simulation analysis result shows that the railway vehicle second level vertical suspension and the parameter determining method thereof, the Sperling index of railway vehicles can be effectively lowered in the riding process, and the riding stability of the railway vehicles can be improved.

Owner:JIANGSU UNIV

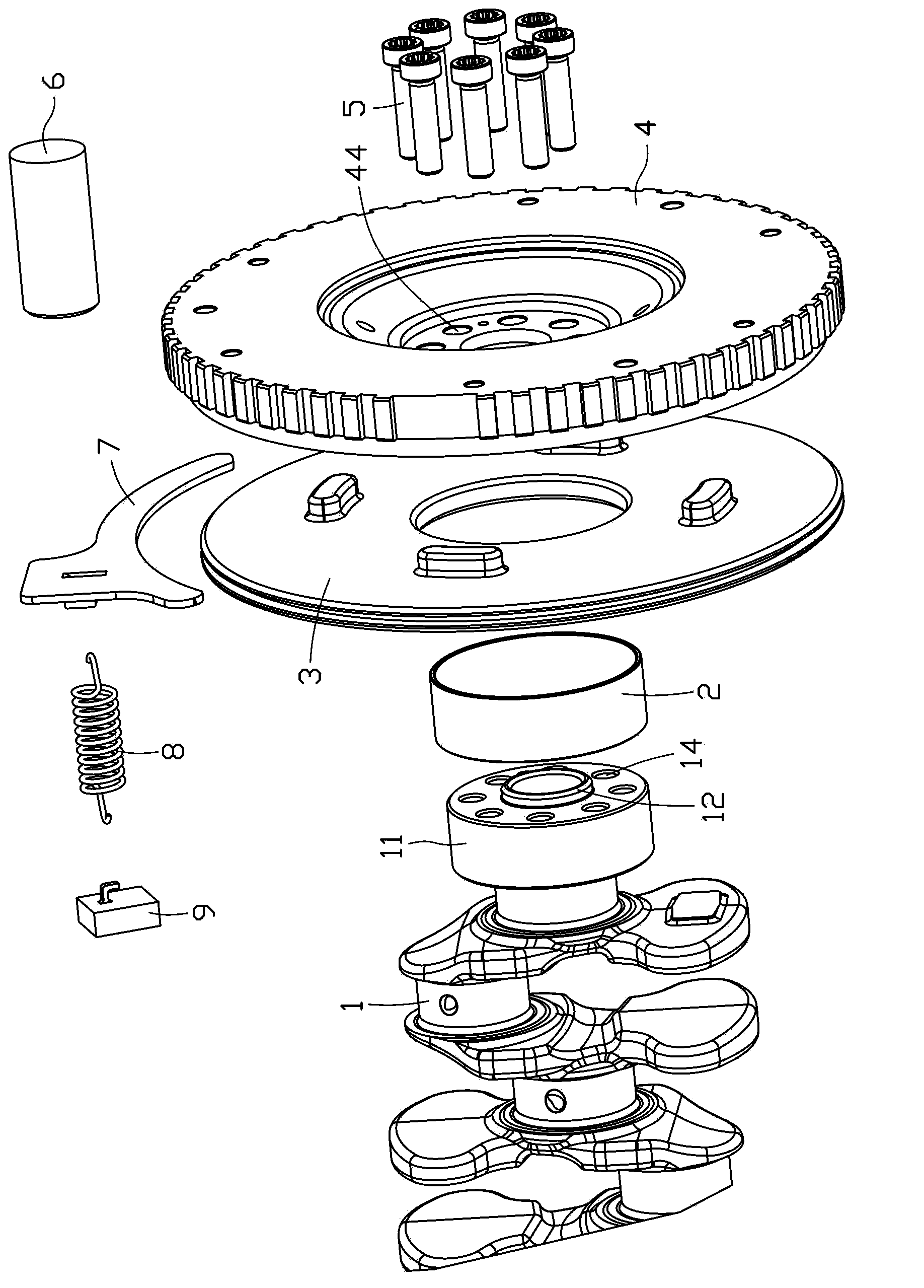

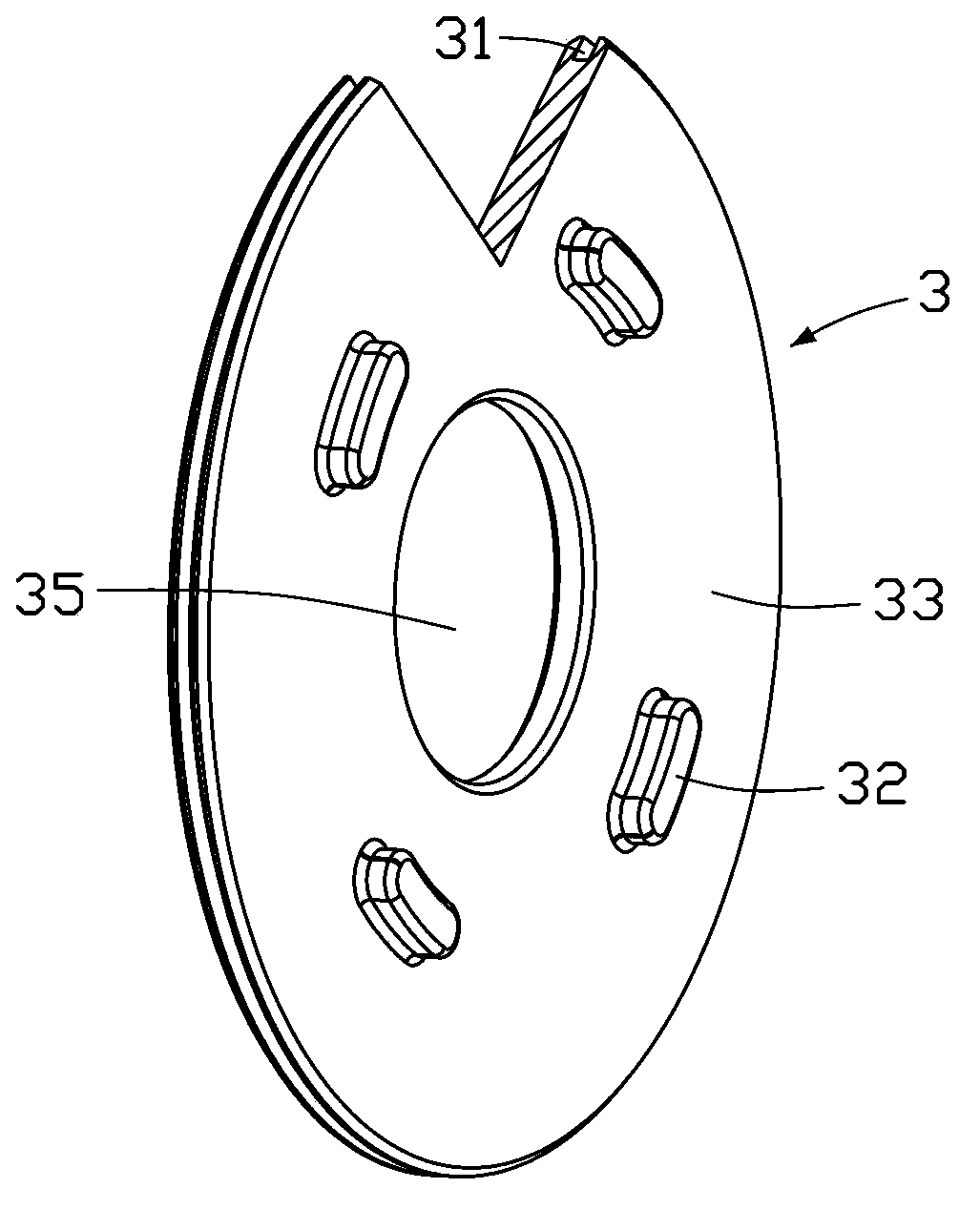

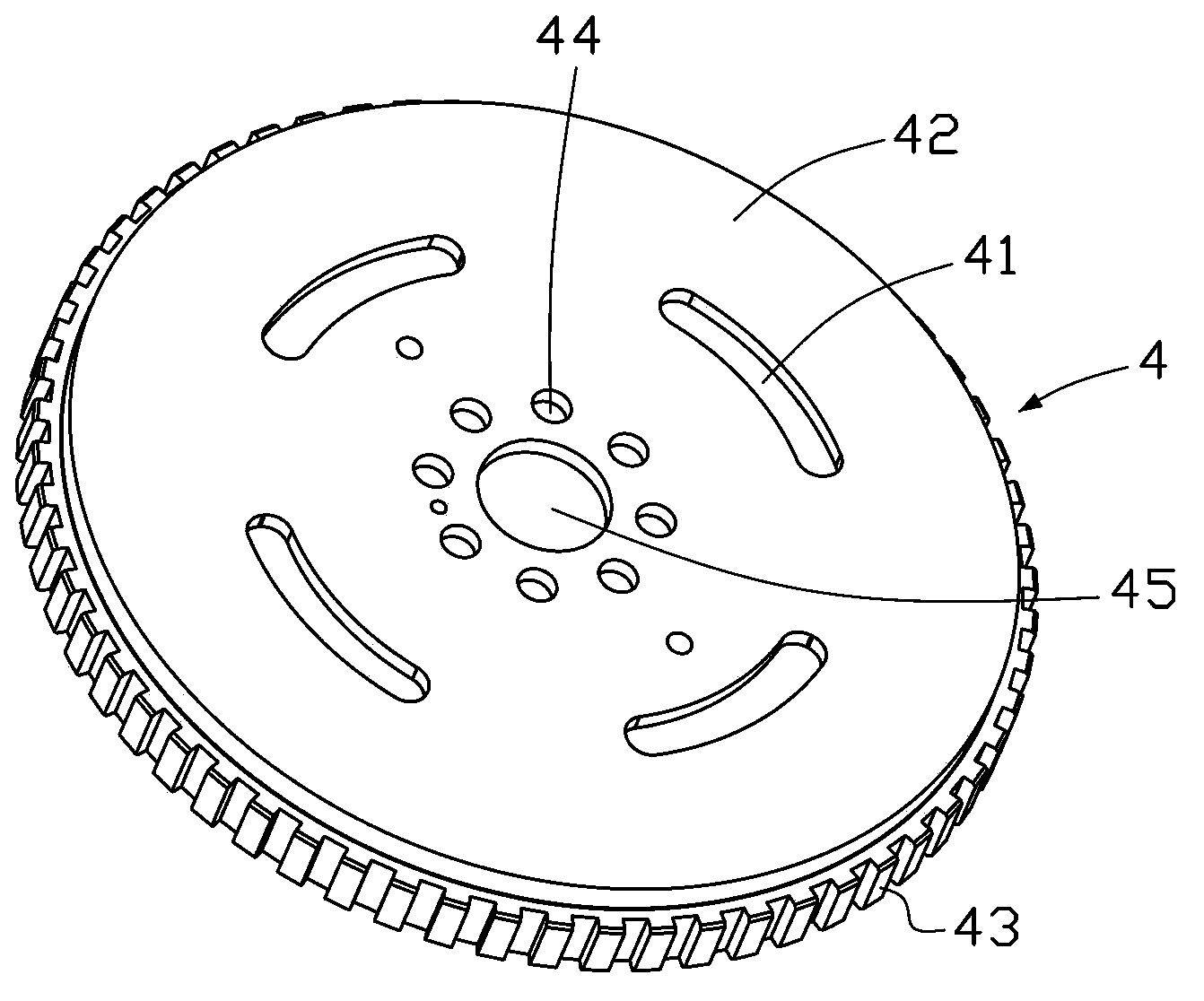

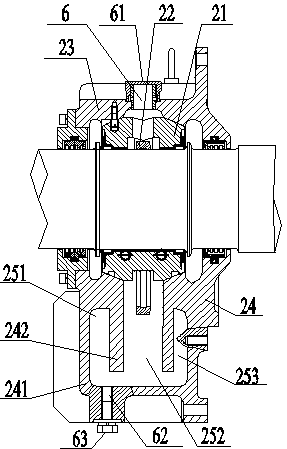

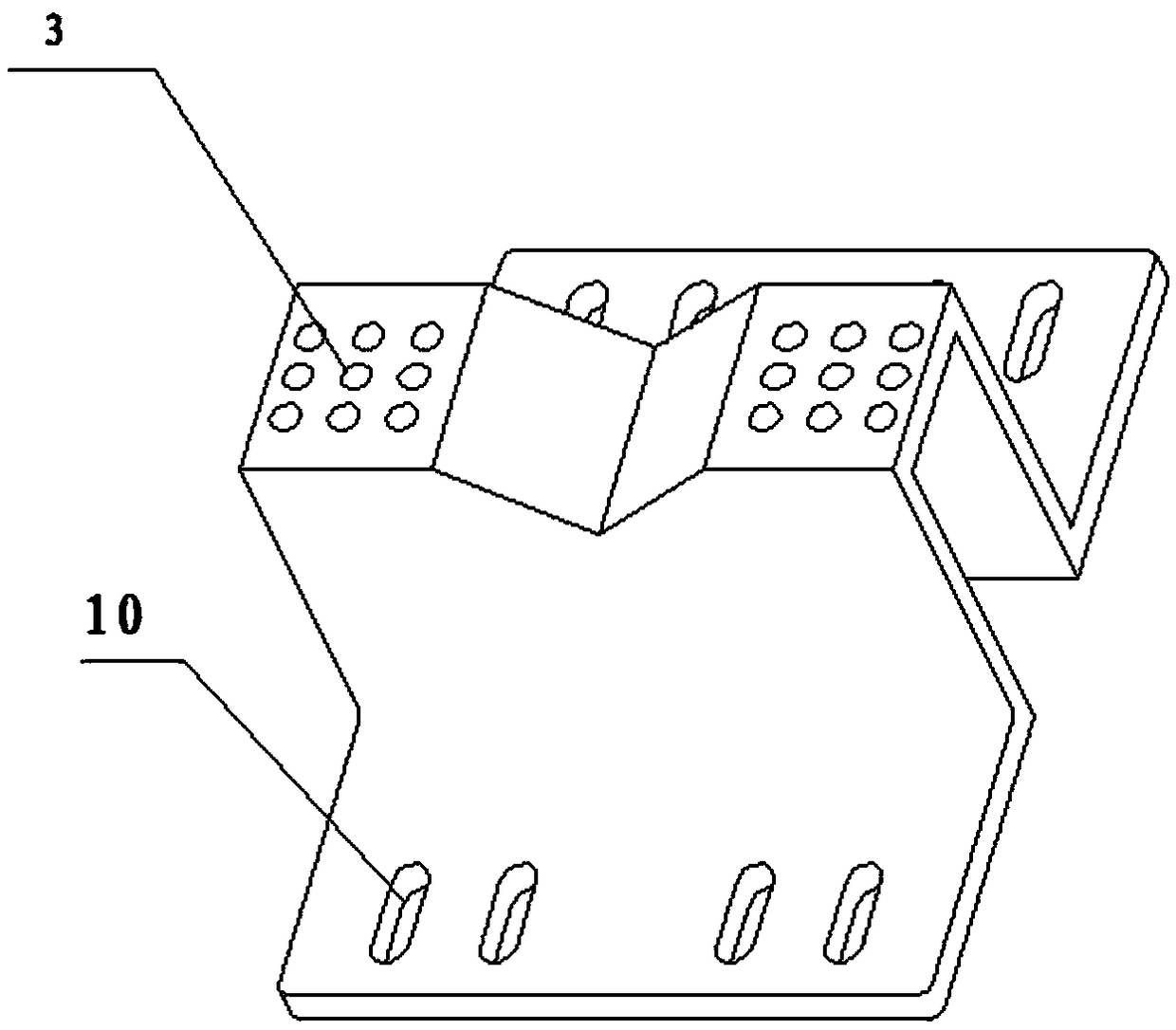

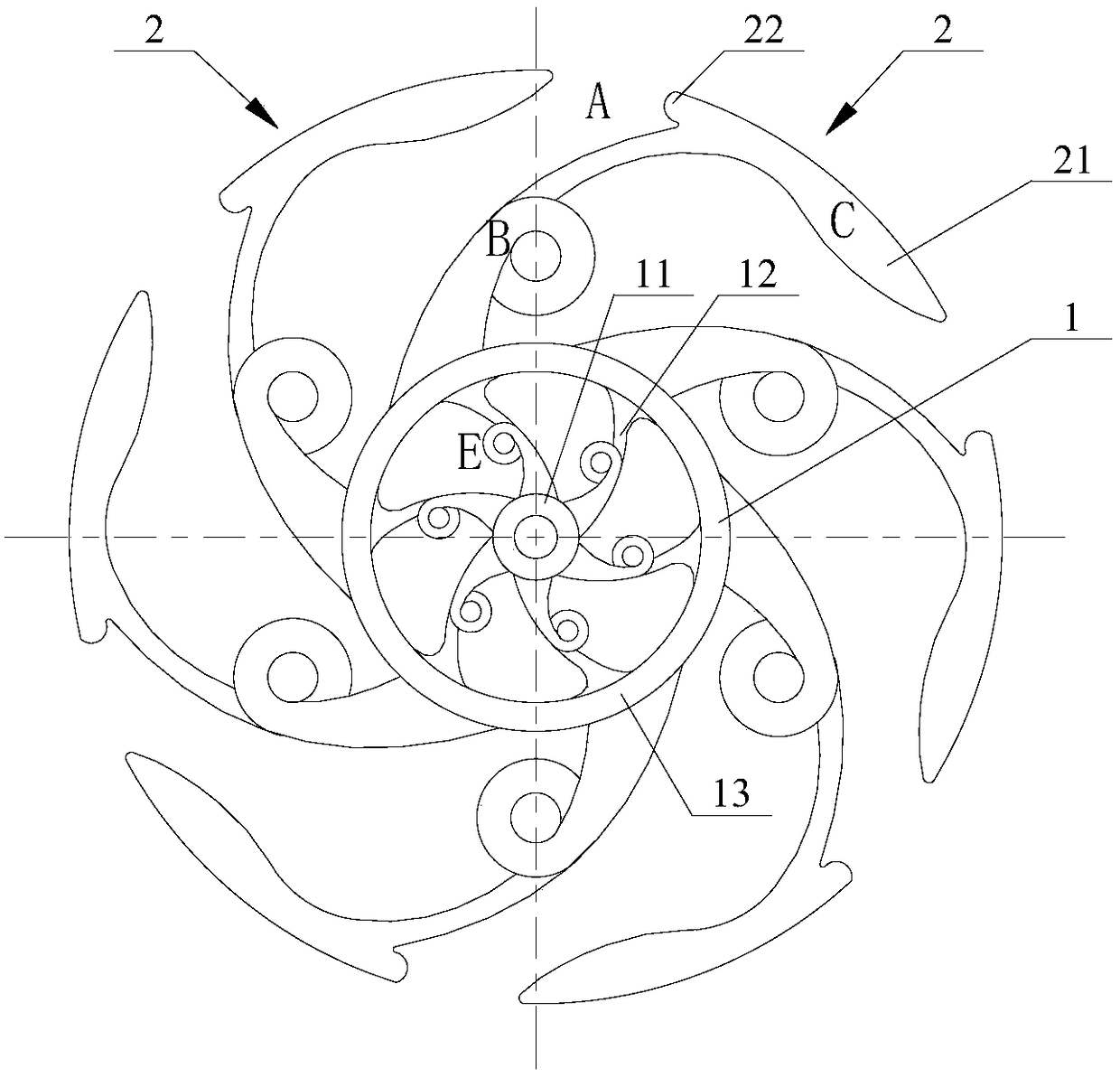

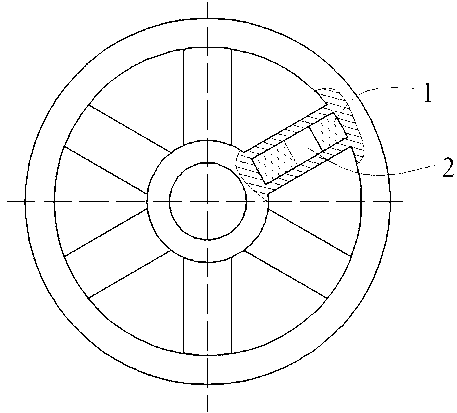

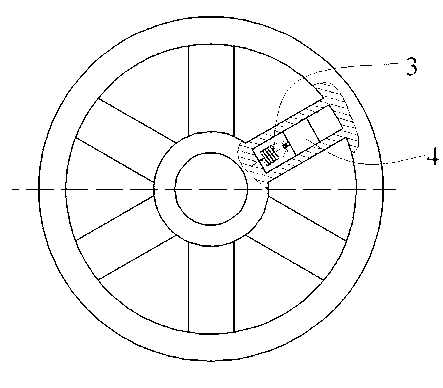

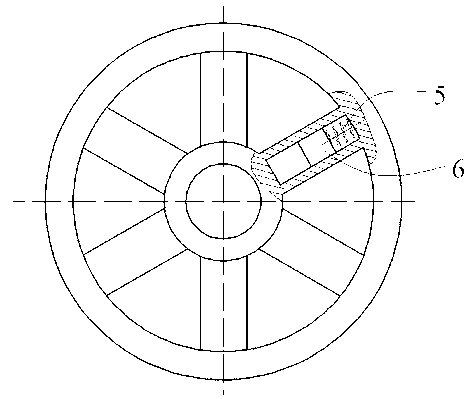

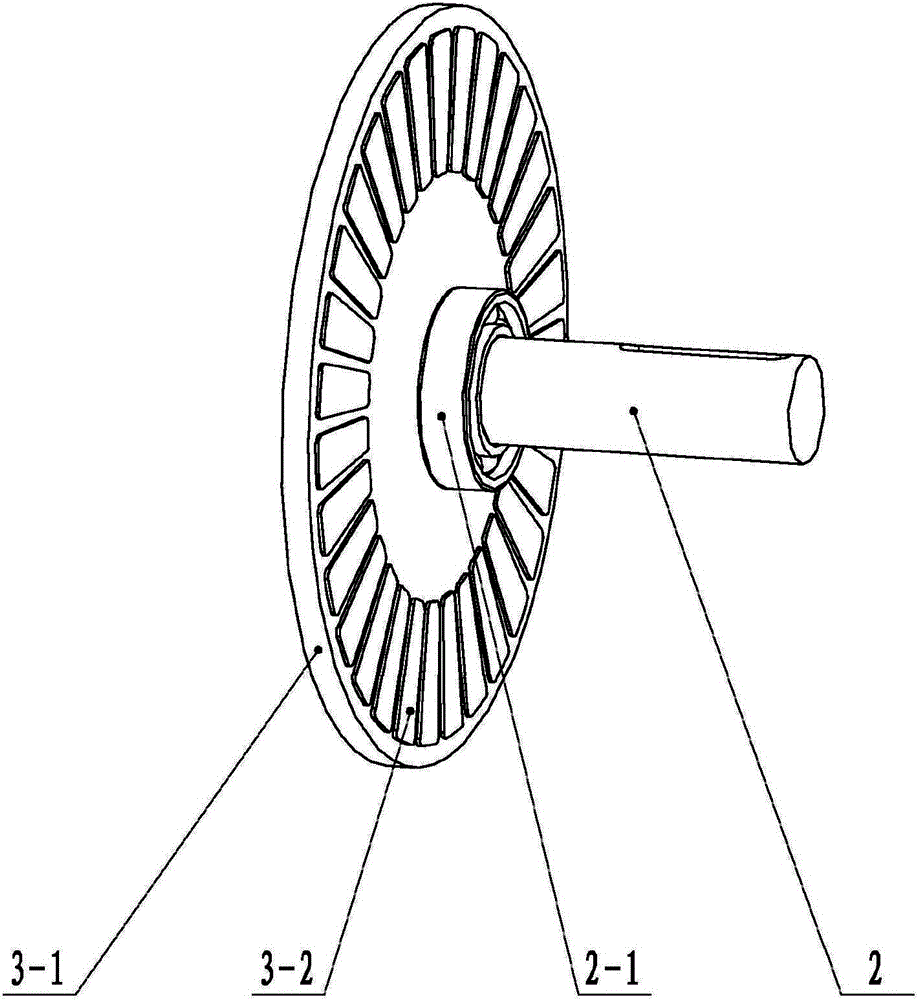

Variable inertia flywheel structure

The embodiment of the invention discloses a variable inertia flywheel structure, which comprises a first flywheel and a second flywheel, wherein the first flywheel is used for being fixedly connected with a crankshaft, and the first flywheel comprises a first flywheel disk; the second flywheel comprises a second flywheel disk, and a pawl slot is arranged on a disc surface of one of the first flywheel disk and the second flywheel disk; and a pawl is convexly arranged on a disc surface of the other one of the first flywheel disk and the second flywheel disk, and the pawl is correspondingly matched with the pawl slot. When the large inertia of the flywheel is needed, the pawl extends into the pawl slot, and the first flywheel drives the second flywheel to rotate together; when the small inertia of the flywheel is needed, the pawl is separated from the pawl slot, and the first flywheel rotates and the second flywheel does not rotate with the first flywheel. According to the variable inertia flywheel structure, when an engine runs at low speed, the inertia of the flywheel increases so as to improve the smoothness of operation; and when the engine runs at high speed, the moment of inertia of the flywheel is reduced, and the fuel consumption is saved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

