Cradle head

A gimbal and roll axis technology, applied in the field of aircraft, can solve the problems of small rotational inertia of the pan axis, unable to achieve stability enhancement, etc., and achieve the effect of light overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

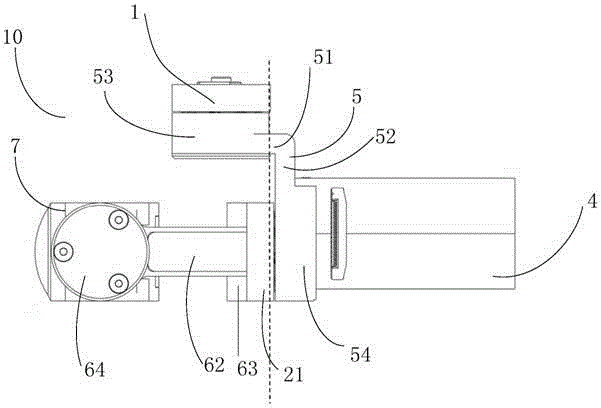

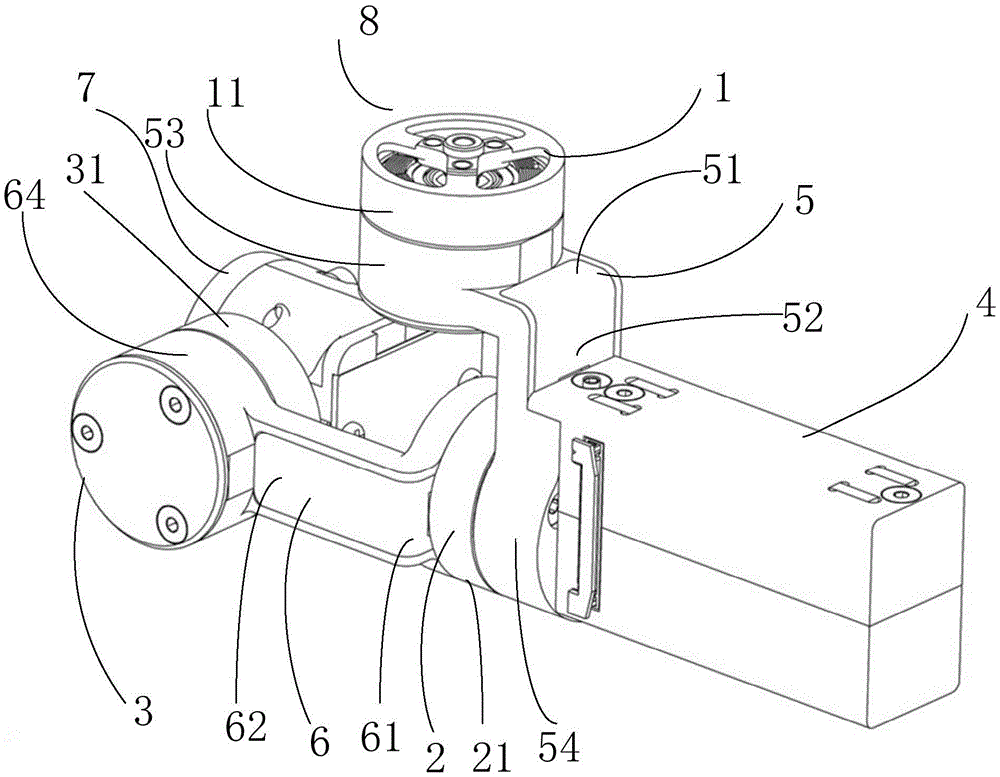

[0022] see figure 1 , a kind of cloud platform 8 is provided in the present embodiment, and this platform comprises yaw axis motor 1, roll axis motor 2, pitch axis motor 3 and controller 4, and wherein the top of yaw axis motor 1 is provided with connected with aircraft A connecting platform (not shown in the figure), the panning axis motor 1 and the rolling axis motor 2 are connected through the first connecting axis arm 5, the rolling axis motor 2 and the pitching axis motor 3 are connected through the second connecting axis arm 6, and the controller 4 It is located under the yaw axis motor 1 or on the aircraft.

[0023] When the controller was positioned under the yaw axis motor 1, the roll axis motor stator (not shown) was connected to the first connecting shaft arm 5, and its rolling axis motor rotor 21 was connected to the second connecting shaft arm 6; The shaft motor stator (not shown) is connected to the second connecting shaft arm 6 , and the imaging device 7 is pro...

Embodiment 2

[0032] The differences between this embodiment and Embodiment 1 are:

[0033] In this embodiment, the controller 4 is located in front of the roll axis motor 2 , and the controller 4 is fixed on the roll axis motor 2 or the second connecting arm 6 .

[0034] In this embodiment, the front of the roll axis motor 2 specifically refers to the front of the roll axis motor rotor 22; at the same time, in order to meet the above structural layout, the length of the first connecting shaft arm 5 in this embodiment should be greater than that of the first connecting shaft arm 5 in Embodiment 1. One is the length of the connecting shaft arm 5 .

[0035] The rest of the structure in this embodiment is the same as that in Embodiment 1, so it will not be repeated here.

Embodiment 3

[0037] The differences between this embodiment and Embodiment 1 are:

[0038] The controller 4 is fixedly arranged behind the pitch axis motor 3 . That is, the imaging device and the controller 4 are respectively located at the front and rear positions of the pitch axis motor 3 , and the controller 4 will not rotate with the pitch axis motor 3 during the rotation of the imaging device 7 driven by the pitch axis motor 3 . At the same time, the length of the first connecting shaft arm 5 in this embodiment is greater than that of the first connecting shaft arm 5 in Embodiment 1, so as to prevent the whole aircraft from being unstable due to the deviation of the center of mass caused by the weight change.

[0039] The rest of the structure in this embodiment is the same as that in Embodiment 1, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com