Centering mechanism for narrow-band flow-merging machine end portion roller

A deviation adjustment mechanism and narrow-band confluence technology, applied in the direction of rollers, conveyors, conveyor objects, etc., can solve the problems of large spacing, affecting the confluence effect, and the length of no power section, so as to simplify the deviation adjustment steps and improve the confluence effect. , the effect of shortening the unpowered segment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

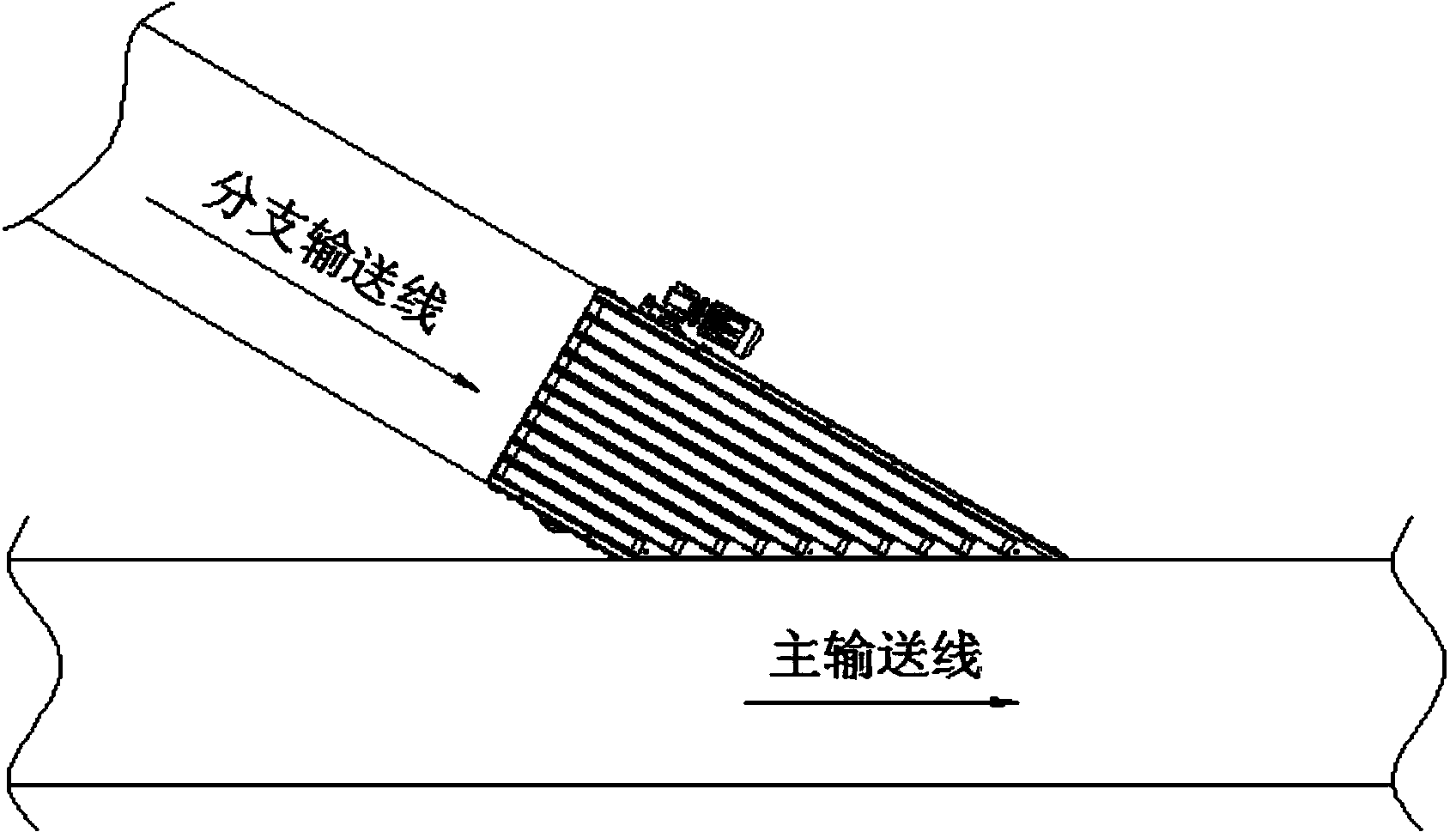

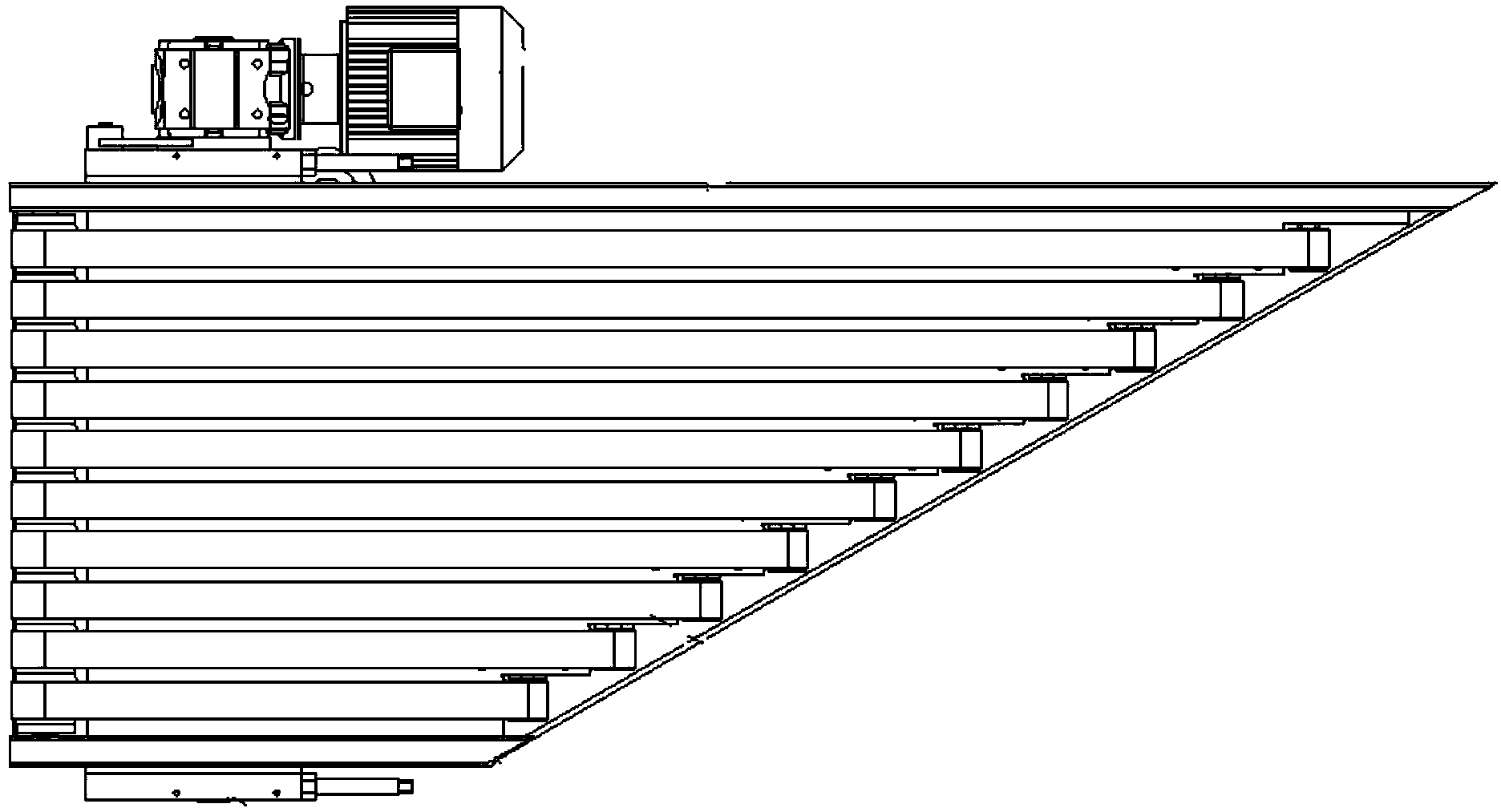

[0036] see Figure 1-2 , the deflection adjustment mechanism of this implementation is applied to the end rollers at both ends of the narrow-band converging machine, so that the narrow belt is located at the center of the end rollers as much as possible.