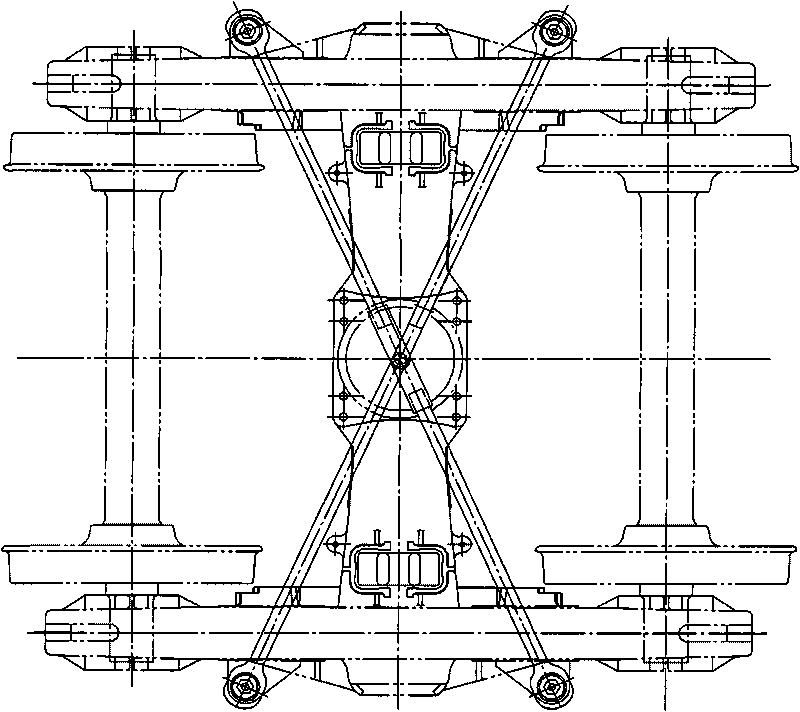

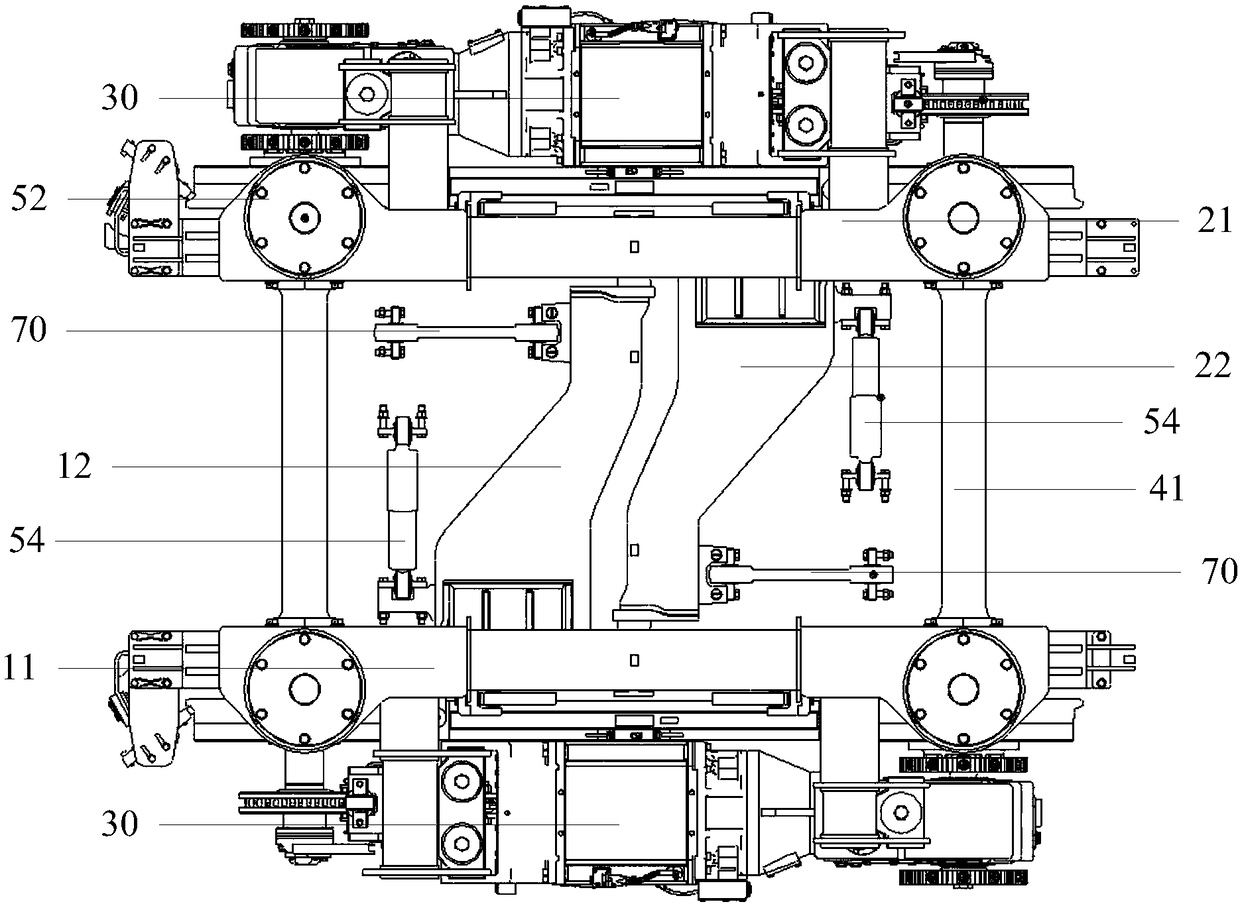

Bogie for freight car and freight car

ActiveCN101700775APrevent rhomboid deformationImprove running smoothnessWagons/vansBogiesTruckBolster

The invention discloses a bogie for a freight car and the freight car. The bogie for the freight car comprises two wheel pairs, two side frames arranged at the outer side the wheel pairs, a swing bolster fixedly connected with the centers of the two side frames, and a K-shaped support device. The K-shaped support device passes through preset holes at both sides of the abdominal region of the swing bolster, a first upper end part, a second upper end part, a first lower end part and a second lower end part of the K-shaped support device are respectively and elastically connected with the two side frames, the first upper end part, the second upper end part, the first lower end part and the second lower end part are symmetrical relative to the central line of the swing bolster. The bogie for the freight car ensures that reinforced ribs for bearing vertical loads can be arranged on the middle part of the swing bolster without arranging the K-type support device on the middle part of the bolster, thereby increasing the rigidity of the bogie against diamond deformation, and increasing the strength of the bolster for bearing the vertical loads.

