Anti-buckling supporting member with lattice type double-rectangular-pipe cross section

A kind of anti-buckling bracing, lattice technology, applied in building components, anti-vibration and other directions, can solve problems such as difficulty in achieving ideal axial compression, insufficient energy dissipation capacity, and damage to anti-buckling bracing members.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

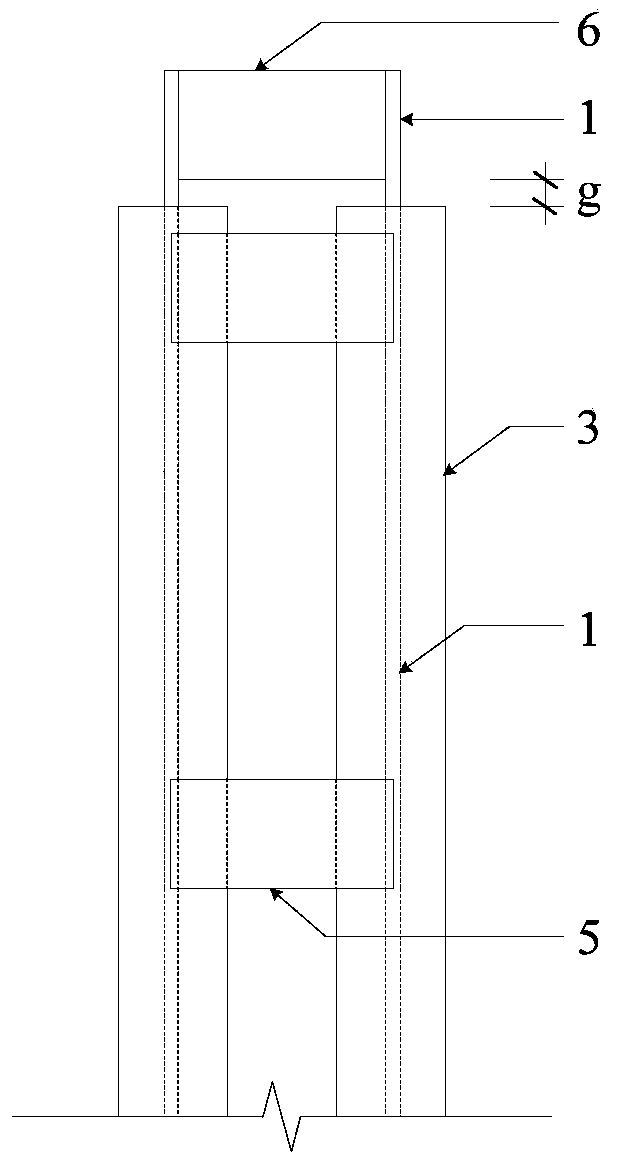

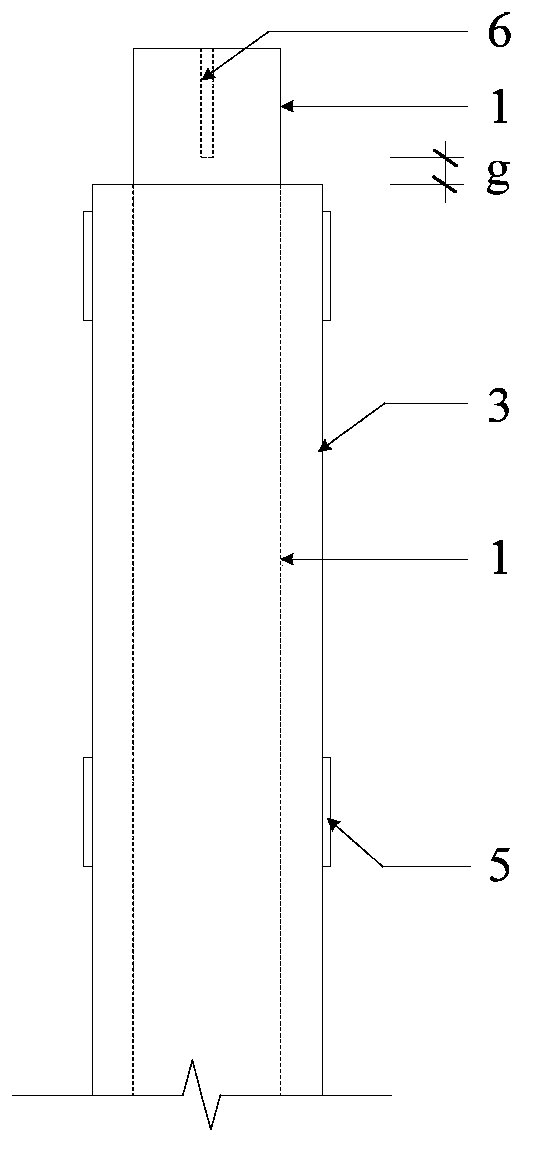

[0019] Attached below Figure 1~6 , to describe in detail the specific embodiments of the present invention.

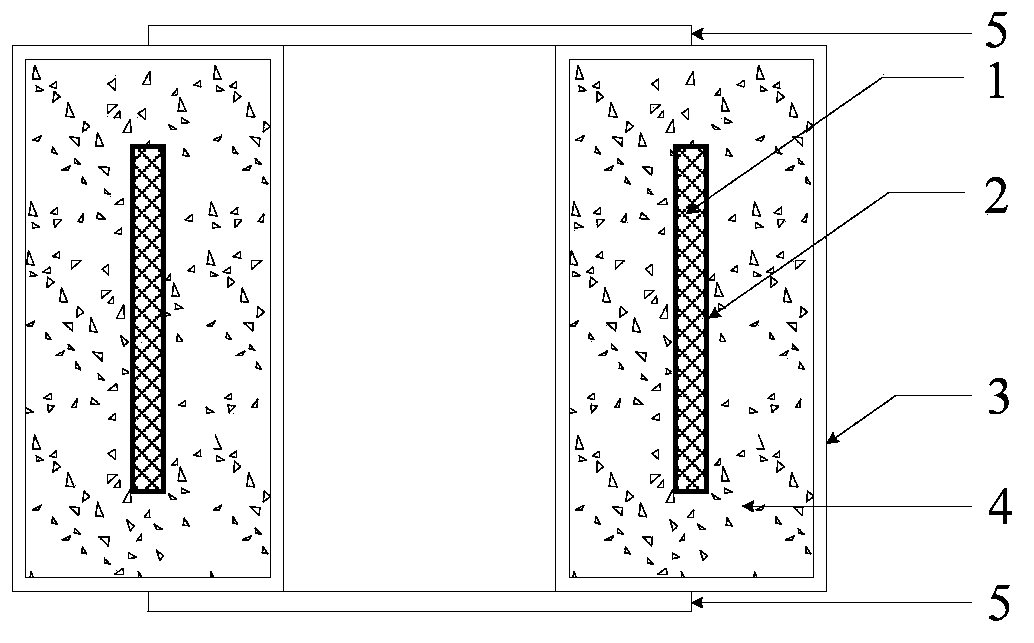

[0020] Such as Figure 1~3 As shown, a buckling-resistant bracing member with latticed double rectangular tube section includes the following components:

[0021] 1——Inline core components, two in total;

[0022] 2——No bonding material;

[0023] 3—constrained rectangular steel pipes, two in total;

[0024] 4 - Concrete;

[0025] 5——Steel panel;

[0026] 6—end ribs;

[0027] Such as figure 1 , 4 , 5, the buckling-resistant bracing member of the lattice double-rectangular tube section is formed by connecting two buckling-resistant limbs through a number of steel panels 5 distributed along the longitudinal direction; Constrained anti-buckling bracing member, composed of in-line core member 1, unbonded material 2, constrained rectangular steel pipe 3, and inner poured concrete 4;

[0028] Such as Figure 4 , 5 As shown, there are two constrained rectangular st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com