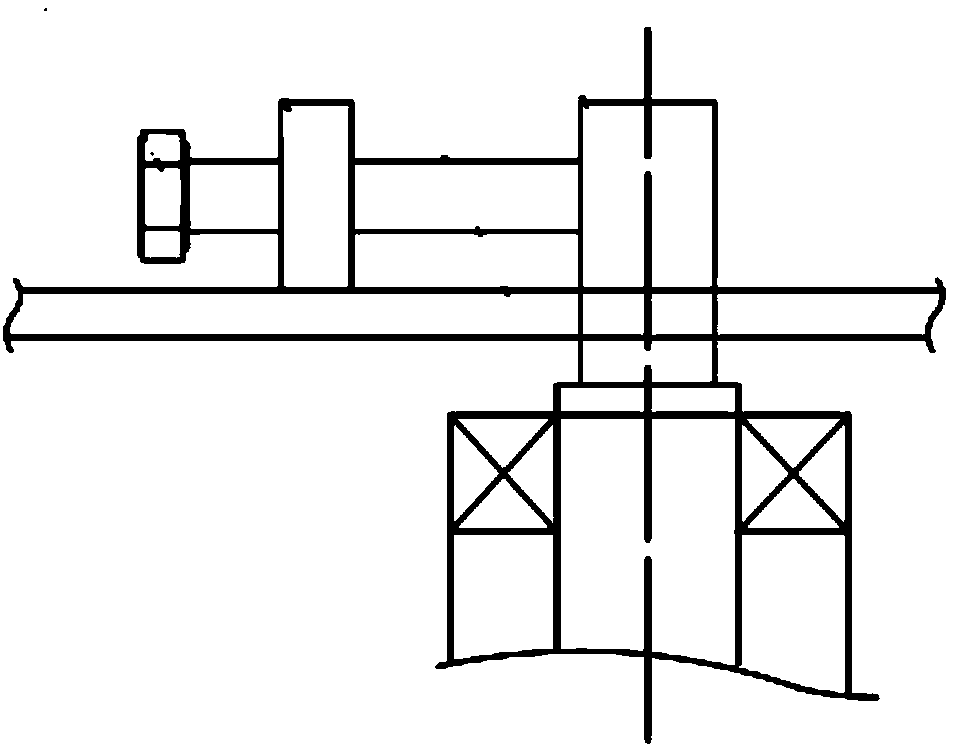

[0037] Such as Figure 5 As shown, the deviation adjustment device is mainly composed of a U-shaped fixed plate 1, an end roller 6, an adjusting bolt 5, an eccentric sleeve 2, a rivet nut 3, and a spring washer 4.

[0038] see Figure 6-7 , the U-shaped plate is the support frame of the end roller and its deflection adjustment mechanism. There are through holes of different sizes on the left and right sides of the plate, which are respectively the first round hole and the second round hole. Figure 6 It can be seen from the above that the second circular hole is inscribed on the inner side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com