Owner:CRRC QIQIHAR ROLLING CO LTD

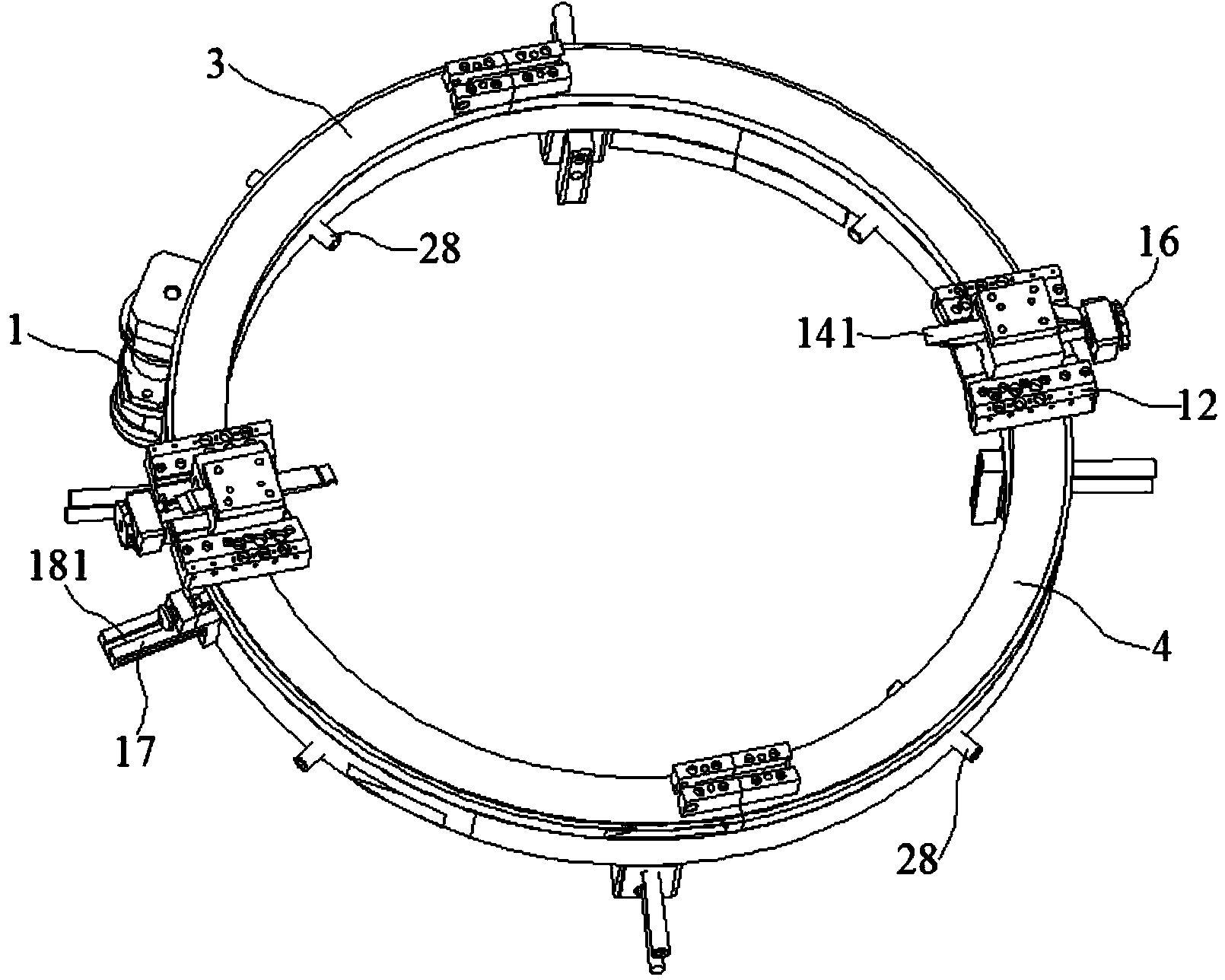

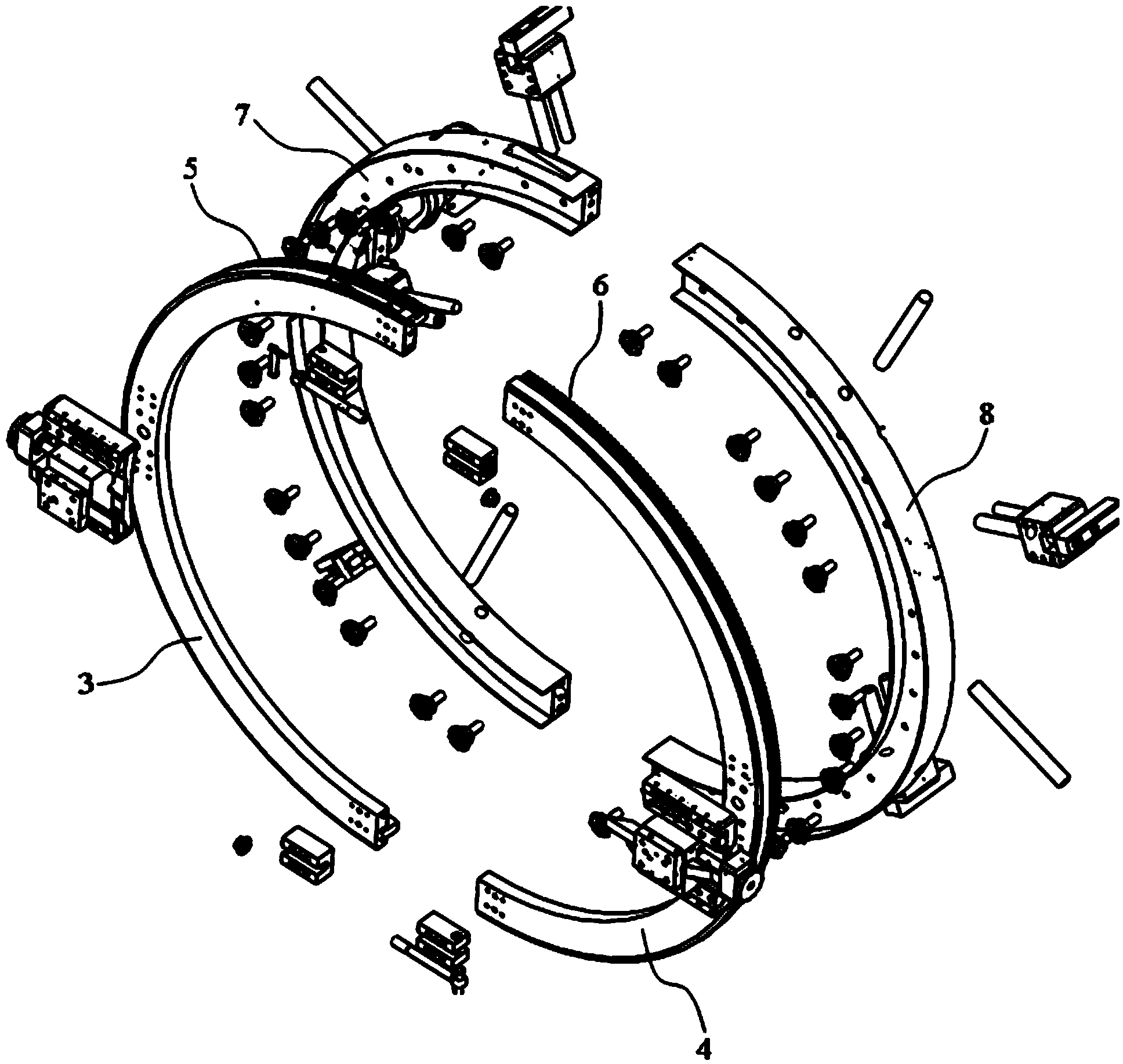

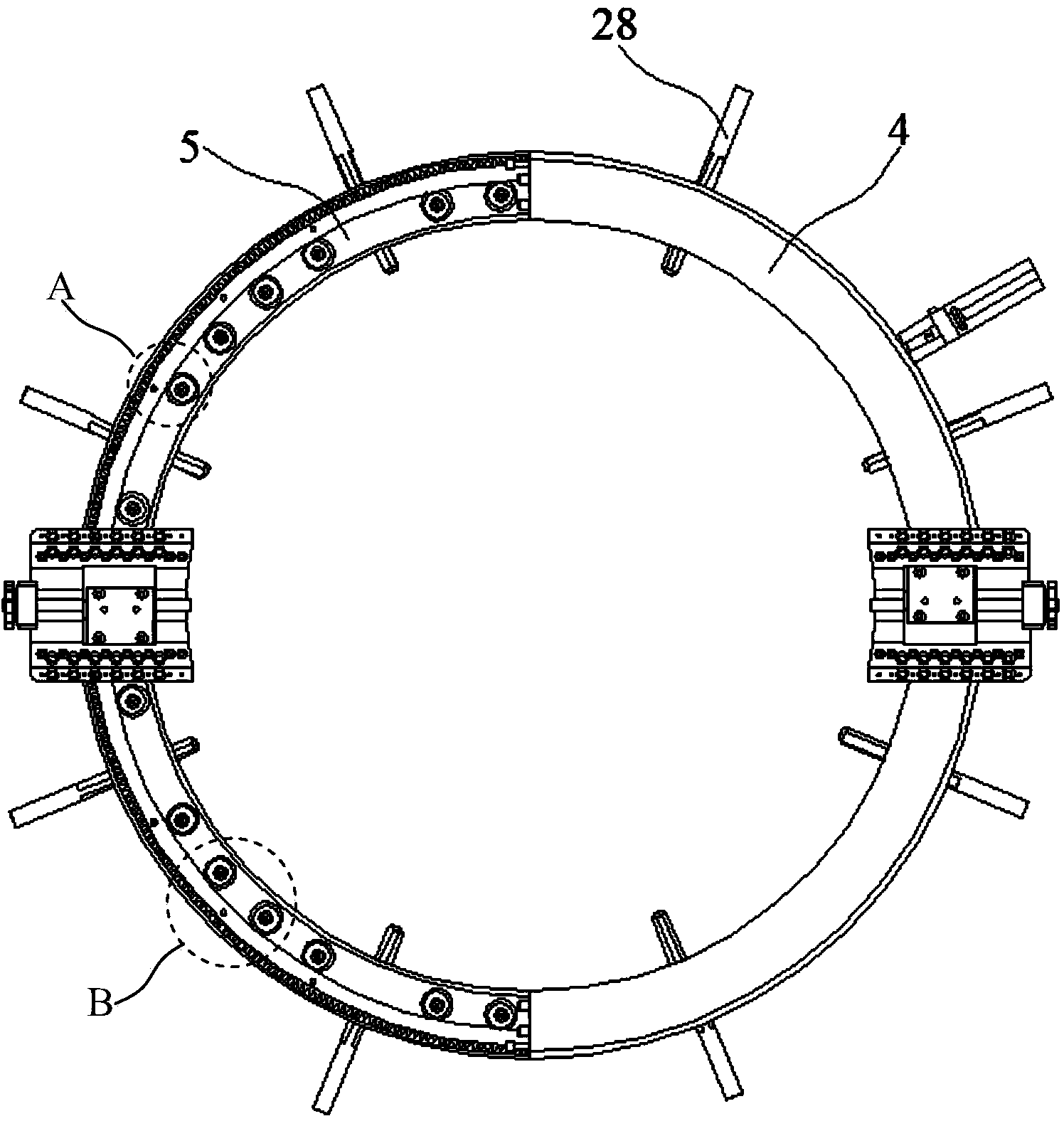

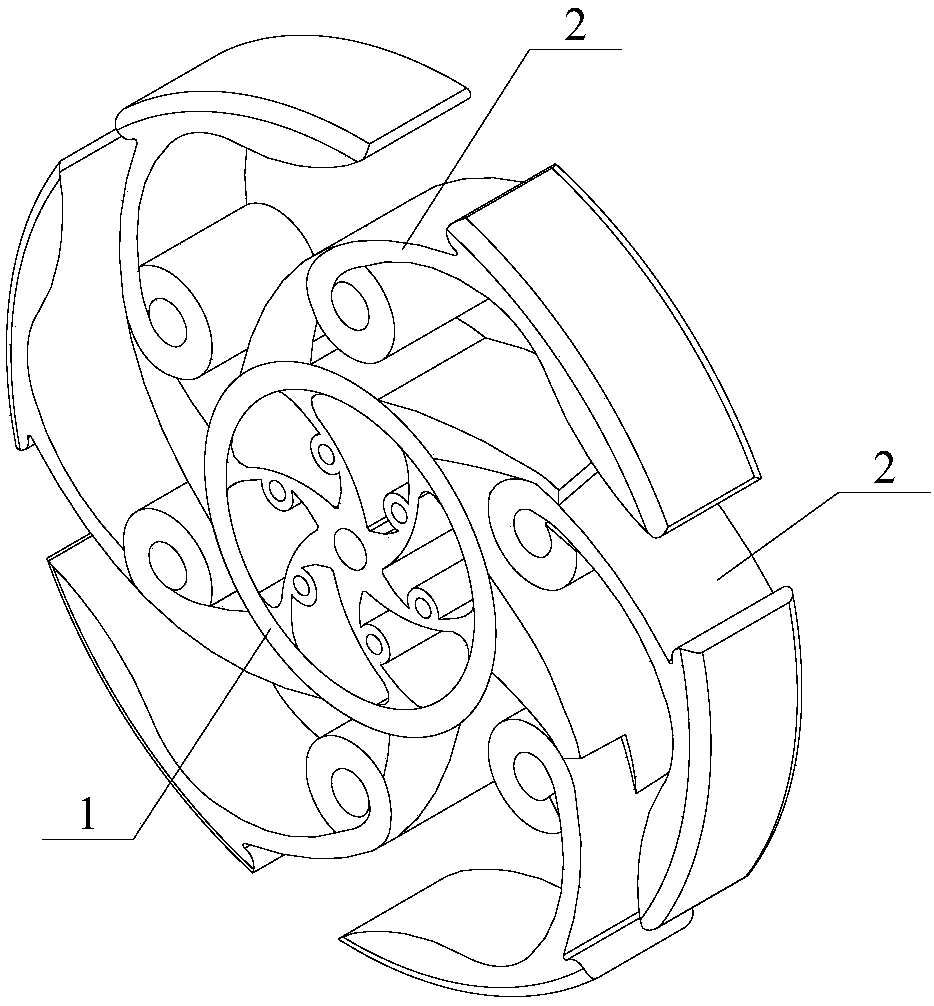

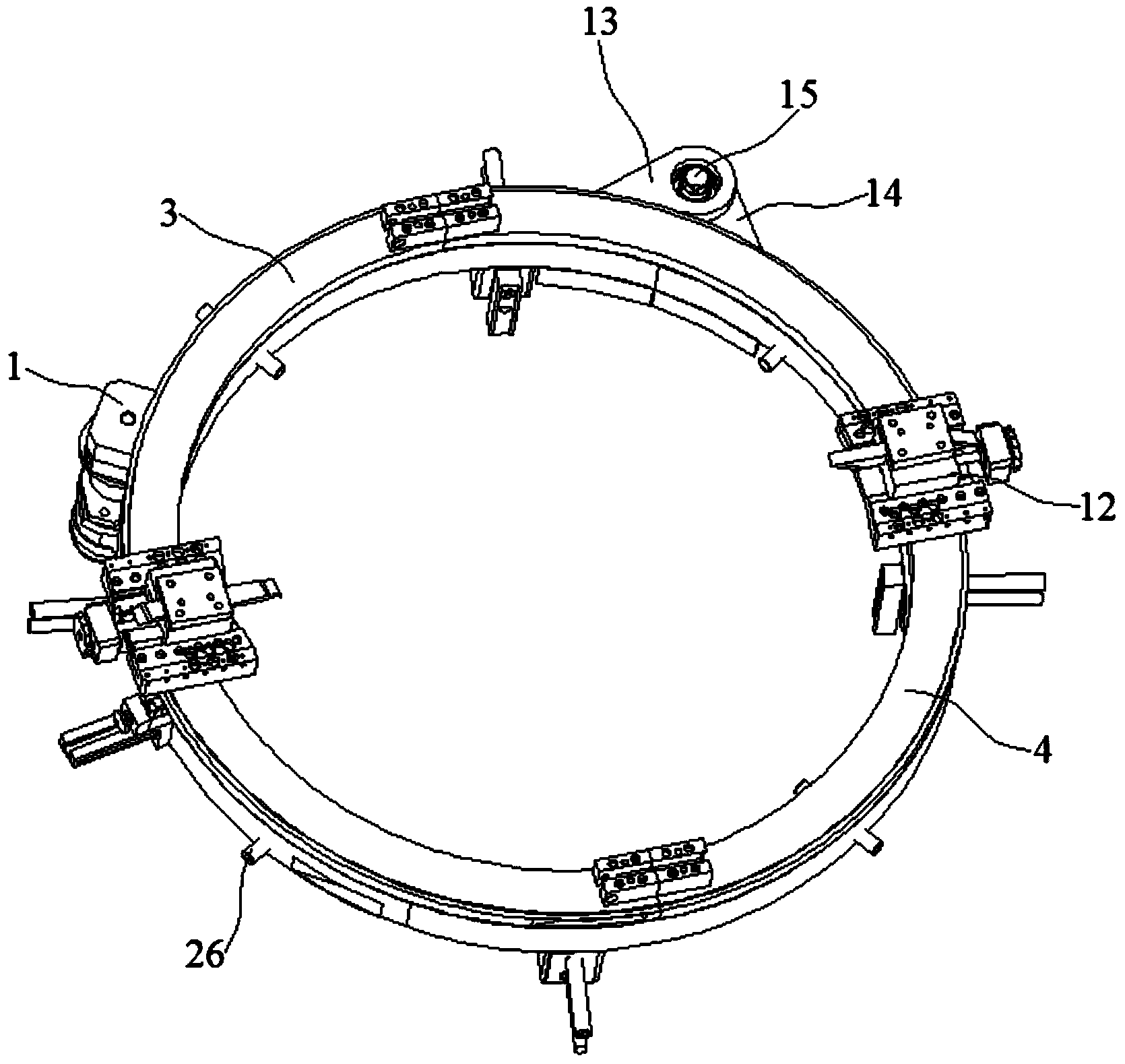

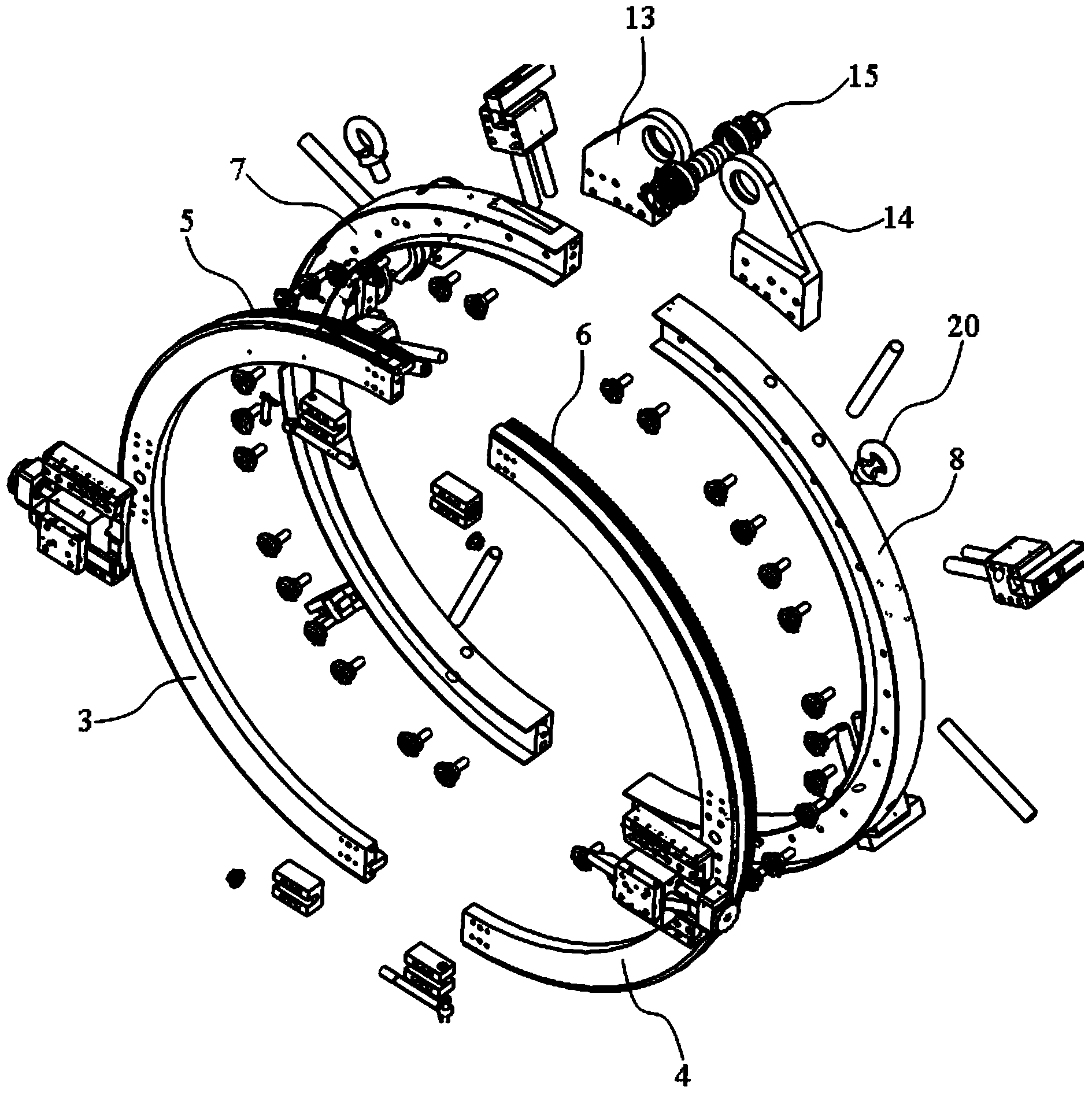

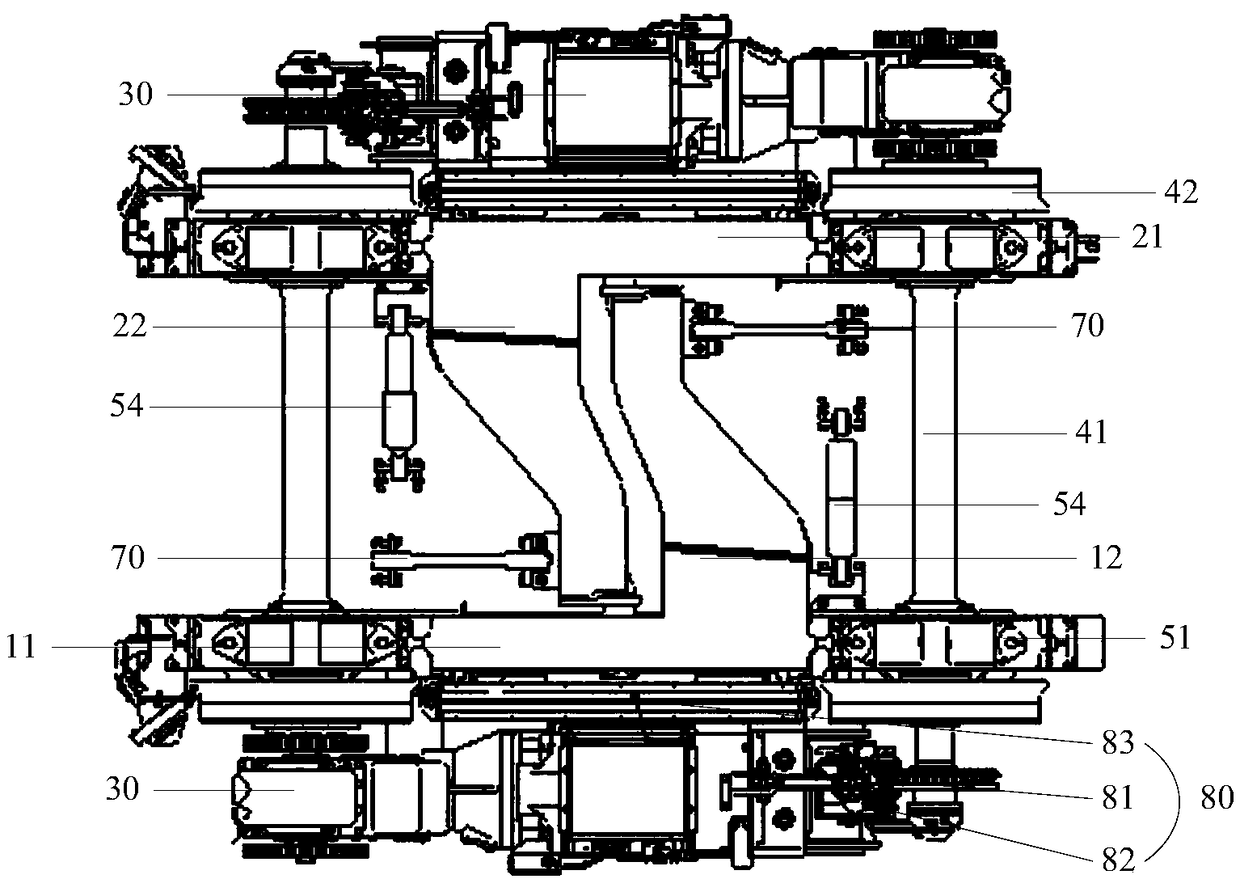

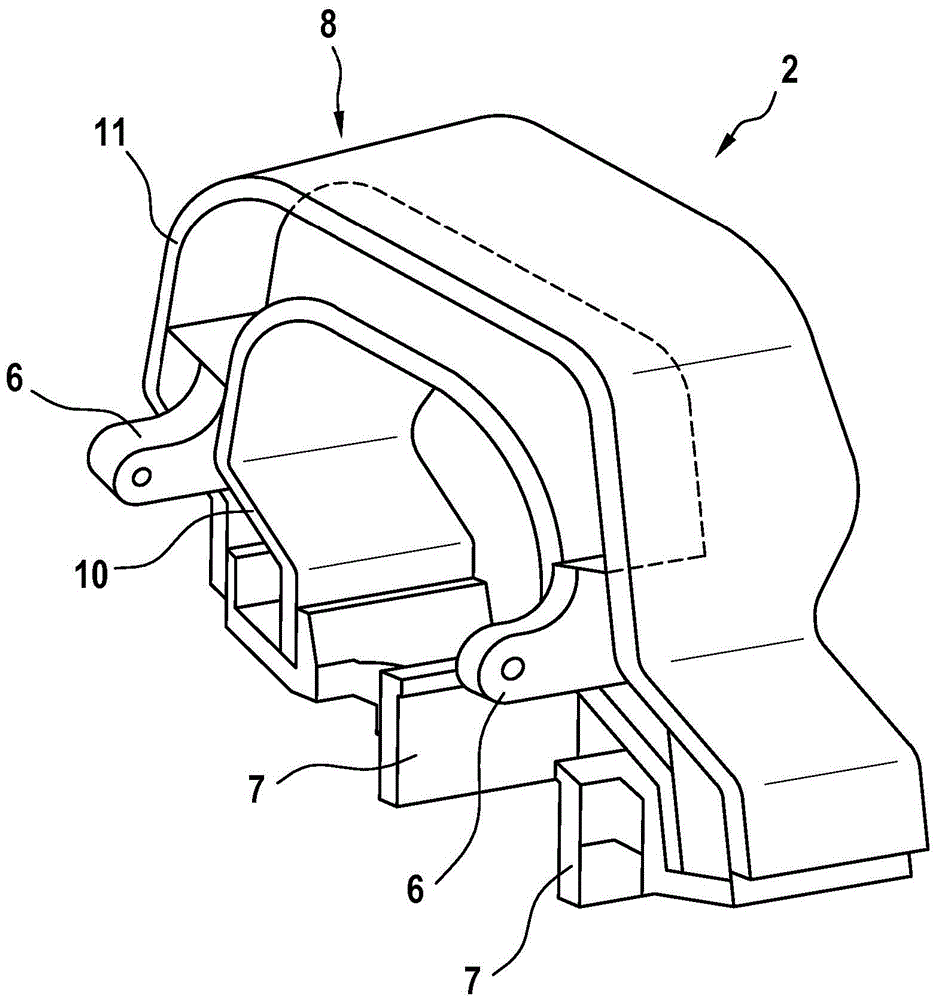

Outer clamp type bevelling machine

The invention discloses an outer clamp type bevelling machine, which comprises a power mechanism, a driving transmission gear, left and right movable rings, left and right gear rings and left and right fixed rings, wherein the left and right movable rings are respectively and fixedly arranged on the left and right gear rings, a plurality of eccentric shafts are respectively and fixedly arranged on the left and right fixed rings in the circumferential direction, each eccentric shaft comprises a shaft body and a cylindrical bulge part arranged at one end of the shaft body, the axial line of each shaft body and the axial line of the corresponding cylindrical bulge part are parallel but do not coincide, the shaft body of each eccentric shaft is fixedly arranged on the left and right fixed rings, a rolling wheel bearing is arranged on each cylindrical bulge part, a plurality of rolling wheel bearings are movably embedded in grooves of the inner side surfaces of the left and right gear rings, the driving transmission gear is engaged with the left and right gear rings, the power mechanism drives the driving transmission gear to rotate, a knife rest holder is fixedly arranged on the front end surface of the left movable ring or the right movable ring, and the front end surface of the left movable ring or the right movable ring is fixedly provided with a knife impacting mechanism. The outer clamp type bevelling machine has the advantages that the relative rotation can be realized, good coaxiality is also realized, during the cutting, the operation stability is high, the stable and smooth rotation can be realized, the cutting precision is high, and the risk of gear clamping and gear stubbing is also greatly reduced.

Owner:苏州博合雅工程材料科技有限公司

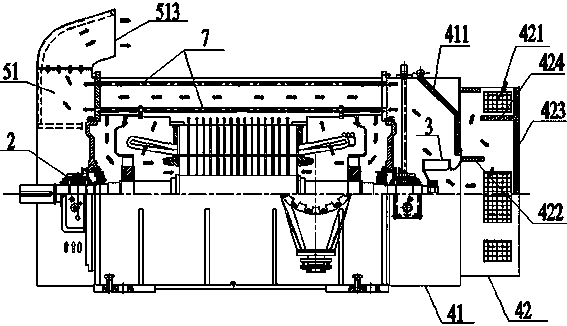

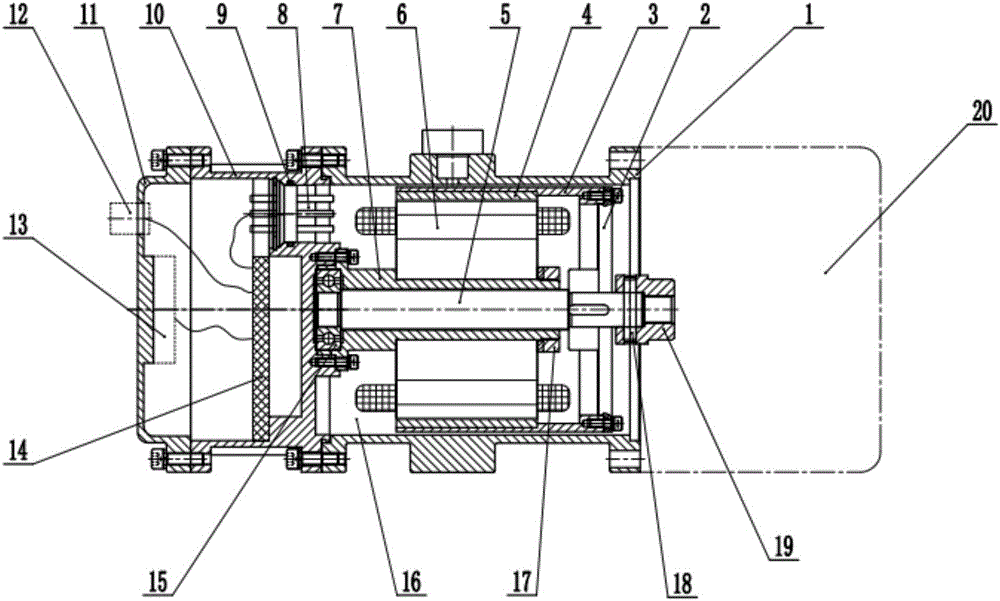

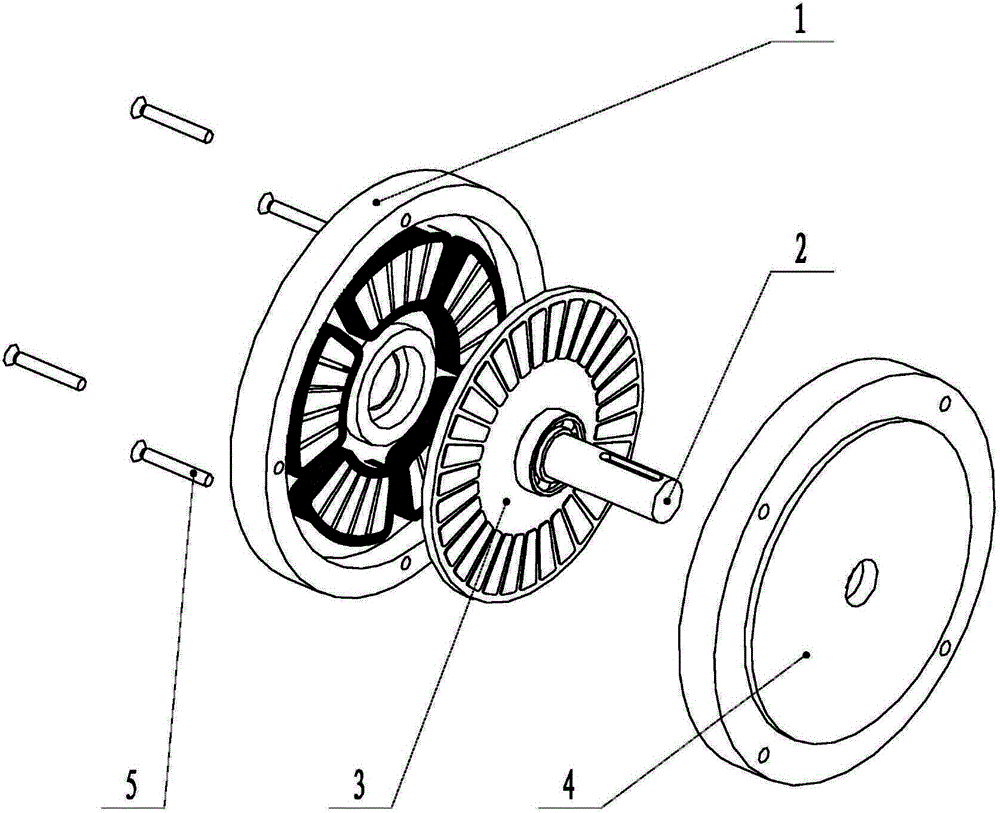

Novel in-line pump dedicated motor

PendingCN108075595ASolve the problem of self-lubricationSimple structureMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringCooling pipe

The invention discloses a novel in-line pump dedicated motor, and the motor comprises a motor base and internal fans. The periphery of a stator iron core is fixedly provided with a plurality of axialthrough cooling tubes on the motor base, and the cooling tubes are communicated with an air outgoing cover disposed at a shaft-extension end of a rotating shaft. A bearing device is installed in a bearing seat, and comprises a bearing bush and an oil slinger, wherein the bearing bush is disposed in the bearing seat. The bearing seat consists of a bearing upper seat and a bearing lower seat. The internal fans are symmetrically disposed on the rotating shaft between the bearing device and a rotor in a fixed manner. The bearing lower seat comprises separator plates which are fixed at left and right sides of the bearing seat body. The separator plates enable the cavity of the bearing seat to be divided into a left oil pool, a central oil pool and a right oil pool, wherein the left, central andright oil pools are communicated. The oil slinger sleeves the periphery of the bearing bush, and is located in the central oil pool of the cavity of the bearing seat. A non-shaft-extension end is provided with an external fan, and is provided with a curved-path fan cover. The motor provided by the invention improves the structure of the bearing seat, improves the self-lubricating effect of a bearing, is additionally provided with the curved-path fan cover, prolongs the propagation path of air, and reduces the noise.

Owner:WOLONG ELECTRIC GRP CO LTD +1

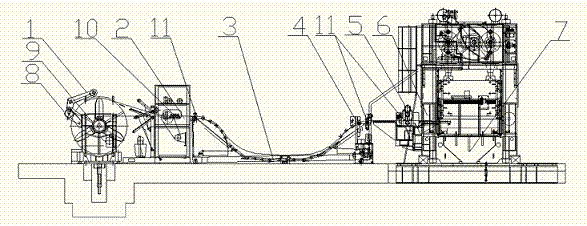

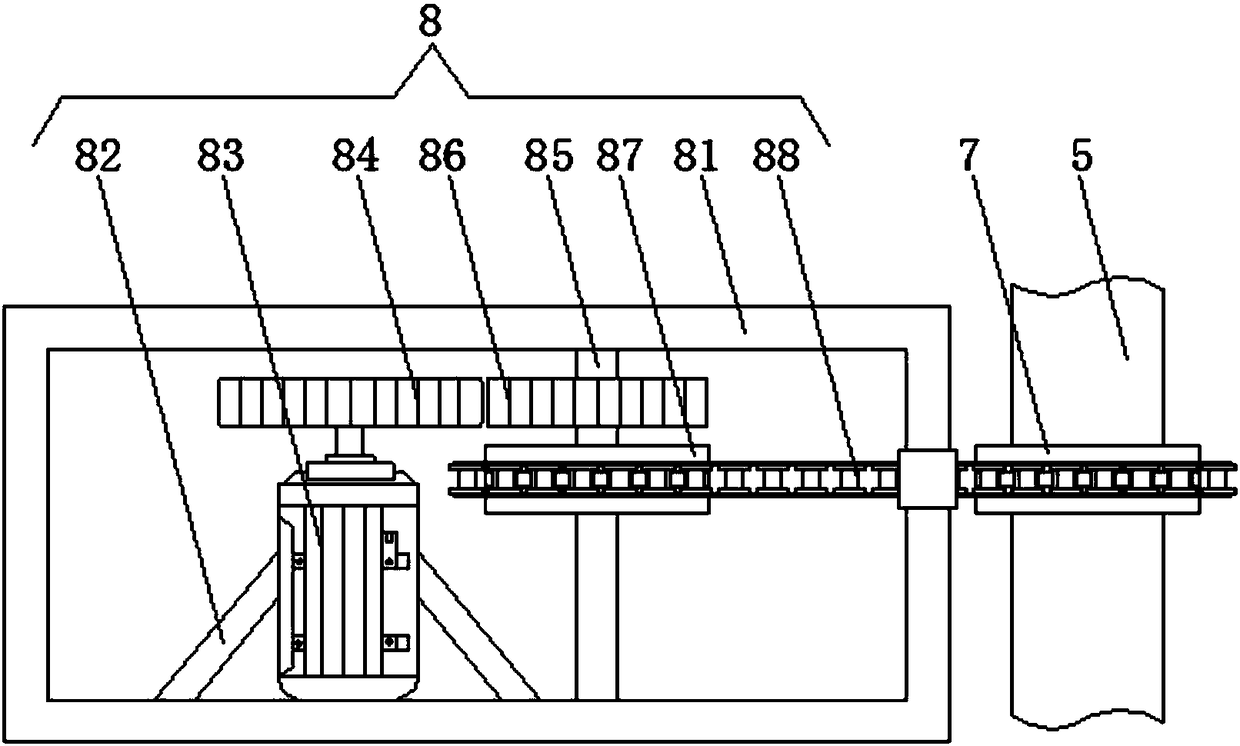

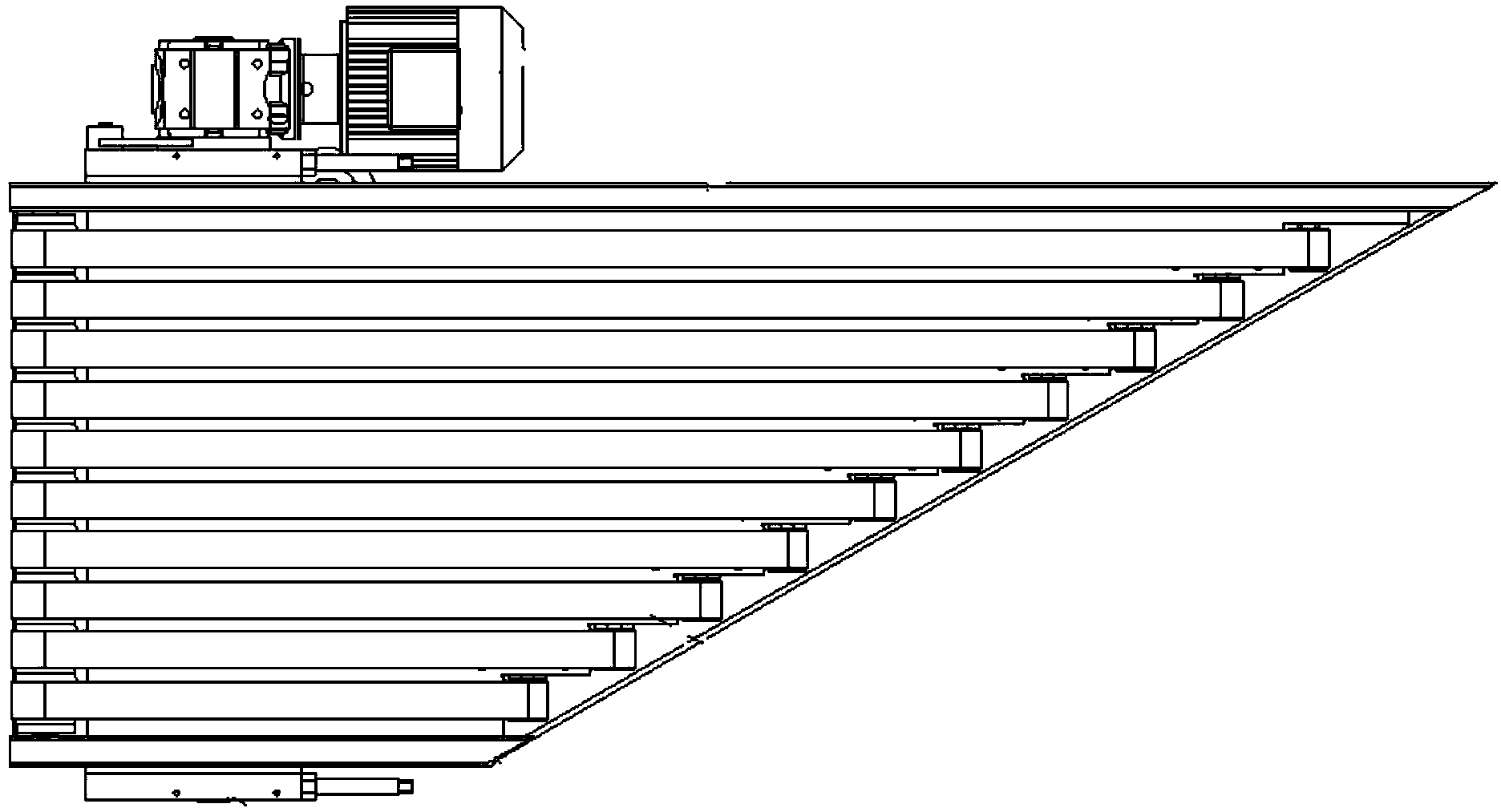

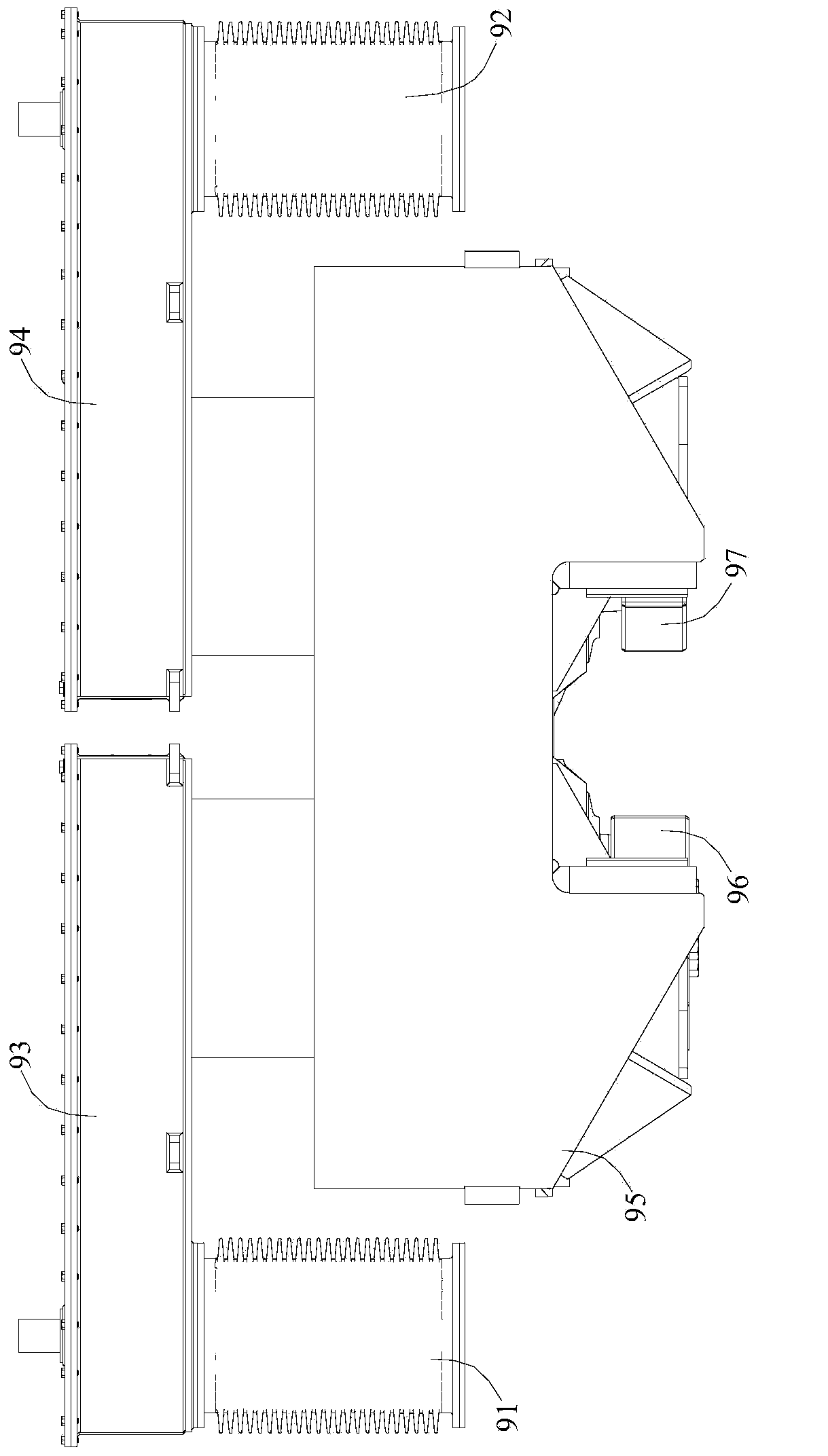

Aluminum coil stamping automation device and stamping method thereof

ActiveCN104759514AGuaranteed feed speedGuaranteed degree of deformationShaping toolsMetal-working feeding devicesControl engineeringProcess engineering

