Centrifugal flywheel

A centrifugal and flywheel technology, applied in the field of flywheels, can solve problems such as difficult to further improve the stability of mechanical operation, and achieve the effect of improving the stability of operation and increasing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation.

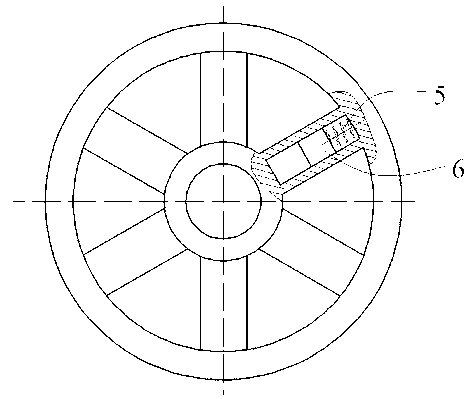

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention is provided with a centrifugally moving cylinder in each spoke slideway of the flywheel, or a cylinder with a spring storing and releasing elastic deformation energy in each spoke slideway of the flywheel.

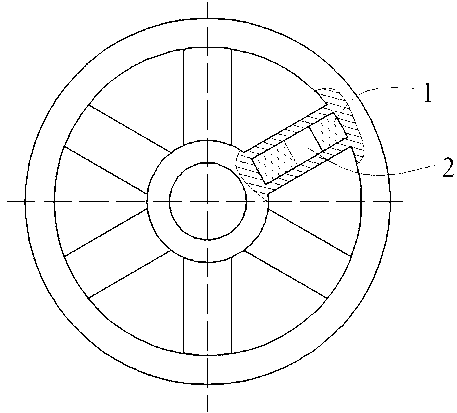

[0027] Such as figure 1 As shown, the two ends of the cylinder 2 in the six spoke slideways are full of viscous medium 1. The cylinder 2 is located in the slideway and can slide radially along the flywheel, and the slideway is filled with a viscous medium 1 to lubricate the movement of the cylinder.

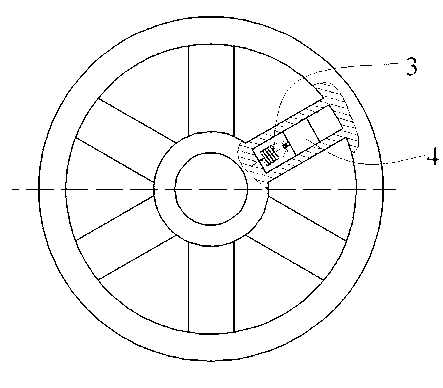

[0028] Such as figure 2 As shown, one end surface of the cylinder 4 near the center in the six spoke slideways is a tension spring 3 . The cylinder 4 is located in the slideway, and is connected with the hub part of the flywheel through the tension spring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com