Six-phase switch reluctance motor system

A technology of reluctance motor and switched reluctance, which is applied in the field of motor system, can solve the problems of torque pulsation and large noise, and achieve the effects of reducing torque pulsation, reducing noise, and improving running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

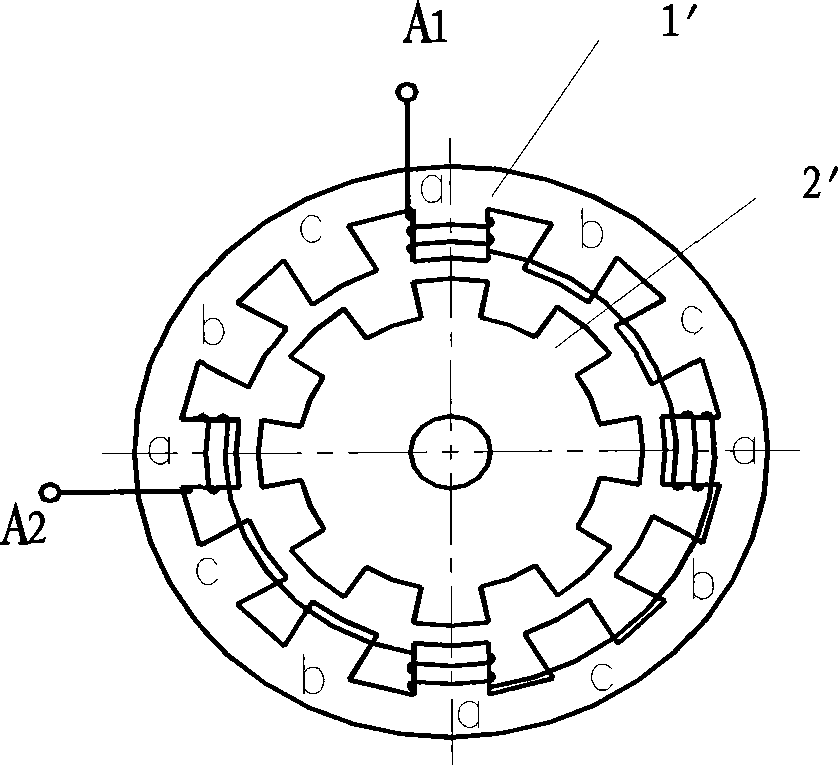

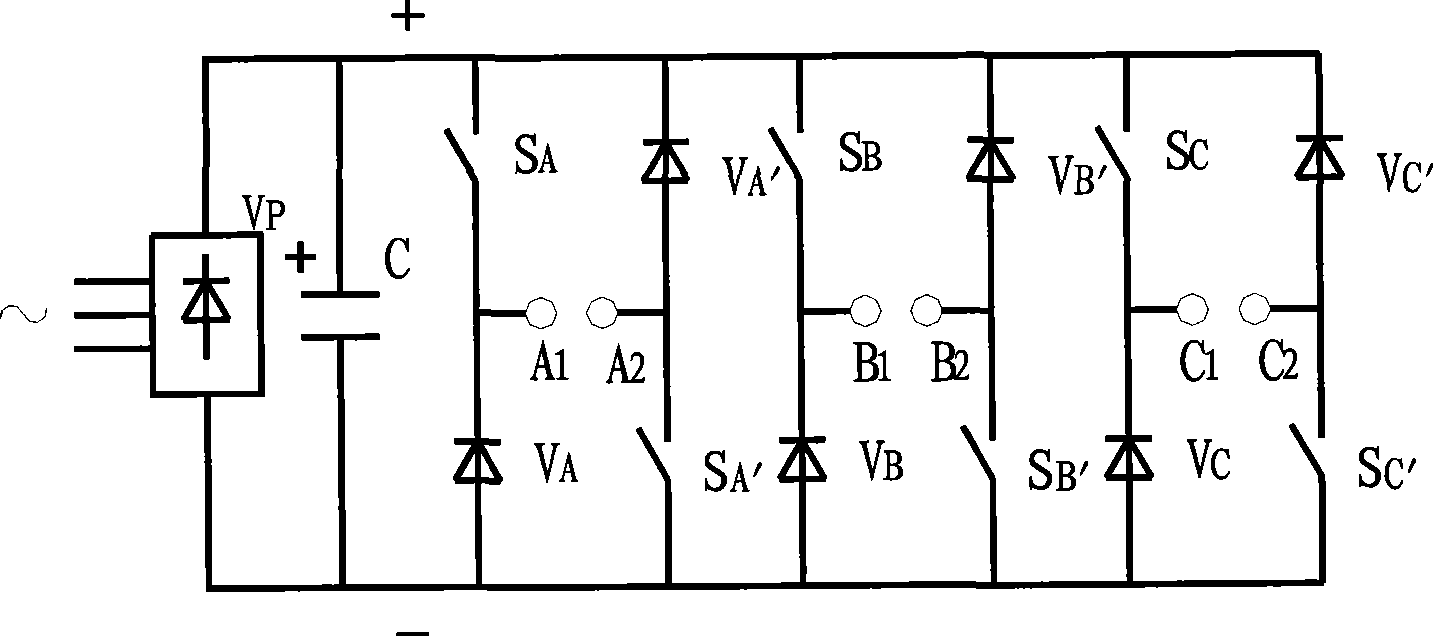

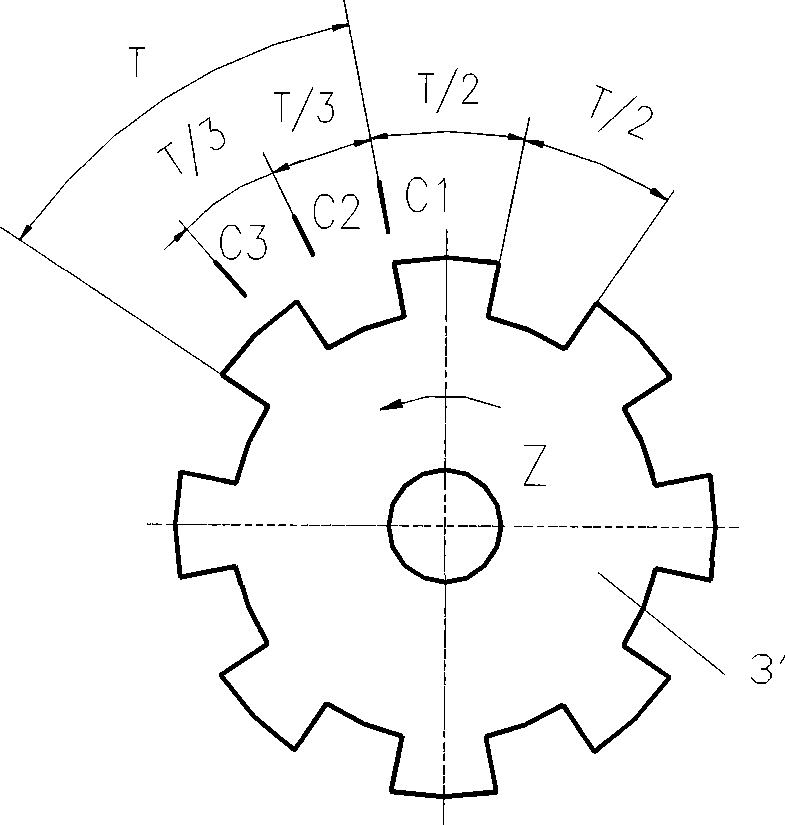

[0038] Based on the existing 3-phase 12 / 8-pole reluctance motor system, the invention only changes the winding connection mode to realize the 6-phase 12 / 10-pole reluctance motor system without changing the number of salient poles and coils of the motor stator. like Image 6 Shown is a schematic diagram of the same pole arrangement of each phase winding of the motor of the present invention; Figure 7 It is a schematic diagram of the different pole arrangement of each phase winding of the motor of the present invention. The stator iron core 1 is the same as the stator iron core 1 of the existing 3-phase 12 / 8-pole motor, but the coils on the two salient poles facing each other on the iron core 1 are connected (in series or in parallel) to form a 1-phase winding, Respectively a, b, c, d, e, f, a total of 6-phase windings, only th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com