The invention discloses an aluminum coil stamping automation device and a stamping method thereof. The aluminum coil stamping automation device comprises an uncoiling mechanism, a leveling mechanism, a feeding mechanism, an oil injection mechanism and a machine tool which are arranged in turn; the uncoiling mechanism comprises a servo motor and a rolling wheel which are connected with each other; the rotational speed of the rolling wheel does not exceed 115 rounds every minute; the feeding mechanism comprises a servo motor and a feeding roller which are connected with each other; the clearance feeding of the feeding mechanism is performed and the feeding speed of the feeding mechanism and the stamping frequency of the machine tool are synchronized; a material lifting and conveying mechanism is arranged between the leveling mechanism and the feeding mechanism; a material buffering area is formed between the material lifting and conveying mechanism and the leveling mechanism; the deformation degree of aluminum coils does not exceed 30 I in the process that the aluminum coil are fed into the machine tool from the uncoiling mechanism. According to the aluminum coil stamping automation device and the stamping method thereof, the rotational speed of the feeding mechanism is controlled so as to effectively ensure that the deformation degree of the aluminum profile can be within the acceptable range in the production process, the quality of subsequent machining products is ensured, meanwhile the machining speed requirement can be met by the feeding speed of the materials, and the production efficiency is ensured.

Owner:奇昊汽车系统(苏州)有限公司

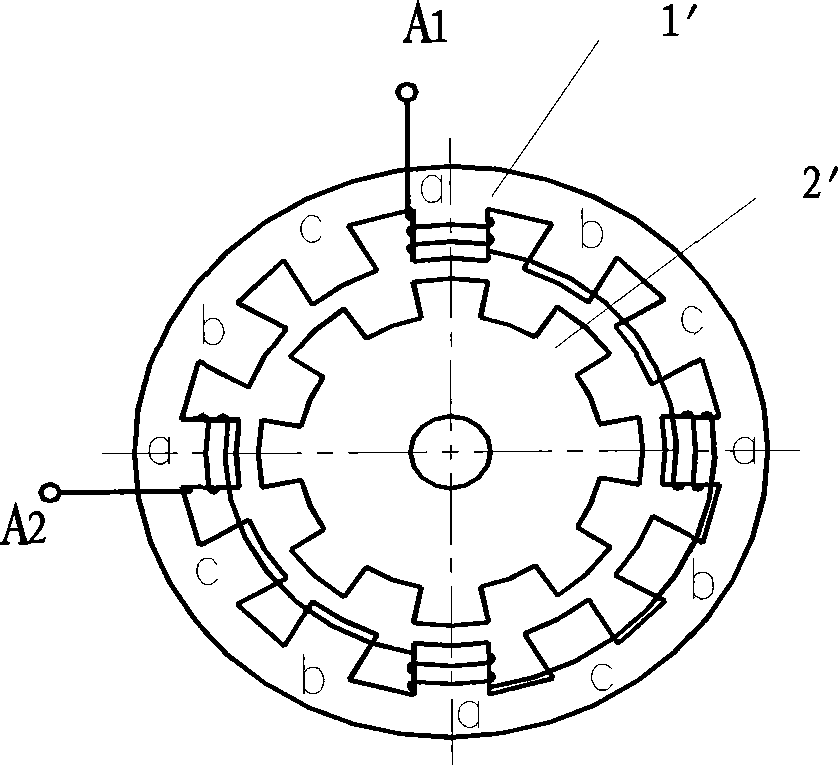

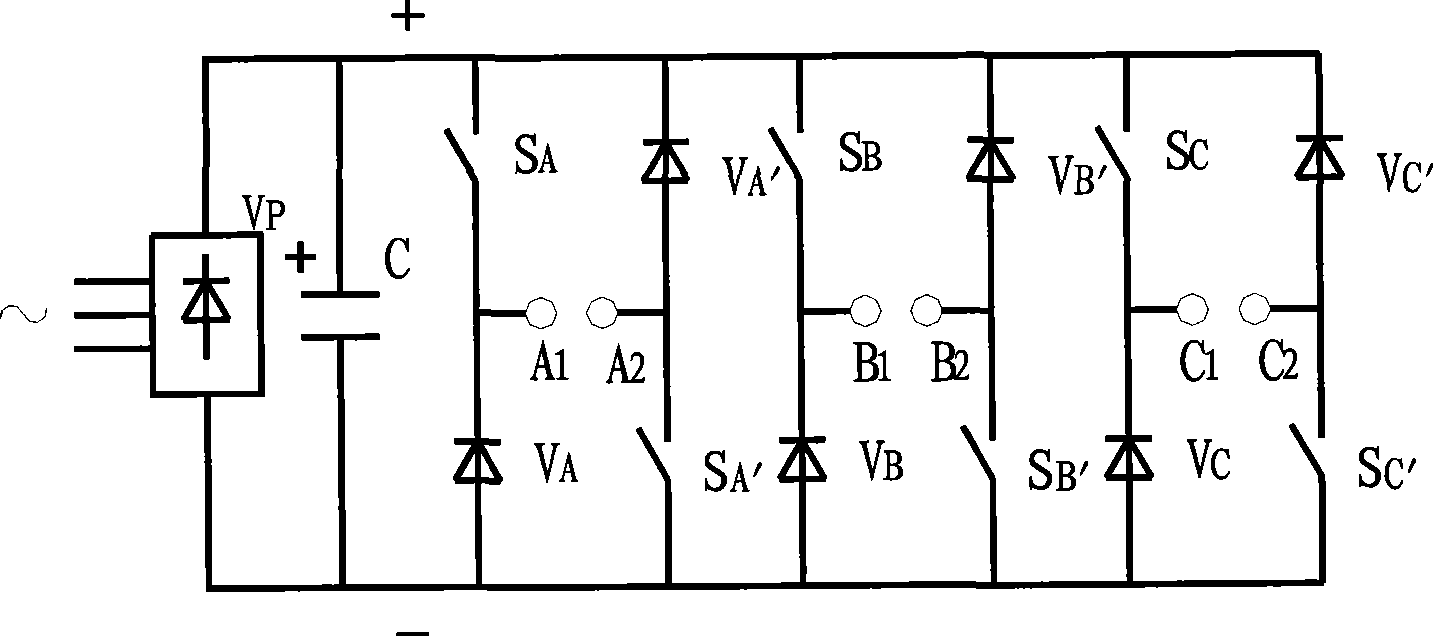

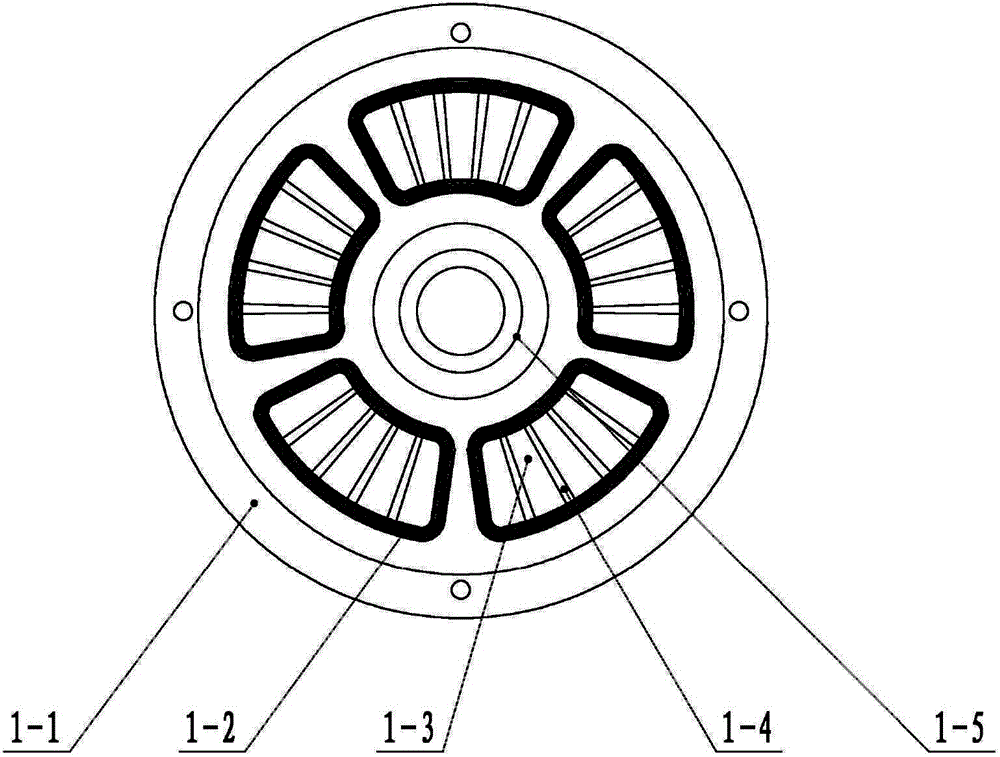

Six-phase switch reluctance motor system

InactiveCN101442247AReduce torque rippleImprove running smoothnessAC motor controlConversion with intermediate conversion to dcPower circuitsThree-phase

The invention relates to a six-phase switched reluctance motor system, which comprises a switched reluctance motor, a power circuit, an angular displacement sensor and a control circuit, wherein the switched reluctance motor is a six-phase winding switched reluctance motor. Therefore, the six-phase switched reluctance motor system achieves a six-phase motor system based on the prior three-phase 12 / 8-stage motor system so as to double the phase number without increasing complexity of the system, reduce torque ripple during running of the motor greatly, improve running stability, and reduce noise.

Owner:BEIJING CHINA TEX MECHANICAL & ELECTRICAL ENG

Electric automobile air conditioner compressor drive DC brushless motor

ActiveCN106059147AImprove running smoothnessNot easy to fall offAssociation with control/drive circuitsMagnetic circuit rotating partsBrushless motorsRotor magnets

The invention relates to the technical field of automobiles, and particularly relates to an electric automobile air conditioner compressor drive DC brushless motor. The motor comprises a motor body, a stator assembly, a stator sleeve, a rotor assembly, a motor shaft, and a back cover assembly. The rotor assembly comprises permanent magnet bars, a rotor drum, and a rotor end cover. The permanent magnet bars are ring-shaped, and are fixed to the inner side of the rotor drum. The rotor drum and the rotor end cover are fixedly connected. The rotor end cover is fixedly connected with the motor shaft through a key. The stator sleeve is fixedly connected with a back end cover. The stator assembly is fixed to the stator sleeve. The stator sleeve movably sleeves the motor shaft. The back cover assembly is equipped with a controller inside. The rotor magnet steel of the motor is not easy to fall off, and can be close enough to the stator, so the efficiency of magnetic action is improved. Moreover, the torque is increased, the number of permanent magnets is increased, and the running stability of the rotor is improved. The motor is convenient to install and easy to match, and the sales thereof is promoted.

Owner:FENGHUA XINGYU SPECIAL MOTOR MFG

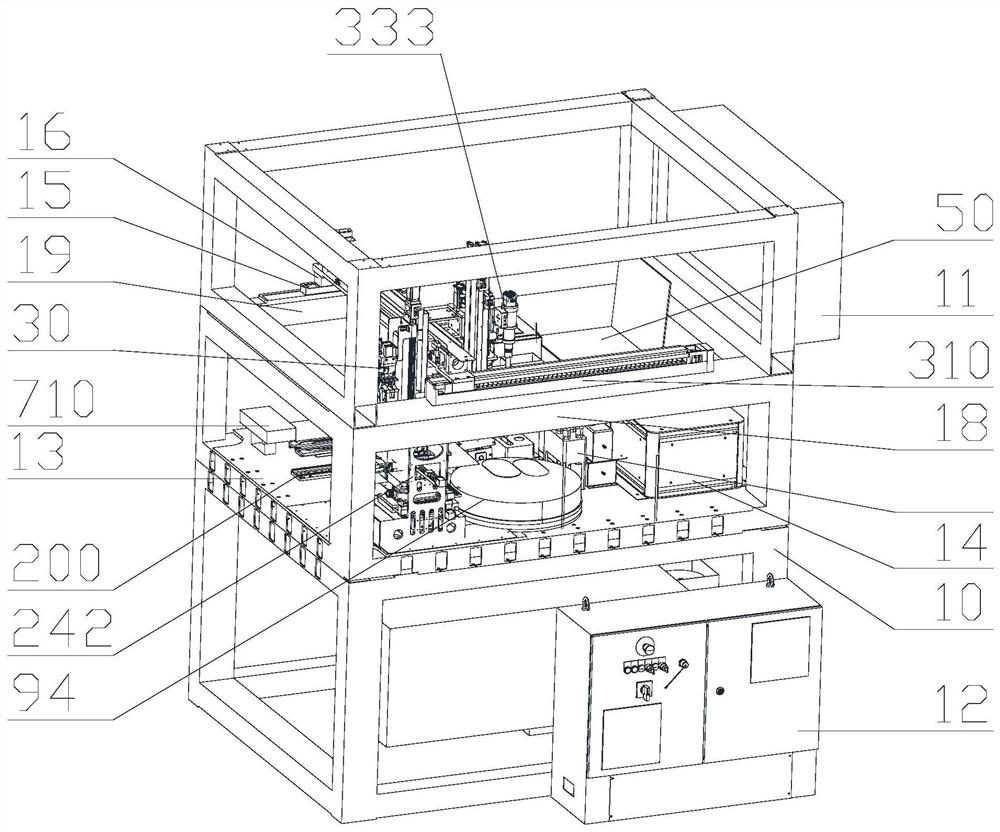

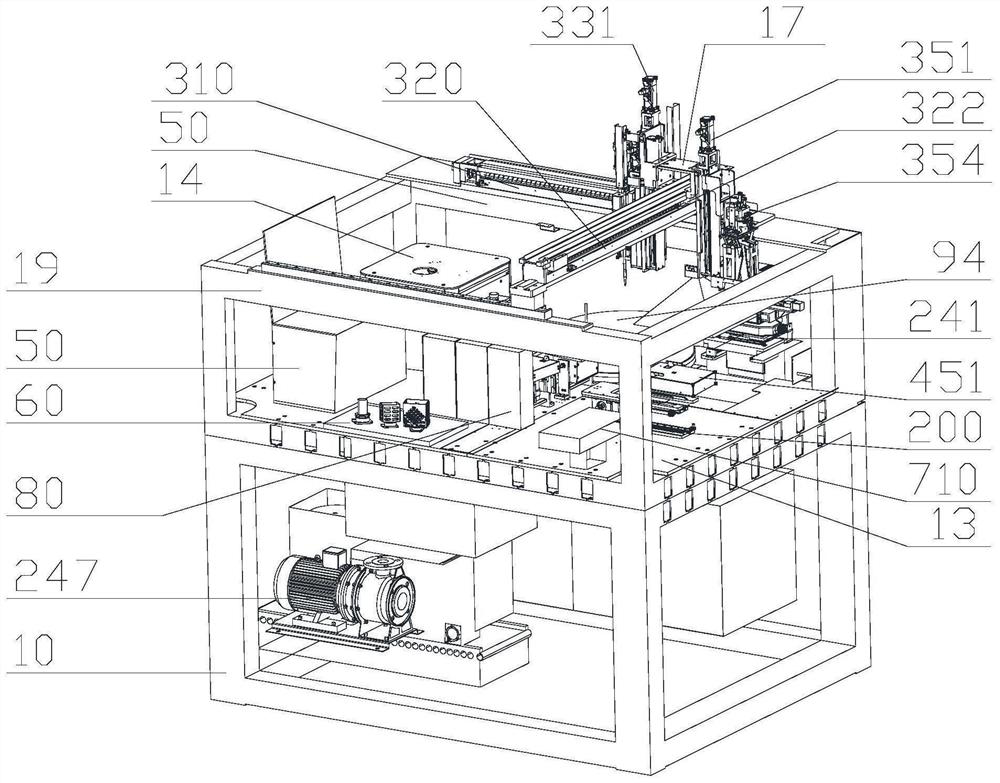

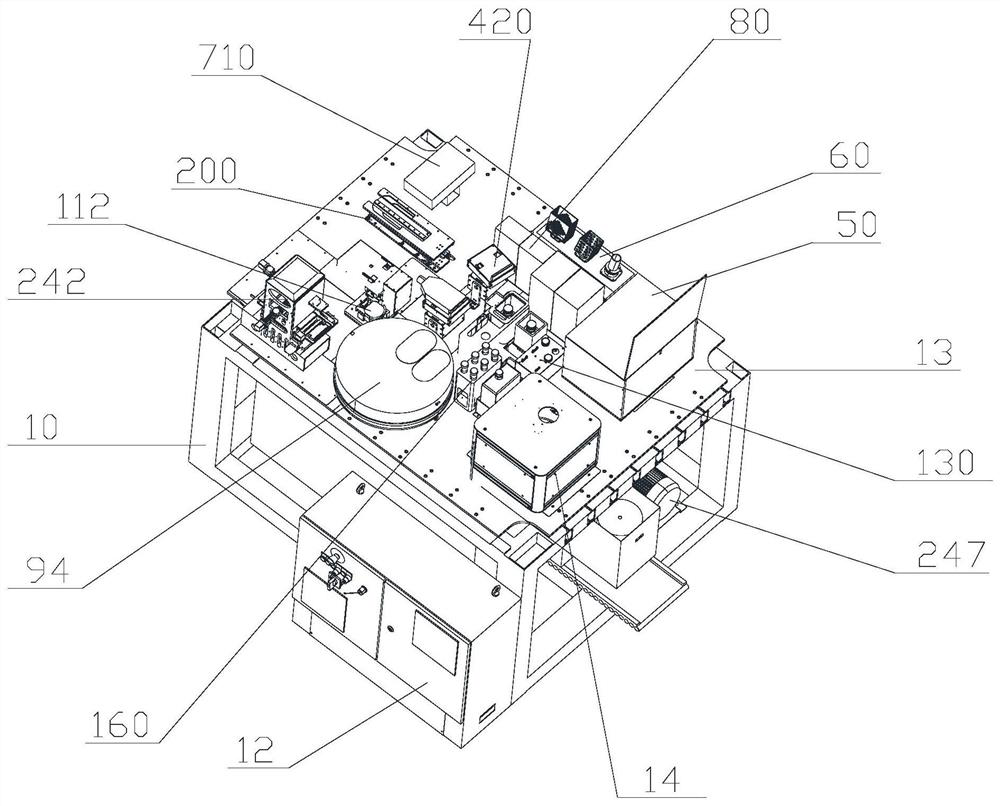

Automatic cell culture equipment

ActiveCN112940917AAvoid problems with large thermal changesEasy to useBioreactor/fermenter combinationsBiological substance pretreatmentsAir filterThree-dimensional space

The invention discloses automatic cell culture equipment which comprises a supporting frame, a mechanical arm moving in a three-dimensional space, functional components, an air filtering device and an electric control system. The mechanical arm is arranged in the supporting frame. The electric control system comprises a master controller with a power source, and the master controller is electrically connected with the mechanical arm. An operation component is arranged on the mechanical arm. A feeding hole is formed in one side of the supporting frame. A first supporting part is arranged on the supporting frame, and the functional assembly is arranged on the first supporting part. A first executing end, a second executing end and a third executing end are arranged on a connecting part of the mechanical arm, a liquid transferring device is arranged at the first executing end, and a bottle clamping device is arranged at the third executing end. The functional components comprise a centrifugal machine, a swinging device for a culture bottle, a microscopic observation device, a refrigeration device and a weighing device. The device is provided with the mechanical arm to control the operation assembly and performs cell culture process operation through cooperation of all the functional components, the automation degree is higher, and the cell culture quality and culture efficiency are improved.

Owner:济南创泽生物医药科技有限公司

Ferromagnetic motor rotor dynamic balance test device

ActiveCN108801551ALow thermal conductivityImprove wear resistanceStatic/dynamic balance measurementBall bearingDynamic balance

A ferromagnetic motor rotor dynamic balance test device relates to the field of motor dynamic balance without a magnetic armature. The ferromagnetic motor rotor dynamic balance test device comprises two movable support plates, two fixed support plates, a main support plate, a pressure plate column, a pressure plate, a ferromagnetic motor rotor, a rotor support tool and two ball bearings; the two fixed support plates are placed symmetrically on both sides of the main support plate; the two movable support plates are fixedly mounted on the outer side walls of the two fixed support plates; the rotor support tool is fixedly installed at the middle of the top end of the main support plate; the ferromagnetic motor rotor passes through the rotor support tool in the axial direction; the pressure plate column is fixedly mounted on the top end of the main support plate, and the pressure plate column is disposed on one side of the rotor support tool; the pressure plate is fixedly mounted on the top end of the pressure plate column and the supporting tool; and the two ball bearings are respectively fixedly mounted on the top ends of the outer side walls of the two movable support plates, and the top ends of the two ball bearings are in contact with the ferromagnetic motor rotor. The ferromagnetic motor rotor dynamic balance test device improves the balance precision of the rotor to a higher level of G0.4, and the dynamic balance performance is consistent.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Wheel and running equipment with same

ActiveCN108656858AReliable pulsed continuous rotationImprove motion stabilityHigh resiliency wheelsEngineeringRigid structure

The invention discloses a wheel. A hub of the wheel is adaptive to a rotating shaft of running equipment; a plurality of elastic supporting pieces are uniformly distributed on the peripheral surface of the hub in the circumferential direction; bodies of the elastic supporting pieces extend outwards to form end part external circular arc sections; the external circular arc sections of the pluralityof elastic supporting pieces are arranged in sequence in a spaced manner in the circumferential direction and have concentric and isodiametric convex circular arc surfaces; the elastic supporting pieces have stress deformation areas and stress position changing areas and are configured in such a way that the stress deformation areas are positioned at the middle sections of the main bodies; the direction of deformation stress generated under an outside force in the moving process tends to be consistent with the tangential direction of the rotation of the hub so that an acting force for pushingthe hub to rotate is formed during releasing the deformation stress; and the external circular arc sections are the stress position changing areas and can generate displacements with the deformations. According to the scheme, as the traditional rigid structure is transformed into rigid and soft combined structure, and an outer tire is eliminated, good running performance can be obtained, and theinfluence of a severe use environment on the service life of the wheel can be effectively avoided. The invention further provides running equipment with the wheel.

