Process for producing L-(S) propylidene glycerin aldehyde solution

A technology of propylidene glycerol and its production method, which is applied in the field of production of L-(S)-propylidene glyceraldehyde solution, and can solve the problems of instability, high production cost and poor purity of L-(S)-propylidene glyceraldehyde. Problems, to achieve the effect of improving equipment efficiency and labor efficiency, low cost, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

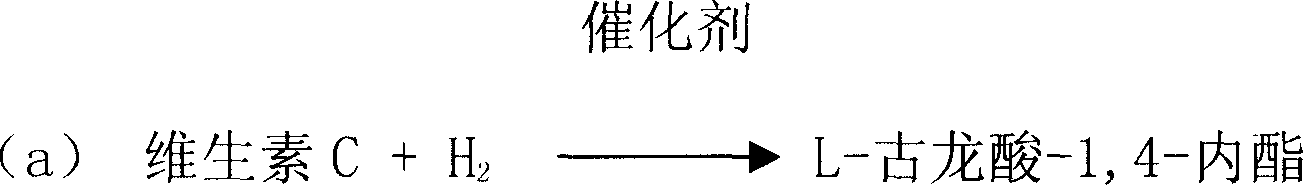

[0032] Synthesis of L-gulonic acid-1,4-lactone

[0033] Dissolve 23.1 grams of vitamin C in 170 milliliters of water, add 2.2 grams of 5% palladium / carbon catalyst, at 50 ° C and 5.05 × 10 5 Catalyzed hydrogenation under Pa for 24 hours, filtered to remove the catalyst, and evaporated the water under reduced pressure to obtain L-gulonic acid-1,4-lactone, which was recrystallized with a mixed solvent of methanol and ethanol to obtain 22 grams of the product with a yield of 95%. , melting point 182-183.5°C; [α]- is +55.2° (c=1, H 2 O);

[0034] IR(KBr)1770cm -1 ;

[0035] 1 H-NMR (Me 2 SO-d 6 ): δ=

[0036] 5.80 (d, 1, OH), 5.30 (d, 1, OH), 4.95 (d, 1, OH) 4.45-4.07 (m, 3), 4.00-3.35 (m, 3), 4.00-3.35 (m, 3).

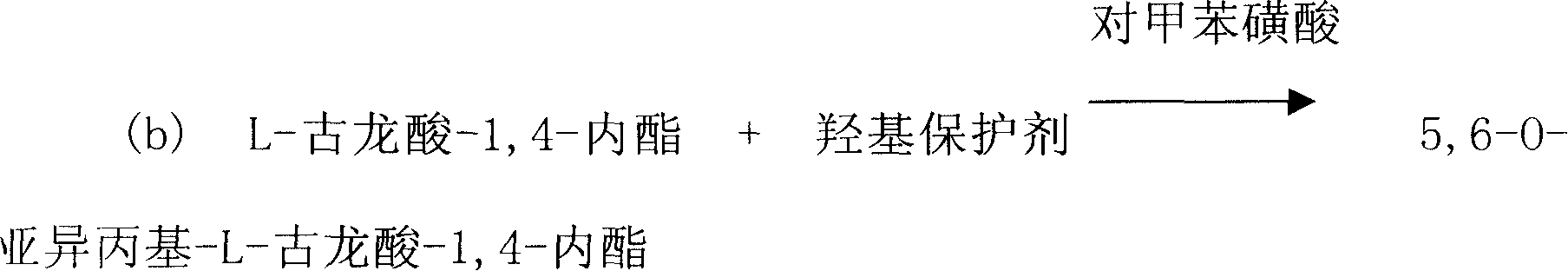

[0037] Synthesis of 5,6-O-isopropylidene-L-gulonic acid-1,4-lactone

[0038]Dissolve 221.6 grams of L-gulonic acid-1,4-lactone in 2000 milliliters of N,N-dimethylformamide, cool to 10°C, add 1.8 grams of p-toluenesulfonic acid while stirring, and keep the temper...

Embodiment 2

[0045] Production of L-gulonic acid-1,4-lactone

[0046] Dissolve 200 kg of vitamin C in 1000 liters of water, add 20 kg of 10% palladium / carbon catalyst, at 50 ° C and 5.05 × 10 5 Catalytic hydrogenation under Pa for 24 hours, remove the catalyst by filtration, distill off the water under reduced pressure to obtain a white solid which is the crude product of L-gulonic acid-1,4-lactone, which is recrystallized with a mixed solvent of methanol and ethanol to obtain a white cube Crystalline L-gulonic acid-1,4-lactone 196 kg, yield 98%, melting point 183-183.5°C, [a] 25 is +55.5° (c=1, H 2 O).

[0047] Synthesis of 5,6-O-isopropylidene-L-gulonic acid-1,4-lactone

[0048] Dissolve 190 kg of L-gulonic acid-1,4-lactone in 1500 liters of DMF, cool to 10°C, add 1.8 kg of p-toluenesulfonic acid while stirring, and add 2,2-dimethyl dropwise while keeping the temperature below 10°C 150 kg of oxypropane, continue to stir at room temperature for 24 hours, then add 220 kg of sodium carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com