Owner:苏冀

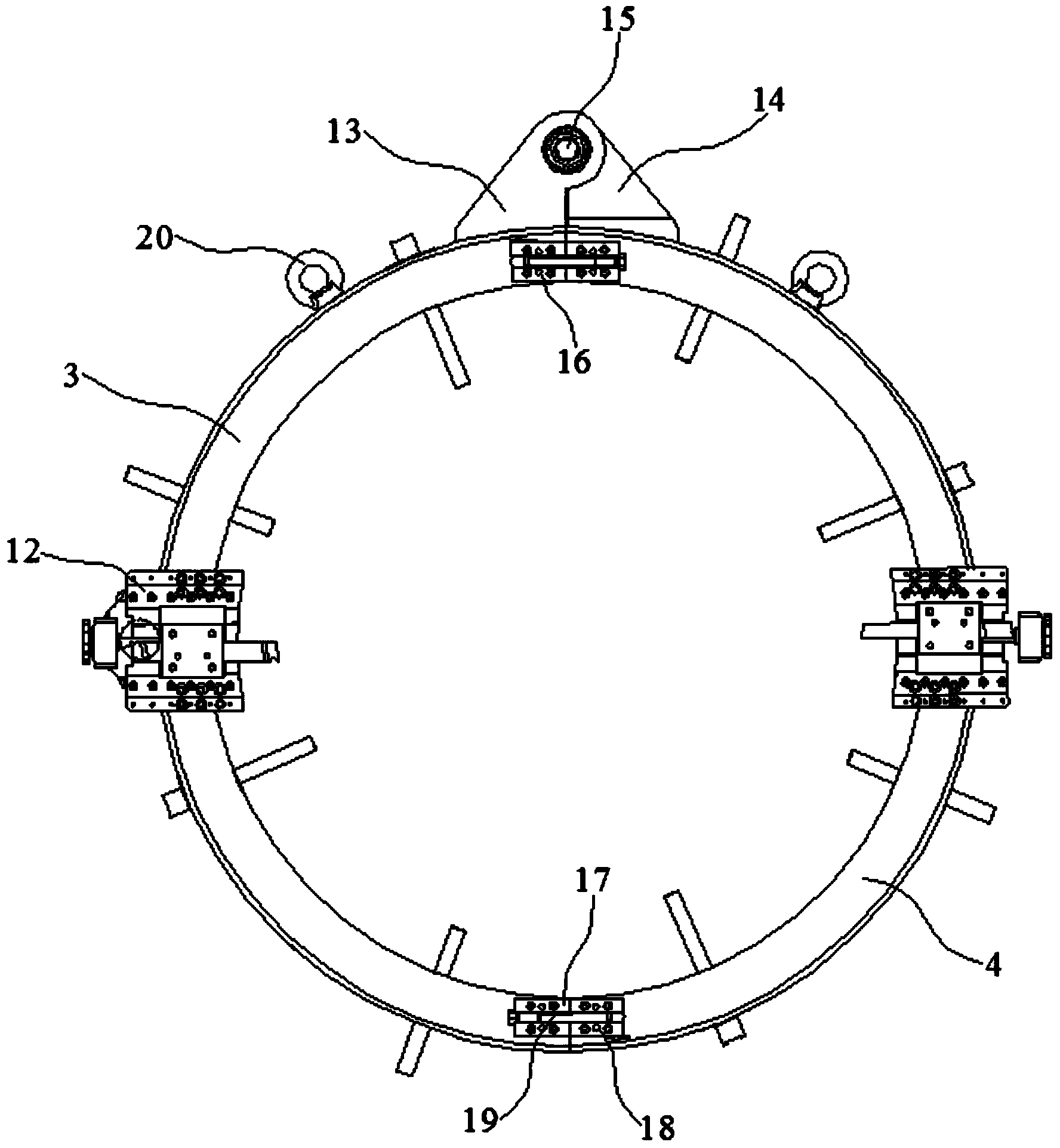

Beveling machine for cutting pipeline

The invention discloses a beveling machine for cutting a pipeline. The beveling machine comprises a left movable ring, a right movable ring, a left gear ring, a right gear ring, a left fixed ring and a right fixed ring, wherein the left movable ring and the right movable ring are respectively and fixedly arranged on the left gear ring and the right gear ring; the left fixed ring and the right fixed ring are respectively and fixedly provided with a plurality of eccentric shafts along the circumferential direction; each eccentric shaft comprises a shaft body and a cylindrical bulge part arranged at one end of the shaft body, and a roller bearing is arranged on each cylindrical bulge part; the multiple roller bearings are movably embedded into grooves at the inner side surfaces of the left and right gear rings; one end of the left fixed ring and one end of the right fixed ring are respectively provided with a left connecting block and a right connecting block; the left connecting block and the right connecting block are movably connected by virtue of a connecting shaft; one end, which is away from the left connecting block, of the left movable ring and one end, which is away from the right connecting block, of the right movable ring are contacted with butting surfaces of the left fixed ring and the right fixed ring; the other ends of the left and right movable rings are contacted with the other butting surfaces of the left and right fixed rings. The beveling machine has favorable axiality, is high in stability during cutting operation, can rotate stably and smoothly, is high in cutting precision and can be used for conveniently positioning left and right parts.

Owner:苏州博合雅工程材料科技有限公司

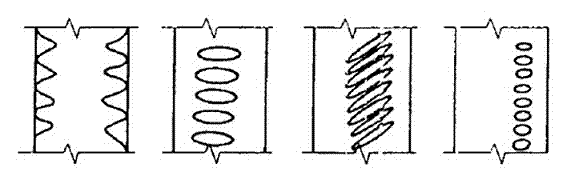

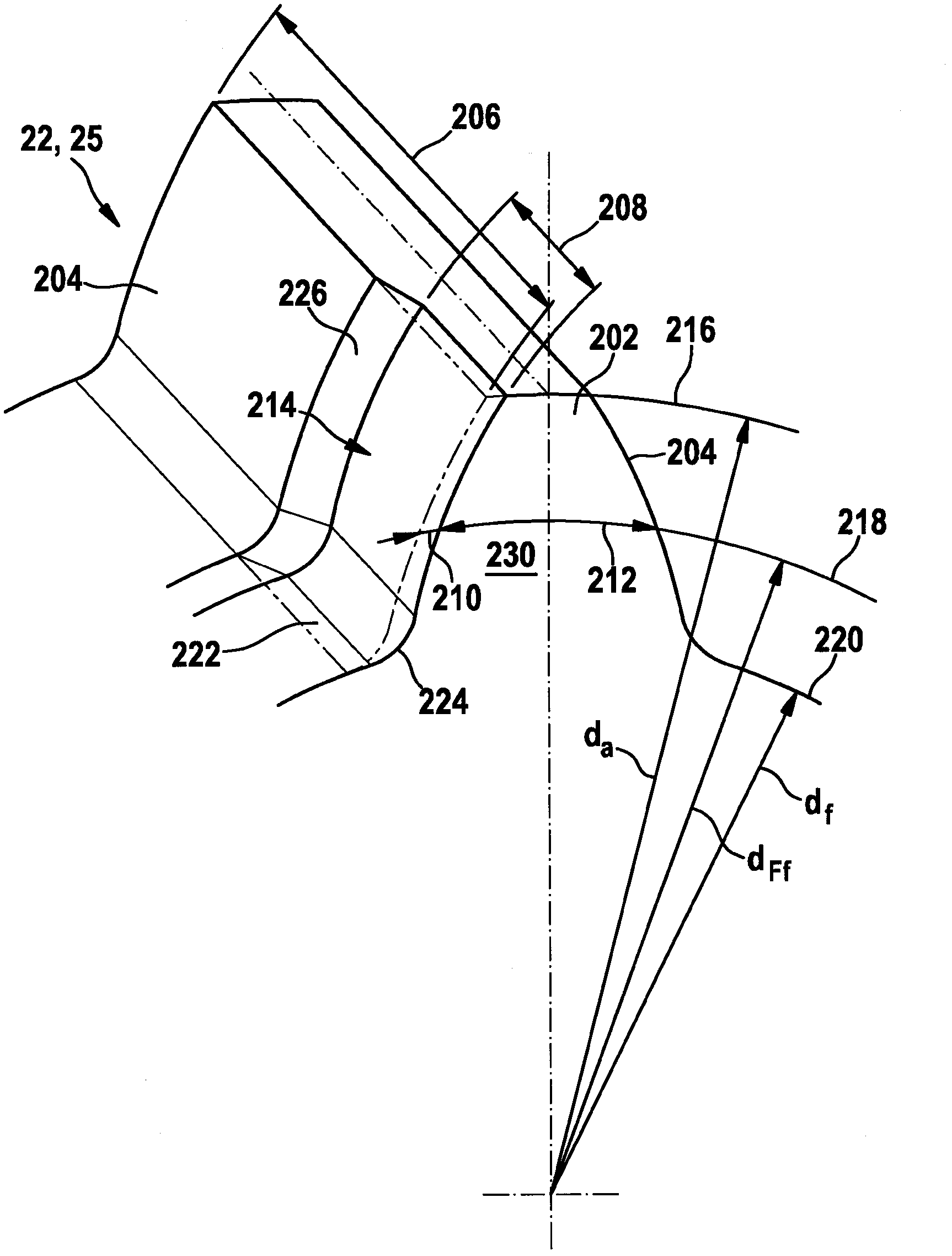

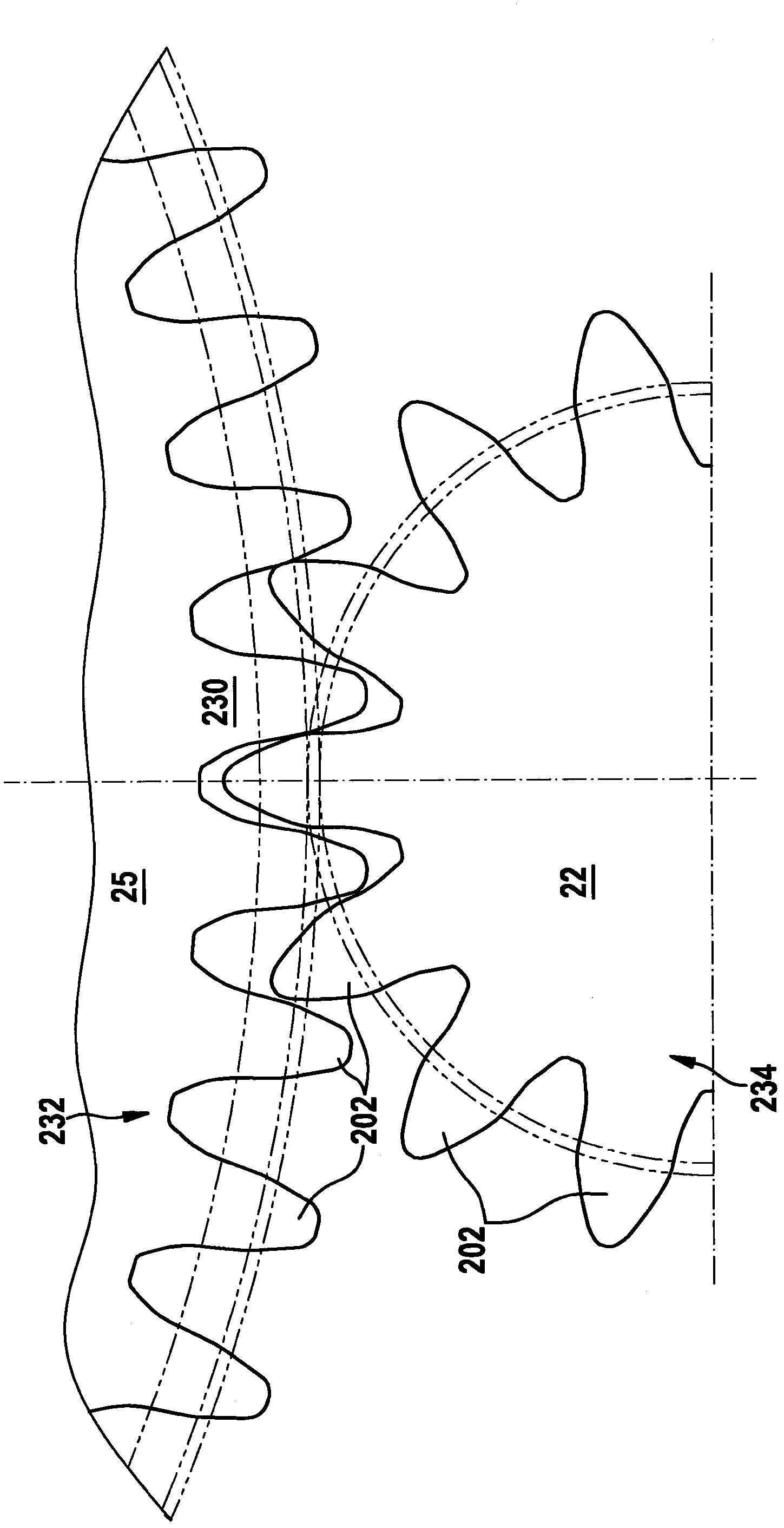

Noise-optimized toothing system

ActiveCN102918257AImprove noiseImproved vibration characteristicsPower operated startersGear vibration/noise dampingElectric machineInternal combustion engine

The invention relates to an electric machine, in particular a starter device (10) for an internal combustion engine. The electric machine comprises a noise-optimized toothing system (232, 234) of two gearwheels (22, 25) which can be brought into engagement with one another. The noise-optimized toothing system (232, 234) is configured as an extra-deep toothing system on at least one of the gearwheels (22, 25). The extra-deep toothing system has an asymmetrical toothing profile (214).

Owner:SEG AUTOMOTIVE GERMANY GMBH

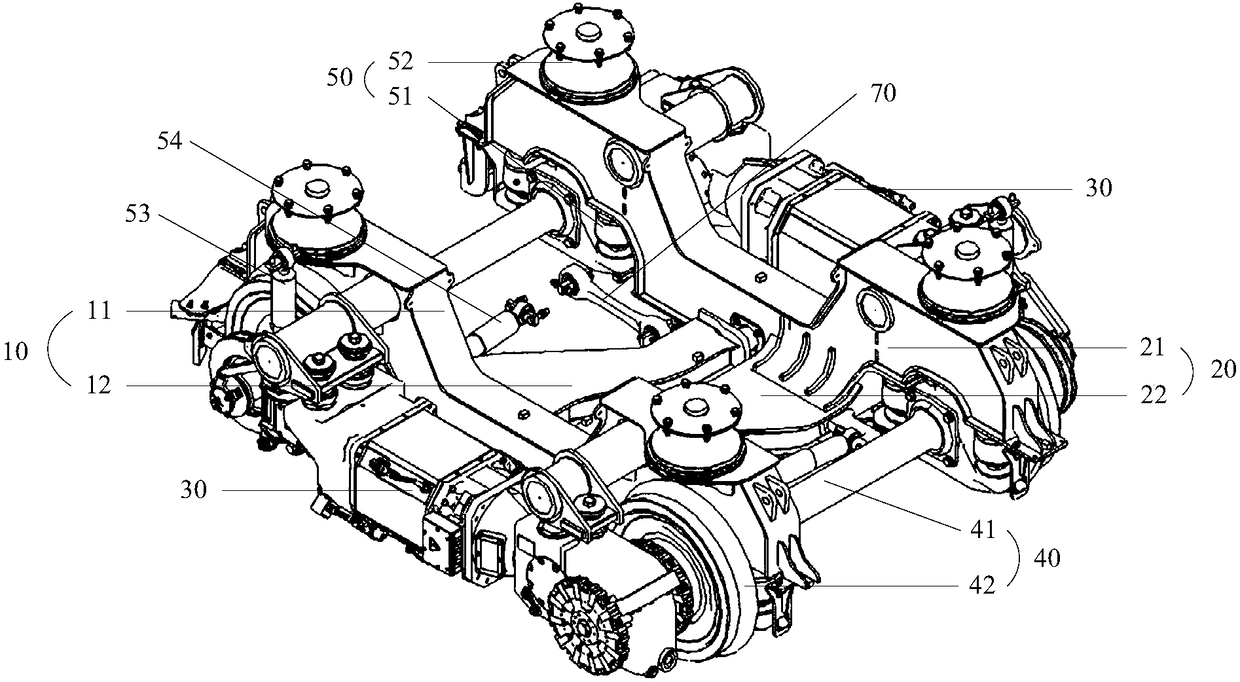

Bogie

The invention provides a bogie which comprises a bogie framework and a wheel set assembly. The bogie framework is arranged on the wheel set assembly which comprises an axle and wheels. The two ends ofthe axle are connected with wheel seats of the wheels, and a driving device is arranged on the bogie framework and used for transmitting control signals output by a control device of a locomotive tothe wheel set assembly to drive the wheels to rotate. The bogie further comprises a hydraulic control device, a damping assembly, a grounding device, a traction rod and a braking assembly. All components of the bogie provided by the invention are compact in structure and reasonable in layout, the effects of locomotive automatic centering and self-guiding are achieved, and thus the bogie has good transverse comfort and anti-snaking capacity when travelling on a straight route and a curve.

Owner:CRRC TANGSHAN CO LTD

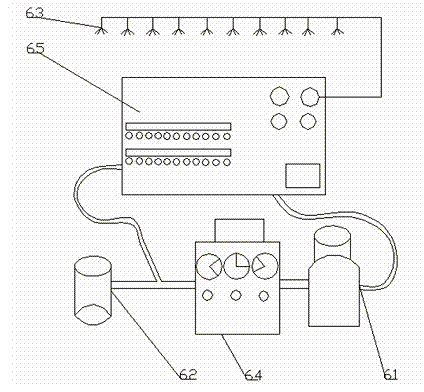

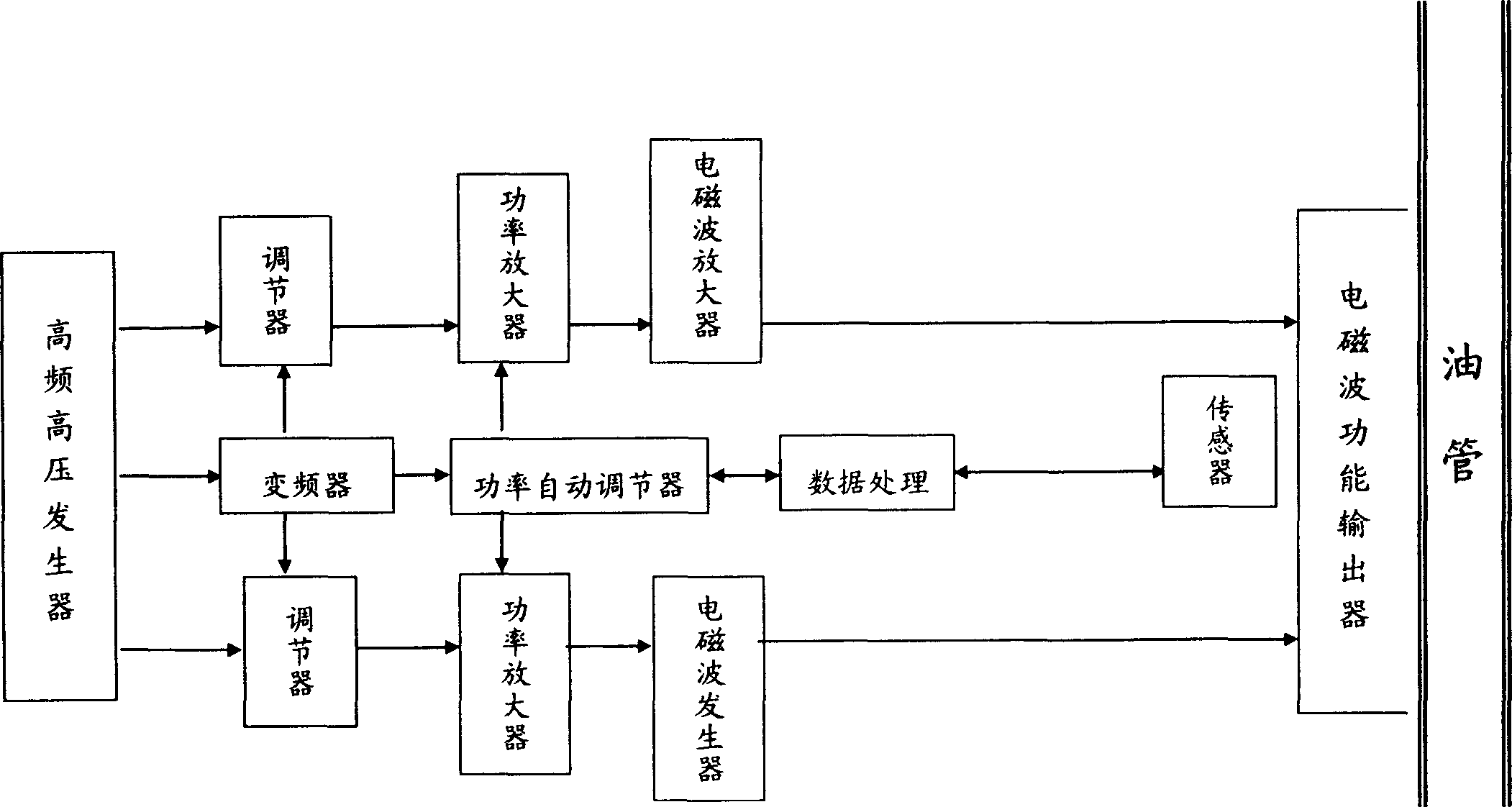

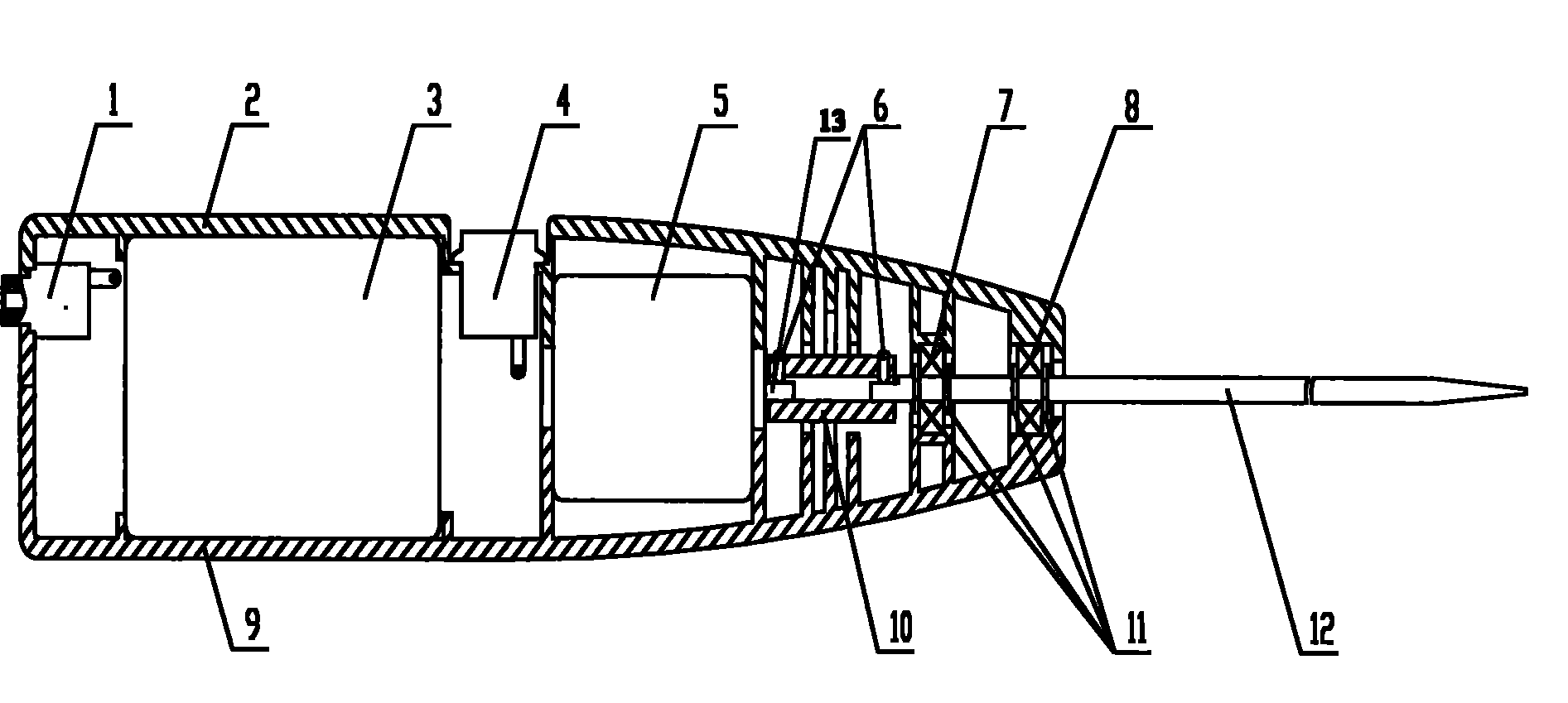

Electronic fuel oil activator

InactiveCN1991156AImprove the effect of activation processingEmission reductionInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustion chamberFuel efficiency

The invention discloses an optimal treatment device for fuel oil before combustion, namely electronic fuel actuator. It relates to the technological area of improving fuel burning efficiency, decreasing oil consumption and harmful gas discharge, preventing and eliminating burning carbon. Aiming to prior existing problems in the area such as single function of physical device and chemical additive, not remarkable and persistent effect, uneasy usage and existing bad action, the invention launches the new technological product with doing work by electromagnetic wave, which is constituted by electronic component and comprises shell, circuit assembly in shell, and metallic or nonmetallic through-tubing with straight or abnormal shape. The end of circuit assembly, namely function follower of electromagnetic wave, receives electromagnetic wave of various frequency energies in circuit assembly and outputs work fuel oil through straight or abnormal tube so that oil micelle is divided into single-bond oil molecule to arrange thoroughly and enters into combustor to combine with oxygen molecule fully and burns. It can improve combustion efficiency, decrease oil consumption and harmful gas discharge, eliminate carbon, prevention generation of new carbon, maintain working efficiency of engine and prolong the service life. It can achieve demands of energy saving, environmental protection and high efficiency.

Owner:王伟林 +1

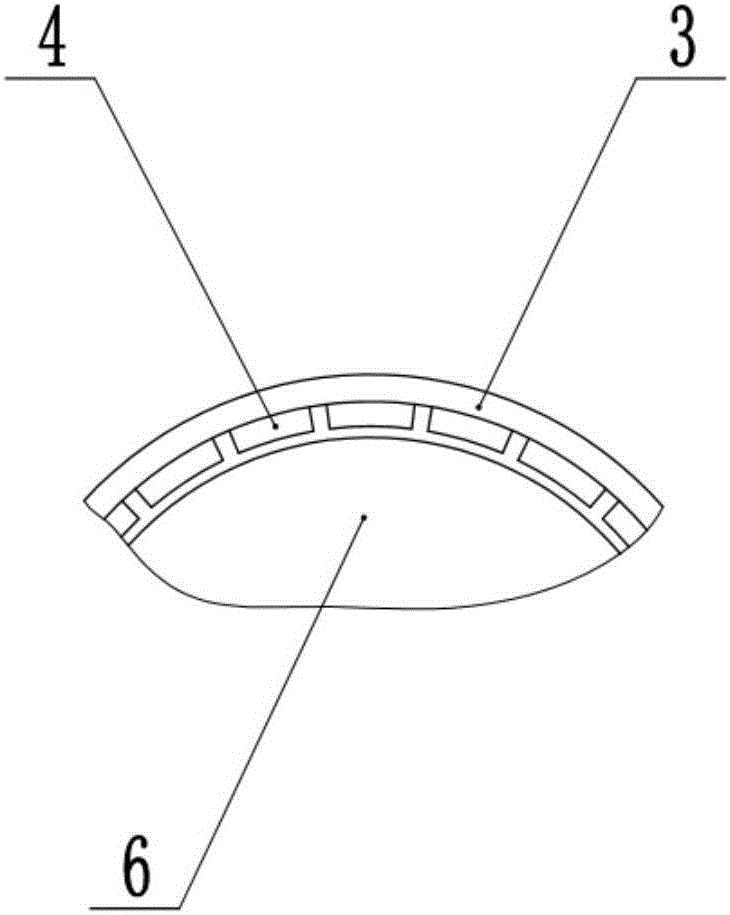

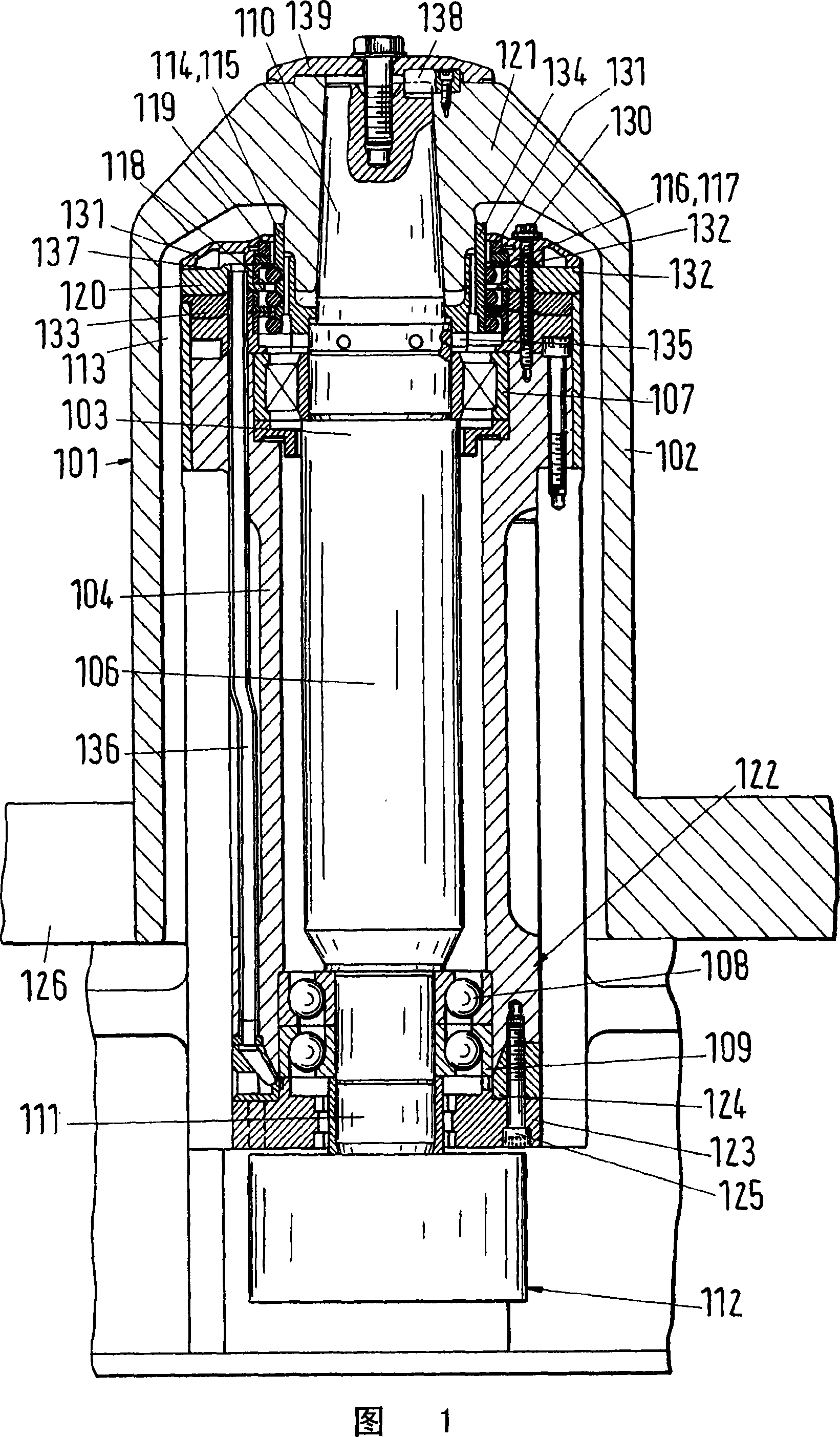

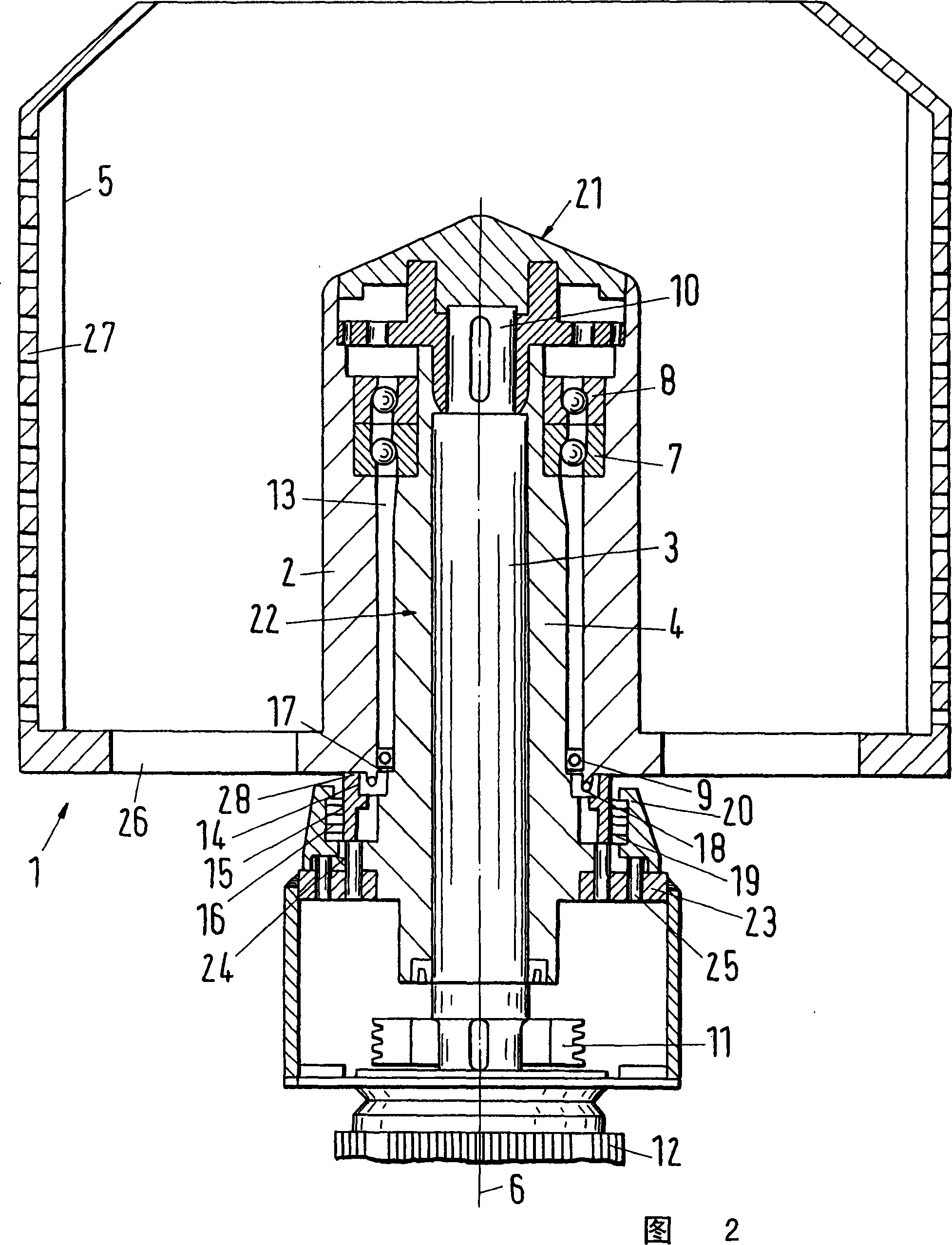

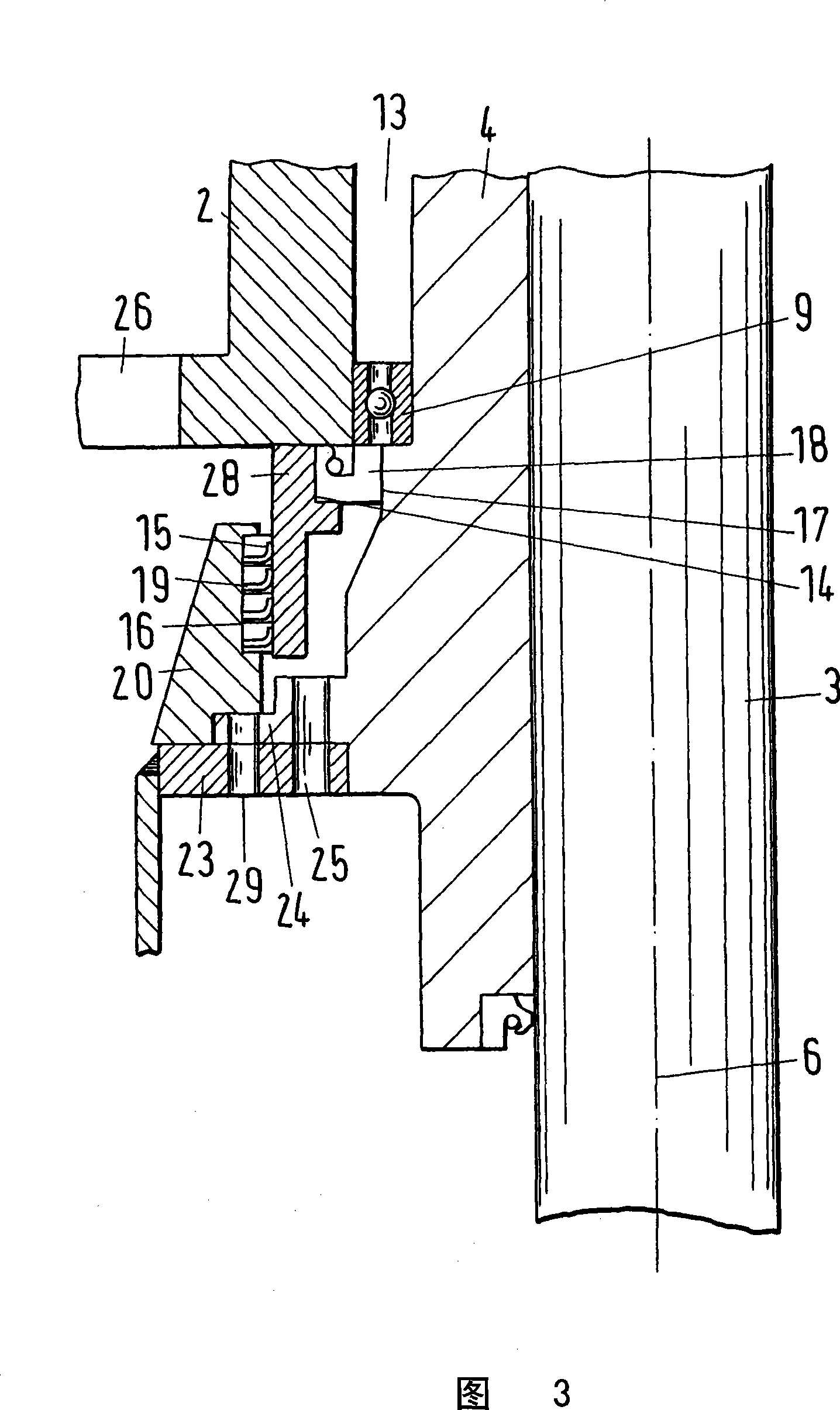

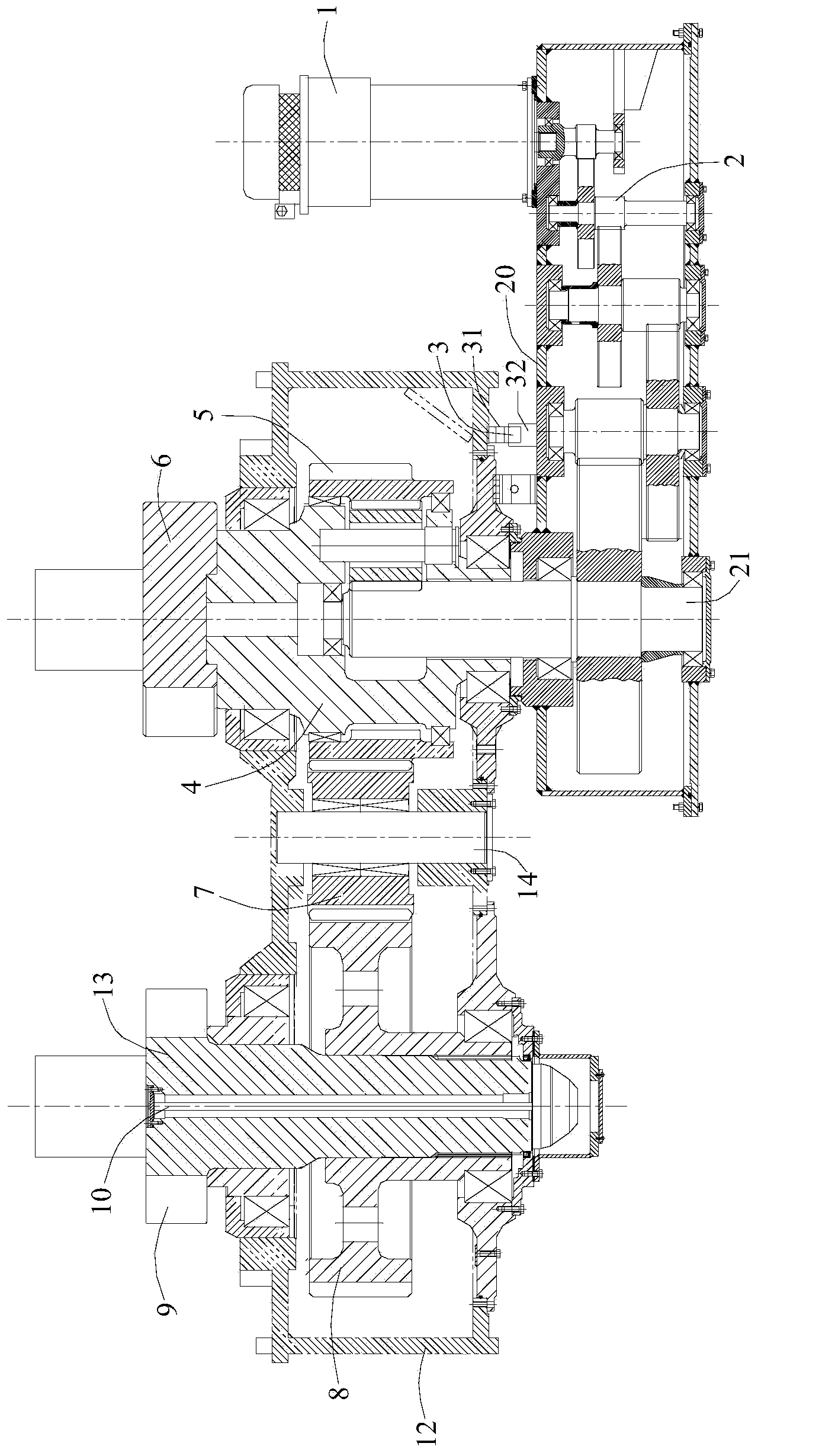

Bearing assembly for a centrifuge

InactiveCN101062489AReduce peripheral speedExtended service lifeEngine sealsCentrifugesDrive shaftEngineering

In a bearing assembly of a centrifugal revolving drum (1) around a spin axis (6), the revolving drum (1) is fixed by rotation through a drum hub (2) and a hanger bracket (21) of the revolving drum (1) and connected with a drive shaft (3). The drive shaft is connected with a drive set (12) and extends along the spin axis (6) in the bearing block (4, 7, 8, 9, 20, 24). The revolving drum (1) is supported on the bearing block (4, 7, 8, 9, 20, 24), thereby basically separating supporting force generated by power from the drive shaft (3).

Owner:FERRUM

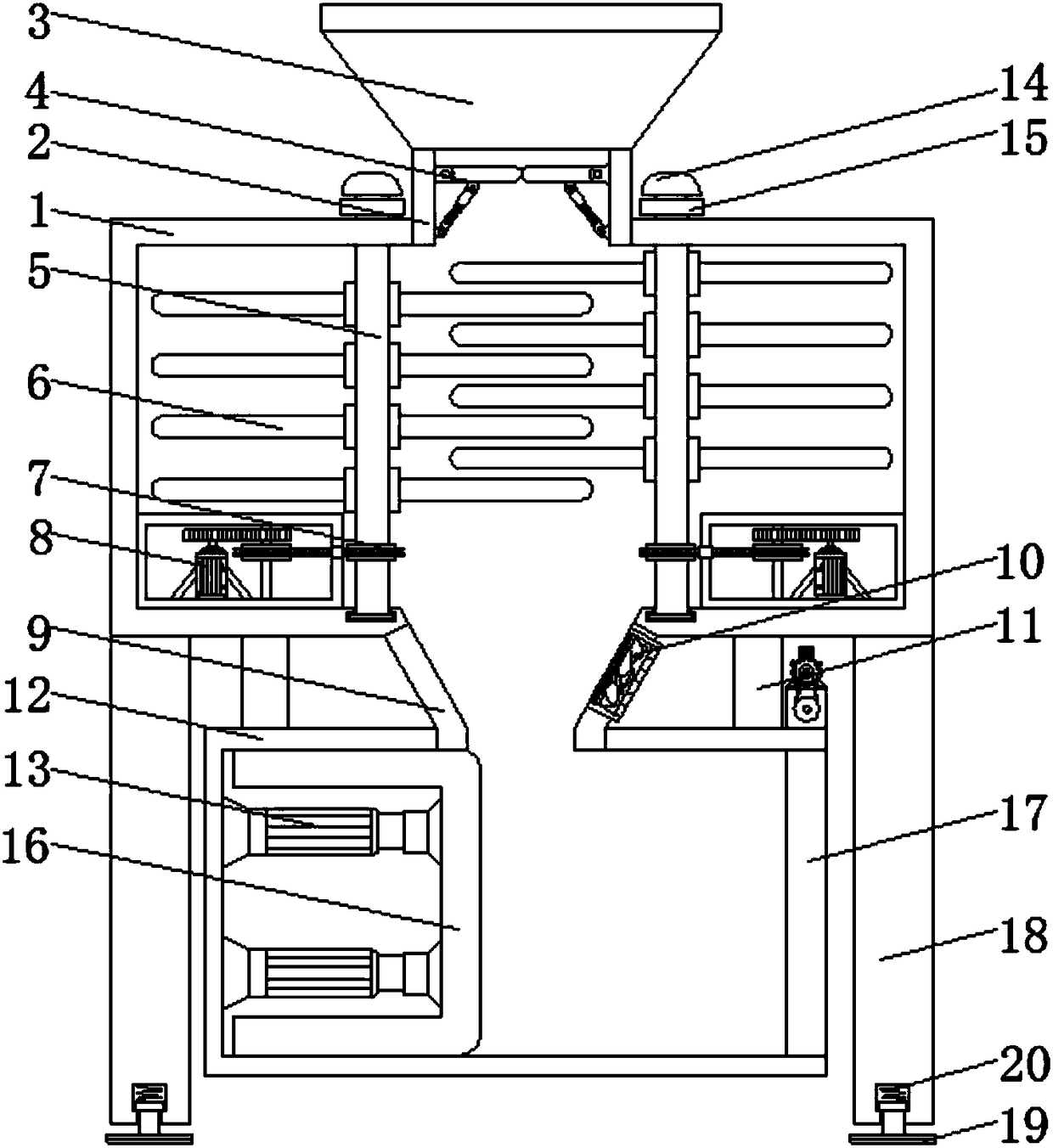

Waste plastic crushing and briquetting device

ActiveCN108262885APrevent pinchingProtect personal safetyPlastic recyclingGrain treatmentsHuman healthEngineering

The invention discloses a waste plastic crushing and briquetting device, which comprises a tank body. A feeding channel is fixedly connected to the center of the top part of the tank body; a feeding funnel communicates to the top part of the feeding channel; a through hole adaptive to the feeding channel is formed in the top part of the tank body; mutually symmetrical anti-pinch splash-proof devices are fixedly connected to two sides of an inner wall of the feeding channel; mutually symmetrical rotary rods are rotatably connected to the upper part and the lower part of two sides of an inner wall of the tank body; and the rotary rods penetrate through the top part of the inner wall of the tank body and extend to the upper part of the tank body. The waste plastic crushing and briquetting device provided by the invention relates to the technical field of plastic processing machine equipment. The waste plastic crushing and briquetting device solves the problems that an existing waste plastic crushing and briquetting device is low in crushing efficiency and produces great noise and dust so as to affect the human health, achieves the aims of reducing the dust pollution, briquetting the crushed plastic and taking out conveniently, and is reduced in occupied area, convenient to transport, simple to operate at the same time, and free of causing secondary pollution on the environment.

Owner:广西乾坤环保科技有限公司

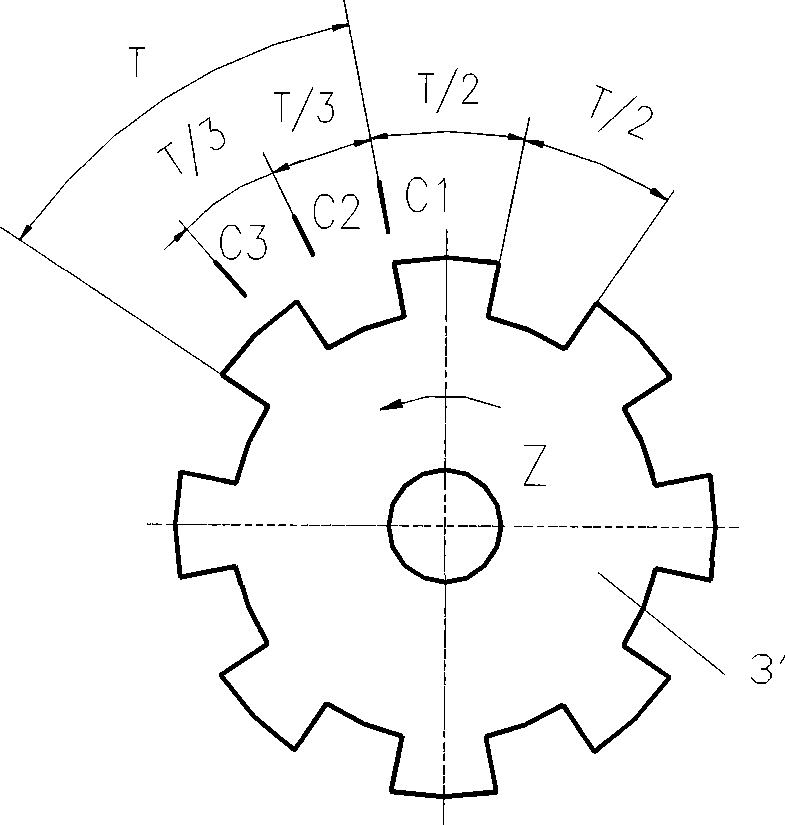

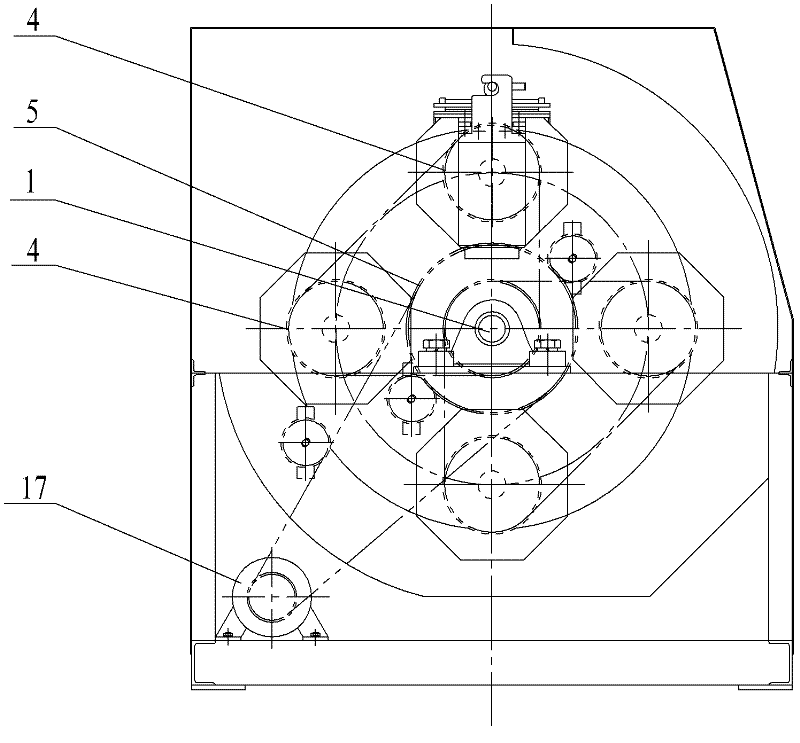

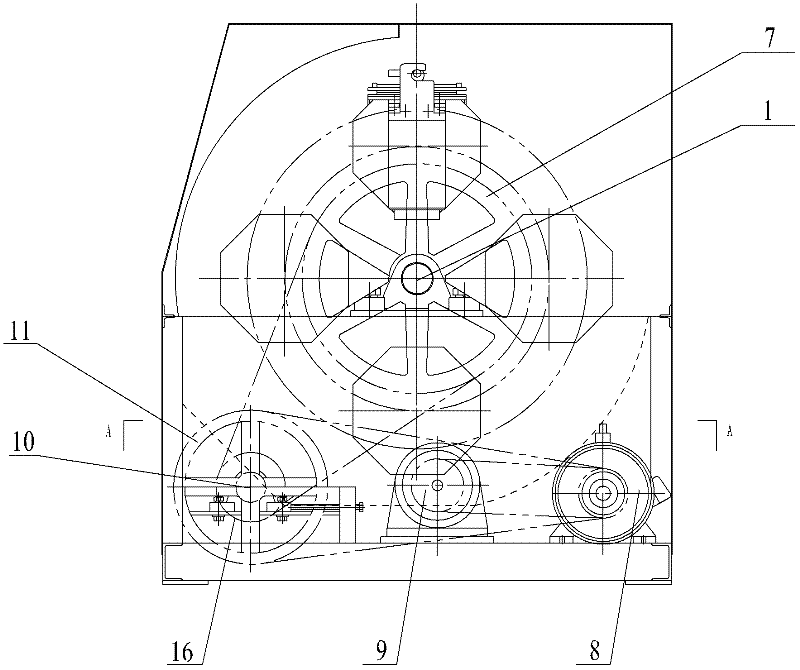

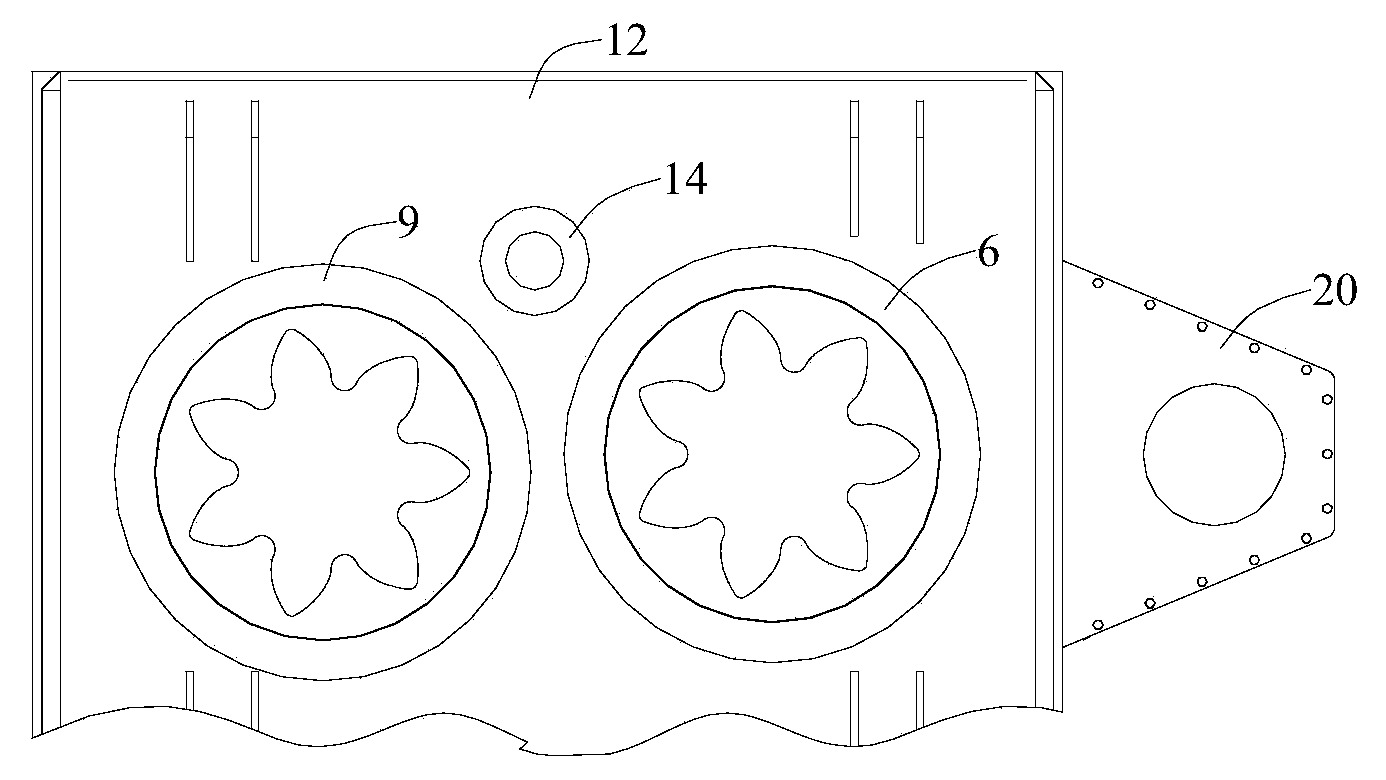

High-speed centrifugal grinding machine

ActiveCN102501160AImprove running smoothnessHigh speedEdge grinding machinesPolishing machinesSprocketOperating speed

The invention relates to a high-speed centrifugal grinding machine which can rotate and revolve simultaneously. A rack is provided with a spindle of a rotating body, the spindle is fixedly provided with a plurality of rotating body plates at intervals, the part of the rotating body between the two rotating body plates is provided with four grinding drums, the axial line of the grinding drums is arranged to be parallel to the axial line of the spindle, one end of each grinding drum is fixedly provided with a driven sprocket wheel, one end of the spindle is provided with a drive sprocket wheel and a transmission sprocket wheel in a rotating way, the drive sprocket wheel and the transmission sprocket wheel are fixedly connected into a whole, the drive sprocket wheel is matched with the driven sprocket wheel, the other end of the spindle is fixedly provided with a transmission pulley, the transmission sprocket wheel is connected with a revolving power mechanism of a shot blasting drum, and the transmission pulley is connected with the rotating power mechanism of the shot blasting drum. The operating smoothness can be improved, noise can be lowered, the operating speed can be increased, rapid braking and accurate positioning can be achieved, and the machine can be operated more conveniently.

Owner:WUXI FODOO PRECISION IND

Centrifugal flywheel

InactiveCN103075463AIncrease the moment of inertiaImprove running smoothnessFlywheelsFlywheelMoment of inertia

The invention discloses a centrifugal flywheel. A cylinder which moves centrifugally is arranged in each spoke slipway of the flywheel; and an adhesive medium is filled into the cylinder; or a cylinder for storing and releasing elastic deformation energy of a spring is arranged in each spoke slipway of the flywheel. The cylinder provided by the invention can slide in the slipway, and slides towards the edge of the flywheel after the flywheel starts running, so that the rotation inertia of the flywheel is increased, and the running stability of a machine is improved; the adhesive medium is filled into the slipway, and plays a role in lubricating in the sliding process of the cylinder; and the cylinder is connected with the flywheel by stretching or compressing the spring to form an energy storing element, so that the rotation inertia can be changed and the elastic deformation energy can be stored and released after the flywheel starts running, and the running stability of the machine is further improved.

Owner:ZHEJIANG UNIV

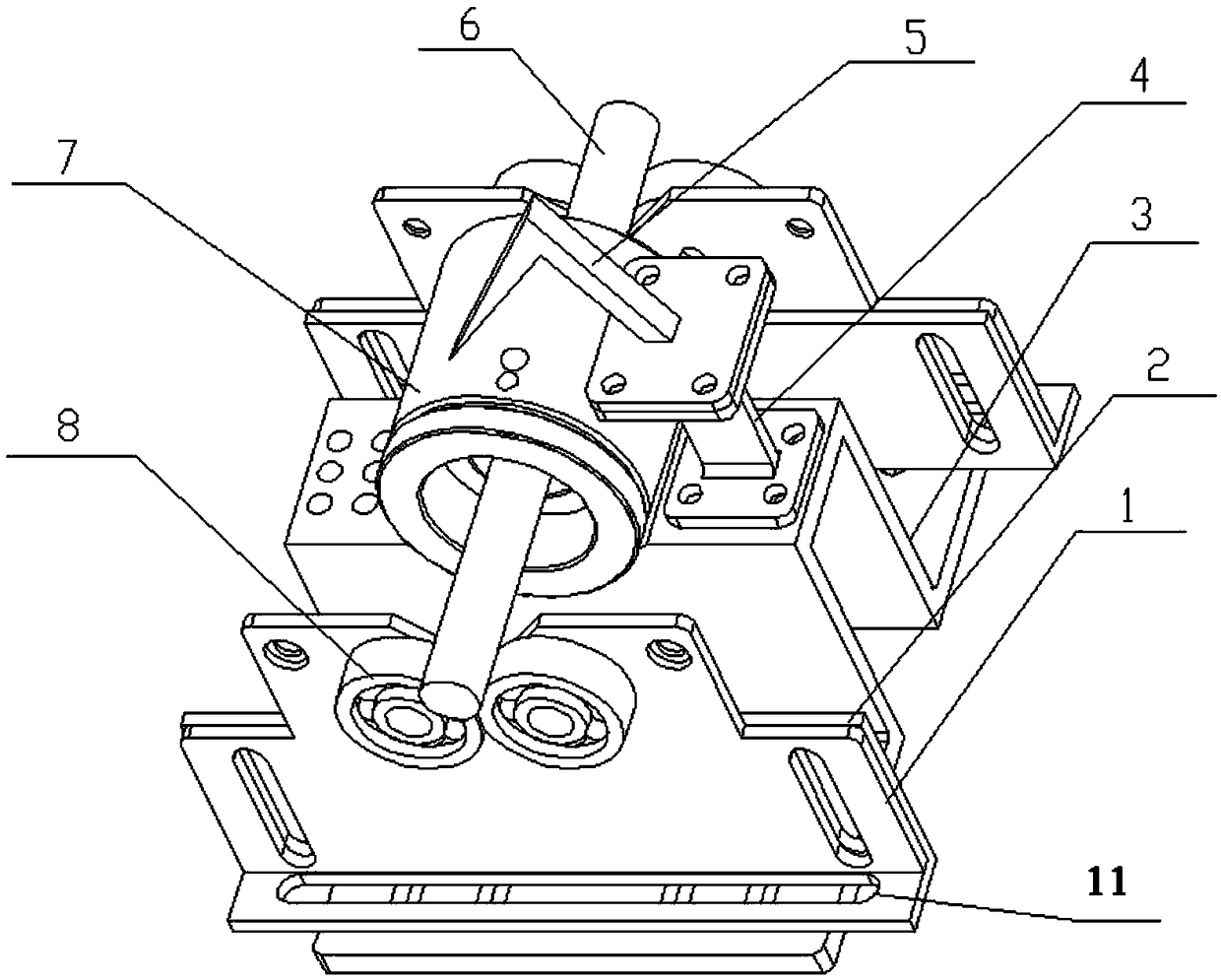

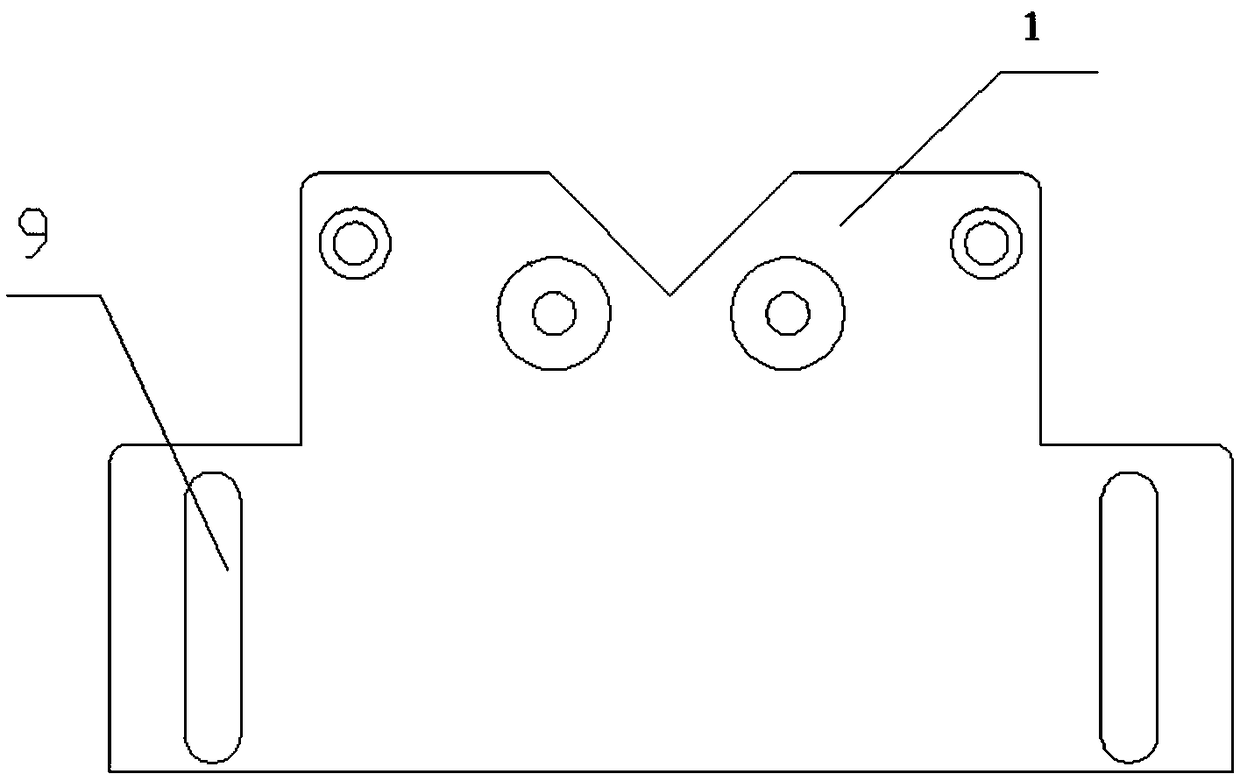

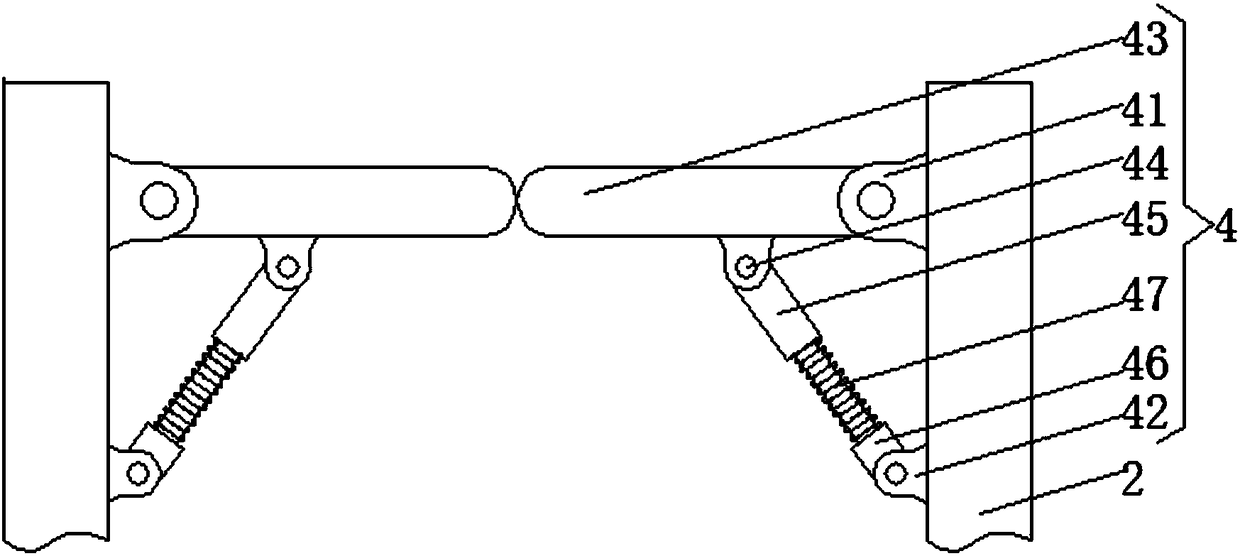

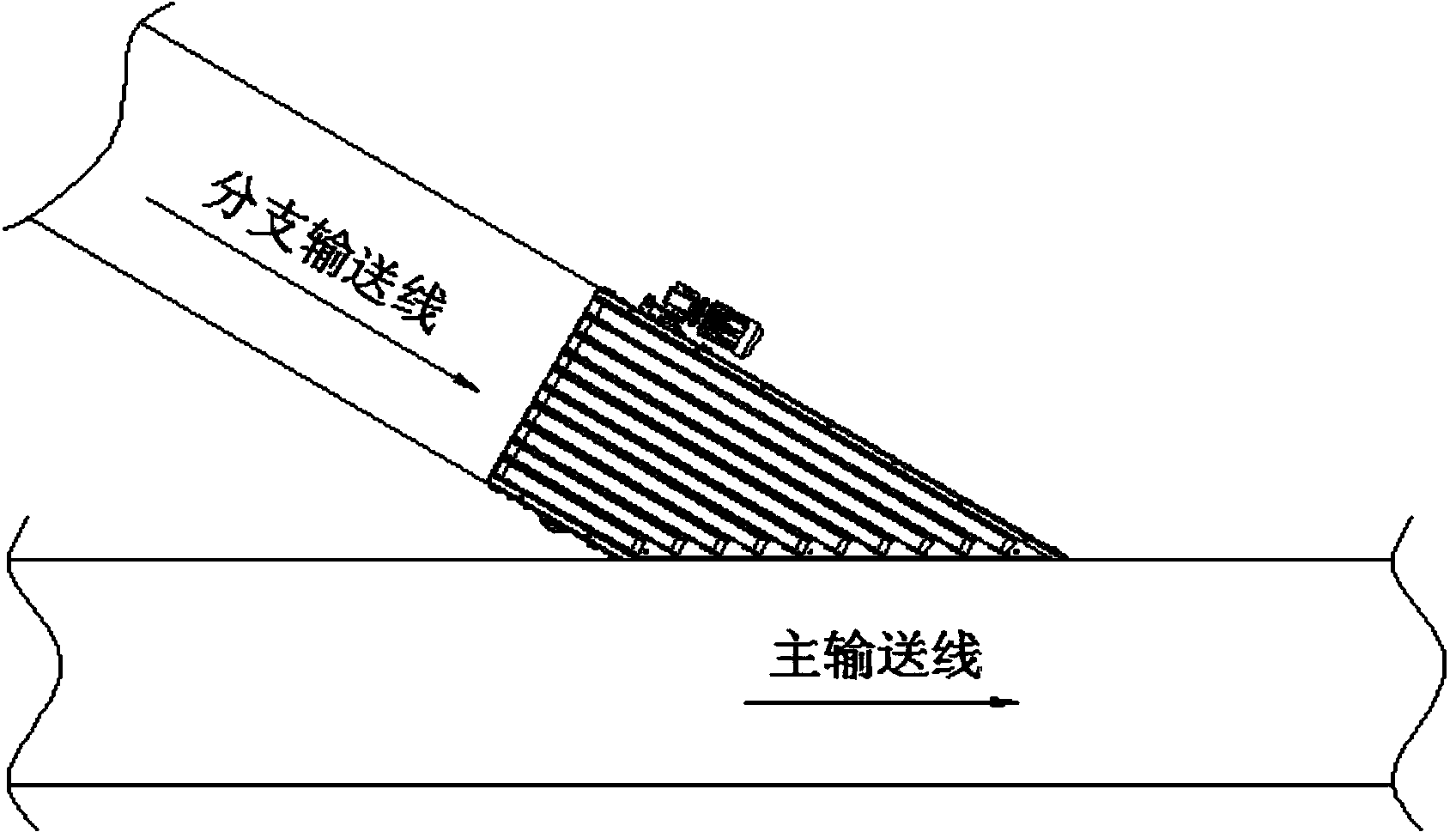

Centering mechanism for narrow-band flow-merging machine end portion roller

The invention relates to logistics automatic conveying sorting machines, belongs to the technical field of logistics sorting, and particularly relates to a narrow-band flow-merging machine, in particular to a centering mechanism for a narrow-band flow-merging machine end portion roller. The centering mechanism for the narrow-band flow-merging machine end portion roller is characterized by comprising a U-shaped fixing plate (1), an eccentric bushing (2) and an adjustable bolt (5), the adjustable bolt (5) serves as an axis of the end portion roller, the two lateral sides of the U-shaped fixing plate (1) are provided with a pair of circular holes including the first circular hole and the second circular hole, the first circular hole and the second circular hole respectively have an eccentric distance h, the eccentric bushing (2) is provided with a circular boss and a center hole, and the circular boss and the center hole respectively have an eccentric distance h. The second circular hole and the circular boss of the eccentric bushing (2) are fixedly assembled, the adjustable bolt (5) is inserted into the first circular hole and the second circular hole, the axial position, corresponding to the first circular hole, of the adjustable bolt and the first circular hole are concentric.

Owner:ZHEJIANG DAMON TECH CO LTD +1

Rechargeable textile cleaning twisting gun

InactiveCN102181975AGuaranteed rotation accuracySmall runoutTextiles and paperEngineeringMechanical engineering

The invention provides a rechargeable textile cleaning twisting gun, which comprises a shell; a battery and a motor are arranged in the shell; the motor is in transmission connection with a roll pin by a rotation shaft; the roll pin is matched with a fixed end bearing by a baffle ring; the fixed end bearing is axially and radially fixed by the shell; and the roll pin is matched with a moving end bearing by a baffle ring; and the moving end bearing is radially fixed by the shell. In the rechargeable textile cleaning twisting gun, the fixed end bearing plays a role in fixing and supporting, the moving end bearing plays a role in moving and supporting, and the rotation precision of the roll pin can be effectively ensured by the two rows of bearings to greatly reduce peripheral jumps, improve the stability of operation, and prevent the roll pin from being stuck when the roll pin is deformed due to heating.

Owner:安徽尚美电气科技有限公司

Sided-intake sealer of agitator

InactiveCN101073755AGuaranteed vacuumSlightly wornEngine sealsRotary stirring mixersEnd face mechanical seal

The invention is concerned with the sealing equipment for the side moving beater, it is: fixes inside end surface machine seal that crosses the inside wall of the container, fixes outside end surface machine seal between the beating axis and the outside wall of the container. The outside end surface machine seal is double end surface machine seal that fixes on the beating axis by the sealing fixing bushing. The invention is small fraying consumption, better sealing efficiency.

Owner:华宝付

Roller brake motor device

ActiveCN102710062ACompact internal structureEasy connection and assemblyToothed gearingsMechanical energy handlingClutchElectric machinery

The invention discloses a roller brake motor device, which comprises a main shaft, a hub shell, a hub end cover, a stator, a rotor, a planetary gear speed reducing mechanism and a clutch, wherein the hub shell is arranged on the main shaft; the hub end cover is fixed on one side of the hub shell; and the stator, the rotor, the planetary gear speed reducing mechanism and the clutch are arranged in the hub shell; and the stator is fixed on the main shaft through a stator bracket on which a gear box cover is fixed. The roller brake motor device is characterized in that the clutch is a wedge type one-way clutch, and comprises an outer circle and an inner circle, the outer circle and the hub end cover are fixed, and an inner gear ring is fixed on the inner circle; and the planetary gear speed reducing mechanism comprises a center shaft fixed together with the rotor, a center shaft gear arranged on the center shaft, and a planetary gear fixed on the gear box cover through a planetary shaft, and the planetary gear is meshed with the center shaft gear and the inner gear ring at the same time. The roller brake motor device is compact in structure, convenient to assemble and high in operation stability.

Owner:BAFANG ELECTRIC (SUZHOU) CO LTD

Two-stage machine tool gearing, in particular spindle gearing

InactiveCN101389884ATransmission motion accelerationSmall rotational inertiaToothed gearingsGear wheelEngineering

Owner:ZF FRIEDRICHSHAFEN AG

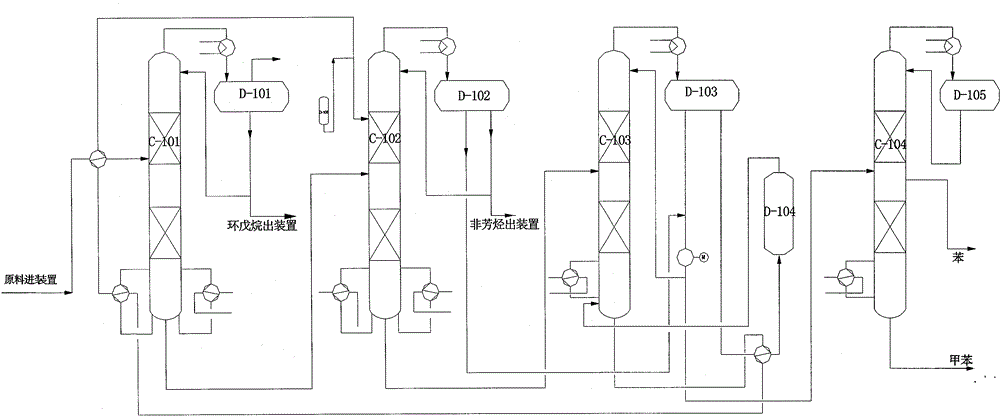

Novel extraction process for aromatic hydrocarbons

InactiveCN105085152AAvoid decompositionReduce decompositionDistillation purification/separationHydrocarbonsDecompositionReboiler

The invention relates to a novel extraction process for aromatic hydrocarbons. Key improvements in the novel extraction process are that a depentanizing tower, an extracting and rectifying tower, a solvent recovering tower and a benzene tower employ novel inward-bending arc fin flat-ring filling material and a unique liquid distribution apparatus and filling material support apparatus are cooperatively used, so resistance drop, a pressure drop ratio and loads of the towers are effectively reduced and production capacity is substantially improved. The depentanizing tower and the extracting and rectifying tower employ main and assistant reboilers for heat adjustment, so optimization of heat supply is realized and long-period stale operation of the towers is guaranteed. Meanwhile, since a sulfonic acid ionic liquid is used as a cosolvent, influence of decomposition and corrosion of the solvent is reduced, usage cost of equipment is lowered, the service life of the solvent is prolonged, the problems of high contents of aromatic hydrocarbons and napthene and easy azeotropy of aromatic hydrocarbons in the extracting process of aromatic hydrocarbons are effectively overcome, investment cost and operation cost of the facilities are substantially reduced, and substantial economic benefits are obtained.

Owner:BEIJING HUAHETUO TECH DEV CO LTD

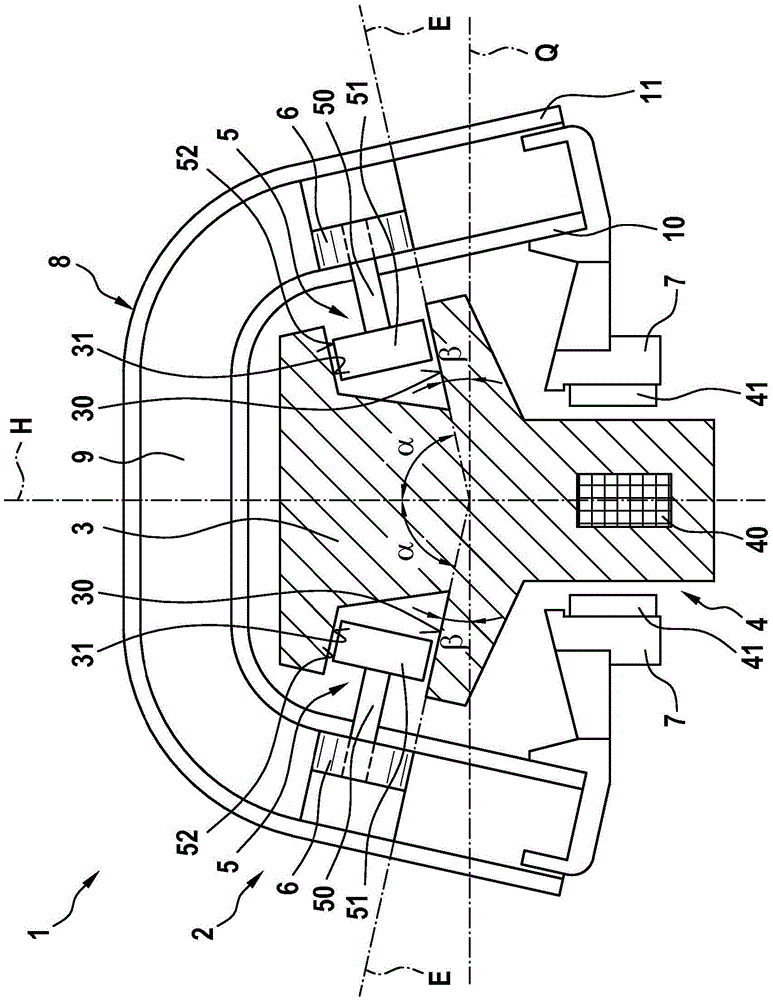

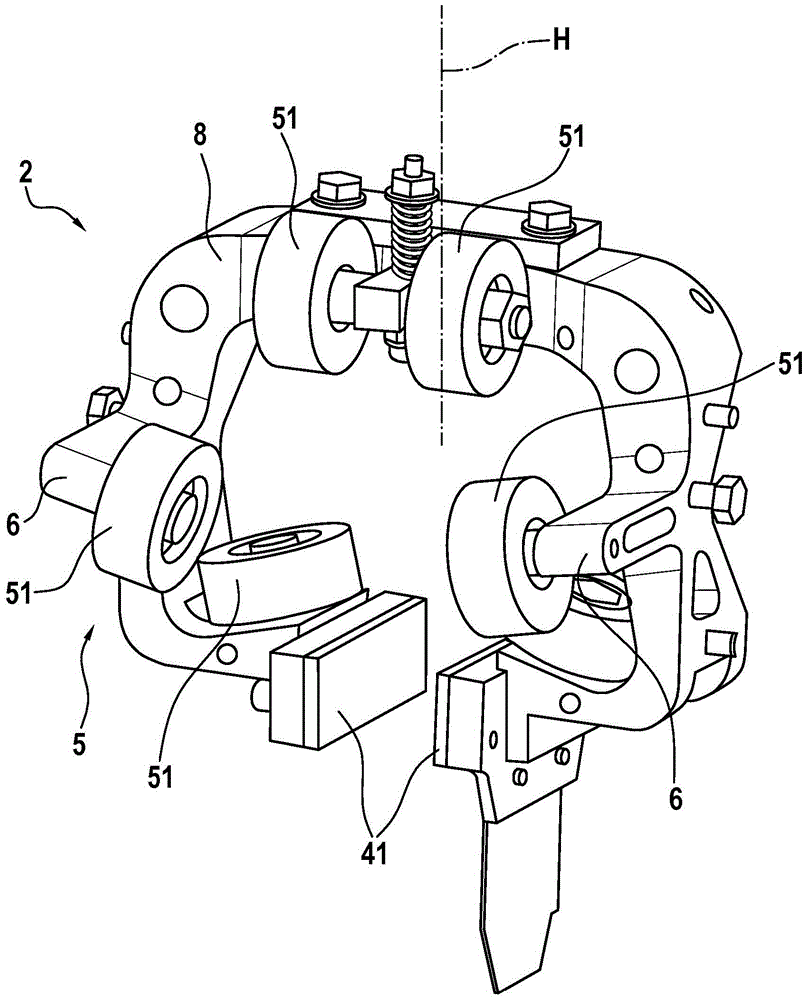

Transfer device

InactiveCN105473473AReduce wear and tearAvoid wear and tearNon-mechanical conveyorsTransverse axisEngineering

The invention relates to a transfer device comprising a moveable element (2), a stationary guide rail (3), and a linear motor drive device (4) for driving the moveable element (2).Said moveable element (2) comprises support elements (5) which can be brought into contact with the guide rail (3), and at least one of the support elements has a contact area which is arranged at an angle (a) not equal to 90 DEG to a vertical axis (H) of the moveable element (2) and at an angle (beta) not equal to 90 DEG to a transverse axis (Q) of the moveable element (2).

Owner:ROBERT BOSCH GMBH

Flat stepping motor

ActiveCN102723841ASmall moment of inertiaRapid responseDynamo-electric machinesMoment of inertiaElectromagnetic field

The invention discloses a flat stepping motor. In a motor, N same magnetic steels are uniformly fixed and embedded on a disc-shaped turntable. The magnetic fields of the magnetic steels are in the same direction. An output shaft is fixed at the center of the turntable, and n same electromagnetic seats are uniformly fixed in a front end cover shell. An electromagnetic coil is fixed on the outer edge of the electromagnetic seat, and m magnetic salient poles identical to the magnetic steels are fixed in each electromagnetic seat. The angle of the center line of m magnetic salient poles in adjacent electromagnetic seats deviating from the center line of the electromagnetic seats is 360 degrees / nN. The rear end cover is the same as the front end cover. The output shaft is rotatably mounted on the front and rear end covers. The magnetic salient poles of the two end covers are opposite in a one-to-one manner, and a rotor is clamped between the two. The opposite electromagnetic coils of the front and rear end covers are connected in parallel or series and then connected with an output pole of the controller. The electromagnetic field of the coil and the magnetic field of the magnetic steel are in the same direction. The controller outputs pulses to the coils sequentially, and the rotor is pulled by the electromagnetic force to rotate. Since the ratio of the axial length to the diameter can reach 1:3, the flat stepping motor disclosed by the invention is convenient to mount; and moreover, the flat stepping motor has the advantages of good torque property, small rotational inertia and stable operation, and is convenient to control.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

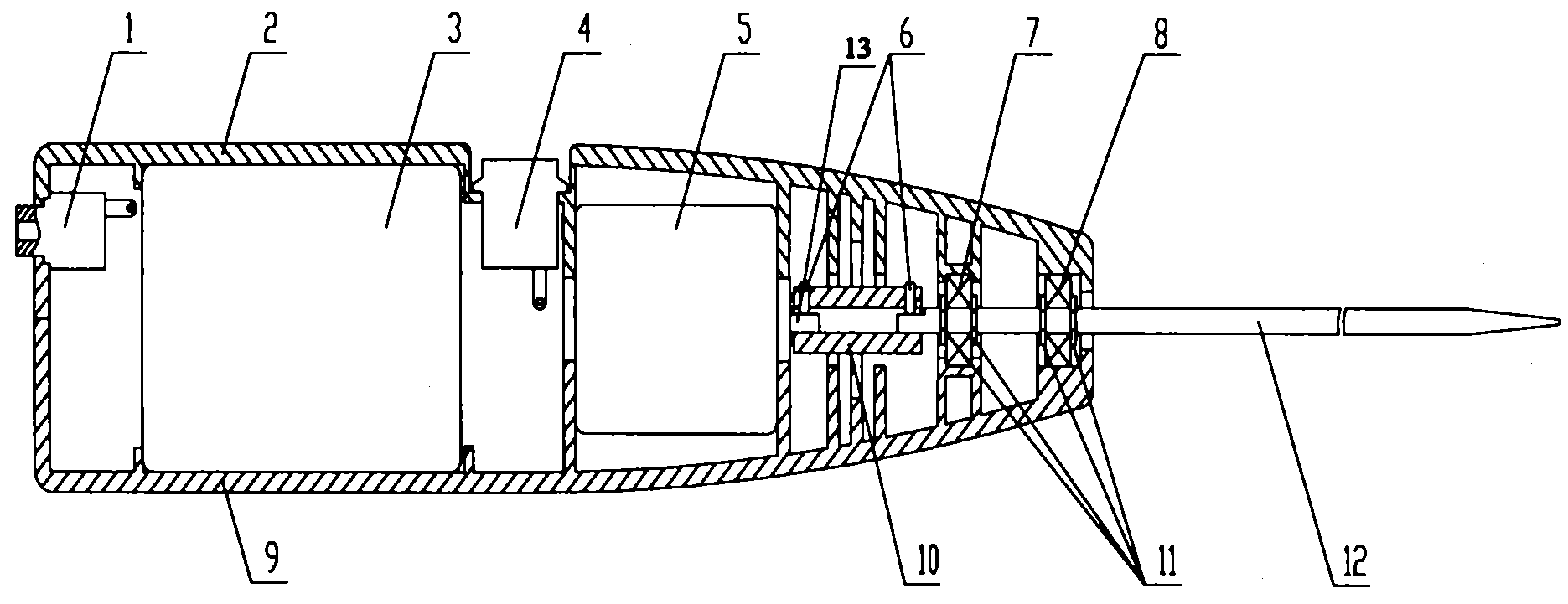

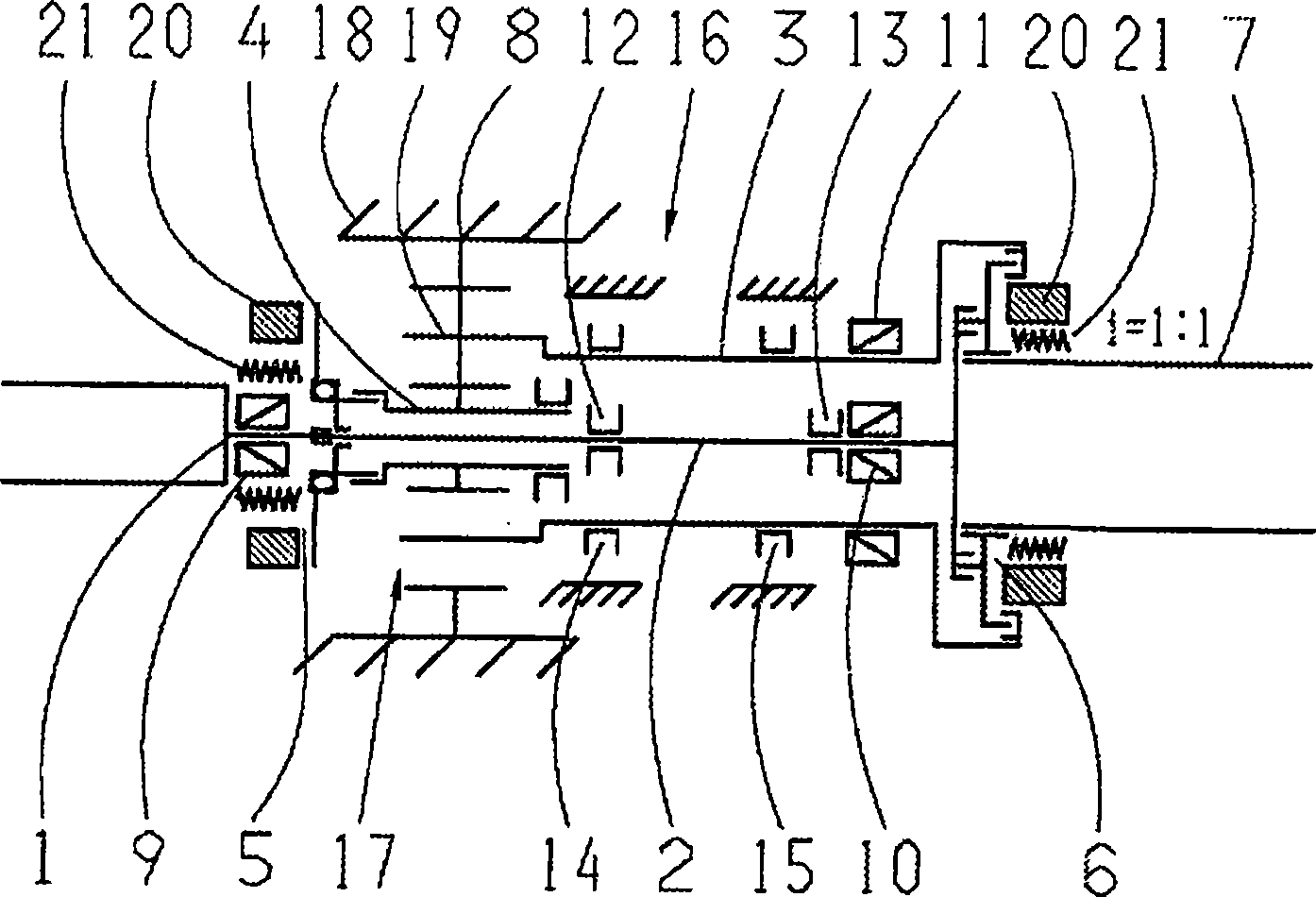

Self-elevating drilling platform and automatic uniform-load planet differential lifting device thereof

InactiveCN104060593AStrong automatic load balancing abilityImprove transmission efficiencyArtificial islandsUnderwater structuresRing deviceReducer

The invention discloses a self-elevating drilling platform and an automatic uniform-load planet differential lifting device of the self-elevating drilling platform. The automatic uniform-load planet differential lifting device comprises multiple lifting units. Each lifting unit comprises a motor, a main speed reducer, a planet mechanism, an idler pulley, a first climbing gear, a driven gear, and a second climbing gear, wherein the motor is provided with a motor shaft, the main speed reducer is provided with an input shaft and an output shaft, the input shaft is connected with the motor shaft, the planet mechanism comprises a planet speed reducer and an inner and outer gear ring device, the output shaft is connected to the planet speed reducer, the inner and outer gear ring device is not connected with the main speed reducer, the first climbing gear is connected with the planet speed reducer, the idler pulley is meshed with the inner and outer gear ring device, the driven gear is installed on a connecting shaft, the driven gear is meshed with the idler pulley, the second climbing gear is fixedly connected to the connecting shaft, and the second climbing gear and the first climbing gear are equal in rotation speed and opposite in direction. The automatic uniform-load planet differential lifting device is safe in structure, high in reliability, high in operation stability, and high in automatic uniform-load ability.

Owner:TAIYUAN HEAVY IND

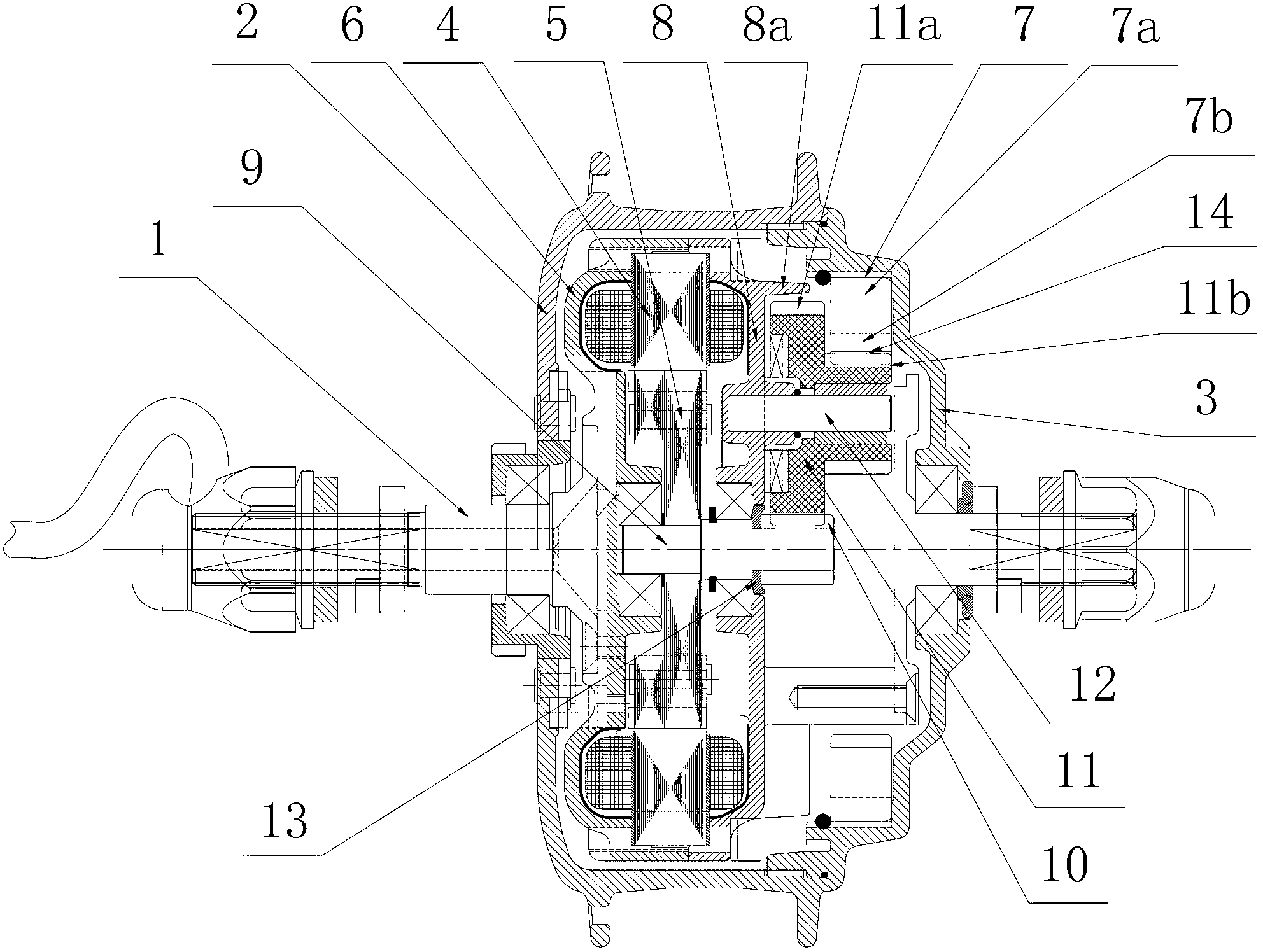

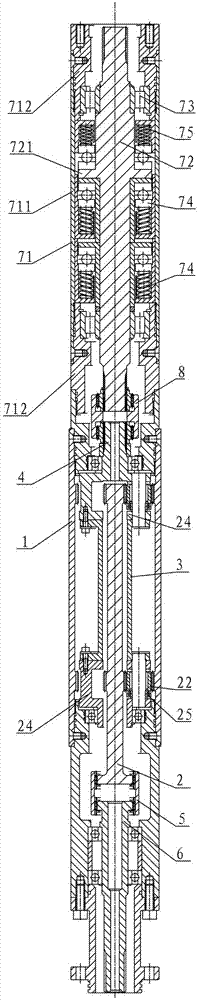

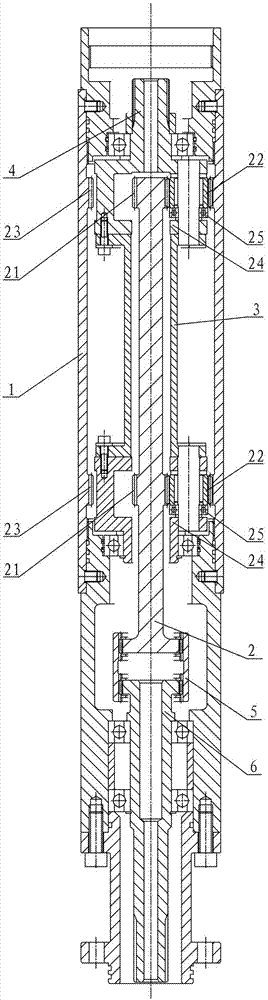

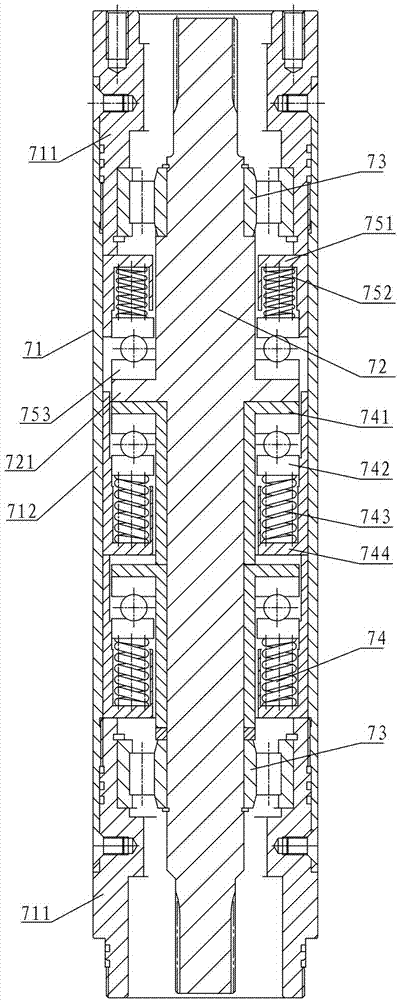

String-type planetary reducer for electric submersible thickened oil screw pump

ActiveCN102788116AImproved torsional power transfer capabilityExtended service lifeToothed gearingsGearing detailsEngineeringGear train

The invention discloses a string-type planetary reducer for an electric submersible thickened oil screw pump. The string-type planetary reducer for the electric submersible thickened oil screw pump comprises a box body. A sun gear axle and more than two sets of planetary gear transmission assemblies respectively arranged along the axial direction of the sun gear axle are arranged in the box body; each planetary gear transmission assembly comprises a sun gear, an inner gear ring, a planetary gear and a planetary gear carrier, wherein the sun gear is fixedly arranged on the sun gear axle; the inner gear ring is fixedly arranged on the box body; the planetary gear is arranged between the sun gear and the inner gear ring; and the planetary gear carrier is used for supporting the planetary gear. The planetary gear carriers in adjacent two sets of planetary gear transmission assemblies are connected through a planetary gear carrier connecting piece; the top end of the planetary gear carrier located at the uppermost end is provided with a reducer output shaft. According to the string-type planetary reducer for the electric submersible thickened oil screw pump, torsional power can be jointly transmitted by a plurality of planetary gear trains, so that the torsional power is evenly loaded, and the service life is prolonged.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com